Testing method and appliance for horizontal conductivity of fuel cell proton exchange membrane

A proton exchange membrane, fuel cell technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

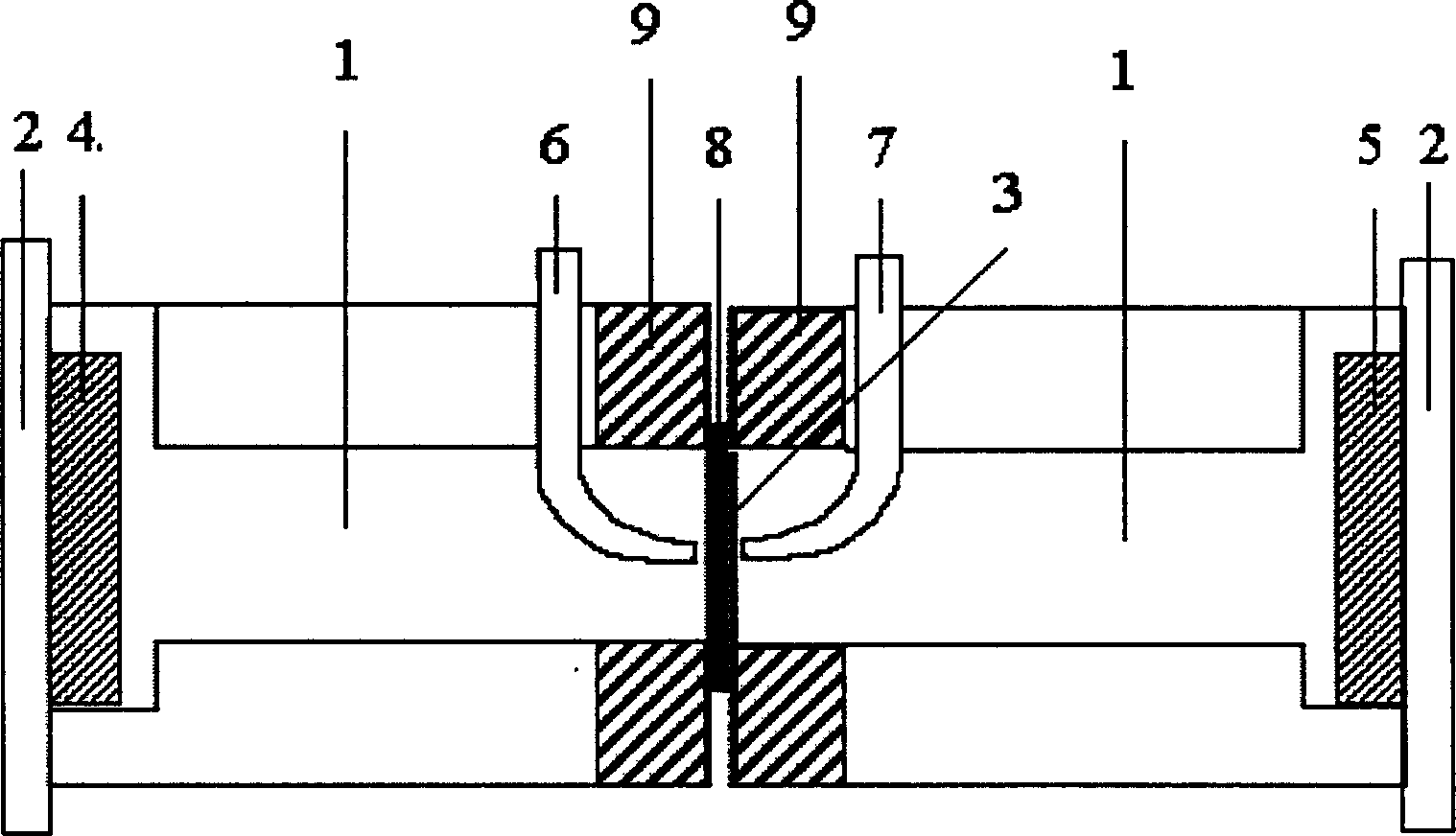

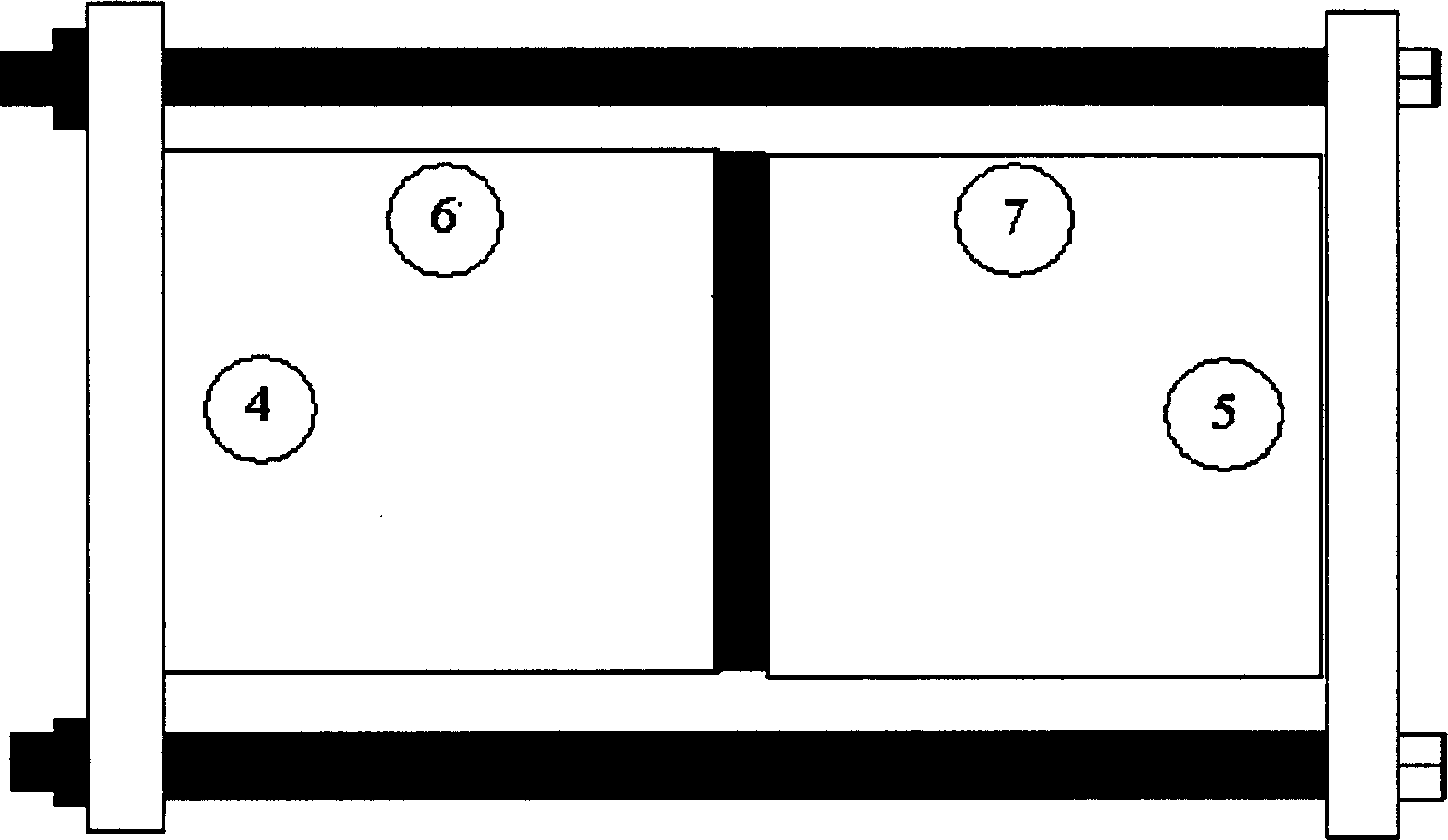

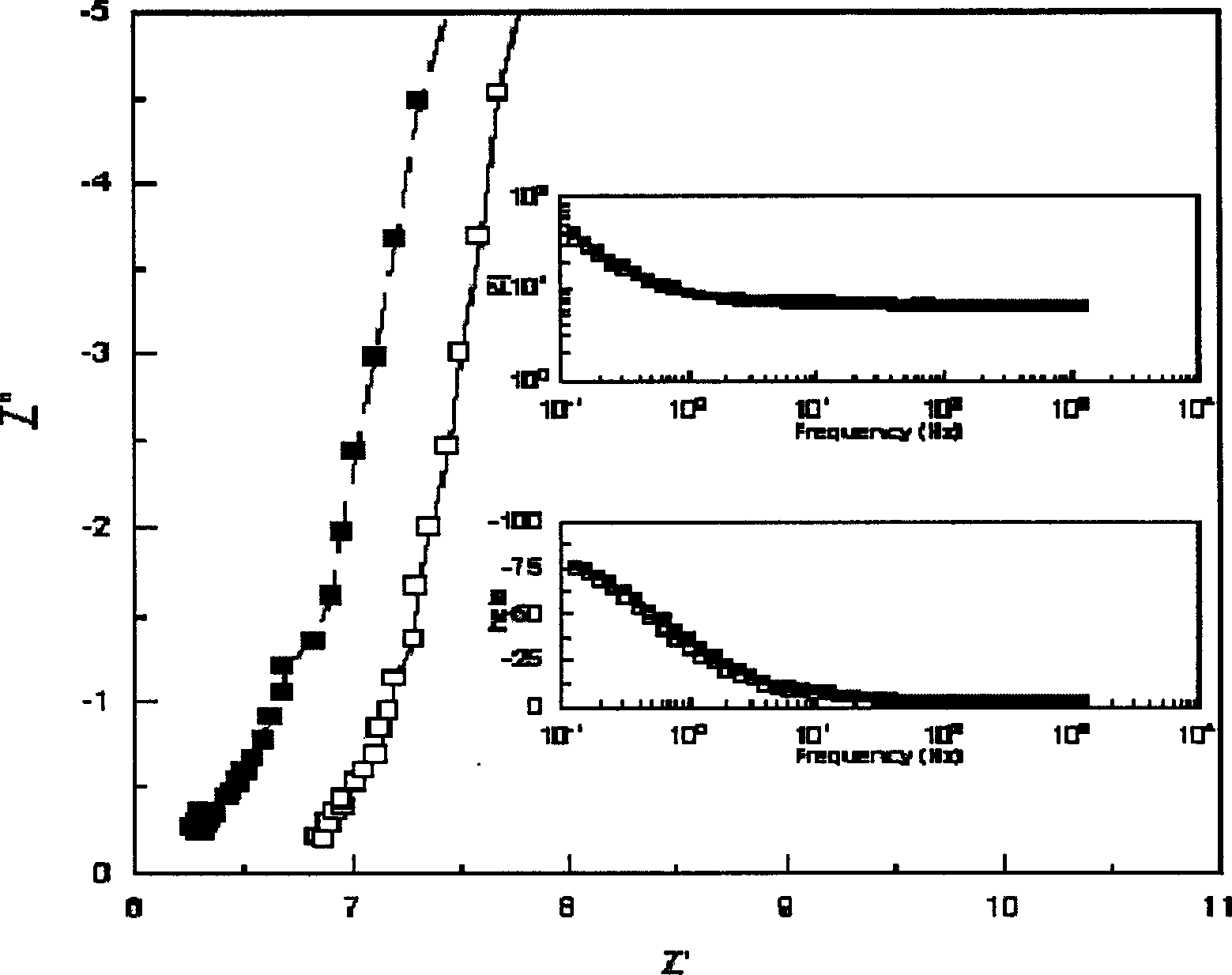

[0015] The conductivity change of the proton exchange membrane (nafion117) after pretreatment was tested by hot pressure test. The hot pressing temperature is 120° C., the time is 3 minutes, and the pressure is 0.4 MPa. The electrolytic cell solution is 0.5mol / LH 2 SO 4 +1mol / L methanol (simulating working conditions of direct methanol fuel cell). Test equipment such as figure 1 As shown, carbon rods were used for the working and auxiliary electrodes, and saturated calomel electrodes were used for the two reference electrodes. The conductivity is measured by the AC impedance method, the scanning frequency is from 20kHZ to 0.1HZ, and the voltage disturbance amplitude is 10mv. image 3 In order to measure the transverse conductivity of the nafion film before hot pressing, the image 3 The resistance of the blank solution can be obtained as 6.1986Ω, and the total resistance of the proton exchange membrane and the solution before the hot pressing of the nafion membrane is mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com