Rare earth electrolytic tank for producing rare earth and alloys thereof

An electrolytic cell and rare earth technology, which is applied in the electrolysis process, electrolytic components, electrodes, etc., can solve the problems of difficulty in controlling anode current density and pole distance, difficulty in the implementation of industrialized production of electrolytic cells, and reducing the contact area between metal and electrolyte. Conducive to purification, recycling, high-efficiency production, and energy-saving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in combination with specific embodiments.

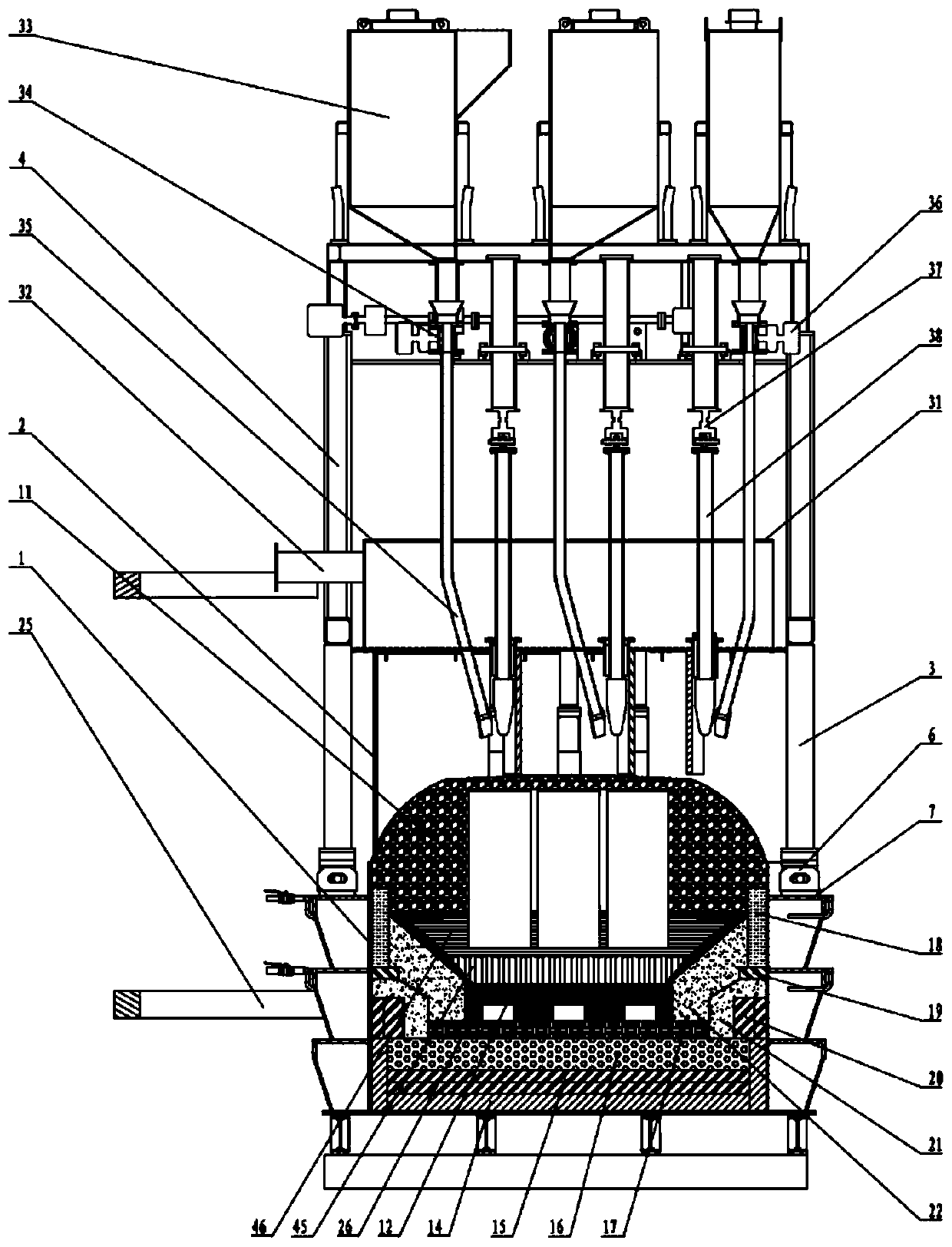

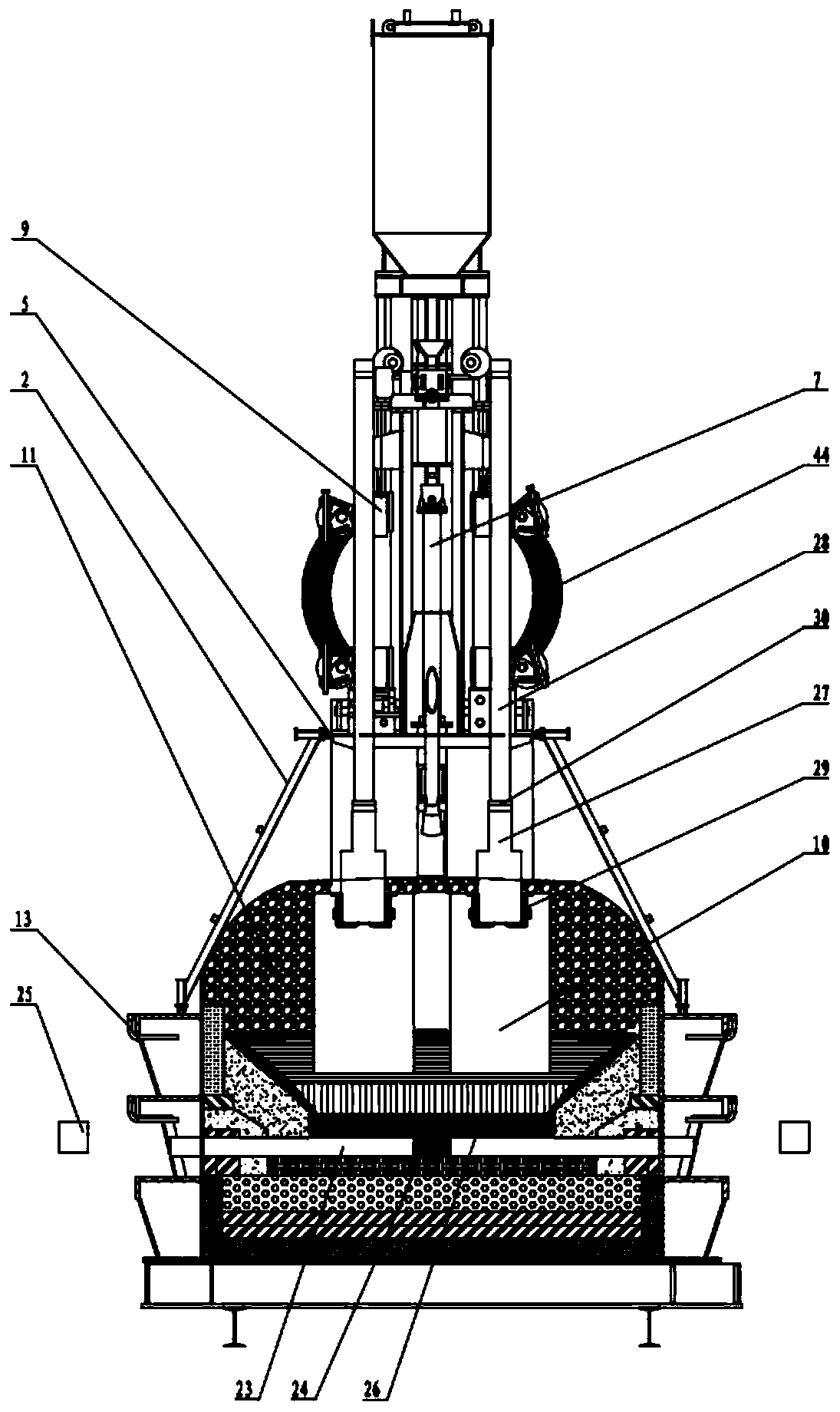

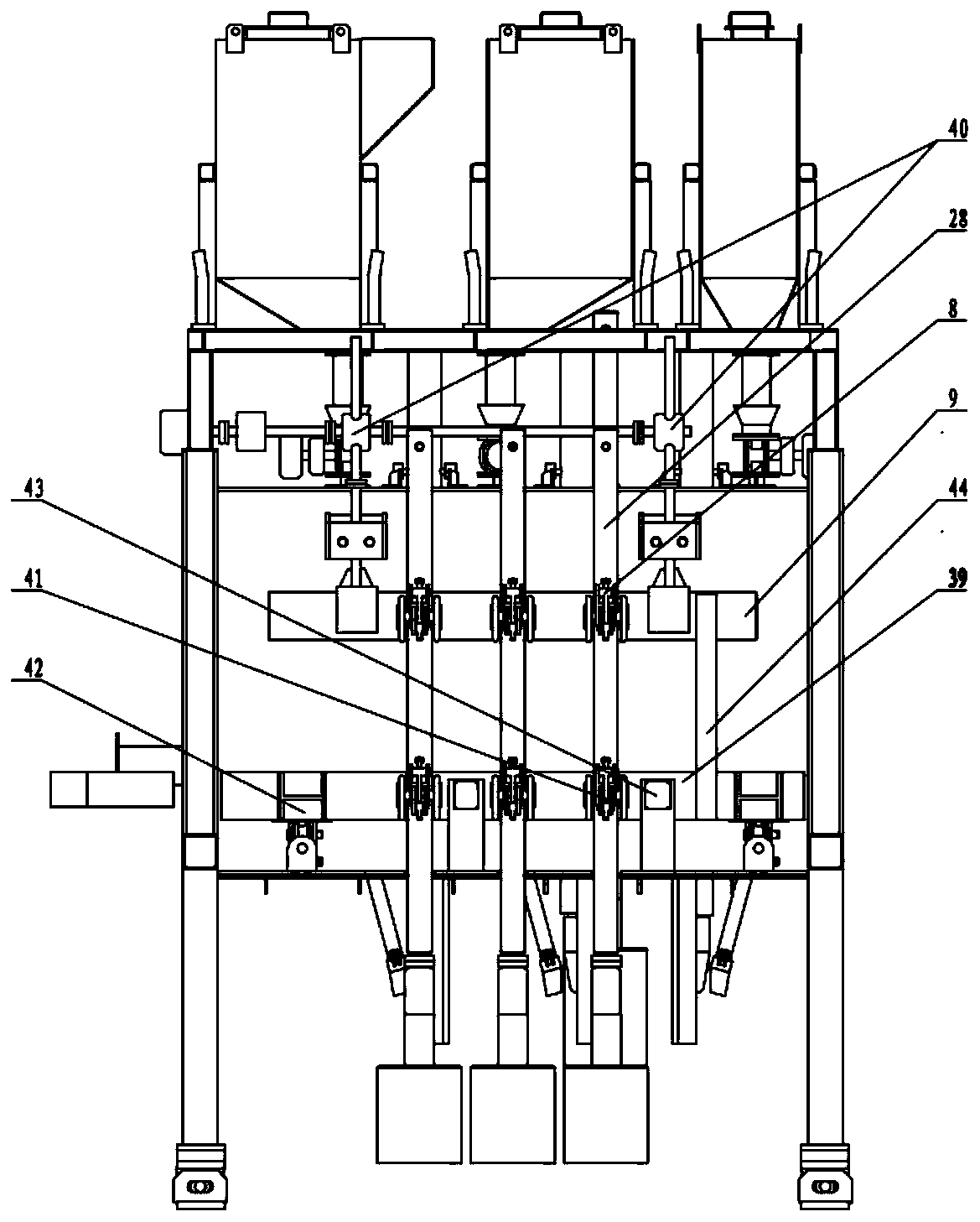

[0026] see figure 1 , figure 2 and image 3 , the rare earth electrolytic cell of this embodiment includes a cell shell, a cell liner, a cathode group structure, an anode assembly, a column girder frame, a cell cover plate, a blanking system, a shell breaking system, a gas collection system, an anode lifting and a bus transfer system And intelligent slot control system. The electrolysis current of the rare earth electrolyzer is 10-200kA, the electrolyte system used is REF3 (86-97%)-LiF (3-14%), the electrolysis temperature is 850-1250°C, and the anode current density is 0.7-2.0A / cm2, The cathode current density is 0.6-3.2A / cm2.

[0027] The tank shell 1 is a rectangular structure welded with steel plates, and the sides are welded with a coaming plate, a tank edge plate 7 , a stiffener plate and a cooling air duct 13 .

[0028] The trough cover plate 2 is a double-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com