Plate width, side shape and side defect measuring instrument and measuring method thereof

A sheet and edge technology, applied in the field of opto-mechatronics measurement, can solve the problems that the maximum, minimum and average width of the section cannot be measured, and the edge defects of the sheet cannot be accurately measured, so as to reduce the difficulty of on-site protection. , low-cost, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

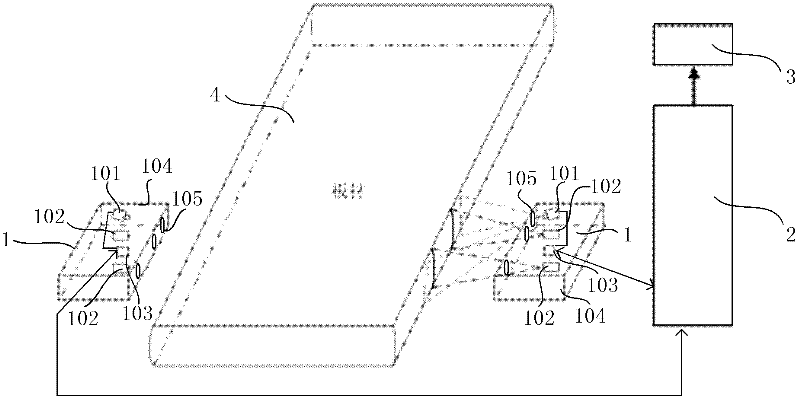

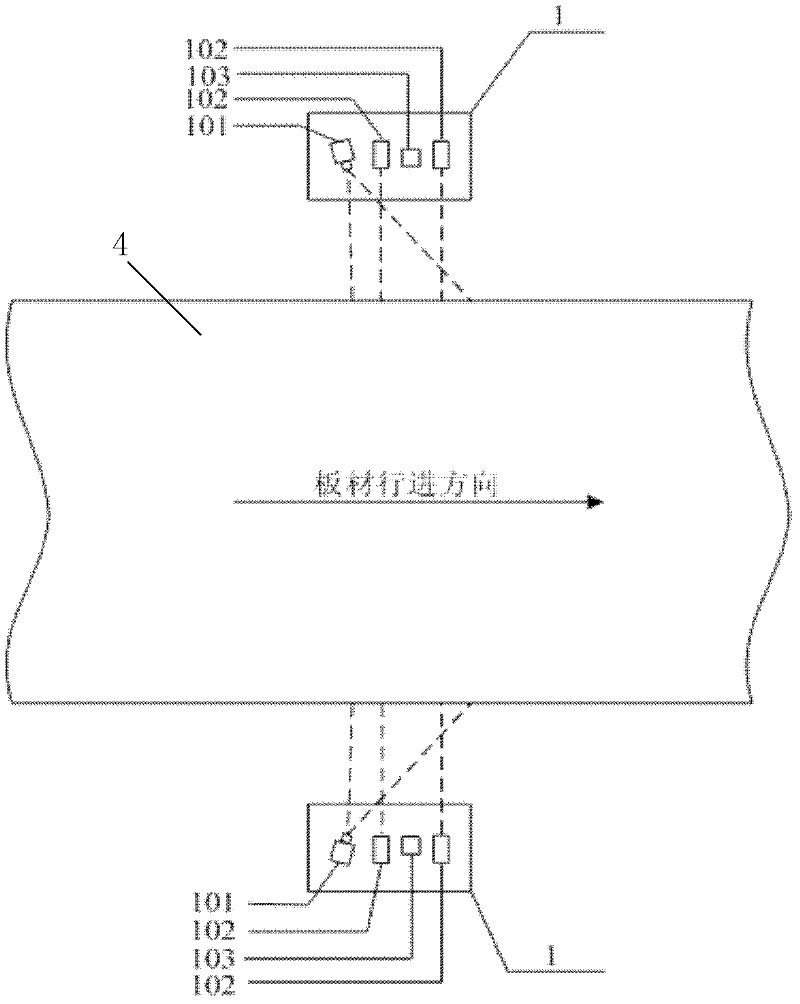

[0060] Embodiment: Take the flat steel production line of certain enterprise as example:

[0061] Thickness range of flat steel products: 6-150mm, width range: 300-800mm, maximum left and right offset of flat steel products: 20mm.

[0062] Considering the measurement margin, the parameters of the comprehensive measuring instrument designed for this production line in this example are:

[0063] Datum distance: w 0 =280mm;

[0064] The distance measurement range of each set of edge measurement device 1: 300mm; the maximum width measurement range is 880mm; the angle between the optical centerline of the full HD area scan camera 101 and the centerline of the line laser 102 is 45°. In this example, the high-definition area scanning camera 101 adopts a 1400×1024 industrial digital camera with a frame rate of 60fps. The field of view of the high-definition area scanning camera 101 is 300mm (in the direction of the width of the plate) × 180mm (in the direction of the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com