A vacuum insulation material with low thermal conductivity, wide temperature range and long life

A vacuum insulation material and wide temperature range technology, applied in thermal insulation, building components, etc., can solve the problems of long refrigeration time, short service life, high thermal conductivity, etc., achieve huge economic and social benefits, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

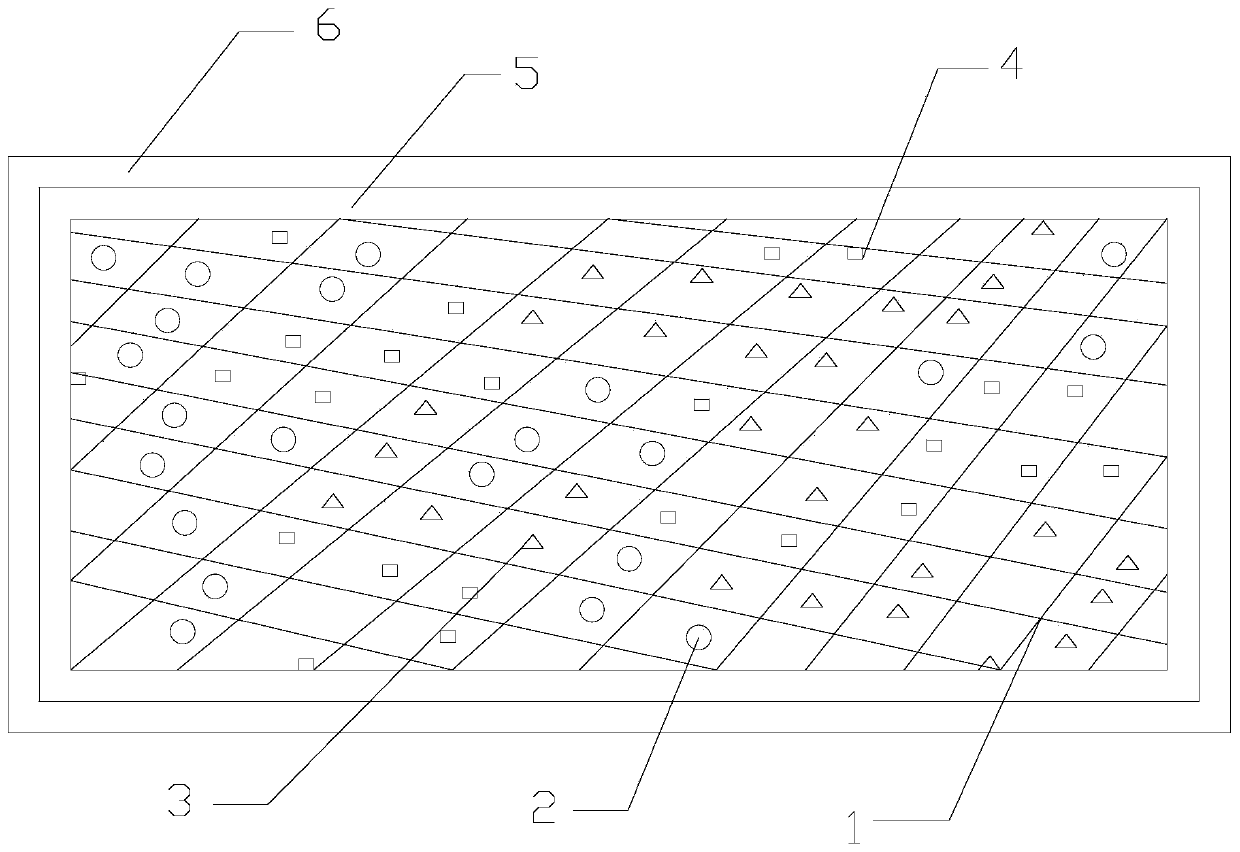

[0024] Weighing parts by weight are 60 parts of superfine glass fiber, 15 parts of airgel powder, 2 parts of carbon black opacifying agent, 1 part of silicon carbide reflector, and 10 parts of phase change material, wherein the airgel is selected as silicon dioxide Airgel powder, the opacifying agent is carbon black opacifying agent, the reflective agent is silicon carbide reflective agent, and it is prepared as a core material multilayer structure, wherein the number of layers is 5-10 layers, and the superfine glass fiber crossed between the two layers The included angle in the radial direction is 90°. The phase change material can be selected as an inorganic phase change material or an organic phase change material, preferably crystal water and salts, metals, alloys, paraffin, acetic acid and the like.

