Patents

Literature

37results about How to "High anode utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy anode material for battery

InactiveCN101388457AHigh anode utilizationImprove electrochemical performanceCell electrodesImpurityGallium alloy

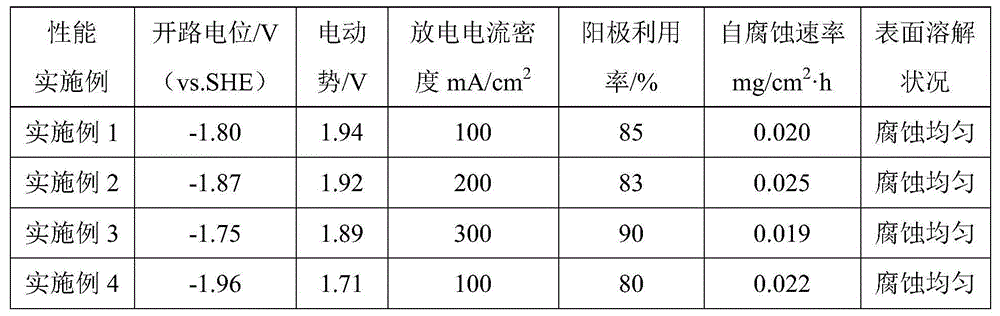

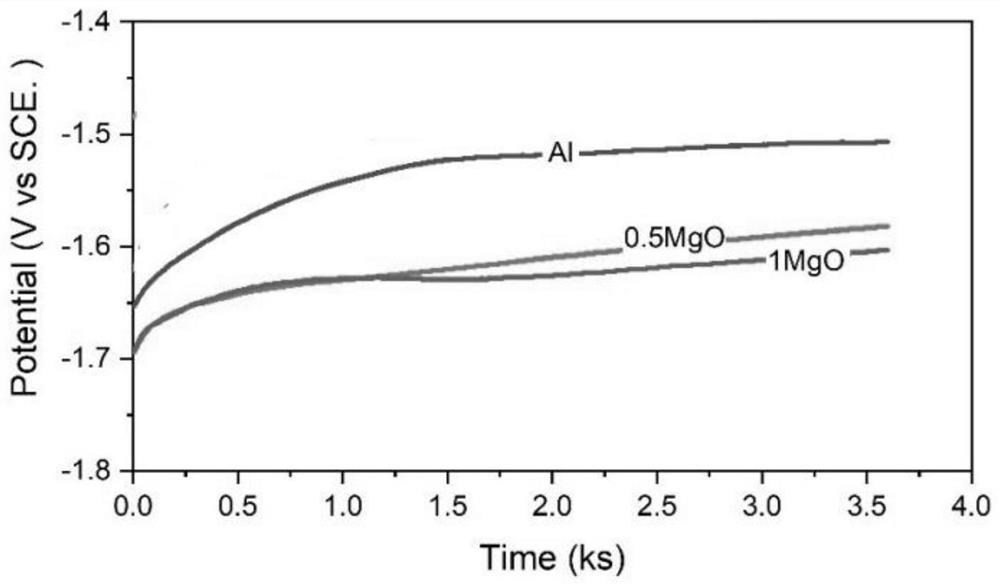

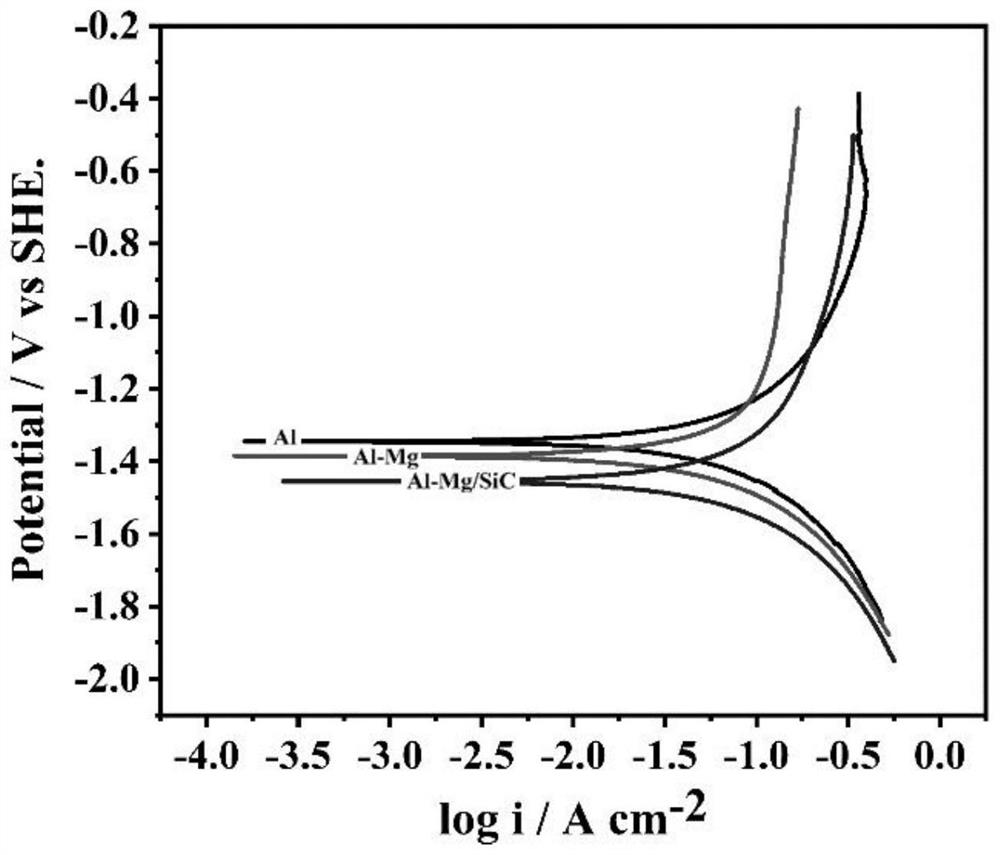

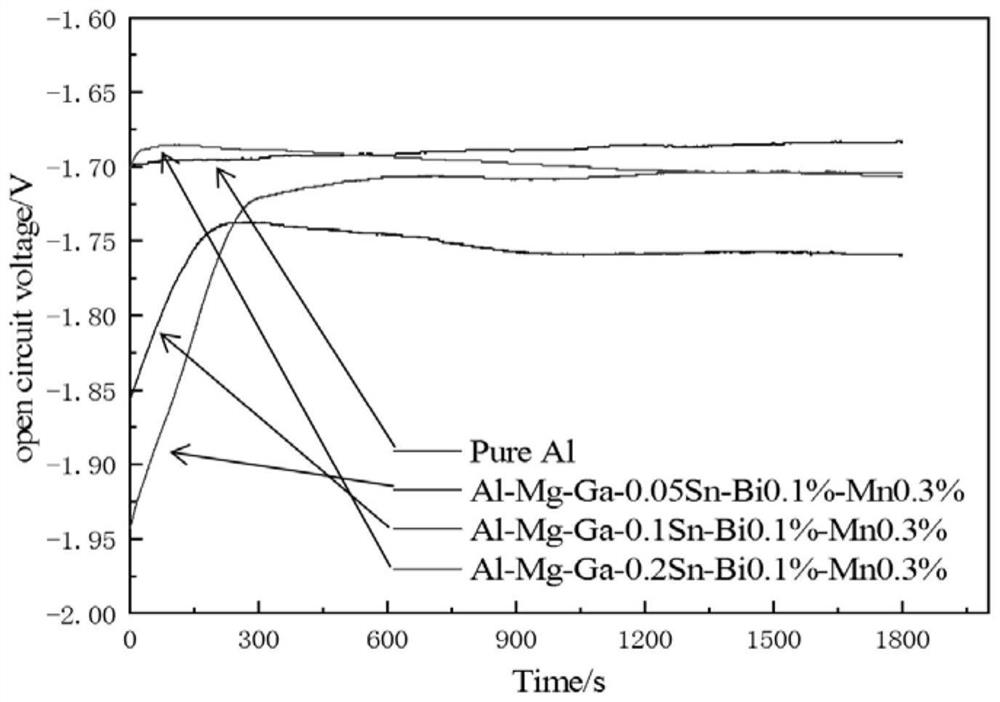

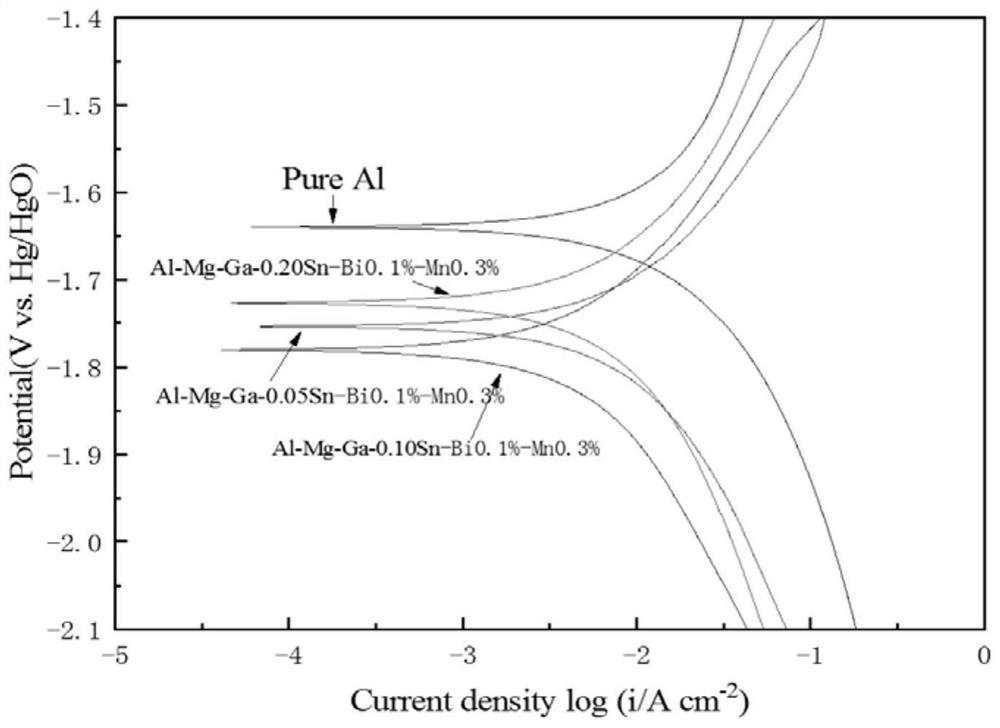

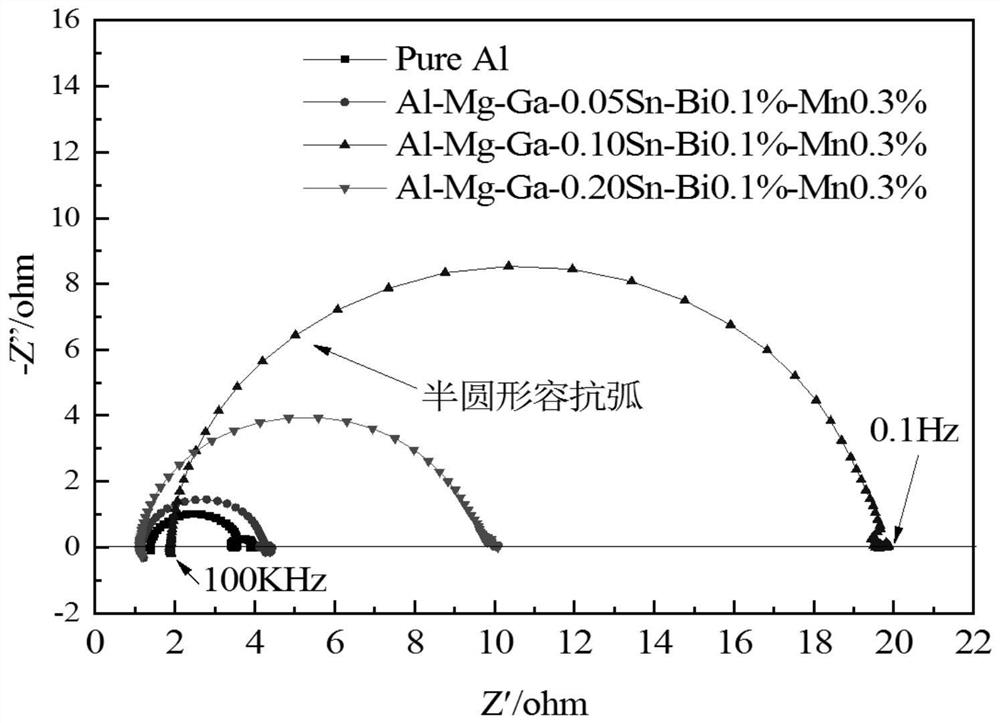

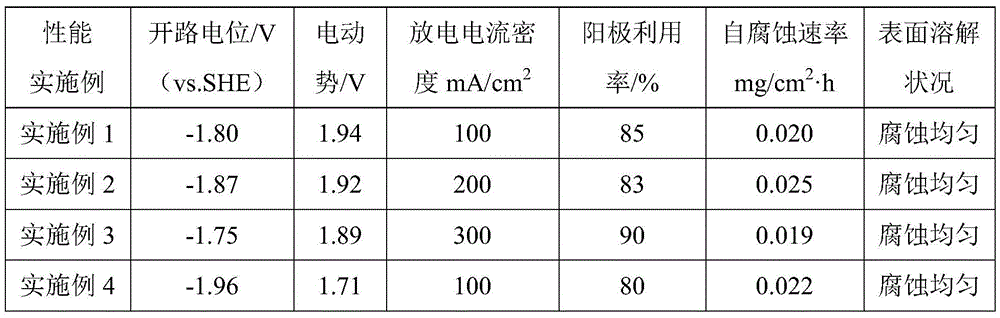

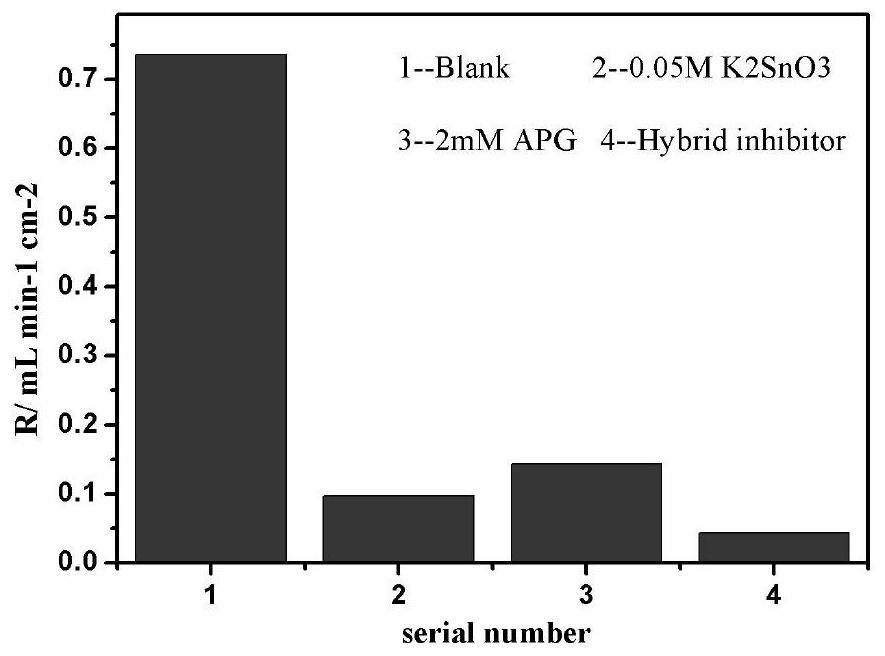

The invention discloses an aluminum alloy anode material of batteries, which uses aluminum whose purity is higher or equal to 99.99% as raw materials. Magnesium (Mg), stannum (Sn), gallium (Ga) and bismuth (Bi) are added, and the mass percentage of elements which are added is that Mg: 0.5-1.5%, Bi: 0.01-0.2%, Sn: 0.01-0.4%, Ga: 0.01-0.3%, and the mass content of impurities is equal to or less than 0.01%. The invention has the advantages of high operating factor of the cathode and the anode of a working potential, stable output of big power and even corrosion on the surface.

Owner:CENT SOUTH UNIV

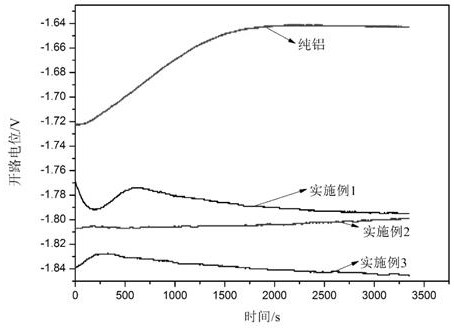

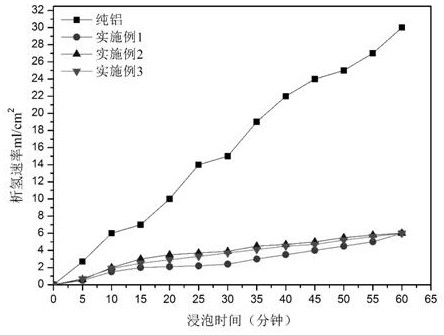

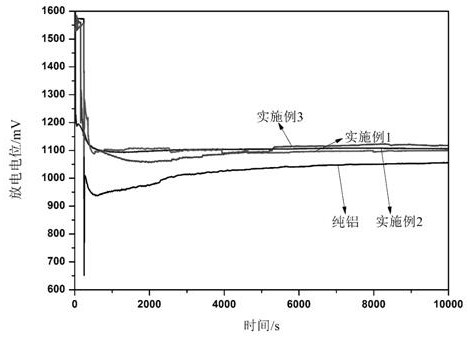

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

Anodic phosphorous copper balls and preparation method thereof

InactiveCN101914801AImprove qualityPhosphorus is evenly distributedElectrodesCopper platingInduction furnace

The invention discloses anodic phosphorous copper balls and a preparation method thereof. The method comprises the following steps of: (1) after yellow phosphorus or red phosphorus and oxygen-free copper are melted by adopting a medium-frequency induction furnace, stirring the melt uniformly through a magnetic stirring tank to obtain phosphorous copper solution; (2) producing a phosphorous copper bar with a diameter of 20 to 50 millimeters by using the phosphorous copper solution prepared in the step (1) and an up-draw process, and continuously stamping the phosphorous copper bar to obtain copper balls of different sizes in different dies; and (3) performing polishing, burr removal, cleaning and drying treatment on the copper balls obtained in the step (2) in turn to obtain the anodic phosphorous copper balls. The anodic phosphorous copper balls have the advantages of compact crystal, thin and small crystal grain, high phosphorous copper film generating speed, exquisite and firm phosphorous copper film texture and dropping resistance, and can reduce the cleaning frequency of an anode, effectively improve the utilization rate of the anode and remarkably improve the copper plating effect.

