Patents

Literature

30results about How to "Suitable for large-scale production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

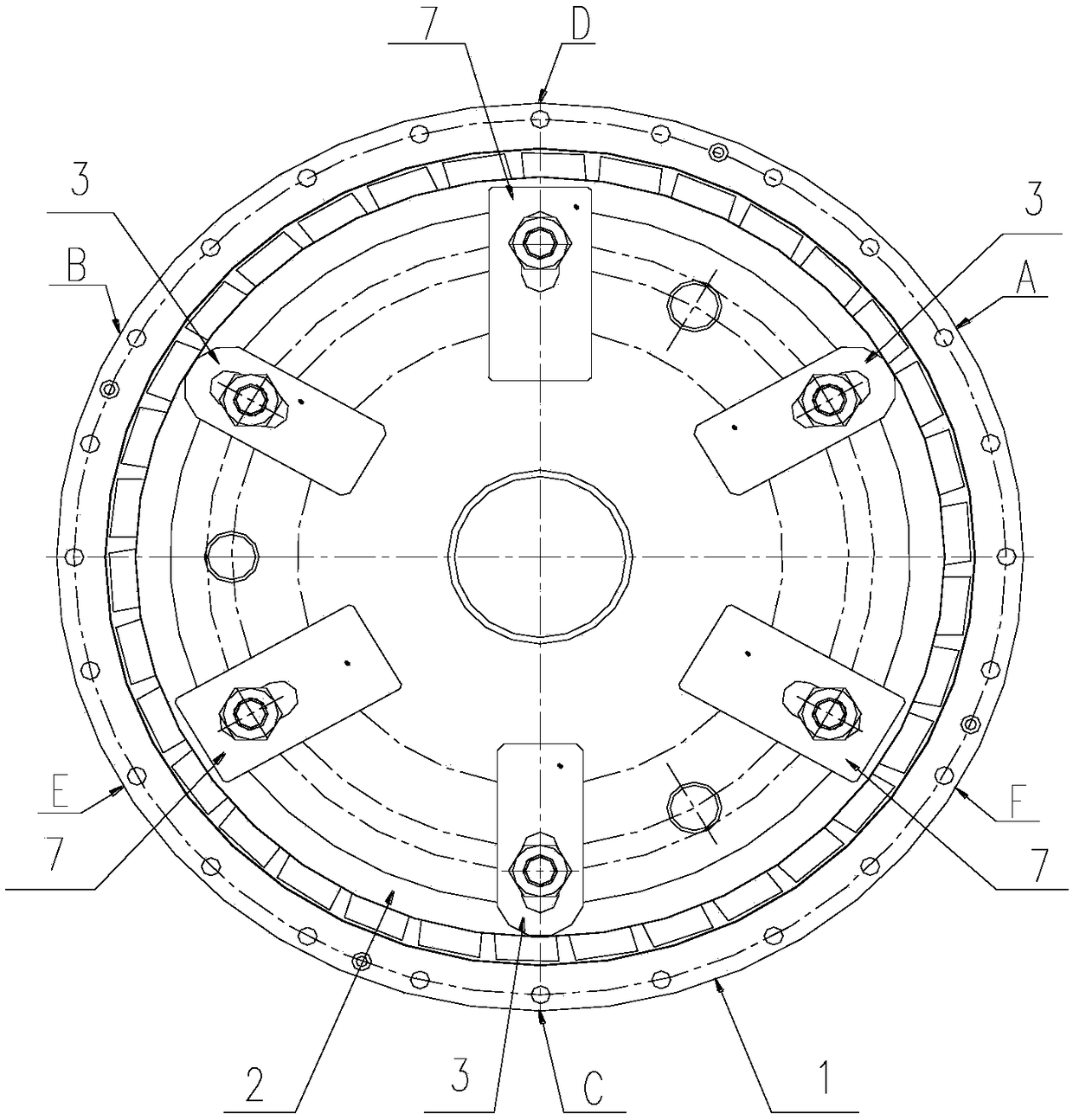

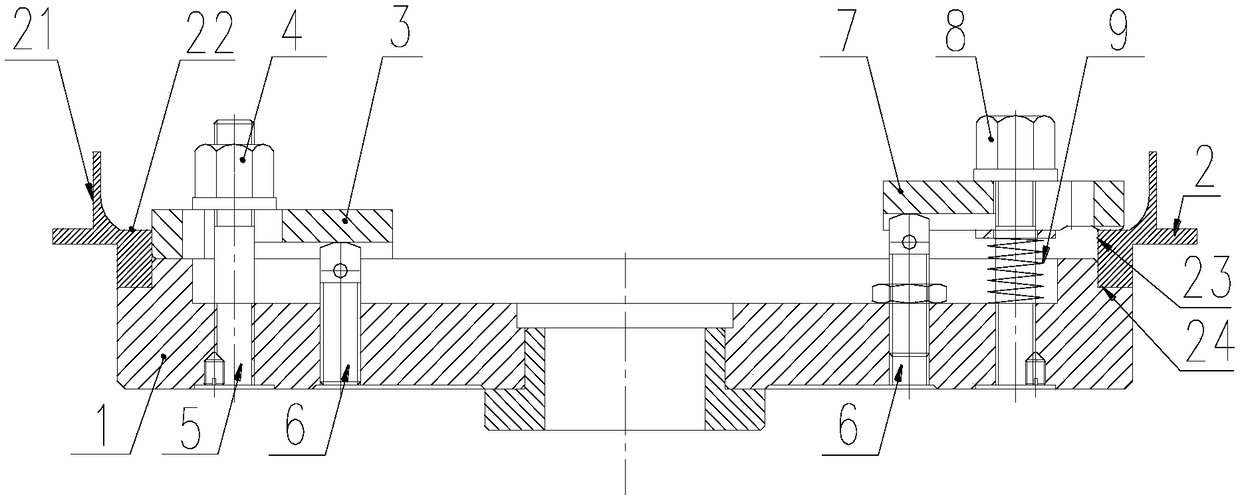

