Alkaline battery anode surfactant and preparation method thereof

A surfactant and alkaline battery technology, applied in the direction of electrode manufacturing, negative electrode, positive electrode, etc., can solve the problems of easy passivation, easy leakage of electrolyte, etc., and achieve convenient control, high anode utilization rate, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

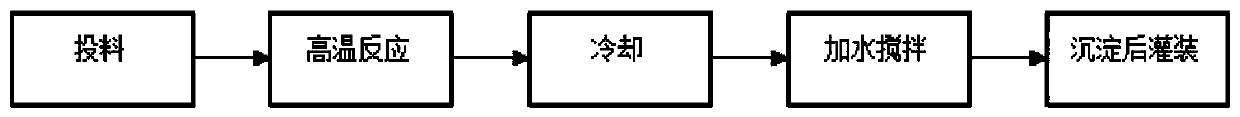

Method used

Image

Examples

Embodiment 1

[0035] In the present embodiment, a kind of alkaline battery anode surfactant, comprises the raw material of following weight portion:

[0036] Potassium hydroxide 51 parts

[0037] Amphoteric metal oxide 20.5 parts

[0038] 38.5 parts of deionized water.

[0039] Further, the amphoteric metal oxide is zinc oxide.

[0040] The preparation method of above-mentioned alkaline battery anode surfactant, comprises the steps:

[0041] Step A: Take 28.5 parts of deionized water, add 51 parts of potassium hydroxide, and keep stirring at high speed;

[0042] Step B: Add 20.5 parts of amphoteric metal oxide, and keep stirring and heating;

[0043] Step C: After the reaction of the amphoteric metal oxide is complete, stop heating and perform the first cooling;

[0044] Step D: After cooling for the first time, add 10 parts of deionized water again, and keep stirring at high speed to obtain mixture I;

[0045] Step E: Precipitate after cooling the mixture I obtained in step D to norm...

Embodiment 2

[0054] In the present embodiment, a kind of alkaline battery anode surfactant, comprises the raw material of following weight portion:

[0055] Potassium hydroxide 48 parts

[0056] Amphoteric metal oxide 18 parts

[0057] 36 parts of deionized water.

[0058] Further, the amphoteric metal oxide is zinc oxide.

[0059] The preparation method of above-mentioned alkaline battery anode surfactant, comprises the steps:

[0060] Step A: Take 27 parts of deionized water, add 48 parts of potassium hydroxide, and keep stirring at high speed;

[0061] Step B: Add 18 parts of amphoteric metal oxide, and keep stirring and heating;

[0062] Step C: After the reaction of the amphoteric metal oxide is complete, stop heating and perform the first cooling;

[0063] Step D: After cooling for the first time, add 9 parts of deionized water again, and keep stirring at high speed to obtain mixture I;

[0064] Step E: Precipitate after cooling the mixture I obtained in step D to normal temperat...

Embodiment 3

[0072] In the present embodiment, a kind of alkaline battery anode surfactant, comprises the raw material of following weight portion:

[0073] Potassium hydroxide 55 parts

[0074] Amphoteric metal oxide 23 parts

[0075] 41 parts of deionized water.

[0076] Further, the amphoteric metal oxide is zinc oxide.

[0077] The preparation method of above-mentioned alkaline battery anode surfactant, comprises the steps:

[0078] Step A: Take 30 parts of deionized water, add 55 parts of potassium hydroxide, and keep stirring at high speed;

[0079] Step B: Add 23 parts of amphoteric metal oxide, and keep stirring and heating;

[0080] Step C: After the reaction of the amphoteric metal oxide is complete, stop heating and perform the first cooling;

[0081] Step D: After cooling for the first time, add 11 parts of deionized water again, and keep stirring at high speed to obtain mixture I;

[0082] Step E: Precipitate after cooling the mixture I obtained in step D to normal tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com