Owner:金峰电路(惠州)有限公司

Aluminum-alloy anode material for battery and preparation method of aluminum-alloy anode material

InactiveCN105244489ACompatibility is reasonableImprove electrochemical performanceCell electrodesElectrochemistryCorrosion

The invention provides an aluminum-alloy anode material for a battery and a preparation method of the aluminum-alloy anode material, belonging to the technical field of an alloy material and solving the problem of non-ideal electrochemical performance of the traditional aluminum-alloy anode material for the battery. The aluminum-alloy anode material comprises the following constitutes based on mass: 0.5-1.0% of Mg, 0.1-1.0% of Ga, 0.5-1.0% of Bi, 0.05-0.8% of Ce, 0.005-1.0% of Pb, 0.005-0.05% of Ca and the balance of Al. The aluminum-alloy anode material for the battery has the advantages of high open circuit potential, low self-corrosion rate, high utilization rate of a positive electrode and the like.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Technique and device for non-membrane electrolytic synthesis of butanedioic acid

InactiveCN101100758AImprove utilization efficiencyReduce current densityCellsElectrolytic organic productionButanedioic acidElectrolysis

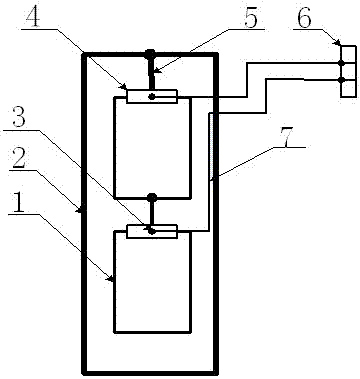

Apparatus and process for non-membrane electrolytic synthesis of succinic acid are both disclosed herewith. It takes stage-series flow process with exchangeable tanks to electrolyzing continuously and discharging periodically. The apparatus consists of an electrolytic bath, tanks, electrolyte distributing pipes, collecting pipes and high level tanks, pumps, and heat exchangers, which form cyclic circuits. An electrode set consisting of an anode and two cathodes are installed the bath. The cathodes are set on both sides of the anode respectively. This invention can produce quality succinic acid on large scale by synthesis with less investment on anode.

Owner:ZHEJIANG UNIV OF TECH

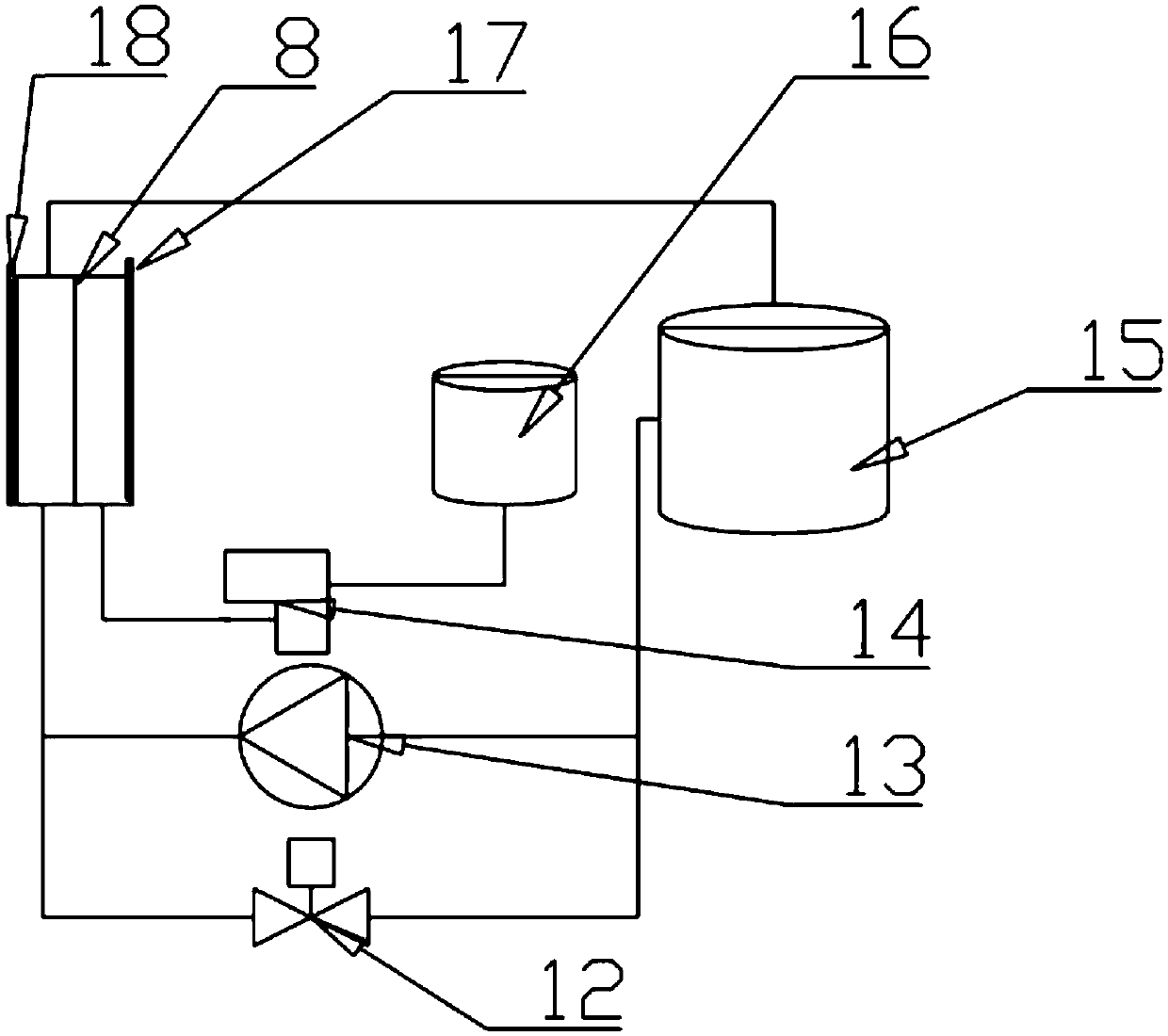

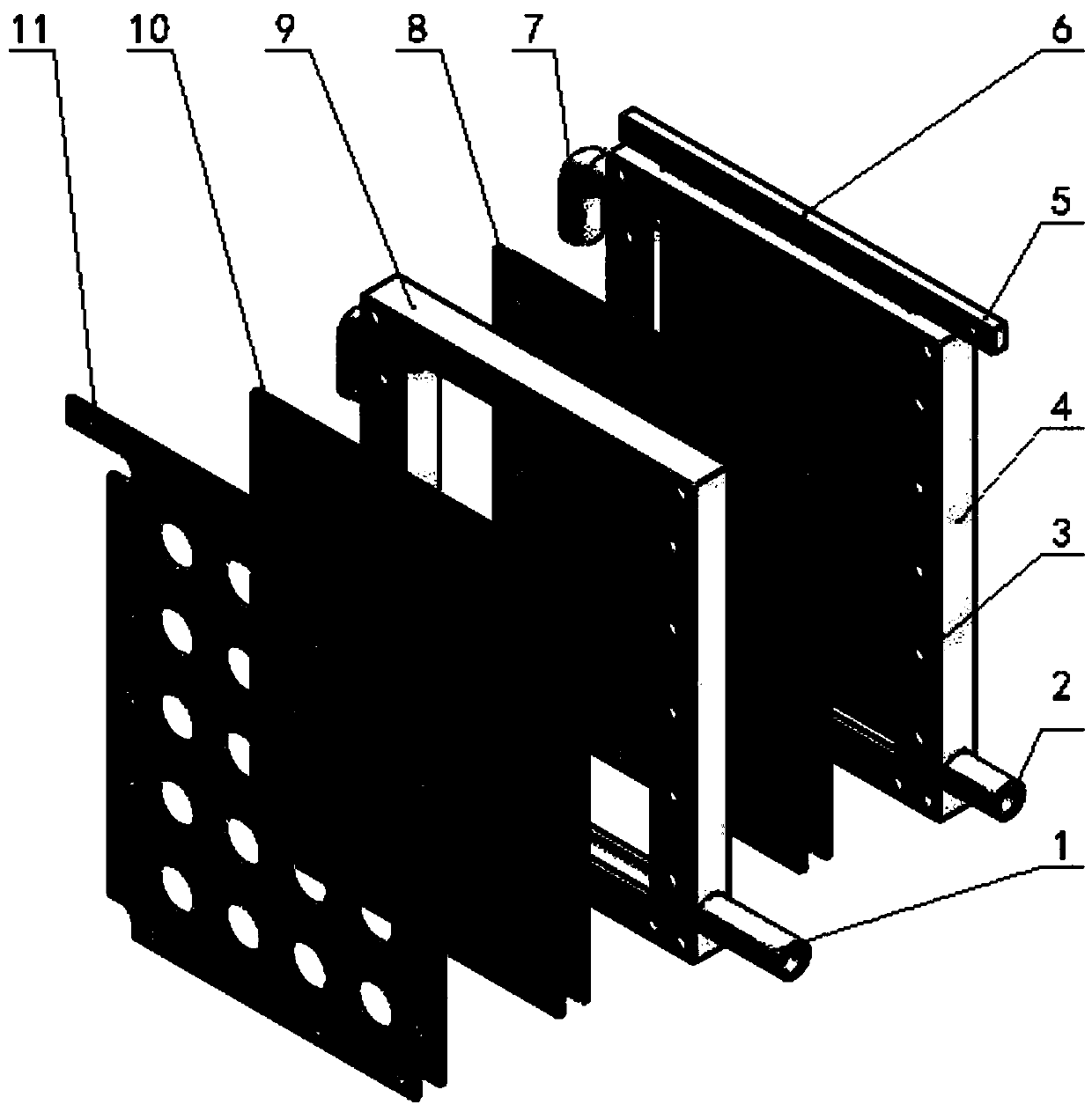

Metal/air battery system

ActiveCN108172948AImprove discharge capacityHigh anode utilizationFuel and primary cellsElectrolyte stream managementMetal anodeEngineering

