A kind of anode material and preparation method thereof, battery

A technology for anode materials and batteries, applied in the field of anode materials and their preparation, can solve the problems of weakened discharge activity, serious self-corrosion, reduced active reaction area, etc., and achieves improved organizational uniformity, high anode utilization rate, and elimination of work hardening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

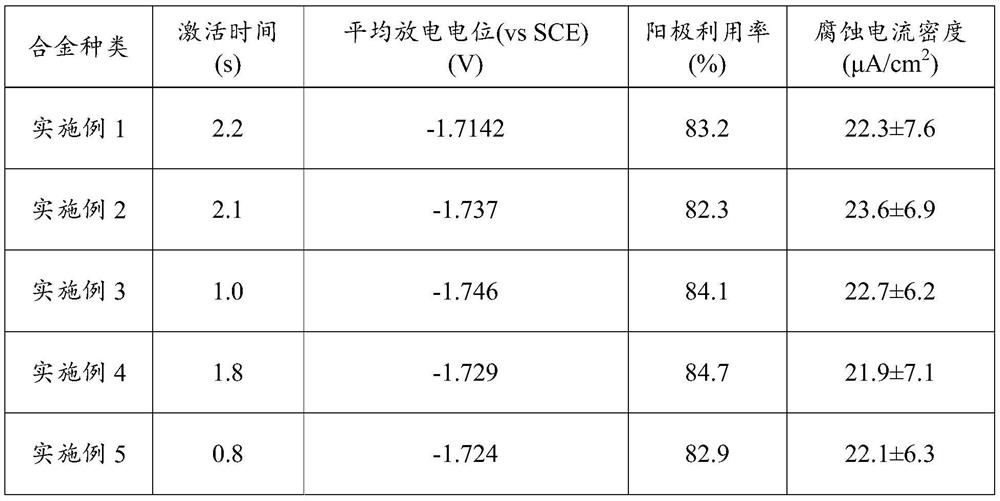

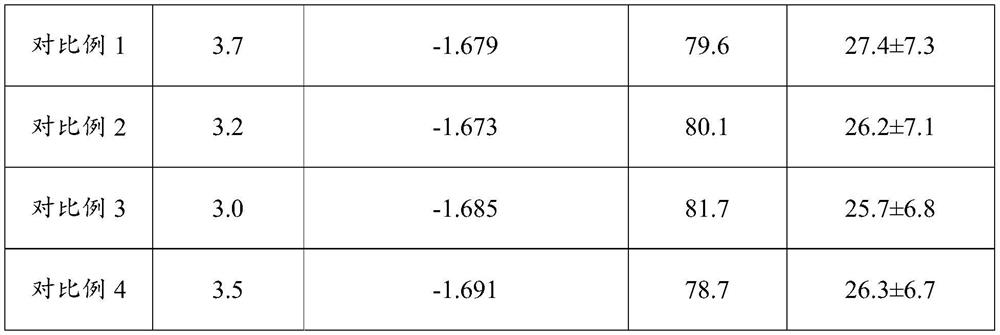

Examples

preparation example Construction

[0029] For reference, the above-mentioned method for preparing the anode material may specifically include the following steps: sequentially performing the first annealing, multi-pass rolling and third annealing on the Mg-Al-Pb slab prepared from the above-mentioned chemical composition according to the ratio , wherein, before the third annealing, a second annealing is also performed after each rolling.

[0030] Wherein, the preparation method of cast slab may include:

[0031] Pure magnesium ingots (for example, 99.99% pure) are melted, followed by addition of alloying elements, followed by refining, standing and pouring.

[0032] In some embodiments, Al and Pb can be added in the form of, but not limited to, pure aluminum and pure lead, and La and Ce can be added in the form of, but not limited to, Mg-15%La and Mg-25%Ce. In some embodiments, the alloying elements are added sequentially in the order of pure aluminum, Mg-15%La, Mg-25%Ce and pure lead.

[0033] Further, stirr...

Embodiment 1

[0051] This embodiment provides a magnesium alloy anode material for a high-power seawater battery. It is Fe≤0.008wt%, Cu≤0.006wt%, Ni≤0.007wt%, and the rest is Mg.

[0052] The preparation process of the magnesium alloy anode material for the above-mentioned high-power seawater battery is as follows:

[0053] First, the pure magnesium ingot with a magnesium content of 99.99% is heated and melted, and the temperature is raised to 730°C under the protection of flux for melting, and pure aluminum, Mg-15% La master alloy, Mg-25% Ce master alloy and pure The lead is poured after being refined, stirred, slag removed and left to stand to obtain a cast billet of magnesium alloy anode material for seawater batteries.

[0054] The cast slab is annealed for the first time at 410°C, and the first annealing is held for 20 hours; after the first annealed slab is removed from the surface oxide layer, it is heated to 250°C, and warm rolling begins after 30 minutes of holding. The roll temp...

Embodiment 2

[0056] This embodiment provides a magnesium alloy anode material for a high-power seawater battery. It is Fe≤0.007wt%, Cu≤0.007wt%, Ni≤0.008wt%, and the rest is Mg.

[0057] The preparation process of the magnesium alloy anode material for the above-mentioned high-power seawater battery is as follows:

[0058] First, the pure magnesium ingot with a magnesium content of 99.99% is heated and melted, and the temperature is raised to 730°C under the protection of flux for melting, and pure aluminum, Mg-15% La master alloy, Mg-25% Ce master alloy and pure The lead is poured after being refined, stirred, slag removed and left to stand to obtain a cast billet of magnesium alloy anode material for seawater batteries.

[0059] The cast slab is annealed for the first time at 460°C, and the first annealing is held for 16 hours; after the first annealed slab is removed from the surface oxide layer, it is heated to 340°C, and warm rolling begins after 25 minutes of holding. The roll temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com