A kind of multi-element alloy anode material for magnesium-air battery and preparation method thereof

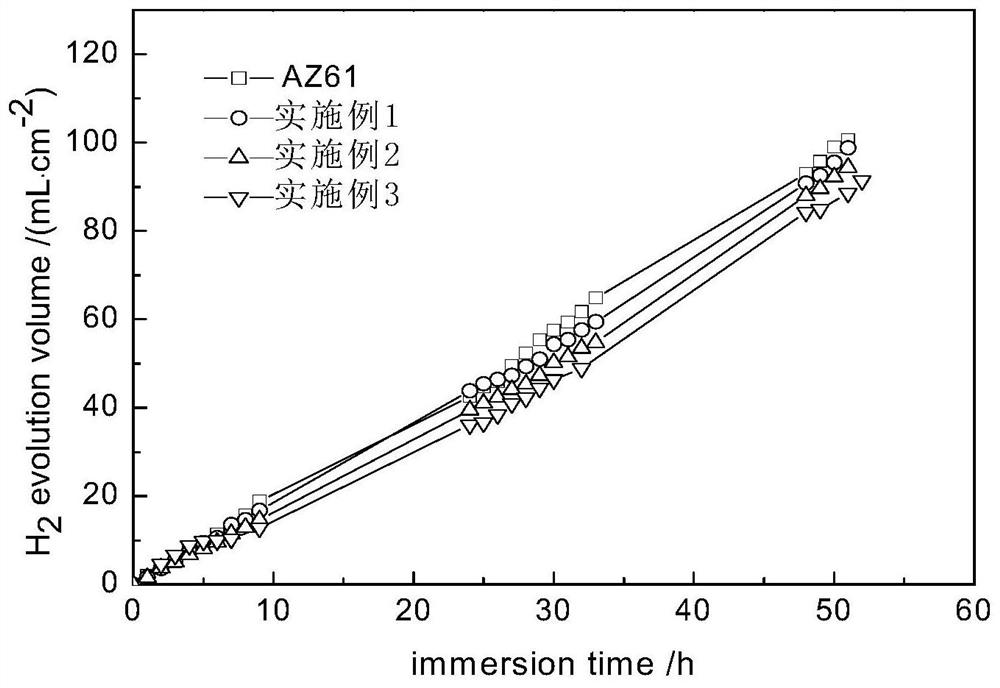

An air battery and multi-element alloy technology, applied in battery electrodes, negative electrodes, electrical components, etc., can solve the problems of high cost, poor environmental protection, insufficient discharge activity and utilization rate, etc., and achieve convenient implementation, strong discharge activity, and inhibition of hydrogen evolution The effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