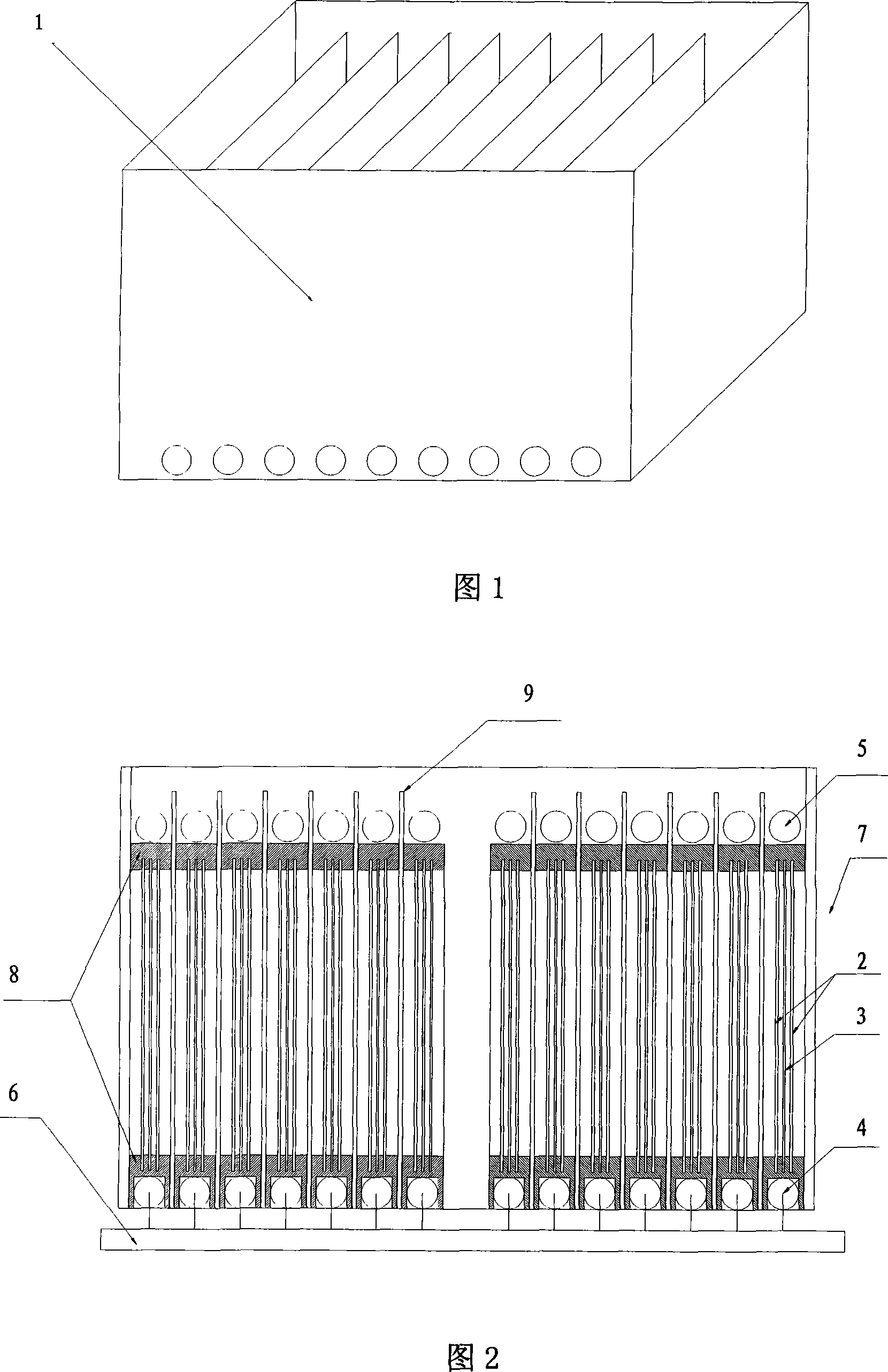

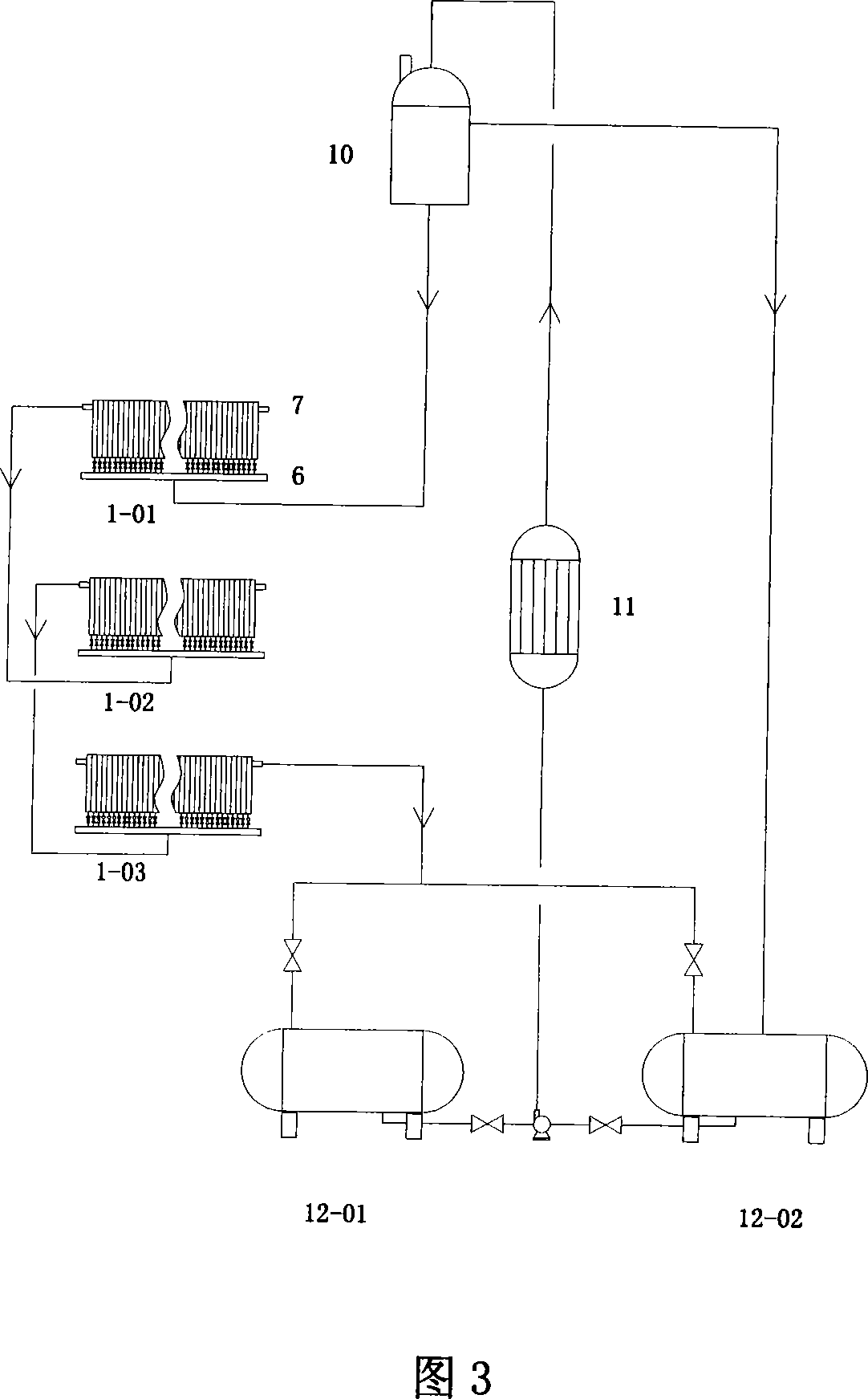

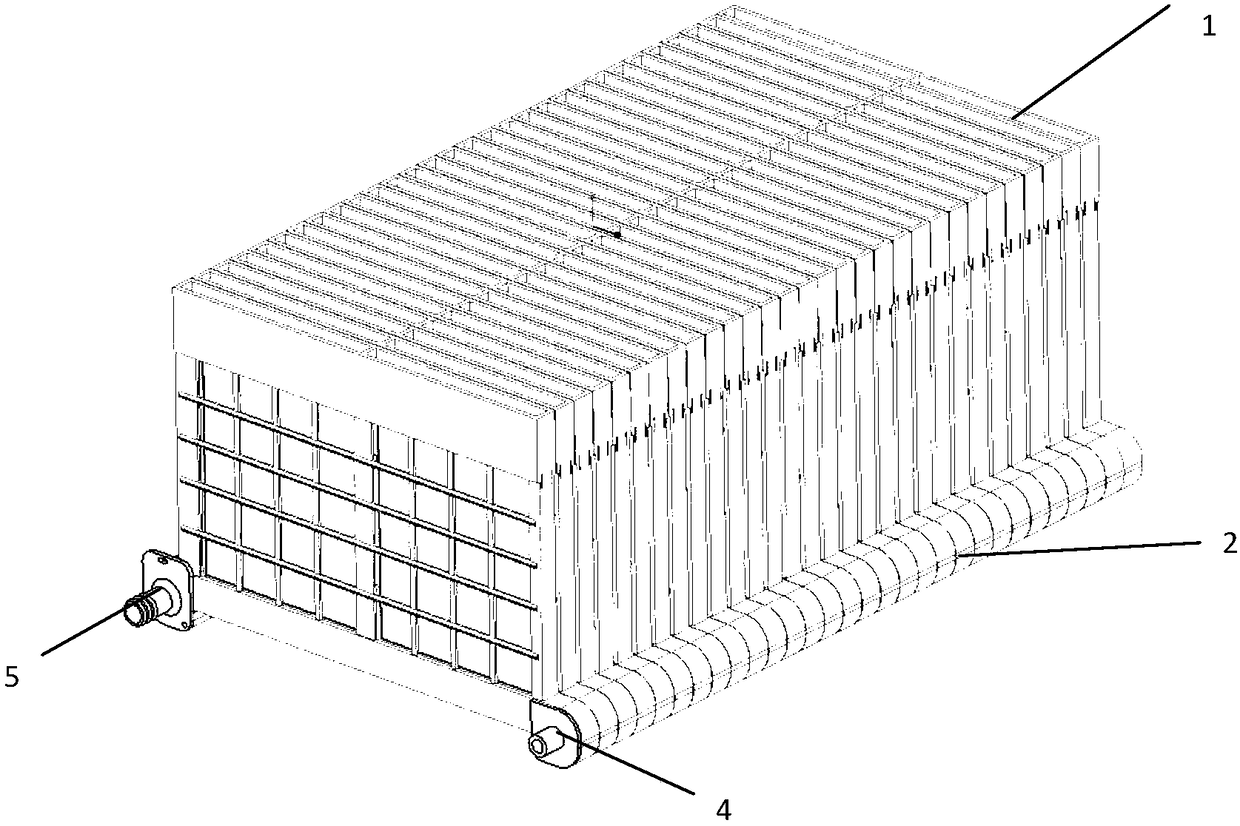

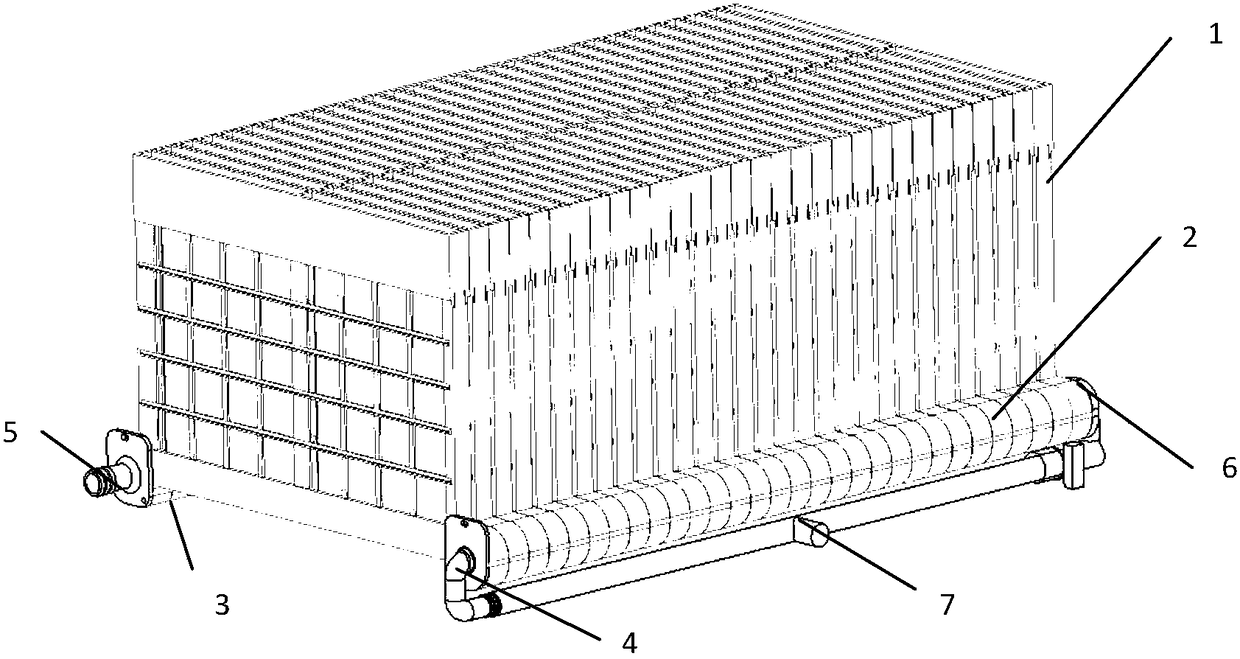

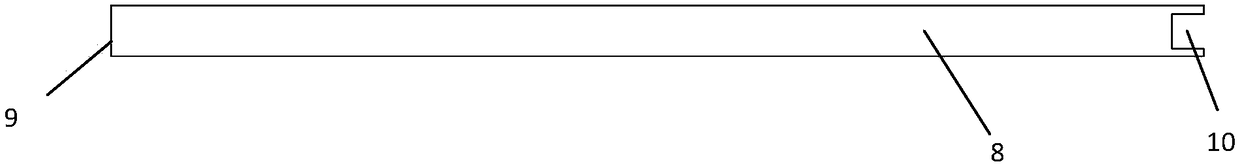

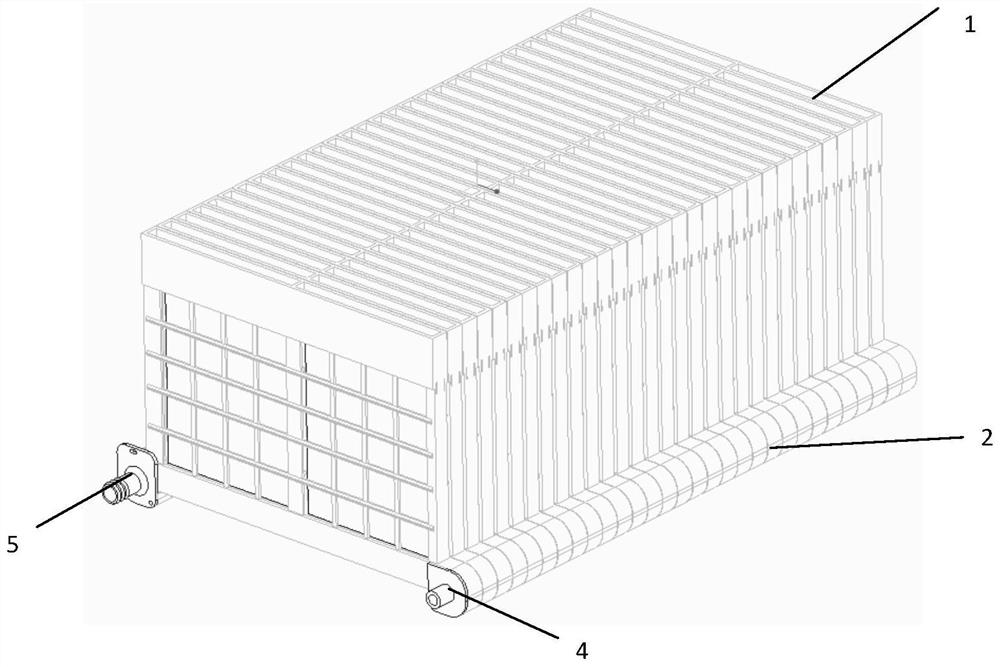

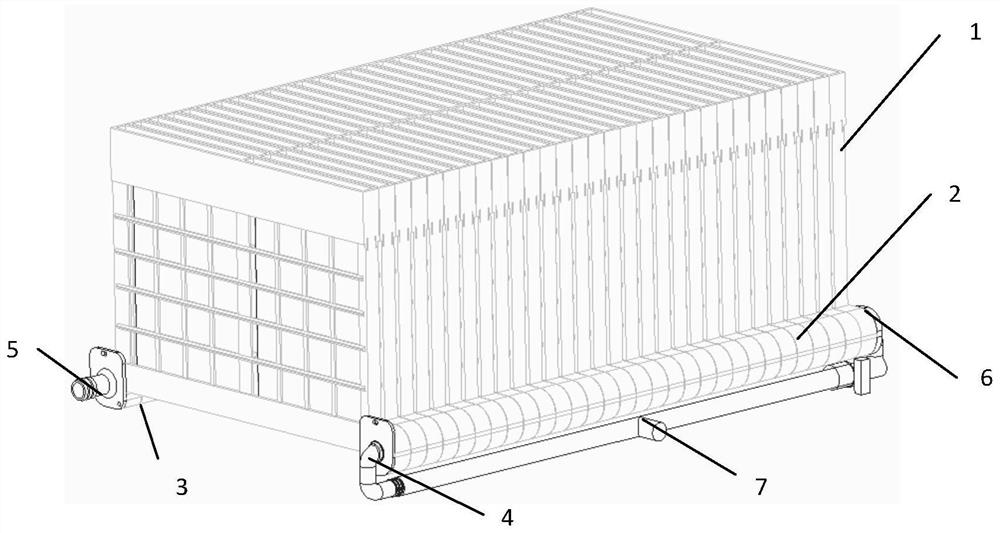

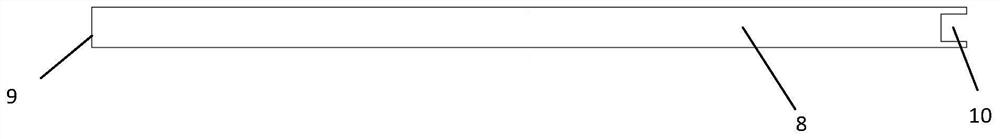

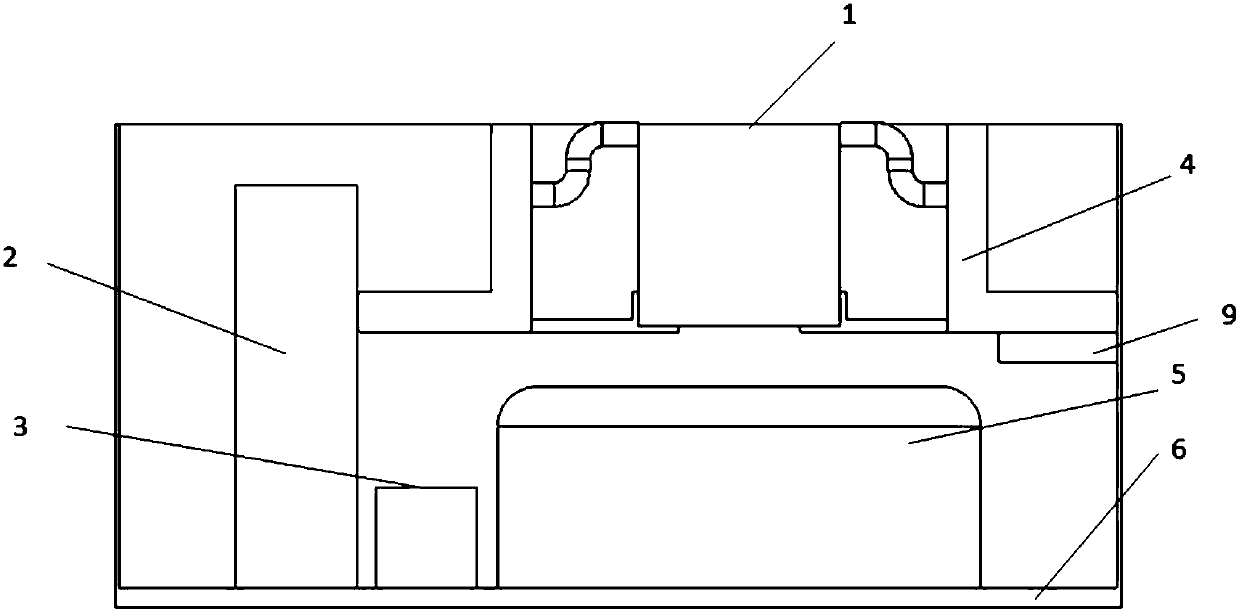

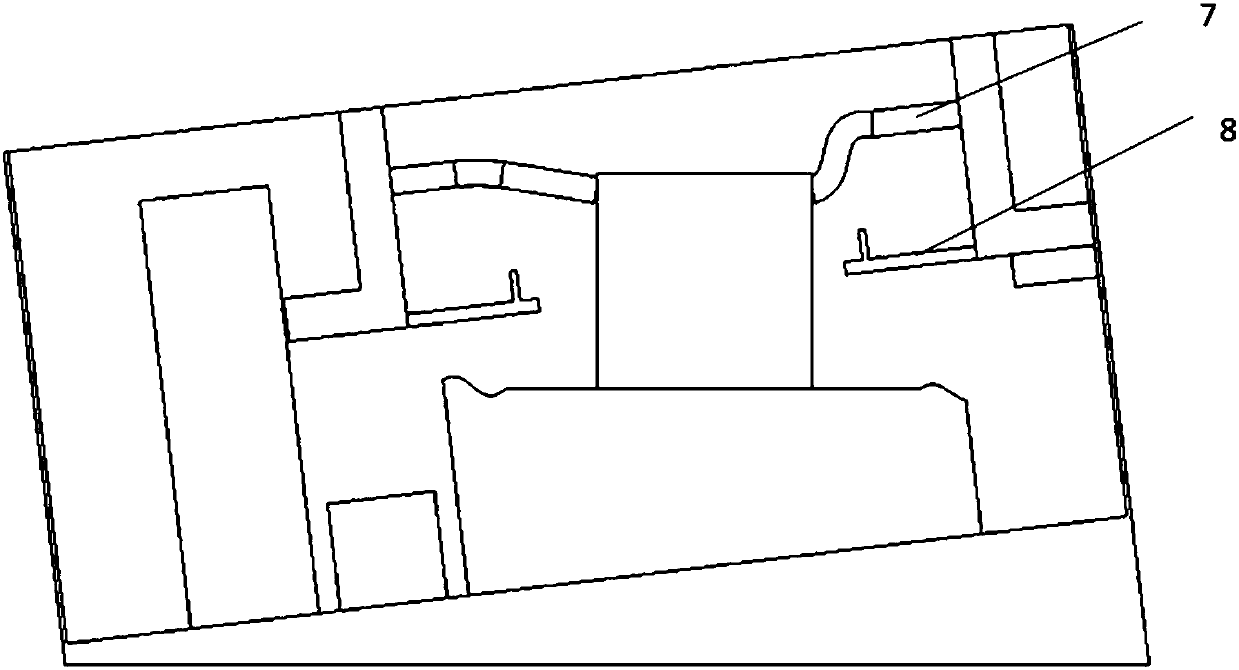

The invention provides a metal / air battery system, which comprises a metal / air battery pack, a liquid pump, a heat exchanger and a liquid storage unit, wherein the liquid inlet of the liquid pump is connected to the liquid storage unit, the liquid outlet of the liquid pump is connected to the liquid inlet of the heat exchanger, the liquid discharge port of the heat exchanger is connected to the electrolytic solution injection port of the metal / air battery pack, the electrolytic solution outlet of the metal / air battery pack is connected to the liquid storage unit to form a closed circuit, a single battery comprises a single battery shell, a metal anode positioned in the single battery shell and perpendicular to the bottom portion of the single battery shell, air cathodes arranged on both opposite sides inside the battery shell and parallel to the metal anode, and an electrolytic solution cavity formed from the single battery shell, the metal anode and the air cathodes, the N single battery shells are sequentially arranged in parallel from left to right, an injected liquid main flowing channel, a discharged liquid main flowing channel and an air flowing channel are arranged between the adjacent single battery shell, and a flow equalization unit is arranged in the injected liquid main flowing channel.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

