Electroplating equipment and electroplating method for foam metal material

A technology of metal foam and electroplating equipment, applied in the direction of electrodes, etc., can solve the problems affecting the plated products (conductive sponge metal plating amount, increase the difficulty of unblocking pipelines, and high resistance of conductive sponges, etc., so as to increase the utilization rate of anodes and reduce product defects. The effect of reducing the efficiency and reducing the energy consumption of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

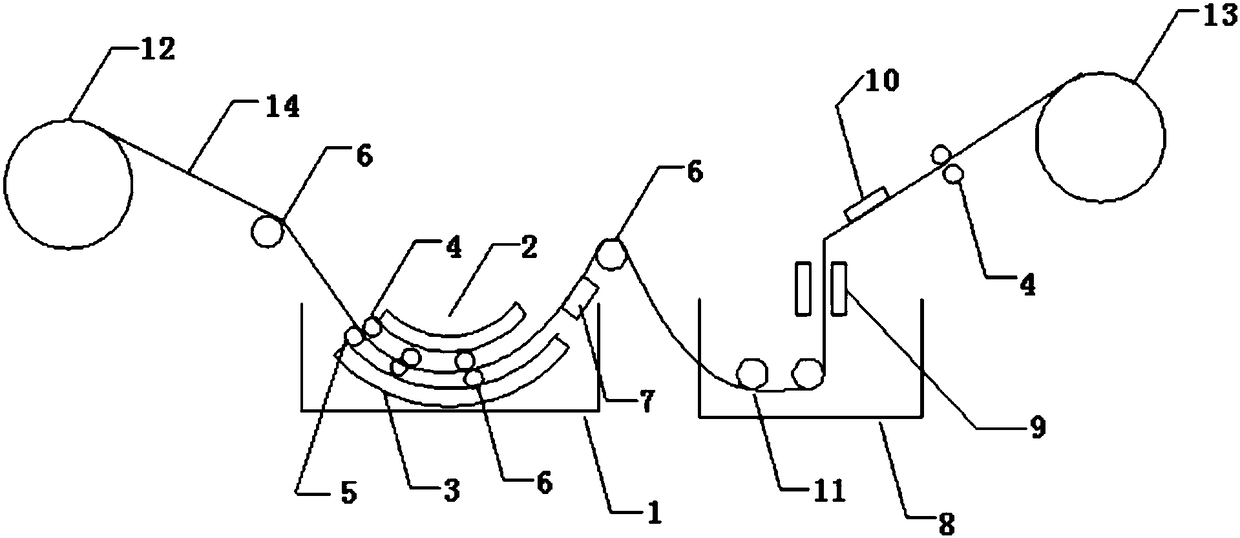

Method used

Image

Examples

Embodiment 1

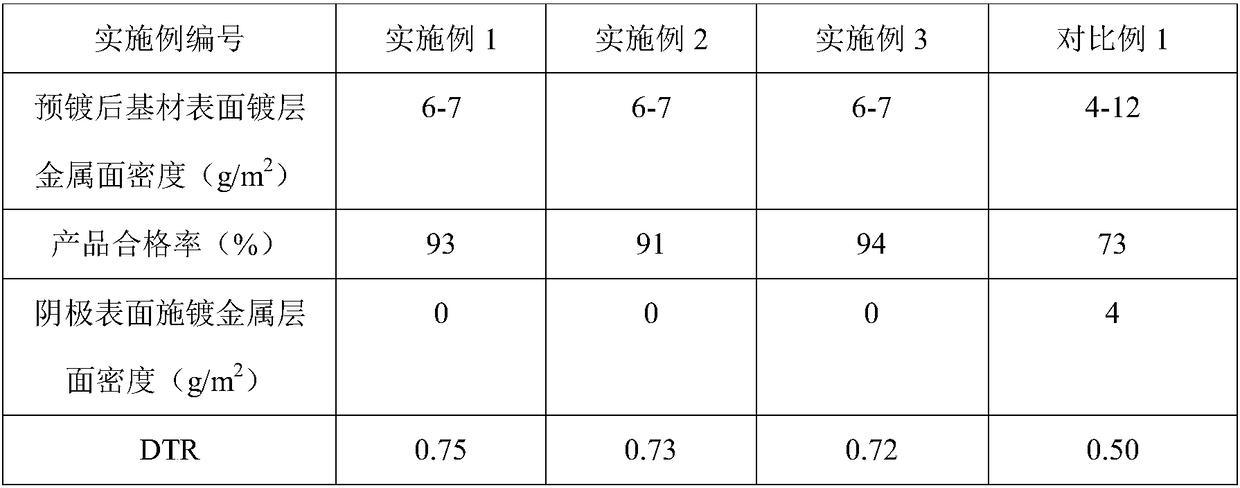

[0042]Adopt the equipment of the present invention, the 1.4mm thick that has been conductively treated, the polyurethane sponge of 110ppi hole number enters in the pre-plating tank through the unwinding machine through the guide roller and the driving roller, and interacts with the driving roller through the hydraulic roller before the pre-plating Squeeze out the internal air, the two anodes distributed up and down provide electroplating cations, and the cathode above the pre-plating solution is powered. The pre-plating solution is Watts plating solution, in which the total nickel is 75-85g / L, and the nickel chloride is 60- 70g / L, boric acid 30-40g / L, bath pH 4.3-4.6, temperature 55°C, pre-plating current 40A, substrate speed 0.1m / min, pre-plating time 2min. The pre-plating foam substrate is subjected to main plating, the composition of the main plating solution is the same as that of the pre-plating solution, the pH value is 4.3-4.6, the temperature is 55°C, the main plating c...

Embodiment 2

[0044] Adopt the equipment of the present invention, with the polyester sponge of 1.0mm thickness that has been conductively treated, the number of holes of 120ppi, enter in the pre-plating tank through the unwinder through the guide roller and the driving roller, and pass the hydraulic pressure roller and the driving roller to interact with each other before the pre-plating. Squeeze out the internal air, the two anodes distributed up and down provide electroplating cations, and the cathode above the pre-plating solution is powered. The pre-plating solution is Watts plating solution, of which the total nickel is 75-85g / L, and the nickel chloride is 60 -70g / L, boric acid 30-40g / L, bath pH 4.3-4.6, temperature 55°C, pre-plating current 50A, substrate speed 0.13m / min, pre-plating time 1.5min. The pre-plating foam substrate is subjected to main plating, the composition of the main plating solution is the same as that of the pre-plating solution, the pH value is 4.3-4.6, the tempera...

Embodiment 3

[0046] Adopt the equipment of the present invention, with the polyether sponge of 1.6mm thickness that has been conductively treated, 95ppi hole number, enter in the pre-plating tank through the unwinder through the guide roller and the driving roller, and pass the hydraulic pressure roller and the driving roller before the pre-plating. Squeeze out the internal air, the two anodes distributed up and down provide electroplating cations, and the cathode above the pre-plating solution is powered. The pre-plating solution is Watts plating solution, of which the total nickel is 75-85g / L, and the nickel chloride is 60 -70g / L, boric acid 30-40g / L, bath pH 4.3-4.6, temperature 55°C, pre-plating current 40A, substrate speed 0.1m / min, pre-plating time 2min. The pre-plating foam substrate is subjected to main plating, the composition of the main plating solution is the same as that of the pre-plating solution, the pH value is 4.3-4.6, the temperature is 55°C, the main plating current is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com