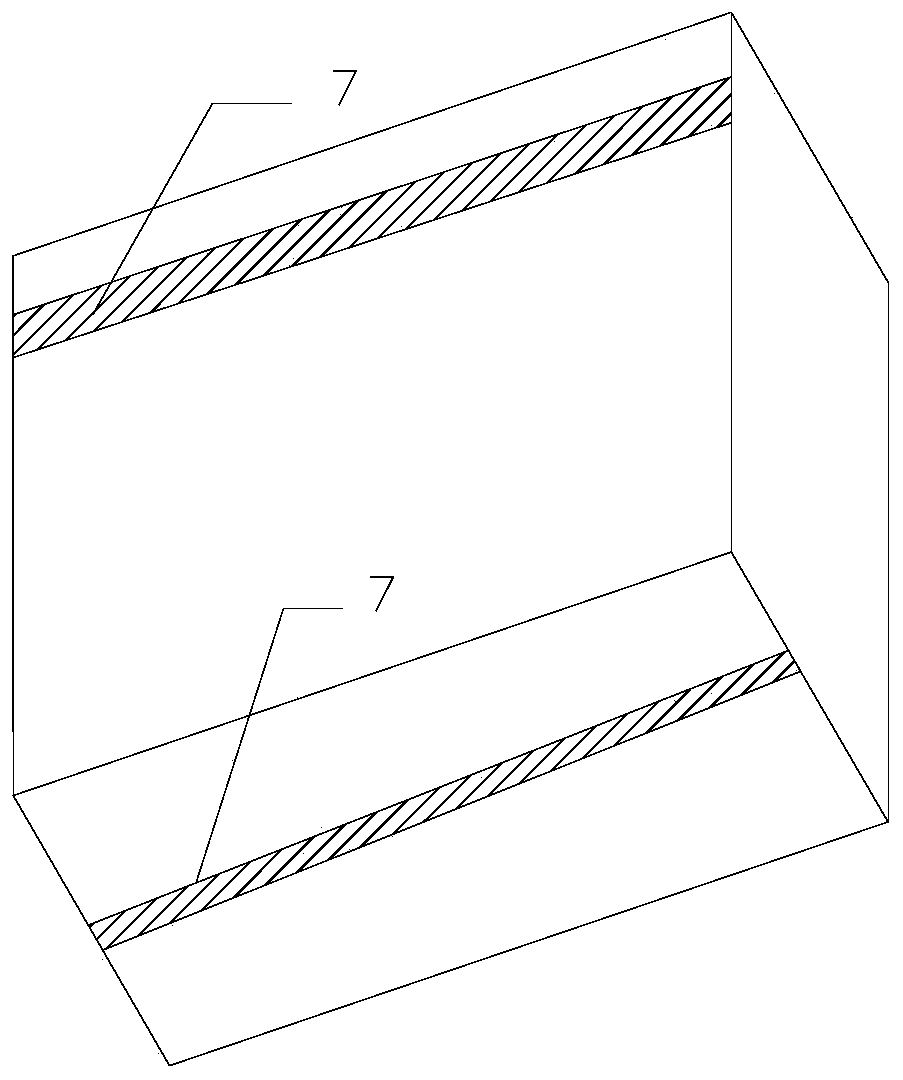

[0025] The core material is covered with a vacuum film layer 5, and the edge of the vacuum film layer 5 is packaged. There are four sets of package structures 7, where the e...

Embodiment 2

[0030] The parts by weight are 85 parts of superfine glass fiber, 11 parts of airgel powder, and 5 parts of opacifying agent, including 3 parts of carbon black opacifying agent, 1.7 parts of silicon carbide opacifying agent, and 0.3 part of zirconium carbide opacifying agent, 1 part of silicon carbide reflector, 25 parts of phase change material. It is prepared as a core material multi-layer structure, wherein the number of layers is 6-8 layers, and the included angle of the radial direction of the superfine glass fibers intersecting between the two layers is 90°. The phase change material can be selected as an inorganic phase change material or an organic phase change material, preferably crystal water and salts, metals, alloys, paraffin, acetic acid and the like.

[0031]The core material is covered with a vacuum film layer 5, and the edge of the vacuum film layer 5 is packaged. There are four sets of package structures 7, where the edge sealing positions are respectively se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com