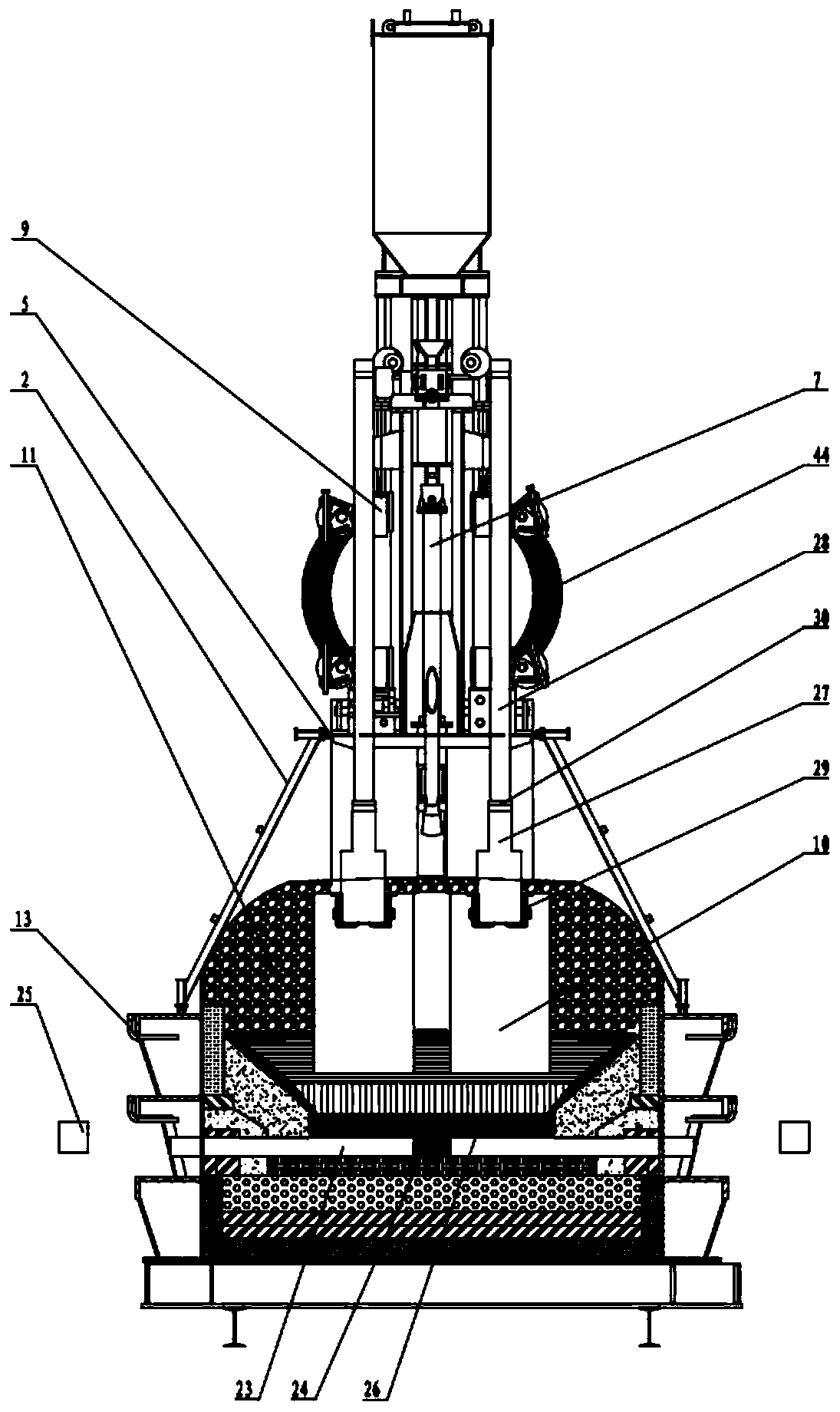

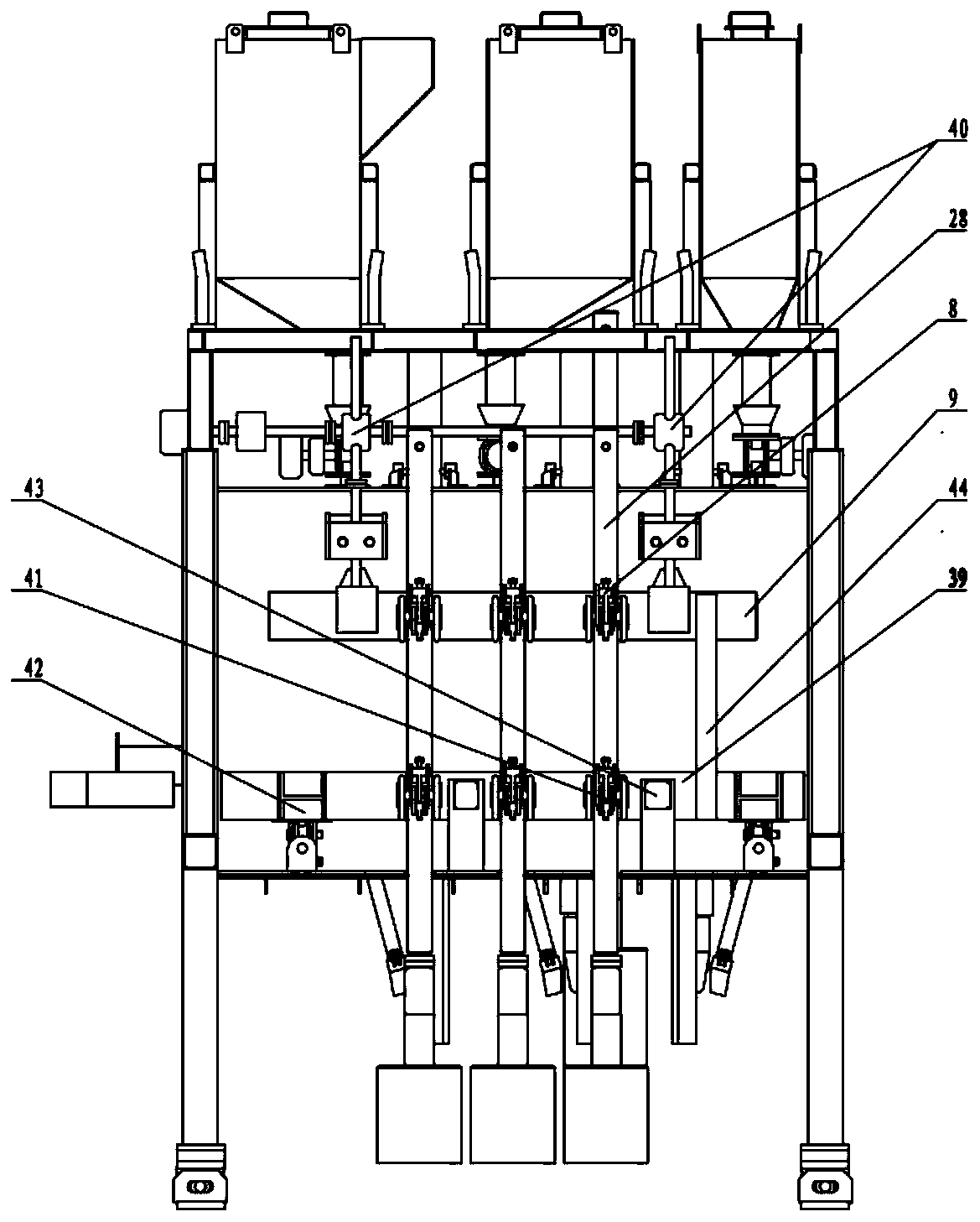

Rare earth electrolytic tank for producing rare earth and alloys thereof

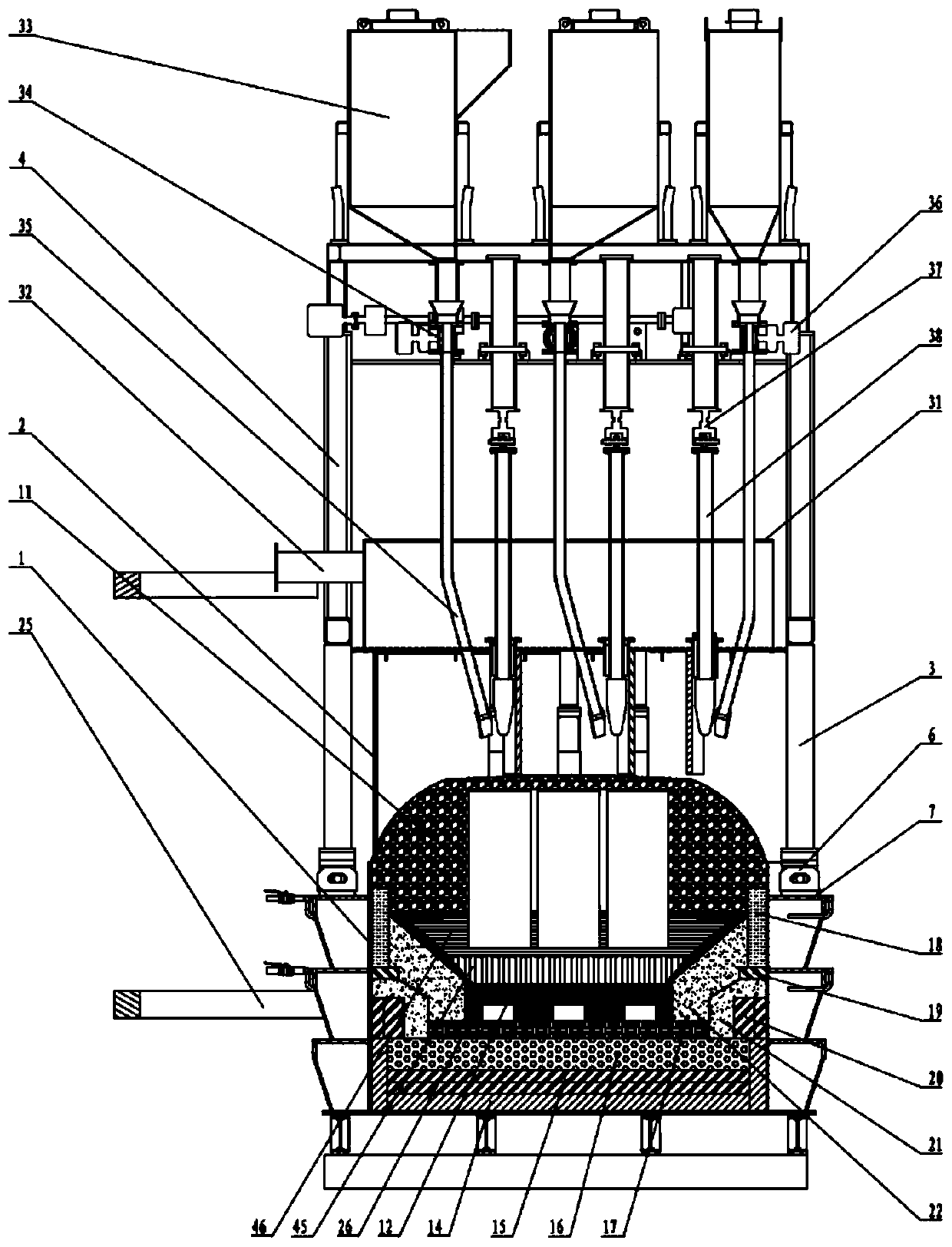

The invention discloses a rare earth electrolytic tank for producing rare earth and alloys thereof. The rare earth electrolytic tank comprises an electrolytic tank body, a cathode group structure, ananode group structure and a tank upper portion structure, wherein the electrolytic tank body comprises a tank shell and a tank lining, the tank upper portion structure comprises a vertical column girder frame, a material feeding system, a shell ramming system, an anode lifting and busbar switching system and a tank hood plate, the upper end of the anode group structure is connected with the anodelifting and busbar switching system, anode blocks at the lower end are vertically inserted in electrolyte inside the tank body, the parts, exposed outside the electrolyte level face, of the anode blocks are covered by an anode covering material, the anode lifting and busbar switching system is used for adjusting the polar distance between the anode blocks and the cathode group structure, the material feeding system, the shell ramming system and the anode lifting and busbar switching system are integrated into an intelligent tank control system, the upper edge of the tank hood plate is connected with the edge of the side portion of a horizontal hood plate, and the lower edge of the tank hood plate is connected with the upper surface of the tank shell to realize closeness of the electrolytictank. By means of the rare earth electrolytic tank for producing the rare earth and the alloys thereof, rare earth electrolytic tank automatic continuous, high-efficiency, low-energy-consumption, low-cost and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

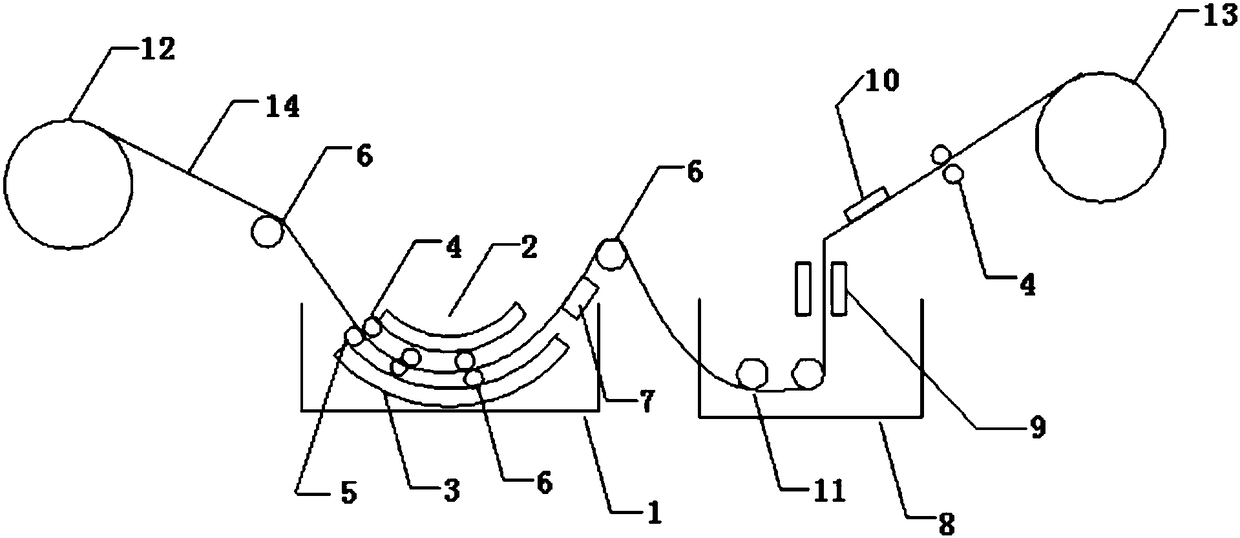

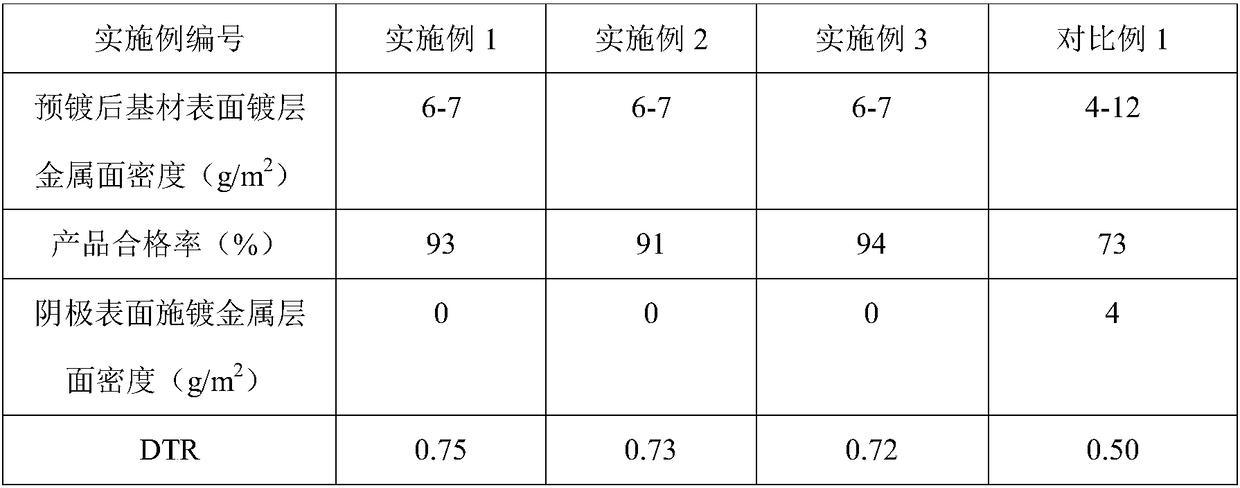

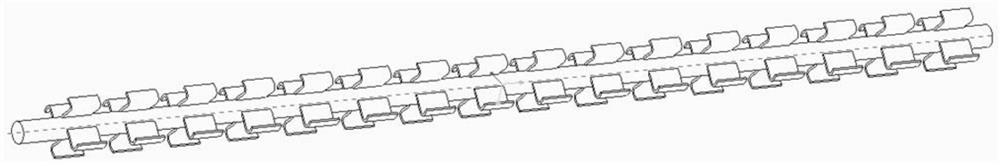

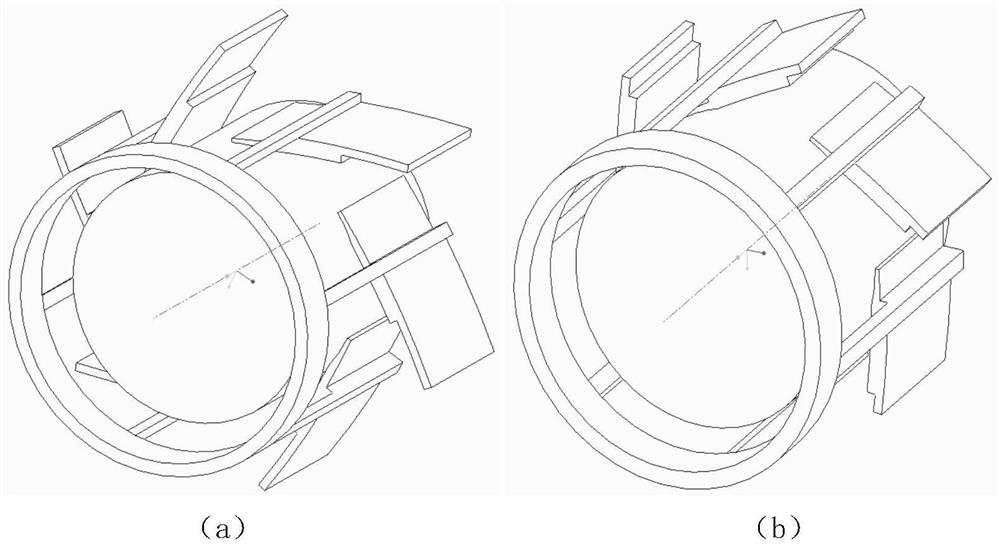

Electroplating equipment and electroplating method for foam metal material

The invention discloses electroplating equipment and electroplating method for a foam metal material. The electroplating equipment comprises an unrolling device, a pre-plating slot, an electroplatingslot and a rolling device, wherein the pre-plating slot comprises a pre-plating slot body, an anode I and an anode II which are distributed up and down in the pre-plating slot body, and a cathode plate I arranged above the pre-plating liquid level; the anode I and the anode II are in an arc shape; and arc length of the anode I is smaller than that of the anode II. The electroplating method comprises the following steps of extruding out air inside a foam base material subjected to conductive treatment before pre-plating through mutual action of a transmission roller and a hydraulic roller, providing electroplating positive ions by the anode I and the anode II, energizing a cathode, and performing primary plating and post-treatment to obtain the foam metal material. The upper and lower anodes are arranged in the pre-plating slot, and thickness of metal plated on front and back surfaces of the base material is more uniform. The cathode in the pre-plating slot body is not soaked into pre-plating liquid, and metal is not deposited or plated on the surface of the cathode, so that a product qualification rate is 90% or more, and a cathode utilization rate is increased.

Owner:CHANGDE LYRUN MATERIAL

Metal/ air battery system

ActiveCN108232368AControl performanceImprove discharge capacityFuel and primary cellsElectrolyte stream managementEngineeringStreamflow

The invention provides a metal / air battery system. The metal / air battery system comprises a metal / air battery pack, a liquid pump, a heat exchanger and a liquid storing unit, wherein the metal / airbattery set comprises N single batteries which are connected in series, and N is an integer not less than 2; each single battery comprises a single battery housing; a main liquid pouring channel, a main liquid draining channel and an air flowing channel are arranged between the adjacently connected single battery housings; flow rate balancing unit is arranged in each main liquid pouring channel,and the outer part of each main liquid pouring channel is connected to a motor; the motor is used for controlling the flow rate balancing units to act to realize the flowing consistency of electrolyte. With the adoption of the metal / air battery system, the electrolyte flowing consistency is high; the performances (such as voltage and temperature) of the single batteries are effectively controlled; the discharge capacity of the system is improved; the anode utilization rate is increased; the service life of a cathode in actual working conditions can be effectively prolonged; the flow rate balancing units are arranged in the main liquid pouring channel, so that the flowing consistency is reasonably improved on the premise that the size of the main flowing channels remain, as a result, the system size is reduced, and the specific energy of the system is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