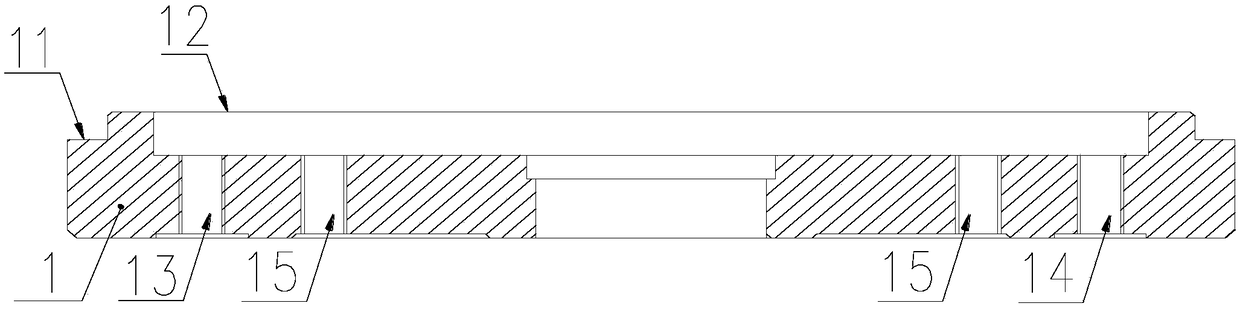

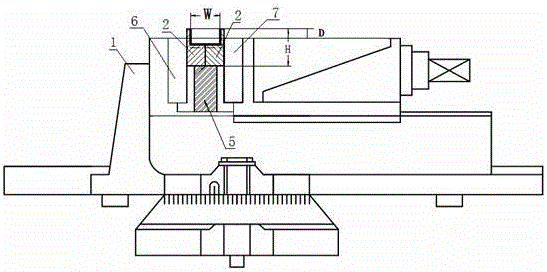

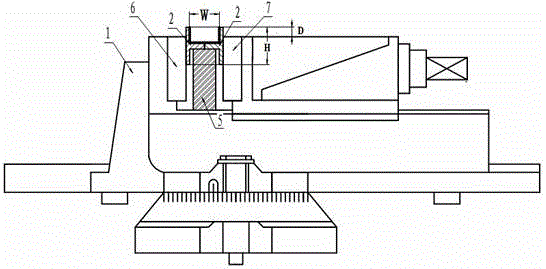

Annular thin-wall parts fixture and method for processing thin-wall outer surface of parts

