System and method for calibrating leak rates of vacuum leak holes of different leak indication gases

A technology for vacuum leaks and gas leaks, which can solve environmental factors by using liquid/vacuum degree for liquid tightness measurement, detecting the appearance of fluid at the leak point, and measuring the rate of increase and deceleration of the fluid. Large size, long experiment period of constant volume method, and difficulty in quickly carrying out leak calibration, so as to achieve the effect of efficient calibration work, compact structure and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

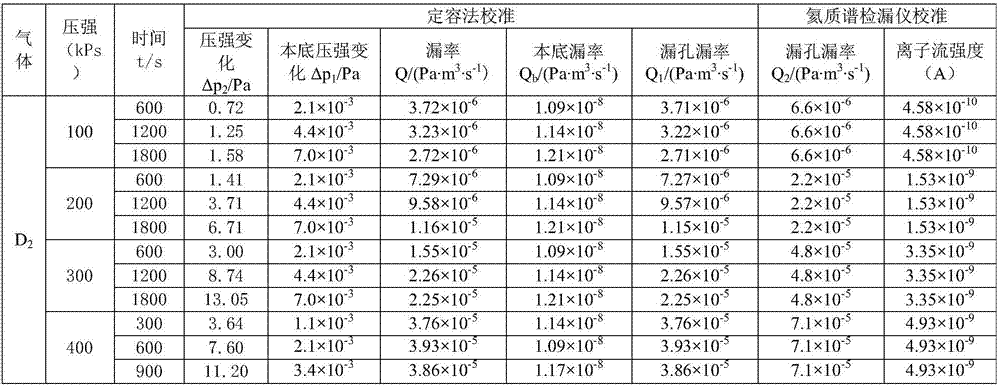

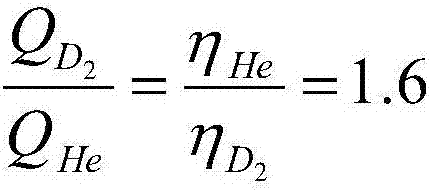

[0043] The purpose of this embodiment is mainly to provide a method for calibrating the leak rate of vacuum leaks of different leaking gases. The leak rates of vacuum leaks in different leak-indicating gas media are obtained, and the conversion relationship between the leak rates when measuring different leak-indicating gas media with a helium mass spectrometer leak detector is obtained.

[0044] In order to realize the above method, a system for calibrating the leak rate of vacuum leaks of different leaking gases is specially designed.

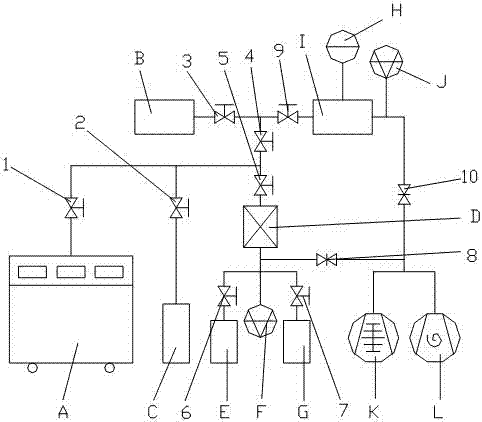

[0045] Such as figure 1 As shown, the system includes an experimental device, connecting pipes between various devices in the experimental device, and valves arranged on the pipes.

[0046] The experimental device includes a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com