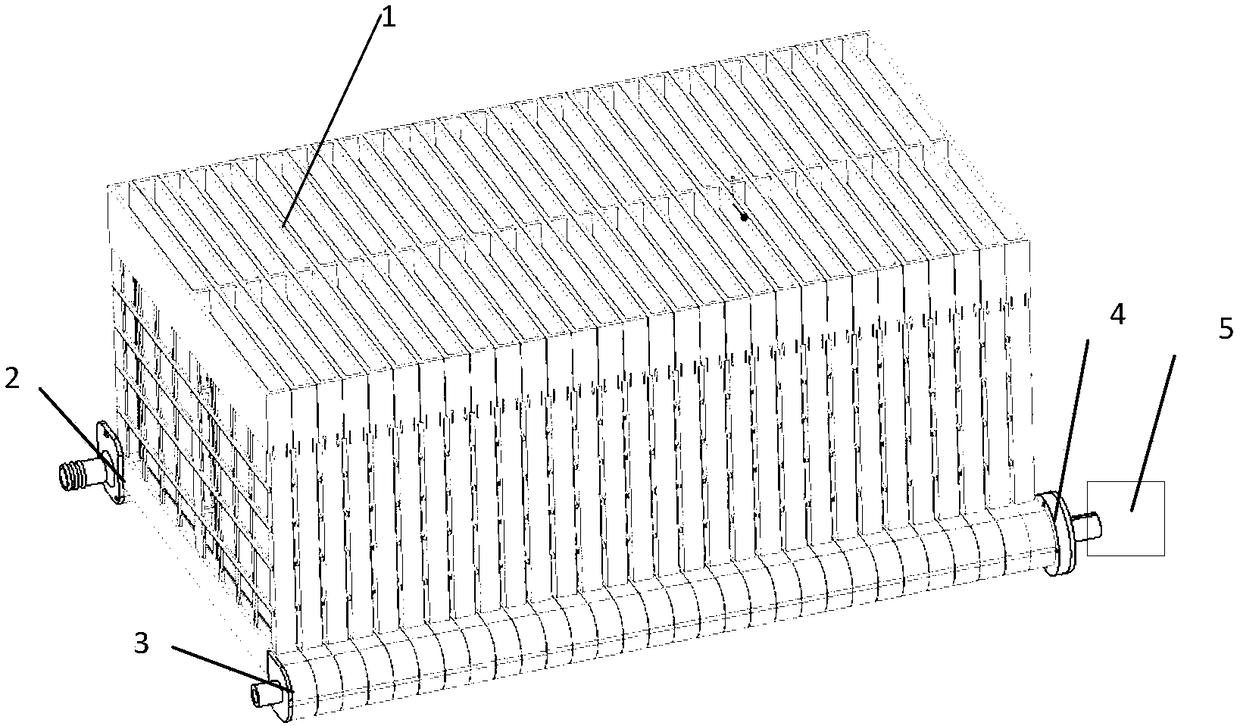

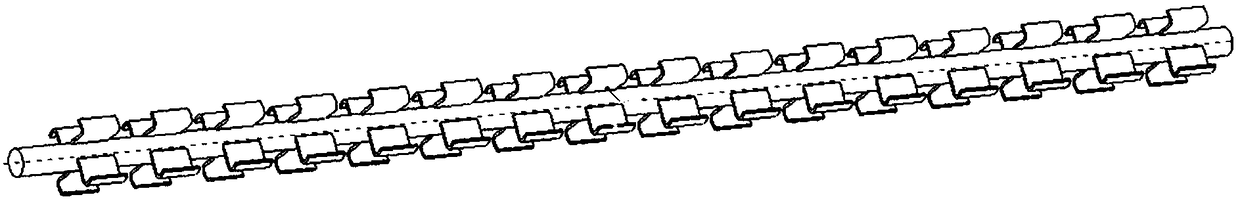

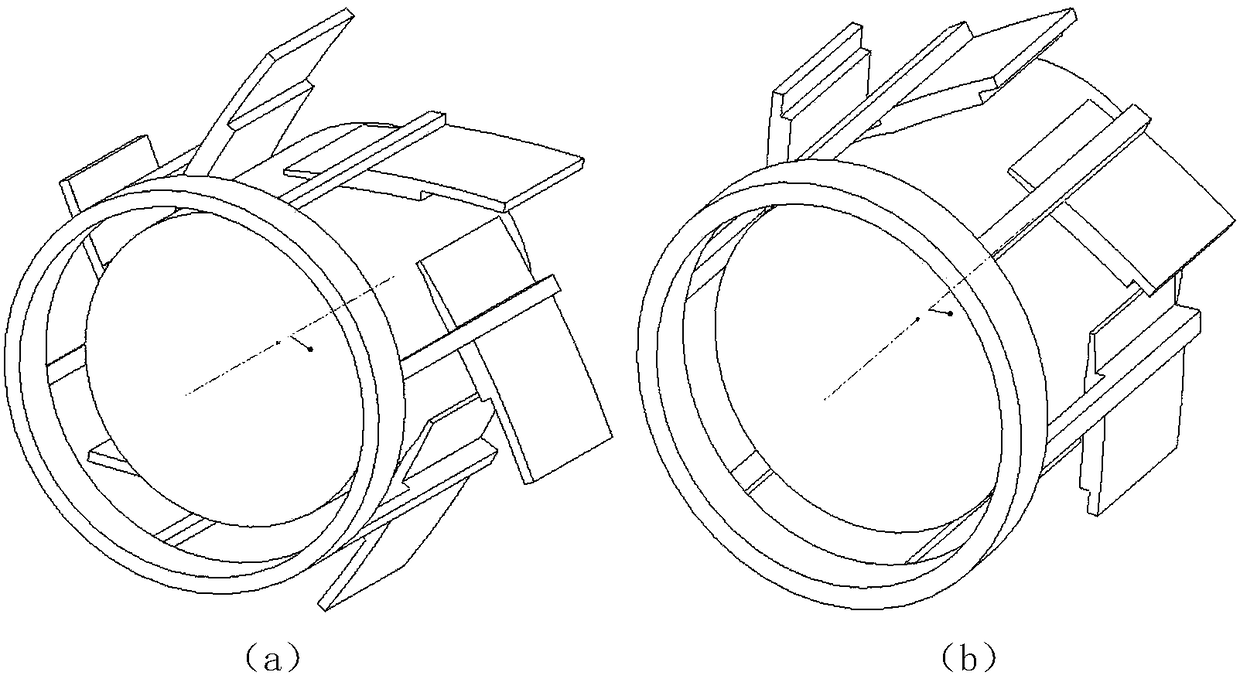

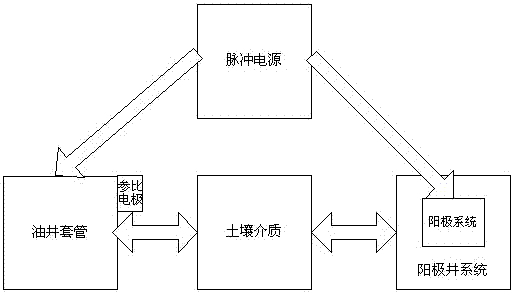

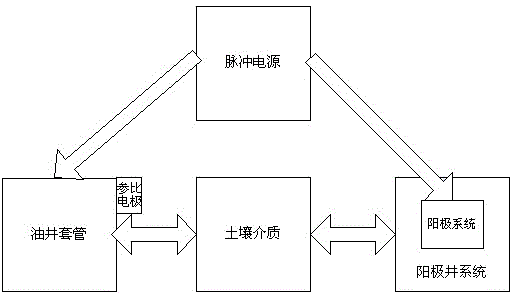

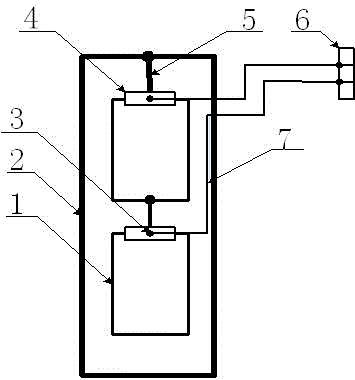

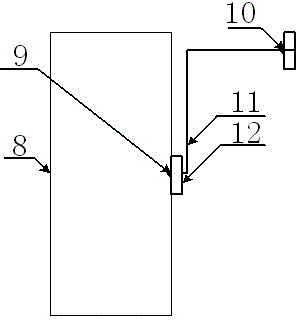

Oil well casing cathodic protection system and electrode layout method based on pulse current

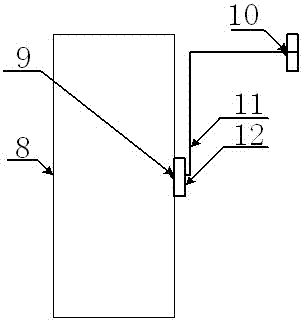

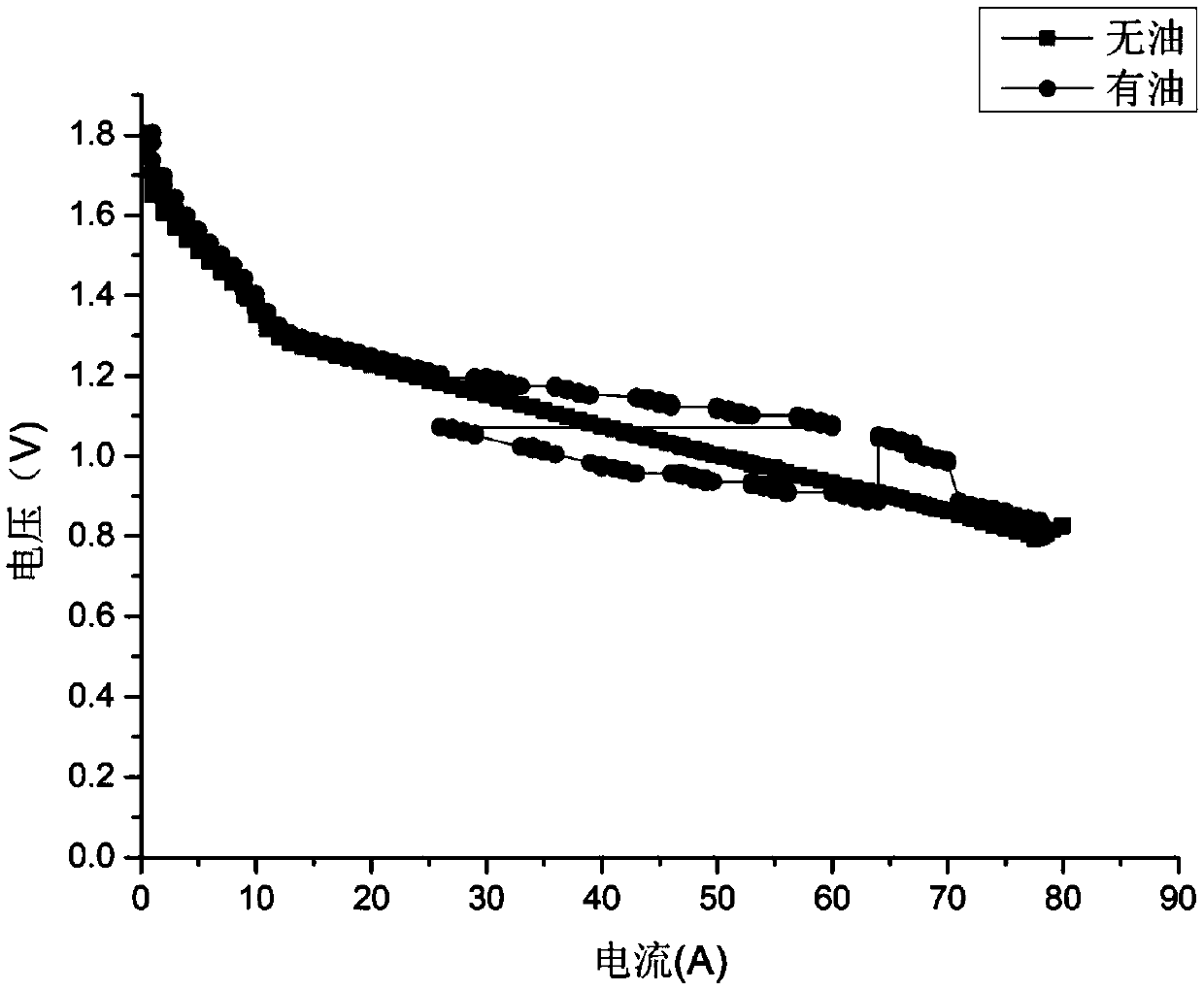

InactiveCN104562043BNo pollution in the processEasy to install and replacePotential measurementPulse power systems

The cathodic protection system for oil well casing based on pulse current includes a pulse power supply respectively connected to the oil well casing and the anode well system; a soil medium is provided between the oil well casing and the anode well system; the location method includes the following steps: 1) Determine the well location of the anode well according to the data; 2) Determine the well depth of the anode well; 3) Determine the connection method of the anode cable; 4) Determine the connection method of the cathode cable; On the top, split-point binding; the potential measuring instrument is respectively connected to the reference electrode and the cathode to monitor the protection potential in real time. Through the feedback data of the potential measuring instrument, the pulse power automatic adjustment system can adjust the protection potential in real time, so that the oil well casing is always in the effective protection range; it has protection current transmission, high anode utilization, high efficiency, wide application range, and long service life of the anode , easy maintenance, and extended protection depth.

Owner:XI'AN PETROLEUM UNIVERSITY

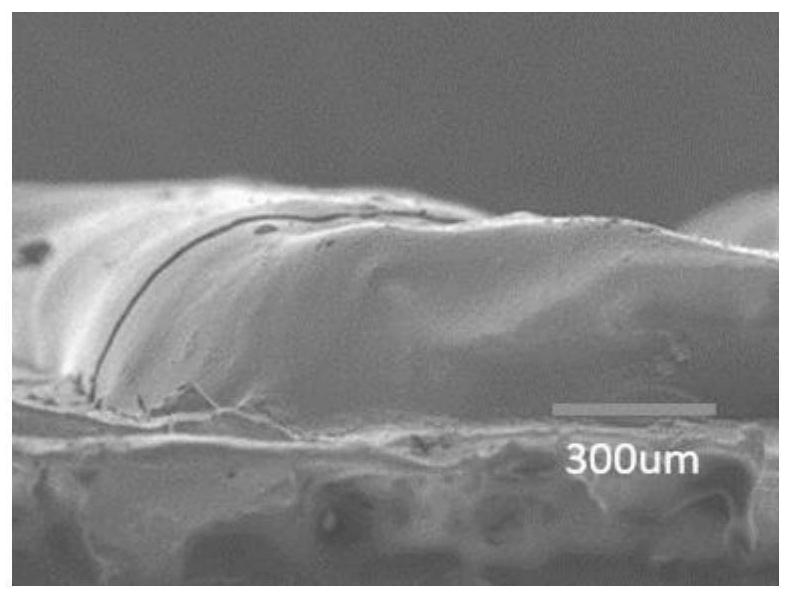

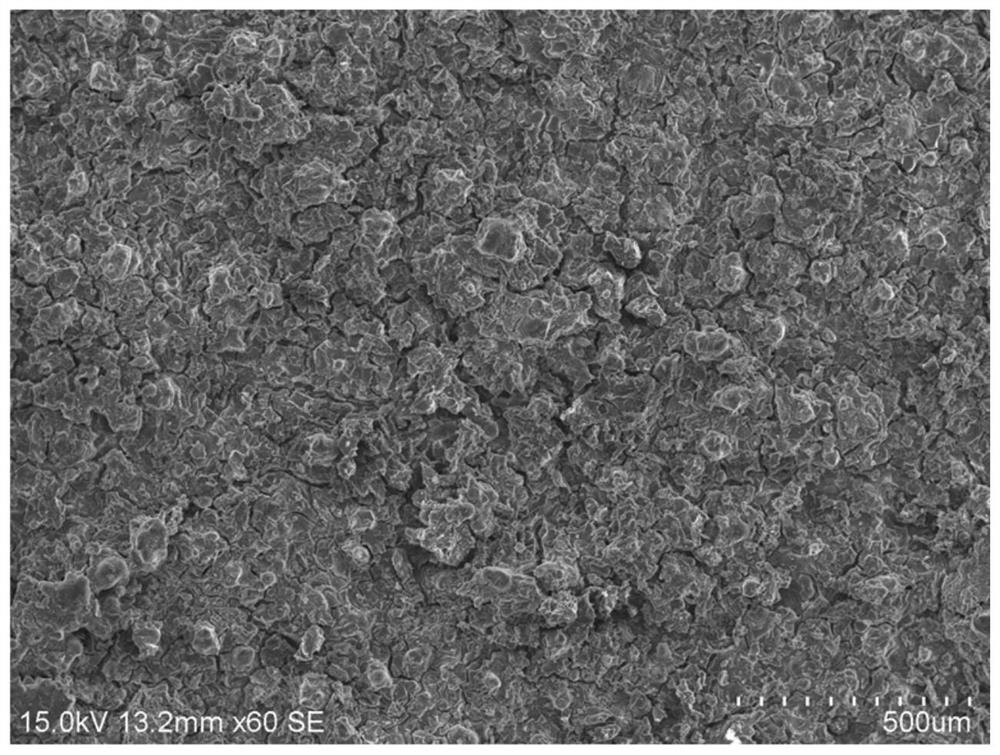

Aluminum air battery aluminum anode slurry for 3D printing and preparation method and application thereof

InactiveCN112820875AHigh porosityIncrease the hydrogen evolution overpotentialFuel and primary cellsAdditive manufacturing apparatusAluminum anodeAlcohol

The invention discloses aluminum air battery aluminum anode slurry for 3D printing and a preparation method and application thereof. The slurry comprises metal mixed powder and slurry, the ratio of the metal mixed powder to the slurry is 1g:(0.3-1.2) mL, the slurry comprises an antioxidant, a dispersing agent, an organic solvent and an organic adhesive, the metal mixed powder comprises Sn, In, Mg and the balance Al with the purity larger than or equal to 99.99%, and the metal mixed powder comprises Al with the purity larger than or equal to 99.99%. The viscosity of the slurry is 1-100 Pa.s; and the preparation method of the slurry comprises the following steps: (1) taking metal powder, and mixing and ball-milling the metal powder and absolute ethyl alcohol; (2) drying the ball-milled mixed solution until the alcohol is completely volatilized to obtain dried metal mixed powder; and (3) adding an antioxidant, a dispersing agent, an organic solvent and an organic adhesive into the dried metal mixed powder for ball milling, and obtaining slurry. The slurry can be applied to an aluminum anode of a 3D printing aluminum air battery. The slurry can increase the porosity of the anode, reduces the self-corrosion of the aluminum anode, is stable in performance, and improves the utilization rate of the anode.

Owner:南京信息工程大学滨江学院

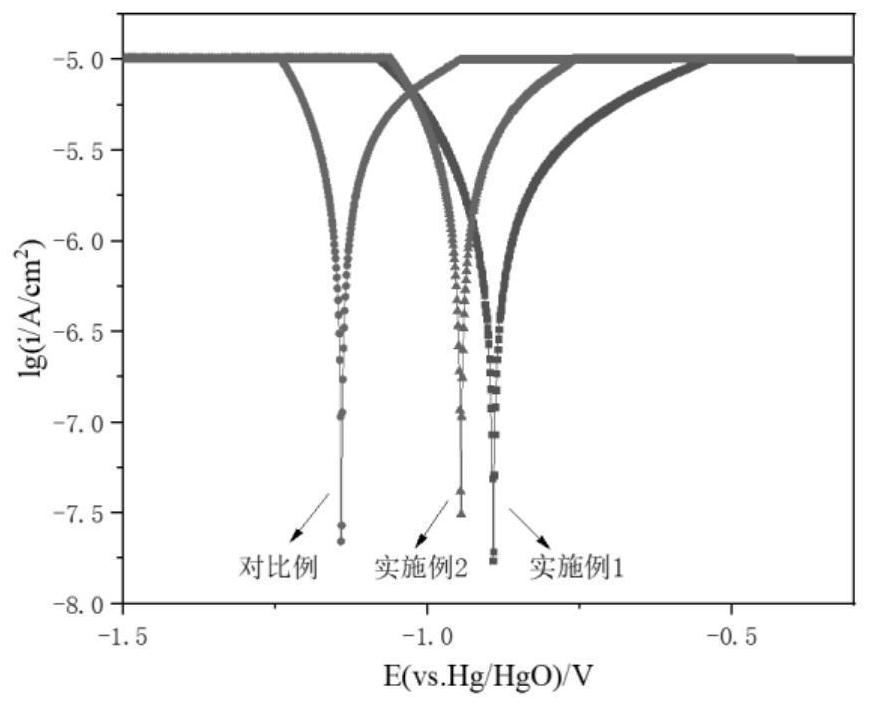

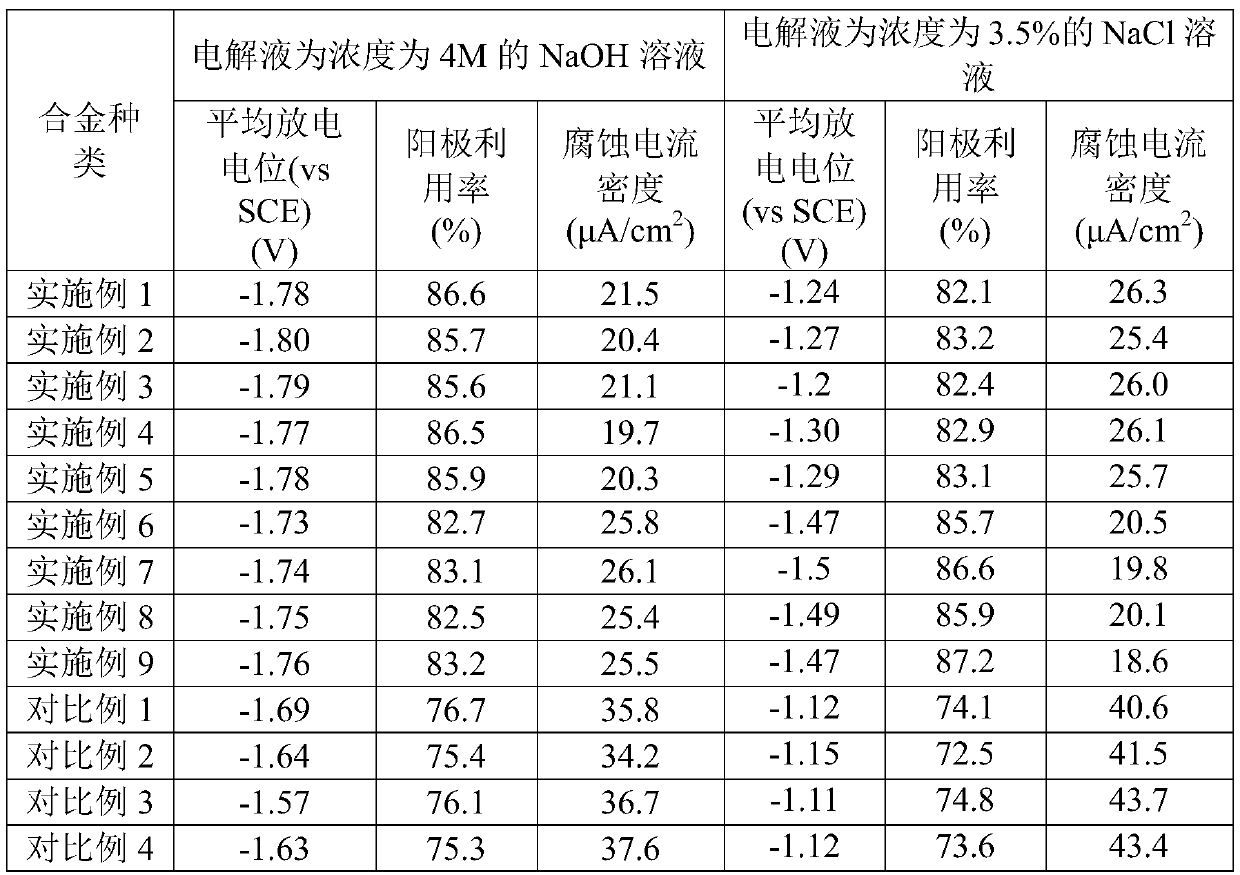

Anode alloy material, preparation method thereof, anode for aluminum-air battery and aluminum-air battery