PendingCN109333092AImprove quality and efficiencyImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention discloses an annular thin-wall parts fixture which comprises a cylindrical fixture support, at least three limiting blocks and at least three pressing blocks. An L-symmetrical-shaped step which is not higher than the upper end surface of the cylindrical fixture support is arranged on the outer side of the upper end surface of the cylindrical fixture support along the circumferentialcircle; an annular thin-wall parts is arranged on the step; the limiting blocks are circumferentially and uniformly distributed and fixedly arranged on the fixture support; one ends of the limiting blocks are arranged on the upper end surface of the fixture support; the side surfaces of the ends of the limiting blocks are close to the inner ring surface of the annular thin-wall parts; the pressingblocks and the limiting blocks are fixedly arranged on the fixture support at even intervals; and one ends of the pressing blocks presses the upper end surface of the annular thin-wall parts. The fixture support is used for supporting and limiting, the at least three limiting blocks are used for further limiting, and the at least three pressing blocks are used for pressing, so that the annular thin-wall parts is fixed and clamped and cannot be deformed when the thin-wall outer surface is processed, and the processing quality and the processing efficiency of the annular thin-wall parts are improved.

Owner:中国航发湖南南方宇航工业有限公司

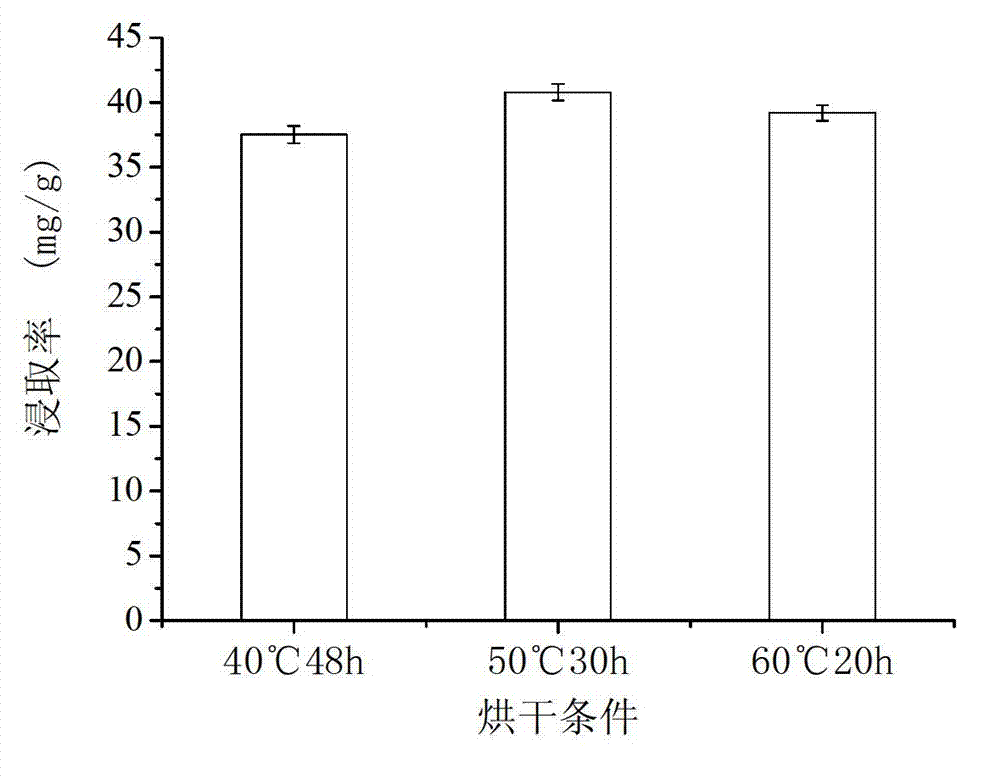

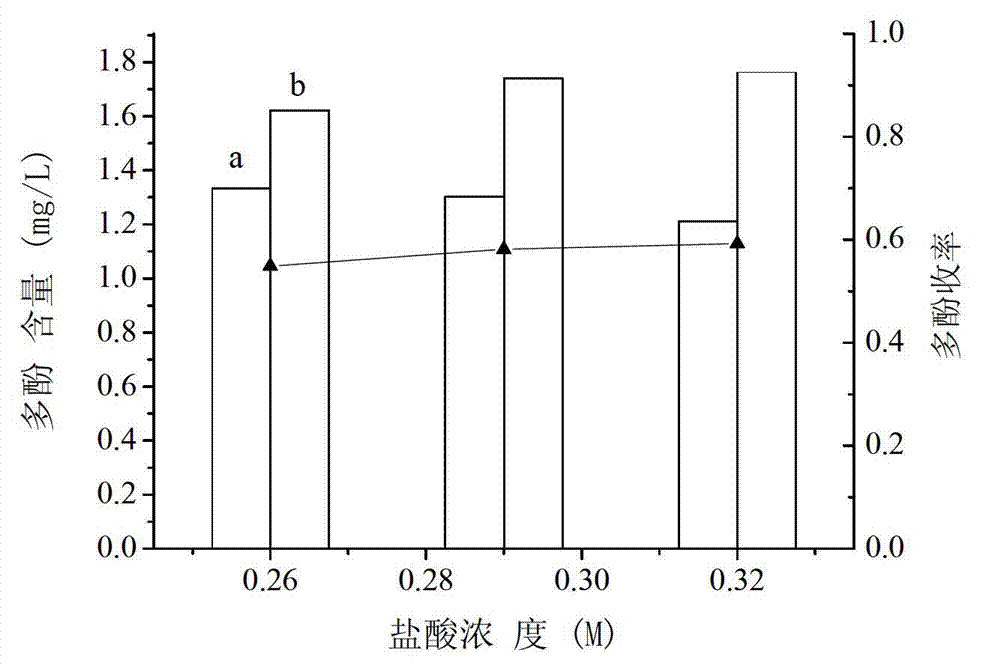

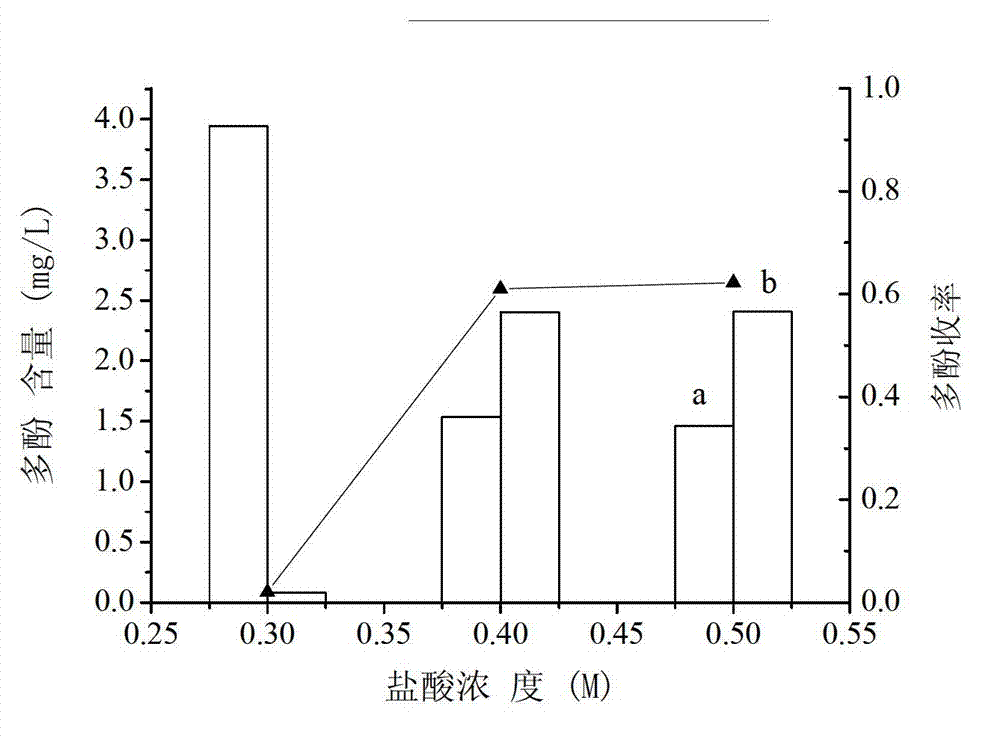

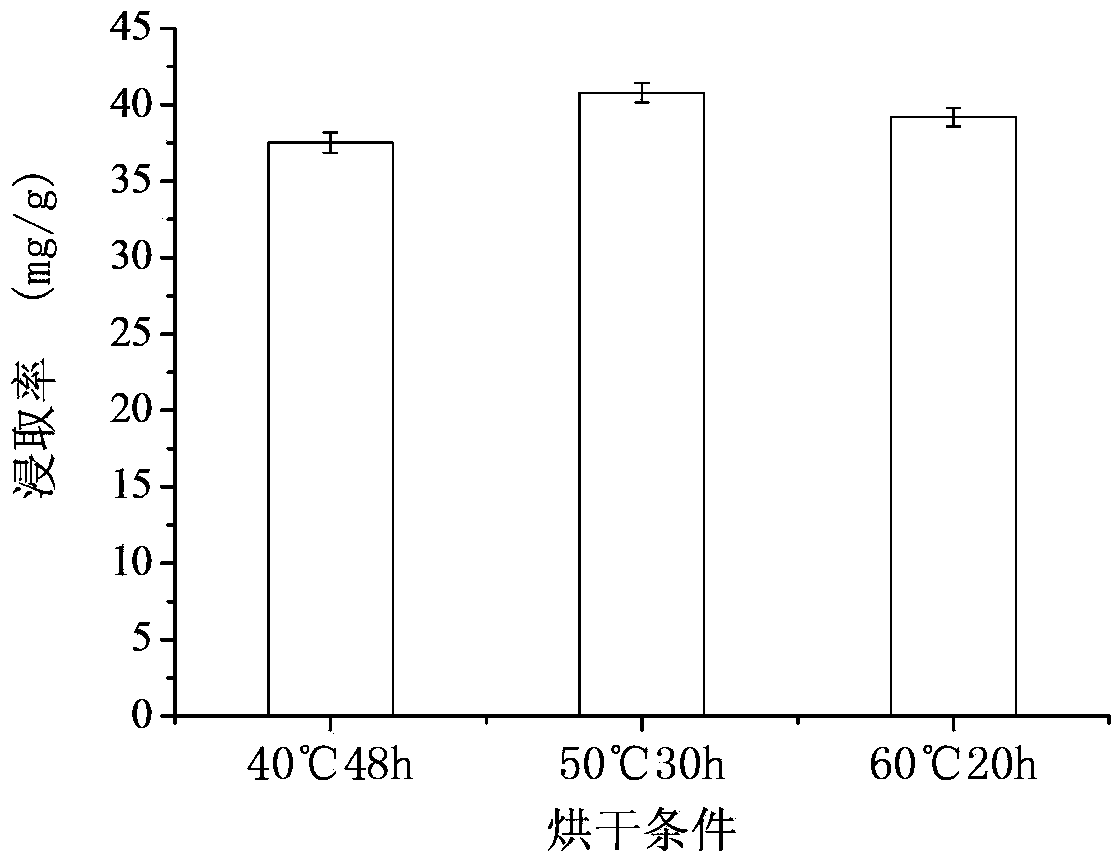

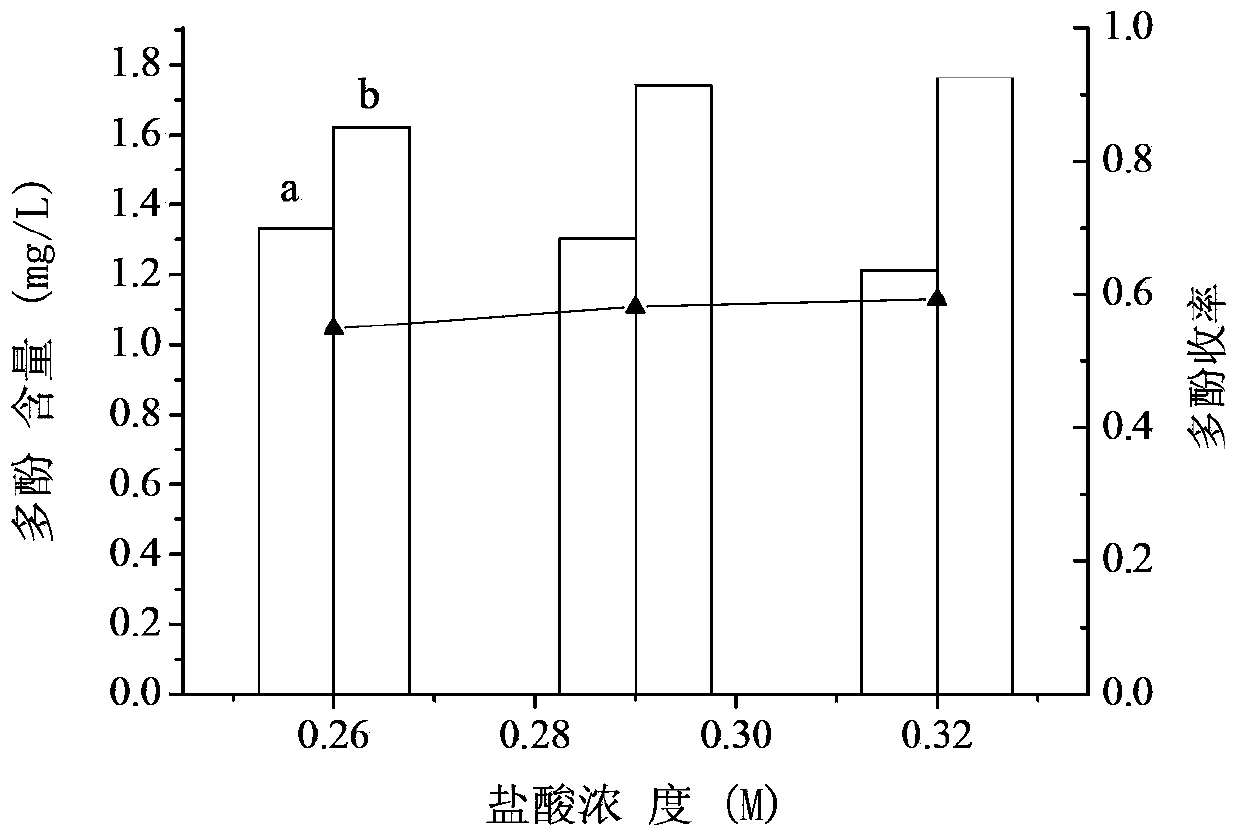

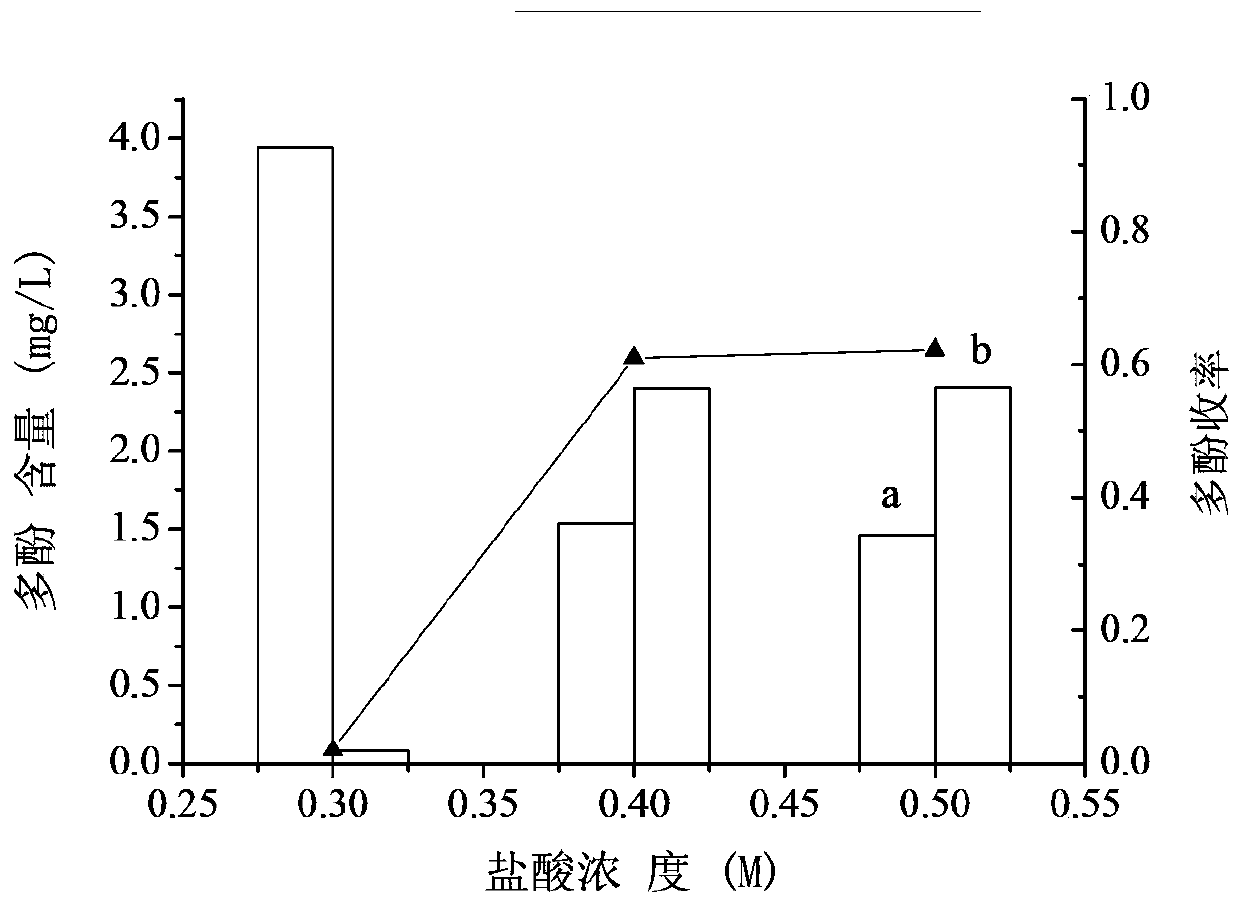

Extraction method of longan seed polyphenol

InactiveCN102961486AReduce oxidase activityReduce pollutionCosmetic preparationsToilet preparationsEconomic benefitsPolyphenol