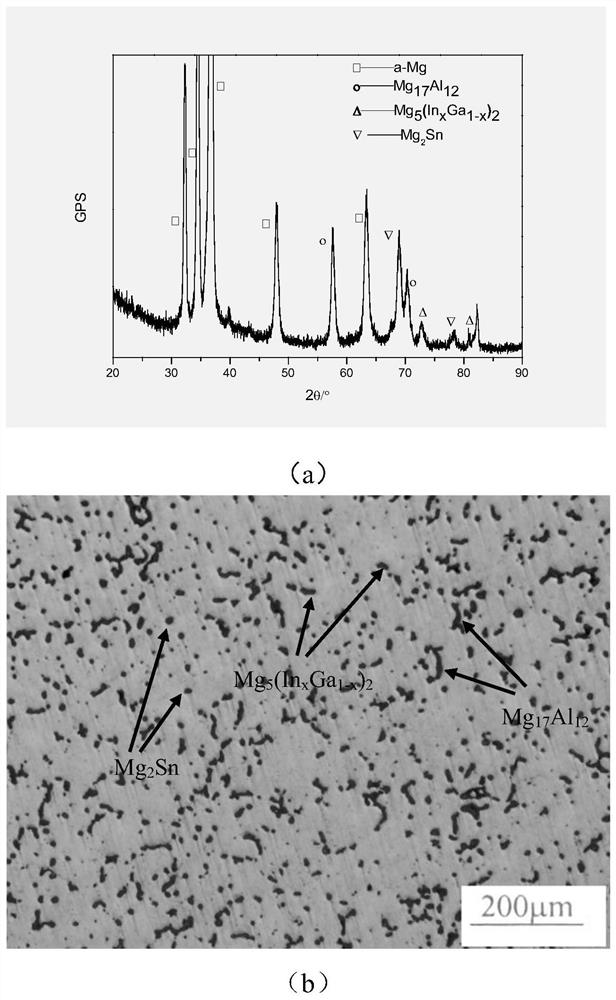

[0050] Take Mg-4Al-0.5Ga-1In-1Sn-0.2Ca-0.2Mn alloy as an example

[0051] The ingredients are made according to the following mass percentages:

[0052] Aluminum 4%;

[0053] Gallium 0.5%;

[0054] Indium 1%;

[0055] Tin 1%;

[0056] Calcium 0.2%;

[0057] Manganese 0.2%;

[0058] The balance is Mg.

[0059] S1. Prepare raw materials:

[0060] The raw materials are properly treated and cleaned to remove the corrosion and solvent, sand, oxide scale, etc. on the surface to prevent them from reacting with the magnesium solution and silicon, iron, hydrogen, oxidation inclusions, etc. from entering the solution. The treatment method mainly adopts the combination of sand blowing, mechanical grinding and chemical acid-base washing. All raw materials should be baked in an oven at about 150 ℃ for 20 to 30 minutes before smelting to remove the moisture.

[0061] S2. Preparation:

[0062] The mold is made of top-injection water-cooled copper mold with a diameter of 60 mm. The...

Embodiment 2

[0075] Take Mg-5Al-1Ga-1In-1Sn-0.2Ca-0.3Sr-0.2Mn alloy as an example

[0076] The ingredients are made according to the following mass percentages:

[0077] Aluminum 5%;

[0078] Gallium 1%;

[0079] Indium 1%;

[0080] Tin 1%;

[0081] Calcium 0.2%;

[0082] Strontium 0.3%;

[0083] Manganese 0.2%;

[0084] The balance is Mg.

[0085] The preparation process and the implementation process are the same as in Example 1, wherein: (4) the step refining temperature is 740 ° C, the total amount of refining agent is 1.5%, and the melt is allowed to stand for 15 minutes after refining, during which the surface melt is removed about every 5 minutes. scum.

[0086] Solution heat treatment:

[0087] The alloy ingot is heated to 400°C, after 6 hours of solution treatment, cooling treatment with room temperature water as the medium, and wire cutting into a magnesium anode plate.

Embodiment 3

[0089] Take Mg-6Al-2Ga-1In-1Sn-0.2Ca-0.3Sr-0.01Ti-0.2Mn alloy as an example

[0090] The ingredients are made according to the following mass percentages:

[0091] Aluminum 6%;

[0092] Gallium 2%;

[0093] Indium 1%;

[0094] Tin 1%;

[0095] Calcium 0.2%;

[0096] Strontium 0.3%;

[0097] Titanium 0.01%;

[0098] Manganese 0.2%;

[0099] The balance is Mg

[0100] The preparation process and implementation process are the same as in Example 1, wherein:

[0101] In the preparation stage, the Al-10Ti master alloy was added before the steps of refining and adding pure metals of tin, gallium and indium. Evenly, then remove surface dross. Add Al-10Ti master alloy. After all melted, the melt was stirred evenly again.

[0102] The temperature of the refining step was 750 °C, the total amount of refining agent was 1.5%, and the melt was allowed to stand for 15 minutes after refining, during which the surface slag was removed about every 5 minutes.

[0103] Solution heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com