ActiveCN111057914AInhibition of hydrogen evolution reactionIncrease profitFuel and secondary cellsCell electrodesMetallurgyBattery cell

The invention discloses an anode alloy material, a preparation method thereof, an anode for an aluminum-air battery and the aluminum-air battery, and relates to the field of anode materials for air batteries. The anode alloy material comprises aluminum and alloy elements added into the aluminum, wherein the alloy elements comprise, by mass, 0.01%-5.5% of Mg, 0.01%-3.0% of Sn, 0.01%-2.5% of Ce, 0.0001%-0.0010% of B and 0.01%-2.0% of Ti. The preparation method comprises the steps of preparing the anode alloy material from the raw materials according to the component matching ratio. The components of the anode alloy material are limited, the dosage of each component of the anode alloy material is adjusted, the optimal component dosage ratio is obtained, the hydrogen evolution reaction of thealuminum alloy anode material can be effectively inhibited, and the anode alloy material with negative average discharge potential and high anode utilization rate is developed.

Owner:GUANGDONG INST OF NEW MATERIALS

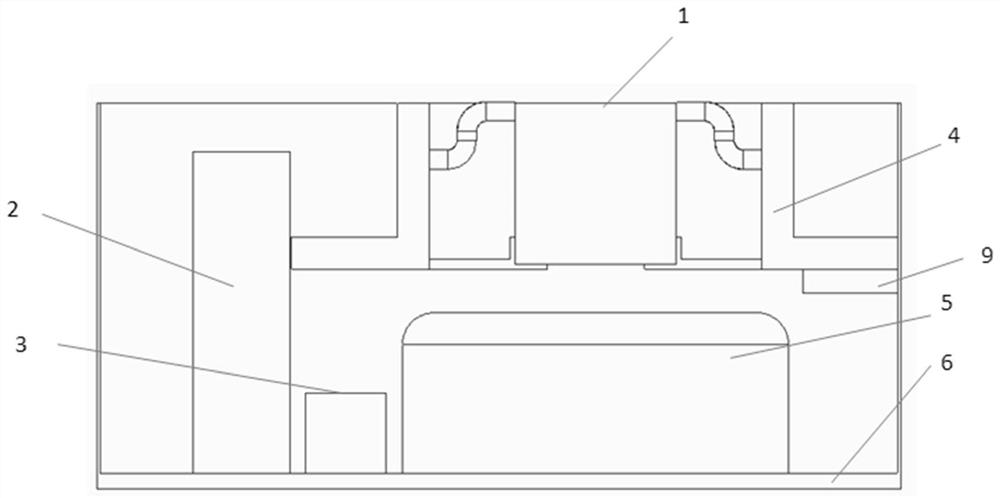

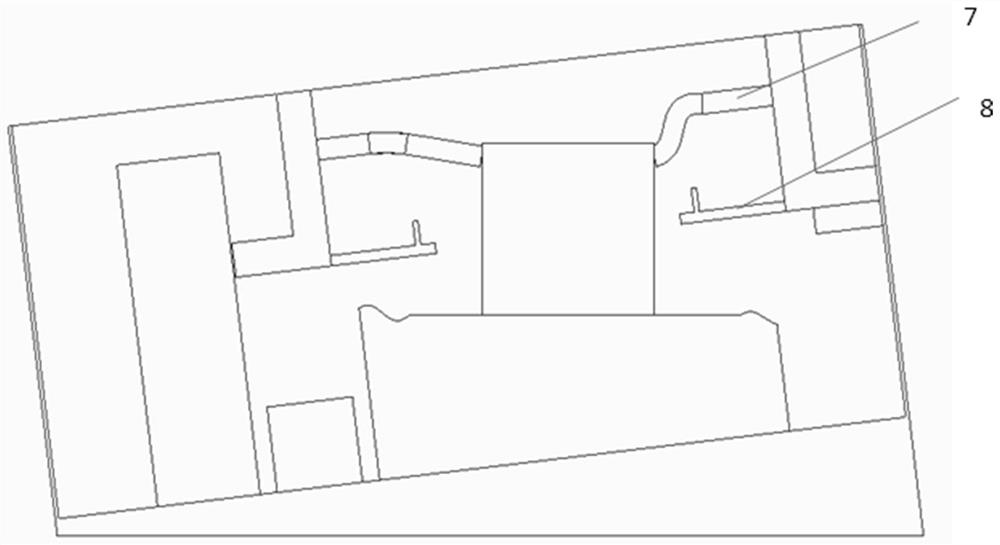

Cathode protection system and method for air battery

ActiveCN109659646AAvoid corrosionInhibition of self-discharge phenomenonFuel and primary cellsHybrid cell detailsLiquid storage tankEngineering

The invention discloses a cathode protection system and method for an air battery. The system comprises: an oil storage tank, a metering pump, an electrolyte liquid storage tank, an electrolyte pump and an electrolyte venting valve. The inlet and outlet of the oil storage tank are connected to the metering pump through oil conveying pipelines. The metering pump is connected to an oil-way inlet andan oil-way outlet of the air battery through an oil conveying pipeline. The outlet of the electrolyte liquid storage tank is connected to the electrolyte pump through a liquid conveying pipeline. Theelectrolyte pump is connected to the electrolyte inlet of the air battery through a liquid conveying pipeline. The inlet of the electrolyte liquid storage tank is connected to the electrolyte ventingvalve through a liquid conveying pipeline. The electrolyte venting valve is connected to the electrolyte outlet of the air battery through a liquid conveying pipeline. By implementing the system andmethod of the invention, the problem of severe anode corrosion under the open state of the metal air battery is solved, and the metal air battery system is promoted to be practical and market-oriented, so that the large-scale application of the metal air battery can be realized.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Pulse current based oil well casing cathode protection system and electrode arrangement method thereof

The invention relates to a pulse current based oil well casing cathode protection system. The pulse current based oil well casing cathode protection system comprises a pulse power supply which is connected with an oil well casing and an anode well system, and a soil medium is arranged between the oil well casing and the anode well system. The electrode arrangement method of the pulse current based oil well casing cathode protection system comprises the following steps: (1) determining the position of an anode well; (2) determining the depth of the anode well; (3) determining the connection method of anode cables; (4) determining the connection method of cathode cables; and (5) directly binding a reference electrode on the oil well casing through coating an insulating material, and communicating a potential measuring instrument with the reference electrode and a cathode so as to monitor the protective potential in real time, wherein the reference electrode can be bound on different points of the oil well casing. The protective potential is adjusted in real time by adopting an automatic adjustment system of the pulse power supply according to the feedback data of the potential measuring instrument so that the oil well casing is in an effective protection range all the time. The pulse current based oil well casing cathode protection system provided by the invention has the characteristics of protective current transmission, high anode utilization rate, high efficiency, wide range of application, long service life of an anode, simple maintenance and high protection degree.

Owner:XI'AN PETROLEUM UNIVERSITY

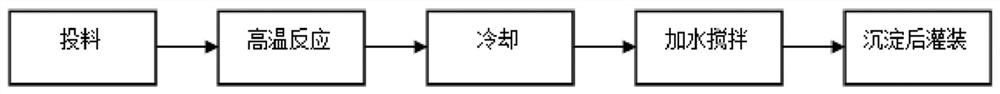

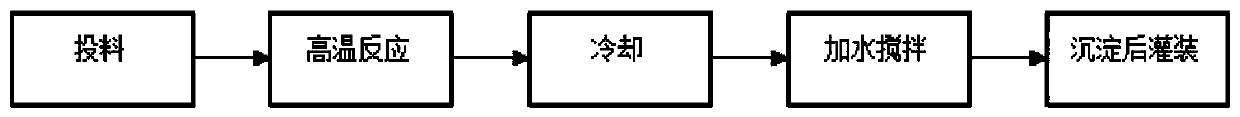

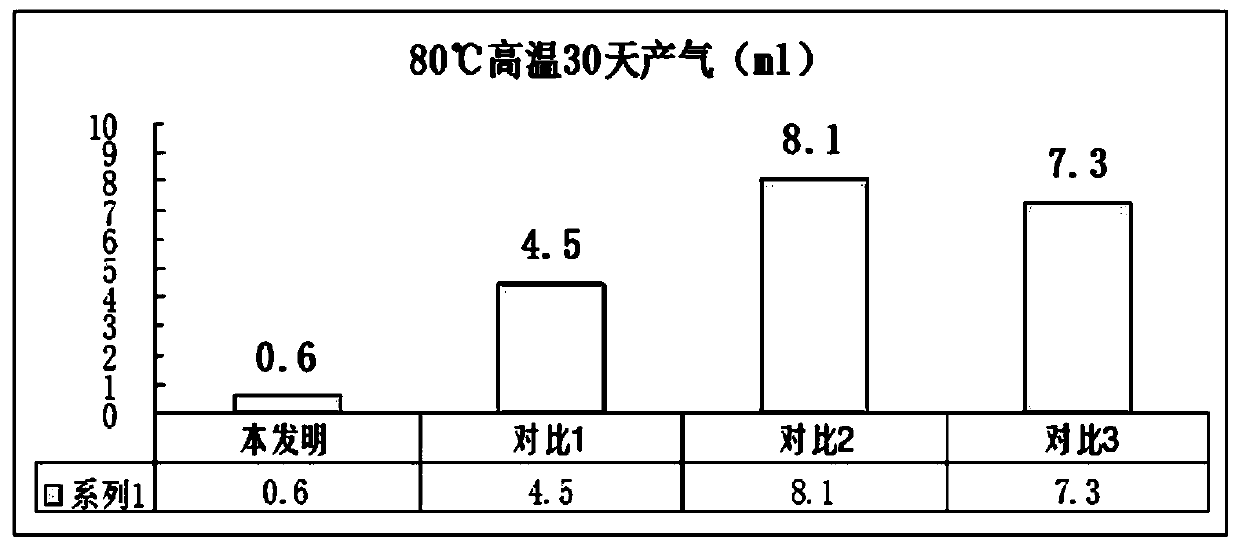

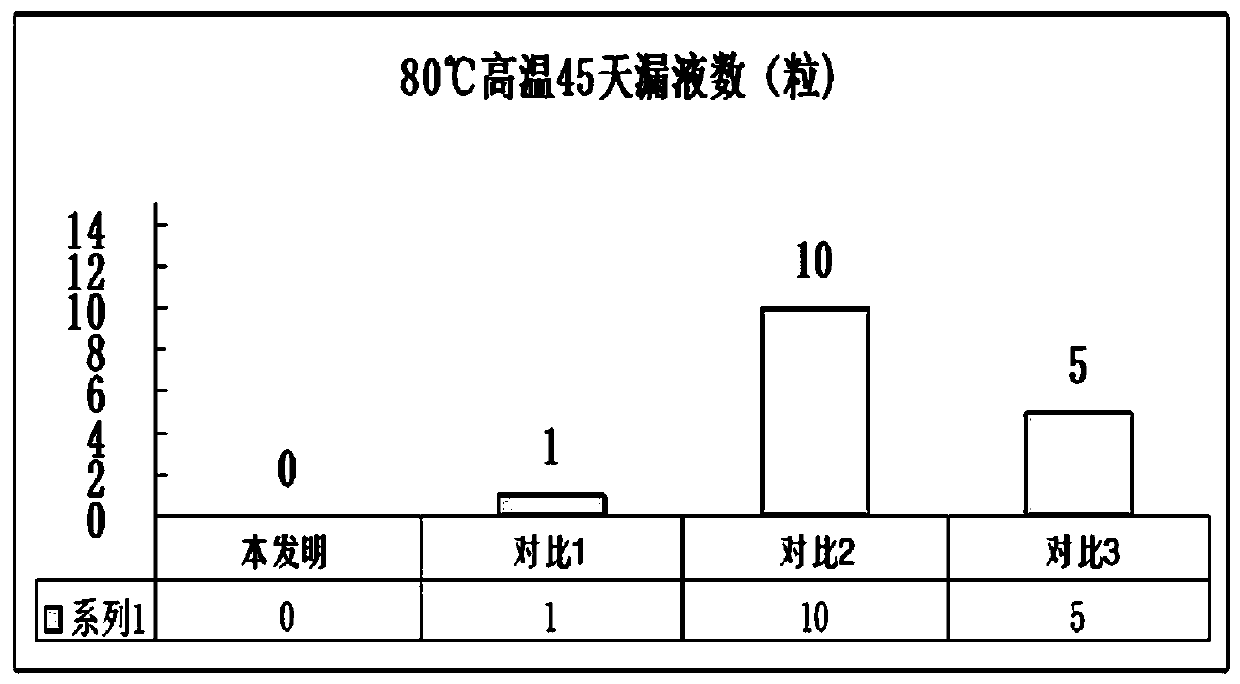

A kind of alkaline battery anode surfactant and preparation method thereof

ActiveCN111342155BImprove storage life at room temperatureReduce leak rateElectrode manufacturing processesNegative electrodesElectrolytic agentActive agent

The invention relates to the technical field of batteries, in particular to an alkaline battery anode surfactant and a preparation method thereof. The alkaline battery anode surfactant comprises the following raw materials in parts by weight: 48-55 parts of potassium hydroxide, amphoteric metal oxide 18‑23 parts, 36‑41 parts of deionized water. The alkaline battery anode surfactant of the present invention is added to the battery formula, which can improve the utilization rate of the anode and the storage life of the battery at normal temperature, greatly reduce the leakage rate of the battery, and can effectively prevent the passivation of the battery anode during the manufacturing and storage process. At the same time, the concentration polarization phenomenon of the system reaction carrier electrolyte is prevented, and the preparation method is simple and convenient in operation, convenient in control, high in production efficiency and low in cost, and can be applied to industrialized production.

Owner:连州市凌力电池配件有限公司

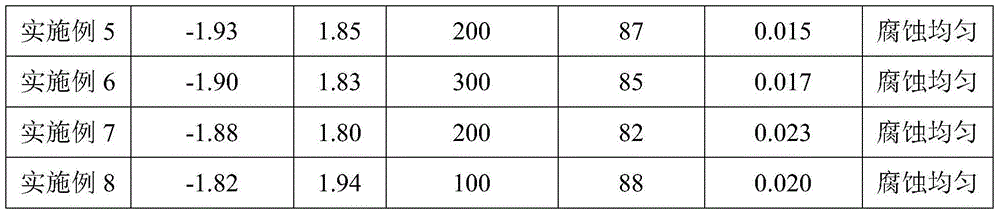

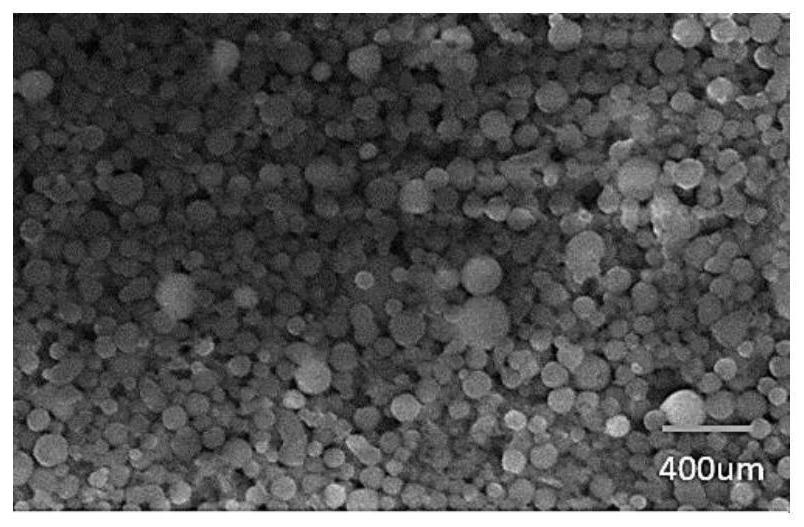

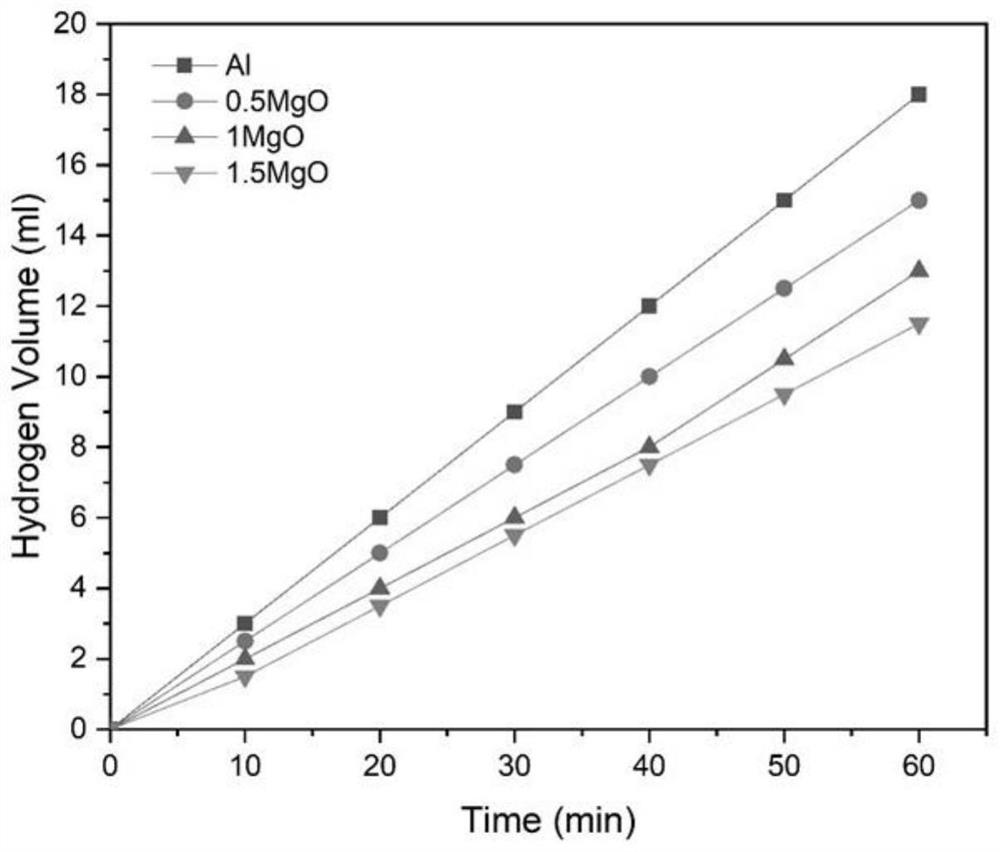

A kind of aluminum-air battery ceramic particle composite anode material and preparation method thereof

ActiveCN112921201BHigh anode utilizationIncrease profitFuel and primary cellsCell electrodesElectrolytic agentMetallic materials

The invention relates to an aluminum-air battery ceramic particle composite anode material and a preparation method thereof, belonging to the field of metal materials. The preparation method provided by the invention includes: preheating the ceramic particles first, and mixing them with heated and melted pure aluminum or aluminum alloy, and then adopting ordinary aluminum melting furnace + mechanical stirring or vacuum semi-solid stirring technology to obtain evenly dispersed particles Composite anode material, the granular composite material obtained by casting is directly cut, or further press processed to make composite anode for aluminum-air battery. Because the preparation method provided by the invention is simple, the cost is low, the obtained composite anode material has good electrochemical activity in alkaline electrolyte, low self-corrosion rate, and high battery anode utilization, so the preparation method provided by the invention is suitable for large-scale Chemical production and processing.