The invention relates to an extraction method of longan seed polyphenol, relating to a processing method of a longan. The extraction method of the longan seed polyphenol can enhance the economic benefit of a longan industry and increase the income of fruit growers. The extraction method of the longan seed polyphenol comprises the following steps of: drying cleaned longan seeds; smashing raw material longan seeds to obtain longan seed powder; adding a sodium phosphate buffer solution to the longan seed powder to obtain a leach solution; pouring out the leach solution, filtering, removing leaching residues, and recovering immersion liquid; concentrating obtained filter liquor to obtain a concentrated solution; adding hydrochloric acid to the concentrated solution, stirring, and then standing for precipitation to obtain a precipitation solution; centrifugalizing the precipitation solution, removing a supernatant, washing precipitates by using the hydrochloric acid, and then drying to obtain fine longan seed polyphenol powder.

Owner:XIAMEN UNIV

Environment-friendly type multifunctional nano modified coating and spraying method thereof

InactiveCN104745025AImprove stabilityImprove sustainabilityLiquid surface applicatorsCoatingsAcrylic resinUltraviolet

The invention relates to environment-friendly type multifunctional nano modified coating and a spraying method thereof, which are used for solving the problems that the existing coating is high in cost and not resistant to ageing. The environment-friendly type multifunctional nano modified coating is prepared from the following components in parts by weight: 50-200 parts of nano titanium dioxide particle slurry, 30-100 parts of an acrylic resin finishing agent, 5-30 parts of a dispersing agent, 10-50 parts of a thickening agent, 5-10 parts of a de-foaming agent and an appropriate amount of