A kind of aluminum-air battery ceramic particle composite anode material and preparation method thereof

An aluminum-air battery, ceramic particle technology, applied in battery electrodes, fuel cell-type half-cells and primary-cell-type half-cells, circuits, etc., can solve the problems of reduced anode electrochemistry, high price, and reduced reactivity, etc. Achieve the effect of good electrochemical activity, simple preparation method and low self-corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

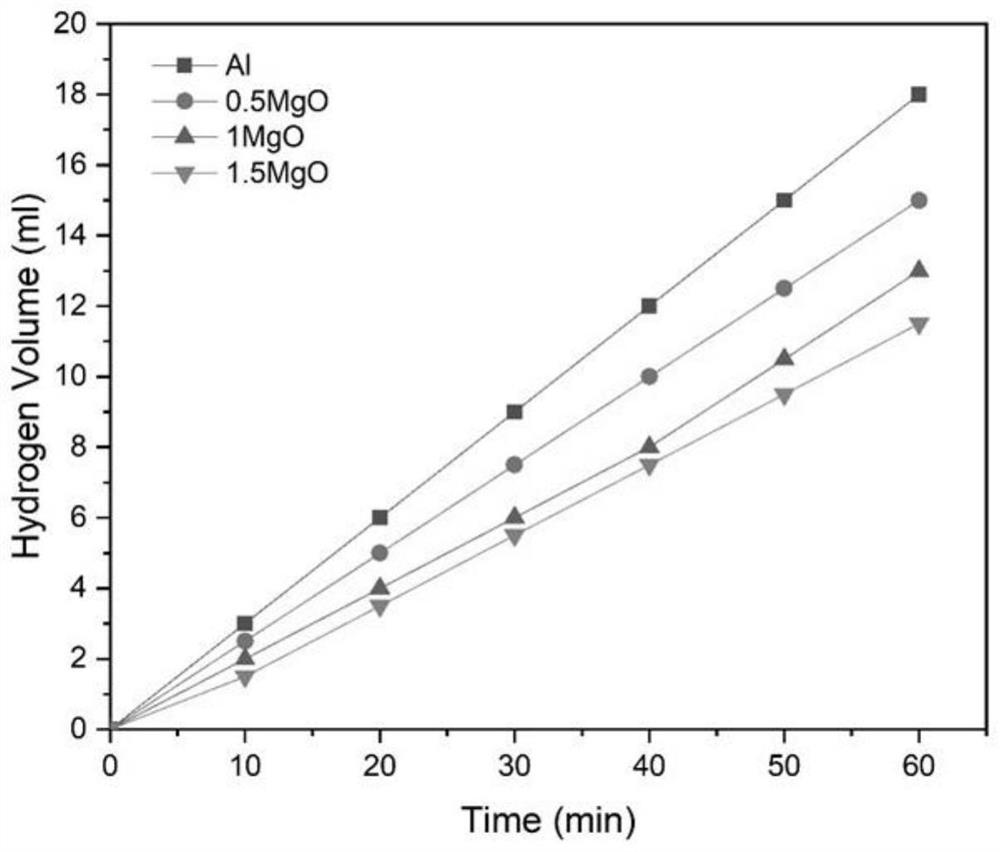

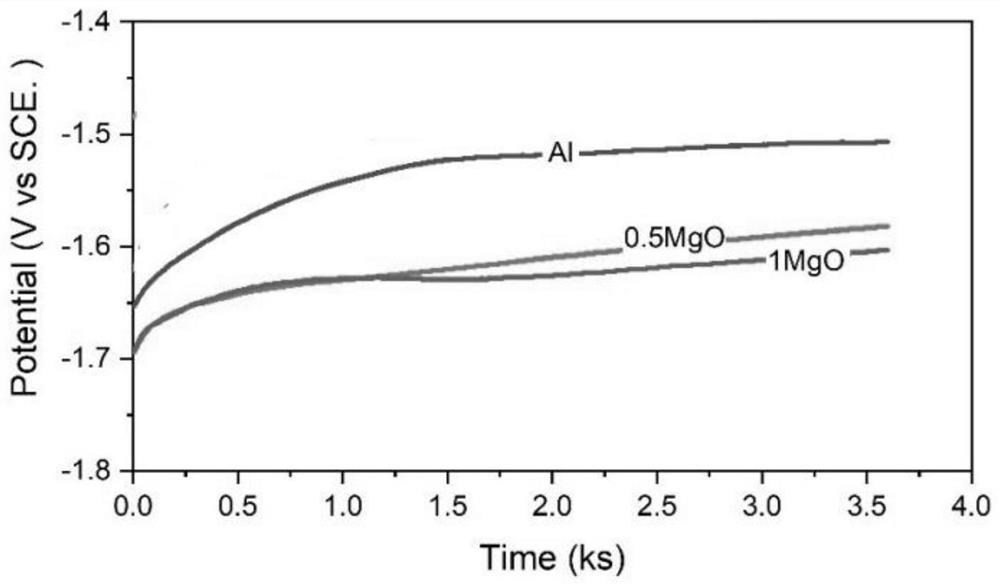

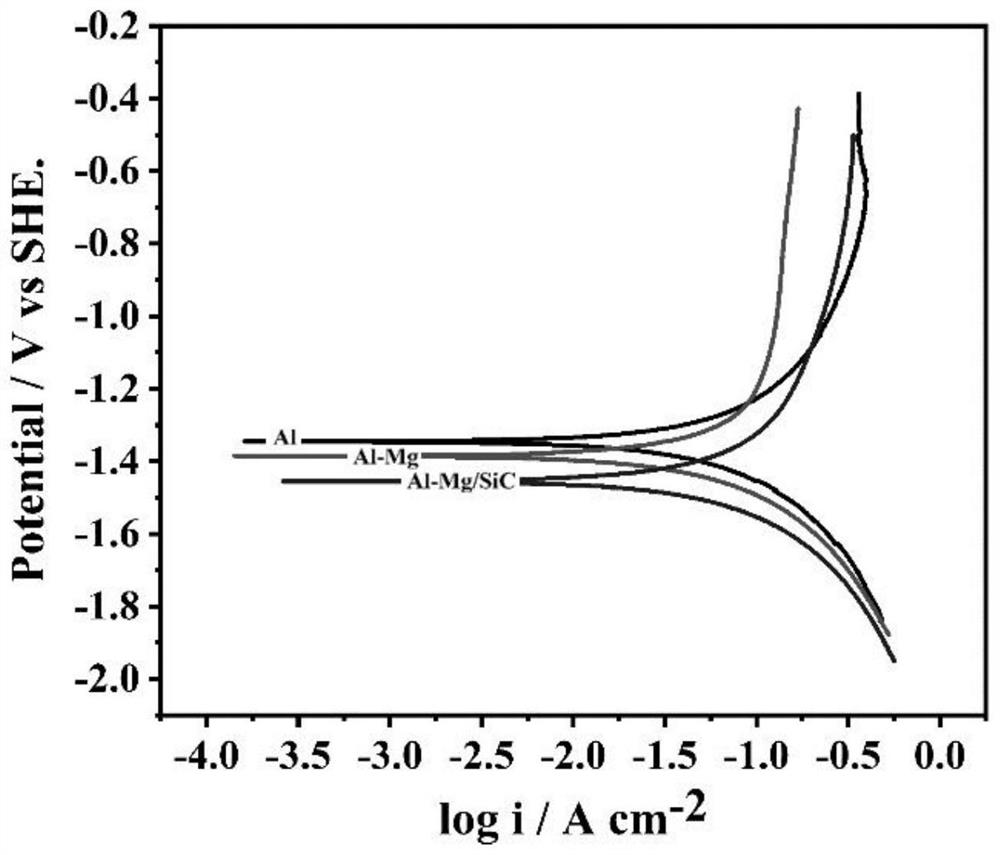

Embodiment 1

[0023] A preparation method of ceramic particle composite anode material for aluminum-air battery

[0024] The preparation method specifically comprises the following steps:

[0025] Step 1, fully cleaning and drying magnesium oxide particles with a particle size of 50 μm, and fully preheating at 300° C., and keeping the temperature for 1.5 hours to obtain preheated magnesium oxide particles;

[0026] Step 2, heating industrial pure aluminum 4N6 (the mass fraction of aluminum is more than 99.9%) to 710°C in a vacuum environment, so that the pure aluminum is completely melted, and then mixed with the preheated magnesium oxide particles with a mass fraction of 0.5wt.%. And stir, reduce the temperature to the semi-solid temperature of 640°C, continue to stir and heat to 690°C, stop heating and stirring, and cast to obtain the Al-MgO composite material;

[0027] Step 3: cutting the cast Al-MgO composite material ingot to obtain the aluminum-air battery composite anode, or rolling...

Embodiment 2

[0029] A preparation method of ceramic particle composite anode material for aluminum-air battery

[0030] The preparation method is the same as in Example 1, except that the mass fraction of 0.5 wt.% preheated magnesium oxide particles in step 2 is changed to 1 wt.% preheated magnesium oxide particles.

Embodiment 3

[0032] A preparation method of ceramic particle composite anode material for aluminum-air battery

[0033] The preparation method is the same as in Example 1, except that the preheated magnesium oxide particles with a mass fraction of 0.5 wt.% in step 2 are changed to 1.5 wt.% preheated magnesium oxide particles.

[0034]

[0035] A kind of preparation method of aluminum-air battery anode material

[0036] The preparation method is the same as that of Example 1, except that industrial pure aluminum 4N6 (the mass fraction of aluminum is more than 99.9%) is directly used as the anode material without adding any ceramic particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com