System and Method for Refilling an Electrolyzer Tank from a Water Reservoir

a technology of electrolyzer and water reservoir, which is applied in the direction of electrolysis components, instruments, optics, etc., can solve the problems of reducing reliability and efficiency below 100%, and achieve the effects of maintaining electrolyzer energy efficiency, high operational reliability and convenient long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

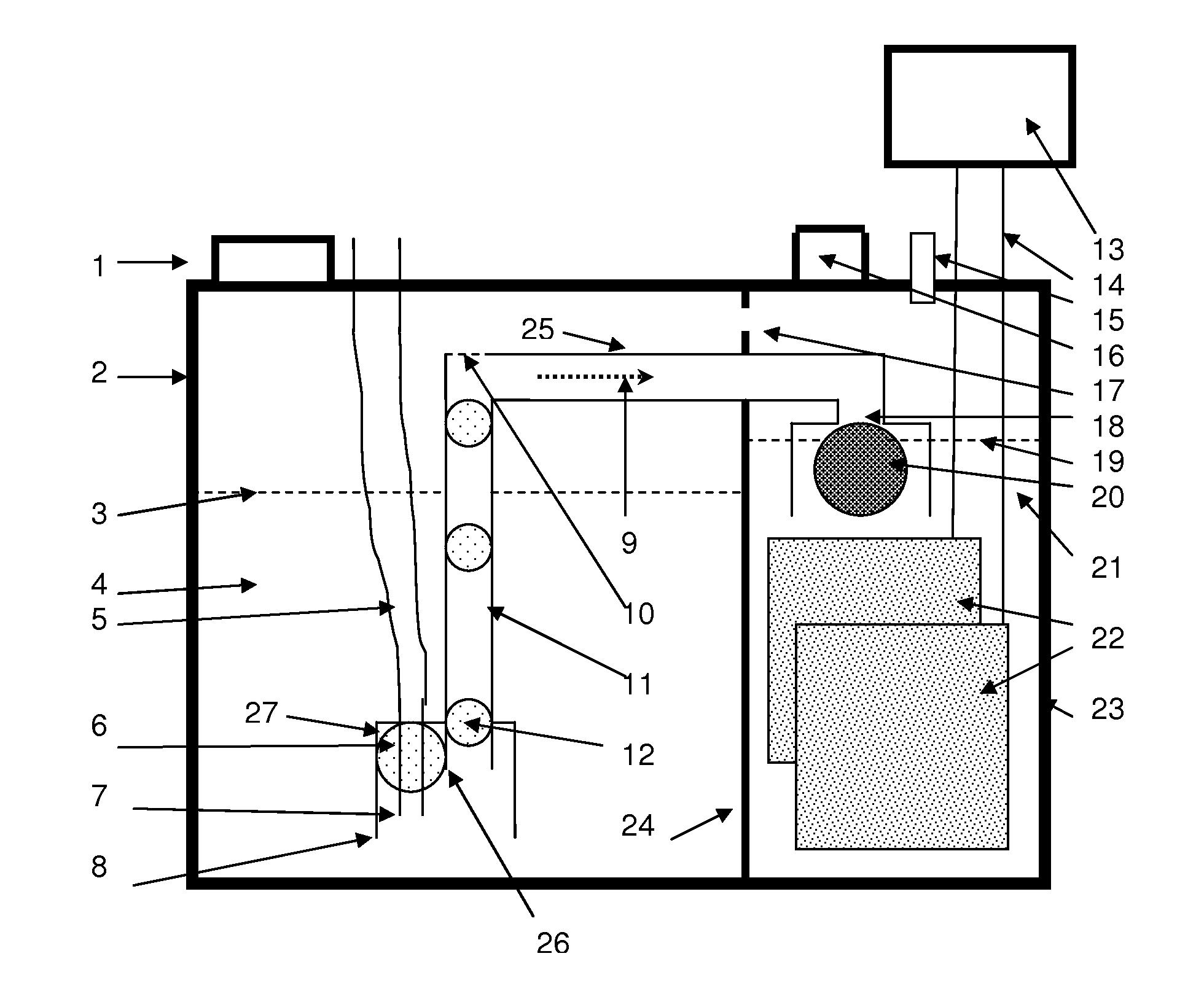

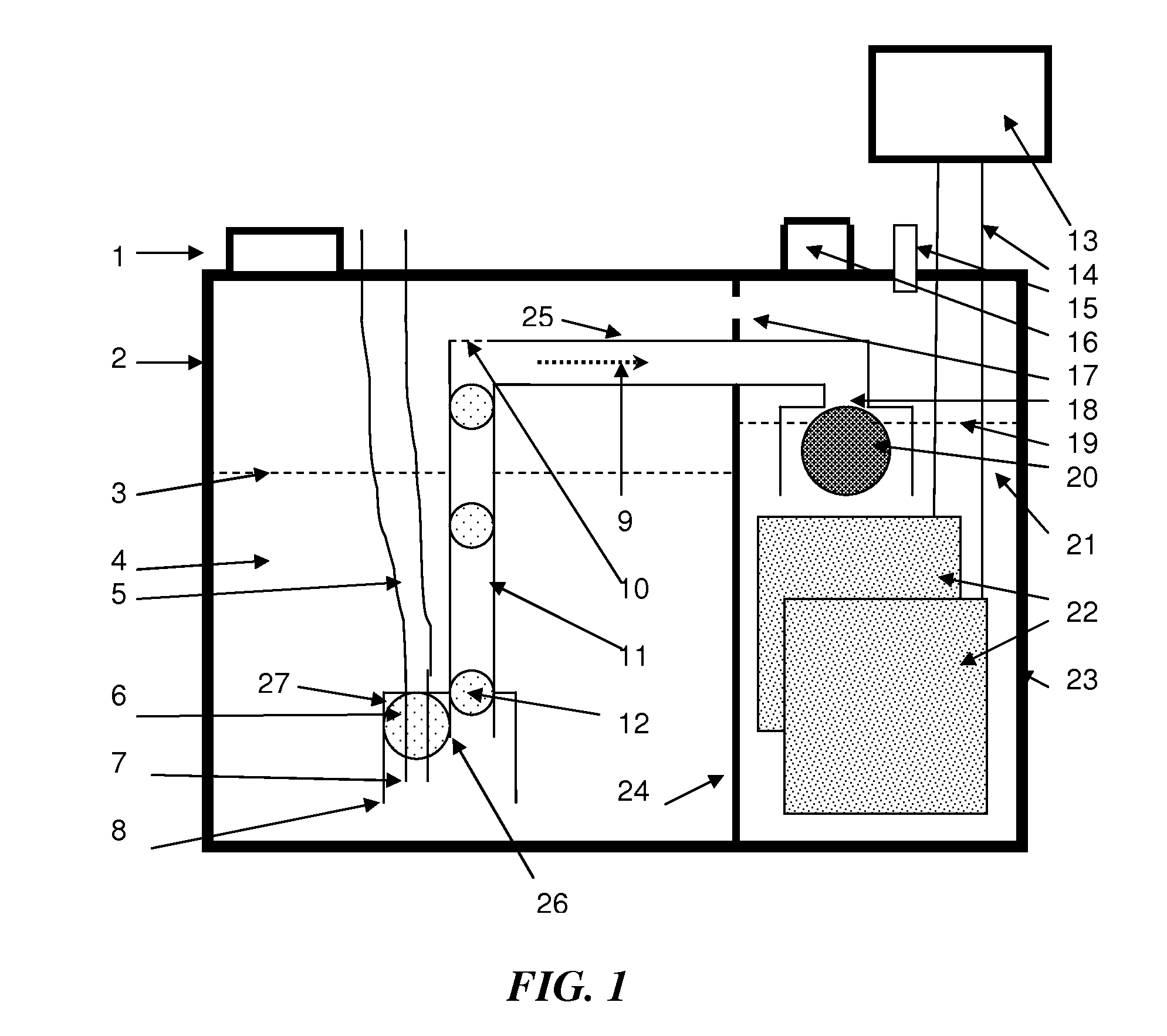

[0051]The following disclosure presents an exemplary embodiment of the invention for refilling an electrolyzer tank from a water reservoir. The invention provides a highly reliable, robust and passive control system (and related methods) for maintaining electrolyte level and electrolyte concentration within an electrolyzer tank. This technology rectifies the limitations of prior fluid level control systems, particularly those employed in water electrolyzers designed for use with internal combustion engines. Using the technology of the present invention, an electrolyzer may be optimized for efficiency and operational life.

[0052]Referring to FIG. 1, an exemplary embodiment of the invention is depicted in the form of a schematic for a water electrolyzer. In normal operation, a container 2 holds an amount of water 4, the free surface of which is labeled 3 and container 23 holds an amount of electrolyte 21, the free surface of which is 19. In one embodiment, containers 2 and 23 may be fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com