Apparatus and method for preparing metal probe tip

A needle tip and metal technology, applied in the nanometer field, can solve the problems of fine control of the radius of curvature of the needle tip, slow electrochemical corrosion process, low yield of nickel needle tip, etc., and achieve the effect of spin resolution, short time and fast corrosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the device and method for preparing metal needle tips provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

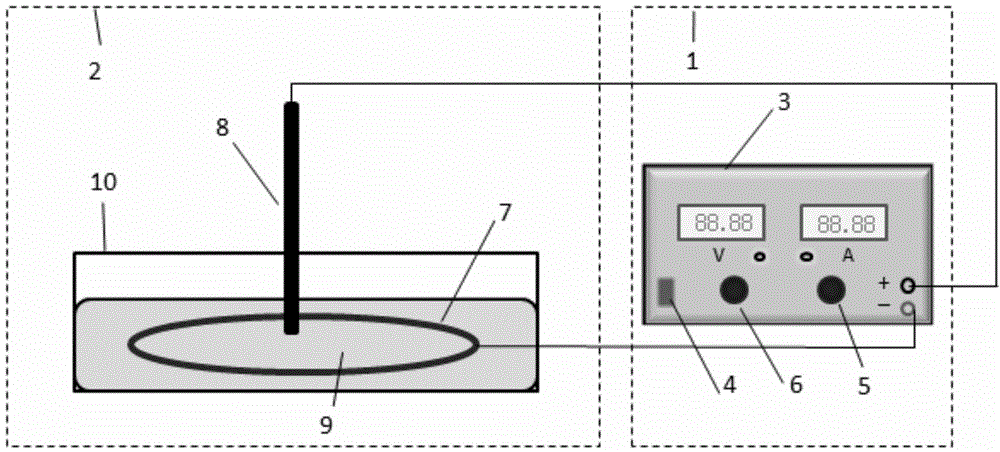

[0027] figure 1 Schematic diagram of the structure of the device for preparing needle tips of the present invention. In this embodiment, the device for preparing a metal needle tip includes a control circuit 1 and an electrochemical cell 2 .

[0028] The control circuit 1 includes a constant current and constant voltage power supply 3 and a switch 4 . The constant-current and constant-voltage source 3 provides electric energy for the device. There are two knobs on the constant-voltage and constant-current source 3 for setting the initial current value 5 and voltage value 6 respectively. After the device is connected, according to the internal circuit design principle of the constant current and constant voltage source 3, if the product of the initial resistance value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com