Owner:TONGJI UNIV

Alkaline battery anode surfactant and preparation method thereof

ActiveCN111342155AImprove storage life at room temperatureReduce leak rateElectrode manufacturing processesNegative electrodesPhysical chemistryPotassium hydroxide

The invention relates to the technical field of batteries, in particular to an alkaline battery anode surfactant and a preparation method thereof, and the alkaline battery anode surfactant comprises the following raw materials in parts by weight: 48-55 parts of potassium hydroxide, 18-23 parts of amphoteric metal oxide and 36-41 parts of deionized water. The alkaline battery anode surfactant disclosed by the invention is added into a battery formula; the normal-temperature storage life of the battery can be prolonged; the preparation method is simple and convenient to operate, convenient to control, high in production efficiency, low in cost and suitable for industrial production, the battery anode can be effectively prevented from being passivated in the manufacturing and storage processes, Meanwhile, the concentration polarization phenomenon of the system reaction carrier electrolyte is prevented.

Owner:连州市凌力电池配件有限公司

A kind of aluminum-air battery anode material and preparation method thereof

ActiveCN109321766BImprove electrochemical performanceLow self-corrosion rateFuel and primary cellsCell electrodesMetallurgyMachining process

The invention discloses an aluminum air battery anode material and a preparing method thereof. The aluminum air battery anode material comprises, by mass percent, 0.10%-0.15% of bismuth, 0.10%-0.15% of lead, 0.015%-0.035% of gallium and the balance aluminum. The anode material is prepared through the machining processes of mixing, smelting, rolling and heat treatment. The anode material componentdesign is reasonable, the cost is low, the product performance is good, the preparing process is simple, and the aluminum air battery anode material and the preparing method of the aluminum air battery anode material are suitable for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Anodic phosphorous copper balls and preparation method thereof

InactiveCN101914801BImprove qualityPhosphorus is evenly distributedElectrodesCopper platingInduction furnace

The invention discloses anodic phosphorous copper balls and a preparation method thereof. The method comprises the following steps of: (1) after yellow phosphorus or red phosphorus and oxygen-free copper are melted by adopting a medium-frequency induction furnace, stirring the melt uniformly through a magnetic stirring tank to obtain phosphorous copper solution; (2) producing a phosphorous copperbar with a diameter of 20 to 50 millimeters by using the phosphorous copper solution prepared in the step (1) and an up-draw process, and continuously stamping the phosphorous copper bar to obtain copper balls of different sizes in different dies; and (3) performing polishing, burr removal, cleaning and drying treatment on the copper balls obtained in the step (2) in turn to obtain the anodic phosphorous copper balls. The anodic phosphorous copper balls have the advantages of compact crystal, thin and small crystal grain, high phosphorous copper film generating speed, exquisite and firm phosphorous copper film texture and dropping resistance, and can reduce the cleaning frequency of an anode, effectively improve the utilization rate of the anode and remarkably improve the copper plating effect.

Owner:金峰电路(惠州)有限公司

Anode material for high-power aluminum air battery at low temperature and preparation method of anode material

ActiveCN114351011AGood open circuit voltageHigh anode utilizationFuel and primary cellsCell electrodesElectrical batteryMetallurgy

The invention discloses a high-power aluminum air battery anode material used at a low temperature and a preparation method thereof, belongs to the technical field of metal air batteries, and provides a high-power aluminum air anode material which takes industrial pure aluminum as a melt and is suitable for the low temperature and a preparation method of the high-power aluminum air anode material aiming at the problems that the discharge performance of the aluminum air battery at the low temperature becomes poor and the discharge is unstable. The invention aims to improve the discharge performance of the aluminum air anode plate under a low-temperature condition and solve the problem of serious self-corrosion of the anode plate taking industrial pure aluminum as a melt, reduce the production cost, and is green and environment-friendly. Compared with the traditional anode material, the anode material provided by the invention has the advantages that the use temperature can be-45 DEG C to room temperature, the highest use temperature can reach + 60 DEG C, and the suitable low-temperature use temperature range is-35 to-25 DEG C. The anode material can keep good open-circuit voltage, current density, performance stability and other effects at low temperature, and has high anode utilization rate in use.

Owner:NORTHEASTERN UNIV

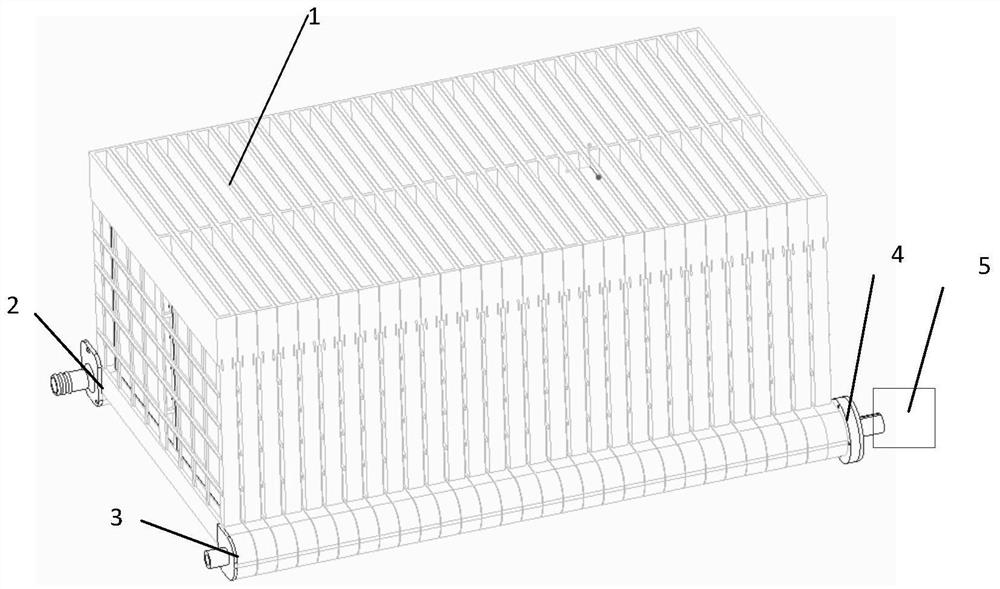

A metal/air battery system

ActiveCN108172948BControl performanceImprove discharge capacityFuel and primary cellsElectrolyte stream managementElectrical batteryEngineering

The invention provides a metal / air battery system, comprising a metal / air battery pack, a liquid pump, a heat exchanger and a liquid storage unit; the liquid inlet of the liquid pump is connected with the liquid storage unit, and the liquid outlet of the liquid pump The liquid outlet of the heat exchanger is connected with the liquid inlet of the heat exchanger, and the liquid discharge port of the heat exchanger is connected with the electrolyte injection port of the metal / air battery pack; the electrolyte liquid outlet of the metal / air battery pack is connected with the liquid storage unit to form a Closed circuit; the single cell includes a single cell casing, the metal anode in the surface of the single cell casing is perpendicular to the bottom of the single cell casing, and the air cathodes placed on opposite sides of the battery casing and parallel to the metal anode are formed by the single cell An electrolyte chamber composed of a battery case, a metal anode and an air cathode; from left to right, N cell cases are arranged parallel to each other and in sequence, and there are liquid injection main channels between the adjacent cell cases, The liquid discharge main flow channel and the air flow channel; the flow equalization unit is arranged in the liquid injection main flow channel.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Metal/air battery system

ActiveCN109904566ARealize automatic horizontal placementImprove consistencyFuel and primary cellsElectrolyte moving arrangementsFixed frameBattery system

Disclosed is a metal / air battery system. The metal / air battery system comprises a metal / air battery pack, a liquid storage unit, a movable connecting mechanism and a fixed frame; the liquid storage unit is a closed liquid storage container prepared from a soft waterproof material at the upper part or a closed liquid storage container made of a soft waterproof material as a whole; the metal air battery system disclosed by the invention can be self-adapted to severe working conditions (inclined), so that automatic horizontal placement of the battery pack is realized, and the consistency of electrolyte flow of the battery pack is improved; and high-consistency electrolyte flow effectively controls the single-battery performance (voltage, temperature and the like), so that the discharge capacity of the system is increased, the utilization rate of an anode is improved, and the service life of the actual working condition of a cathode is effectively prolonged.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of rare earth-containing amorphous/nanocrystalline aluminum anode composite material, preparation method and aluminum-air battery

InactiveCN104372206BImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

Owner:HENAN UNIV OF SCI & TECH

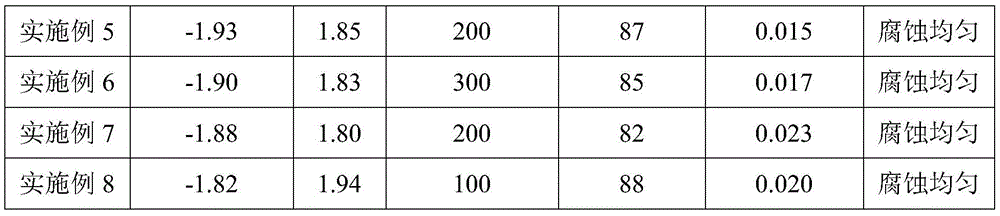

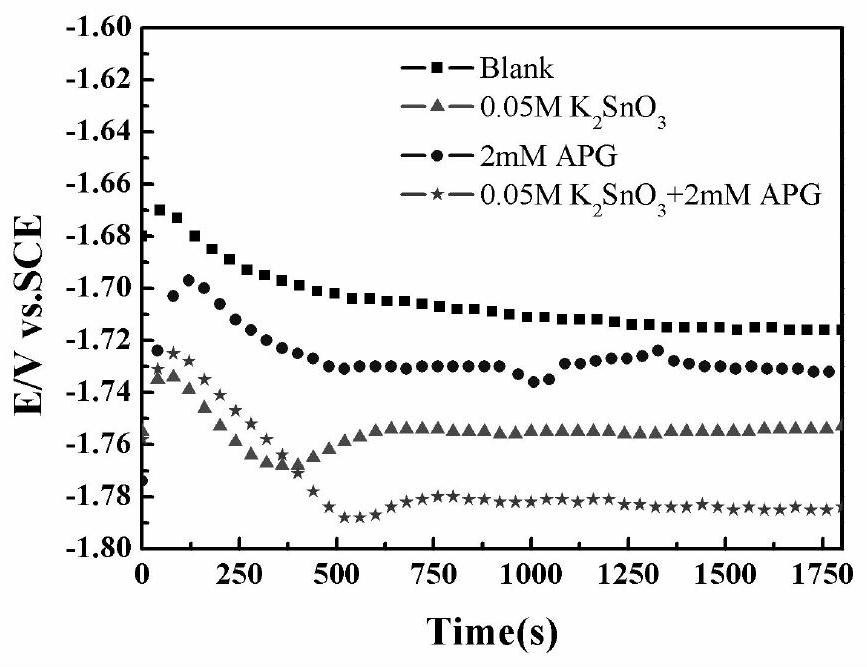

A kind of composite corrosion inhibitor and its alkaline electrolyte and aluminum-air battery added with the composite corrosion inhibitor

ActiveCN110137631BSimple compositionLow costFuel and primary cellsComposite electrolytesElectrolytic agentFuel cells

Owner:CENT SOUTH UNIV

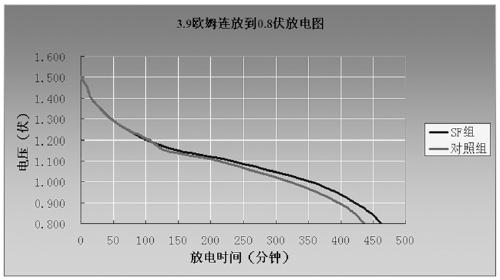

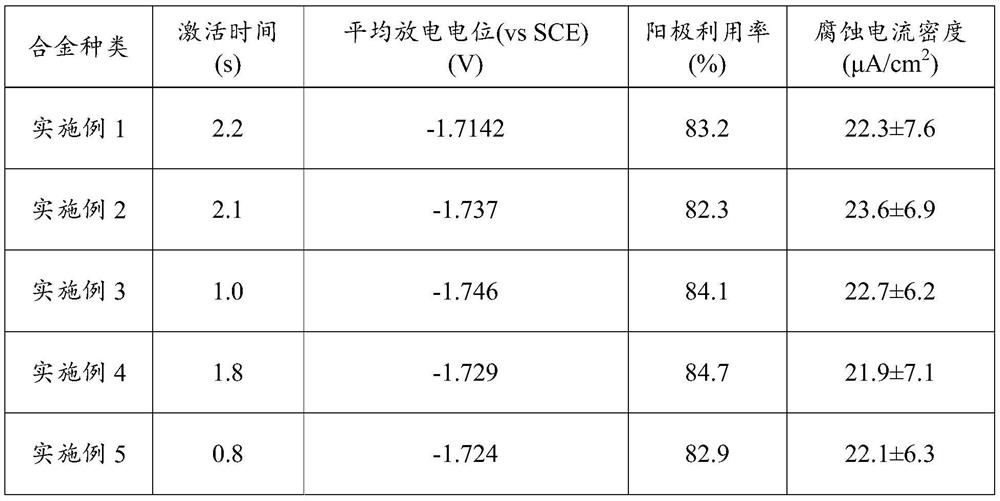

A kind of anode material and preparation method thereof, battery

ActiveCN110112362BShort activation timeNegative discharge potentialPrimary cell electrodesImmersion cellsChemical compositionMetallurgy

The invention provides an anode material, a preparation method thereof and a battery, and belongs to the technical field of batteries. The anode material is obtained by successively subjecting an Mg-Al-Pb casting body doped with La and Ce to first annealing, multi-pass rolling and third annealing, wherein the second annealing is performed after rolling each time. The chemical composition of the casting body includes: 0.01 to 8 wt% of Al, 0.01 to 7.5 wt% of Pb, 0.01 to 7 wt% of La, and 0.01 to 6 wt% of Ce, and not more than 0. 01 wt% of Fe, Cu and Ni, with the balance of Mg. The anode materialhas the characteristics of short activation time, negative discharge potential and a high anode utilization rate. The preparation method is simple, easy to operate, and can prepare an anode material with excellent performance. The battery including the anode material also has the characteristics of short activation time, negative discharge potential, and a high anode utilization rate.

Owner:GUANGDONG INST OF NEW MATERIALS

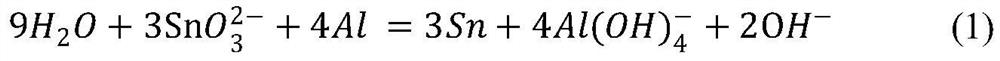

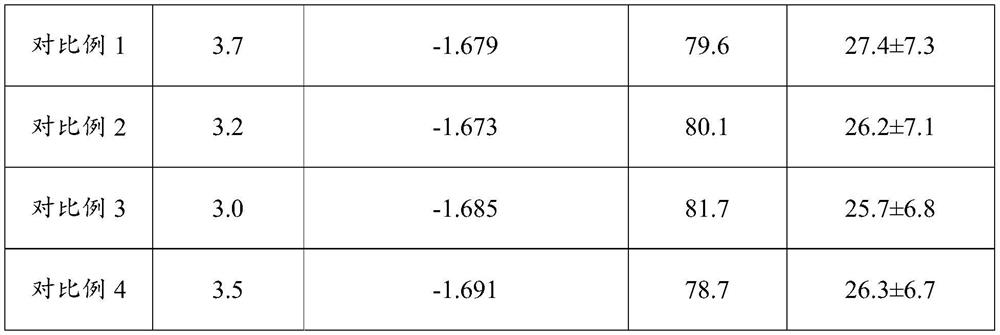

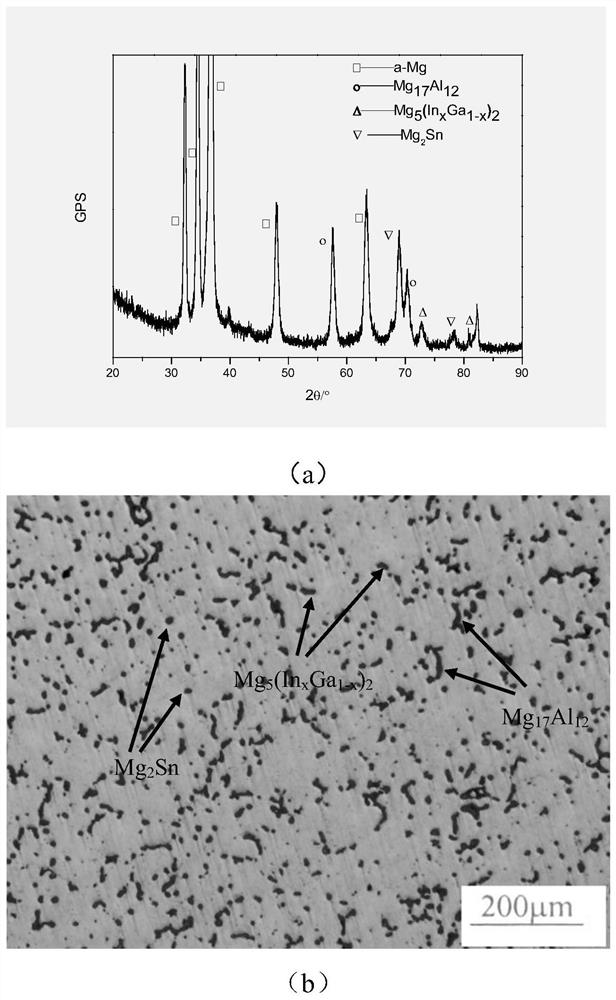

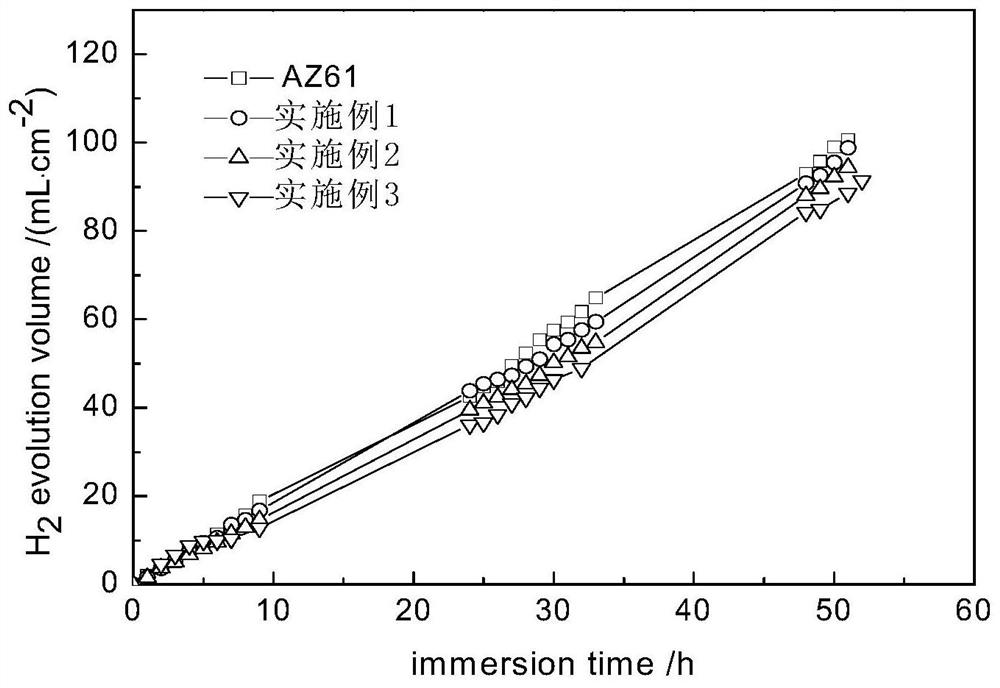

A kind of multi-element alloy anode material for magnesium-air battery and preparation method thereof

ActiveCN113718147BPromote exfoliationEliminates adverse effects of dissolutionFuel and primary cellsNegative electrodesIndiumManganese

The invention relates to a multi-element alloy anode material for a magnesium-air battery and a preparation method thereof. The chemical composition of the alloy anode material is: aluminum, gallium, indium, tin, manganese; one or more of strontium, calcium or titanium; impurity elements; and magnesium. The preparation method is to take pure magnesium, aluminum ingot, Al‑10Mn master alloy, Mg‑27Sr / Mg‑30Ca master alloy, Al‑10Ti master alloy, tin, gallium and indium pure metal raw materials, and put them into the crucible for melting after preheating , the molten metal is cast into an ingot in a water-cooled copper mold, and then the ingot is solid-solution treated to make a magnesium anode plate. Granular Mg Formed in Alloy Anode Materials 5 (In x Ga 1‑x ) 2 with Mg 2 The Sn phase synergistically inhibits the hydrogen evolution side reaction of the anode and accelerates the peeling of the discharge product from the surface of the magnesium anode, maintaining high discharge activity; at the same time, trace amounts of strontium, calcium and titanium elements and solid solution treatment further refine the structure and improve the first phase in the magnesium matrix. The two-phase distribution promotes the uniform dissolution of the anode and improves the utilization rate of the anode.

Owner:NANTONG UNIVERSITY

Alkaline battery

InactiveCN111342037AReduce gas productionElectrical performance decays slowlyNegative electrodesPositive electrodesElectrical batteryLithium-ion battery

The invention relates to the technical field of batteries, in particular to an alkaline battery which comprises an anode material, a cathode material, a diaphragm and a diaphragm electrolyte for the diaphragm, the anode material is prepared from the following raw materials in parts by weight: 63 to 69 parts of zinc powder, 0.3 to 0.4 part of polyacrylic acid, 0.25 to 0.35 part of sodium polyacrylate, 0.65 to 0.75 part of zinc oxide, 26 to 30 parts of anolyte A and 4 to 4.5 parts of anolyte B. The lithium ion battery has the advantages of low gas production, slow electrical performance attenuation, low liquid leakage rate and sufficient discharge in a high-voltage area, and has longer service life compared with a product in the prior art.

Owner:连州市凌力电池配件有限公司

A metal/air battery system

ActiveCN109904566BRealize automatic horizontal placementImprove consistencyFuel and primary cellsElectrolyte moving arrangementsElectrolysisThermodynamics

A metal-air battery system, comprising a metal / air battery pack, a liquid storage unit, a movable connection mechanism, and a fixing frame; A closed liquid storage container made of high-quality waterproof materials; the metal-air battery system of the present invention can adapt to harsh working conditions (inclination), realize the automatic horizontal placement of the battery pack, and improve the consistency of the electrolyte flow of the battery pack; high-consistency electrolysis The liquid flow effectively controls the performance of the single cell (voltage, temperature, etc.), improves the discharge capacity of the system, improves the utilization rate of the anode, and effectively prolongs the service life of the cathode under actual working conditions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A metal/air battery system

ActiveCN108232368BControl performanceImprove discharge capacityFuel and primary cellsElectrolyte stream managementThermodynamicsElectrical battery

The present invention provides a metal / air battery system, which includes a metal / air battery pack, a liquid pump, a heat exchanger and a liquid storage unit; the metal / air battery pack includes N cells connected in series, and the N is an integer greater than or equal to 2; the single cell includes a single cell shell, and the adjacent single cell shells have a main liquid injection channel, a main drainage channel and an air flow channel; the main liquid injection channel is A flow balancing unit is provided in the channel, and is externally connected to a motor. The movement of the flow balancing unit is controlled by the motor to achieve a consistent flow of electrolyte. The invention has highly consistent electrolyte flow that effectively controls the performance of the single cell (voltage, temperature, etc.), improves the discharge capacity of the system, improves the anode utilization rate, and effectively extends the service life of the cathode in actual working conditions; the flow balancing unit is built into the main flow of liquid injection In the channel, the flow consistency can be reasonably improved without increasing the size of the main channel, reducing the system volume and improving the system specific energy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

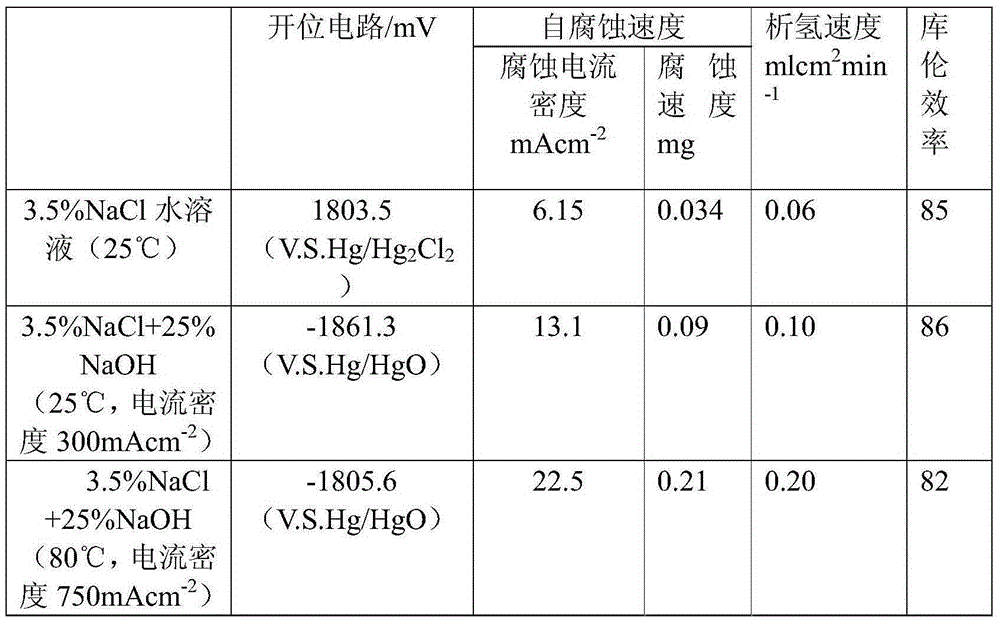

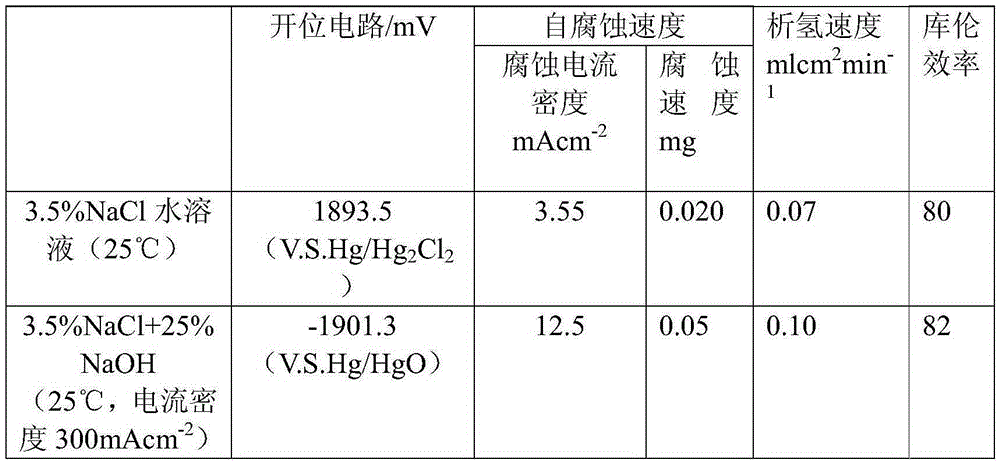

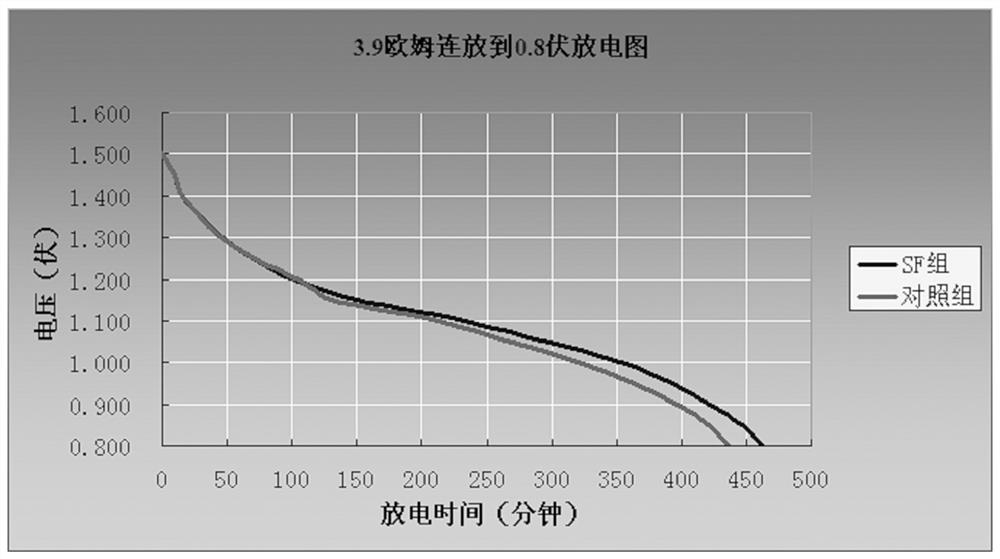

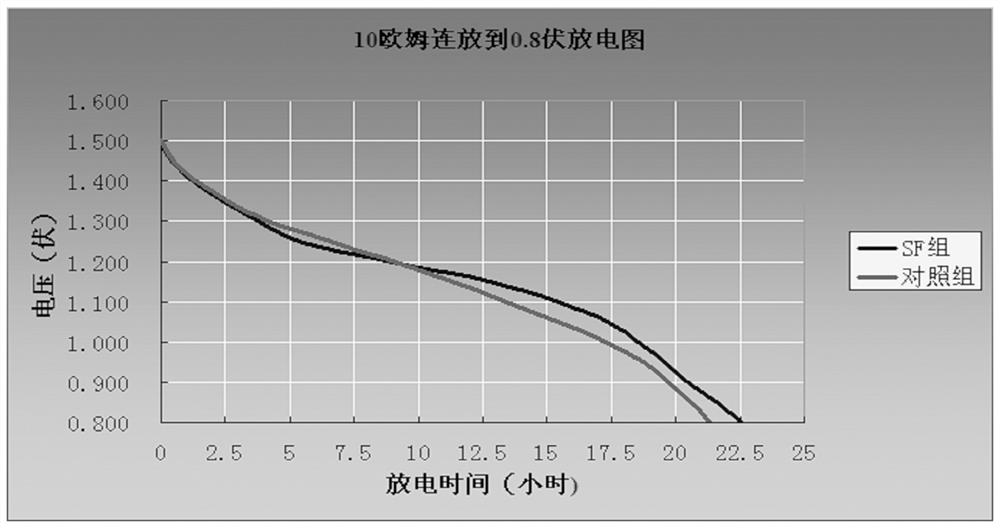

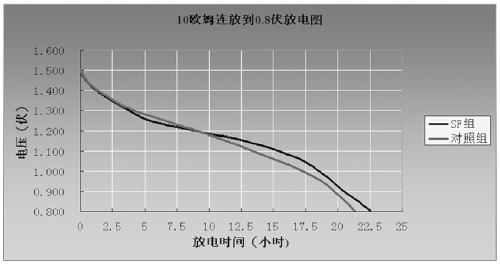

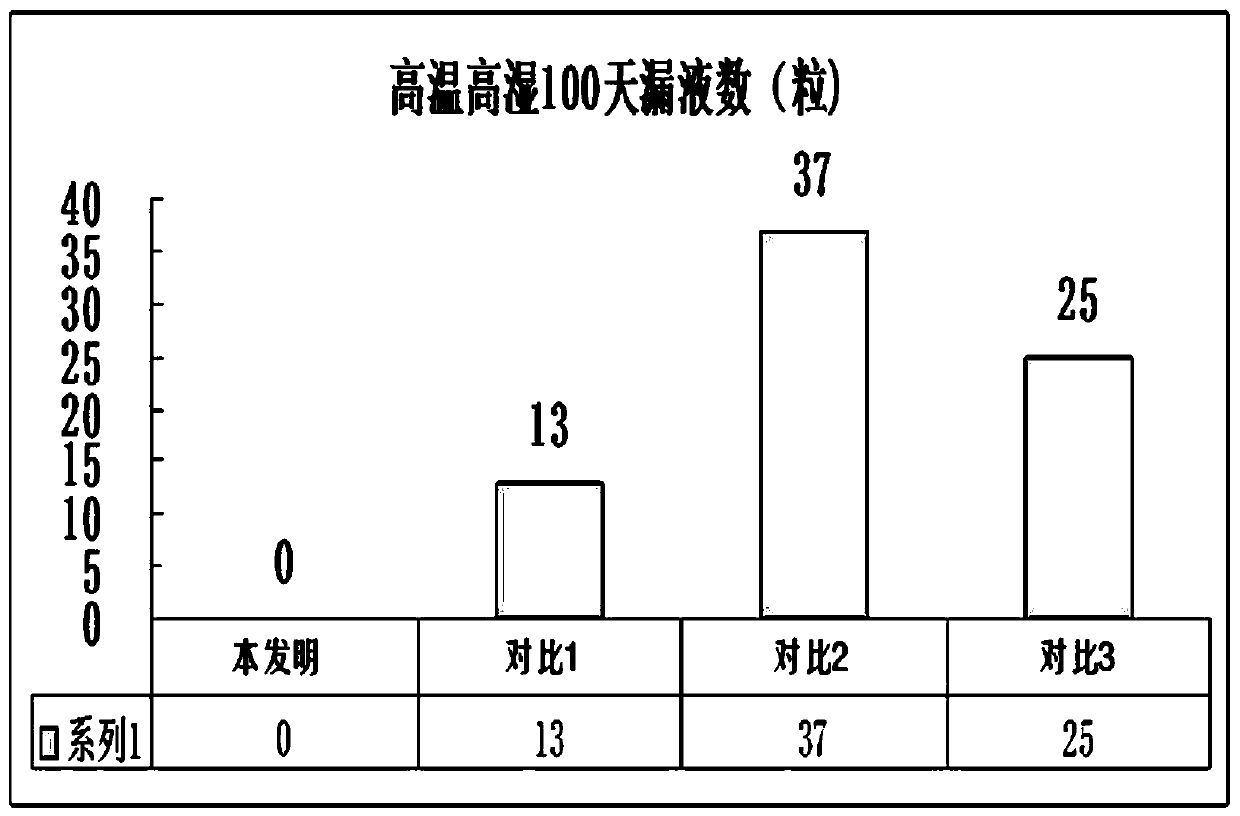

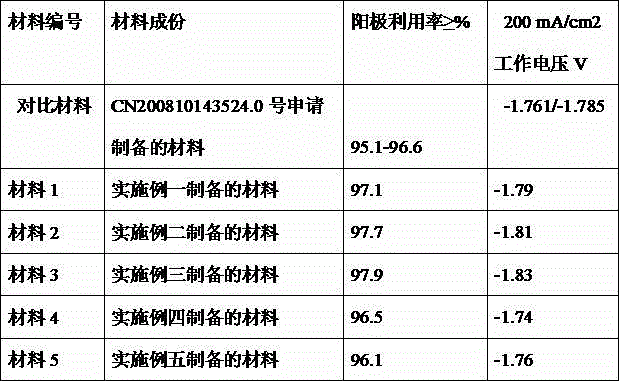

A kind of high anode utilization rate battery material and preparation method

The invention belongs to the field of metal materials, relates to a battery material with a high anode utilization rate and a preparation method thereof, and provides the battery material with the high anode utilization rate. The working potential cathode utilization rate and the working potential anode utilization rate of the alloy material are high. The invention further provides the battery material with the high anode utilization rate and the preparation method of the battery material. The preparation method is simple in technology, low in production cost and suitable for industrialized production. The battery material with the high anode utilization rate is prepared from the components of, by weight, 0.1-0.4% of Si, 0.01-0.03% of Pr, 0.01-0.04% of Ba, 0.02-0.04% of Fe, 0.01-0.03% of Li, 0.01-0.03% of Os, 0.5-0.9% of Cu, 4-8% of Al and the balance Mg.

Owner:常熟紫金知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com