water, wherein the nano titanium dioxide particles in the nano titanium dioxide particle slurry are surface-modified anatase titanium dioxide particles with a photocatalysis function and particle diameters of 10nm-50nm. Airflow atomized spraying of the compressed air is as follows: atomizing a paint liquid into mists by virtue of air flow of the compressed air, spraying the mists to the surface of an object, and forming a thin and uniform paint film on the surface of the sprayed object. Such special functions as super-hydrophobicity, ultraviolet ray resistance, bacteria resistance, self-cleaning, air purifying and the like are achieved without affecting the original color and patterns of the substrate, the functionality and the stability of the special functions are still relatively strong after long-term illuminating or multi-time washing, the cost is low, and the ageing resistance is excellent.

Owner:赵杰

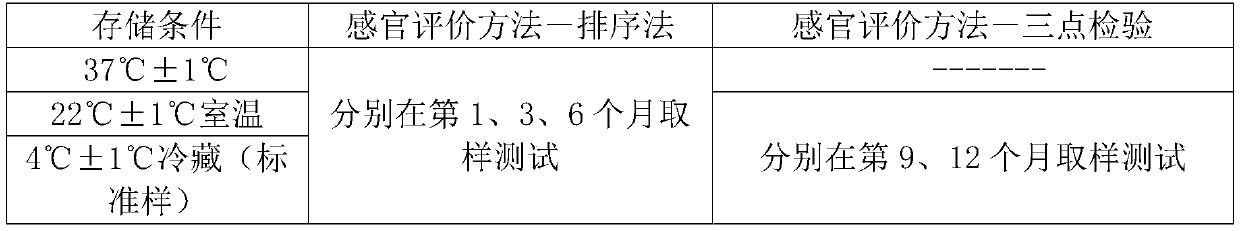

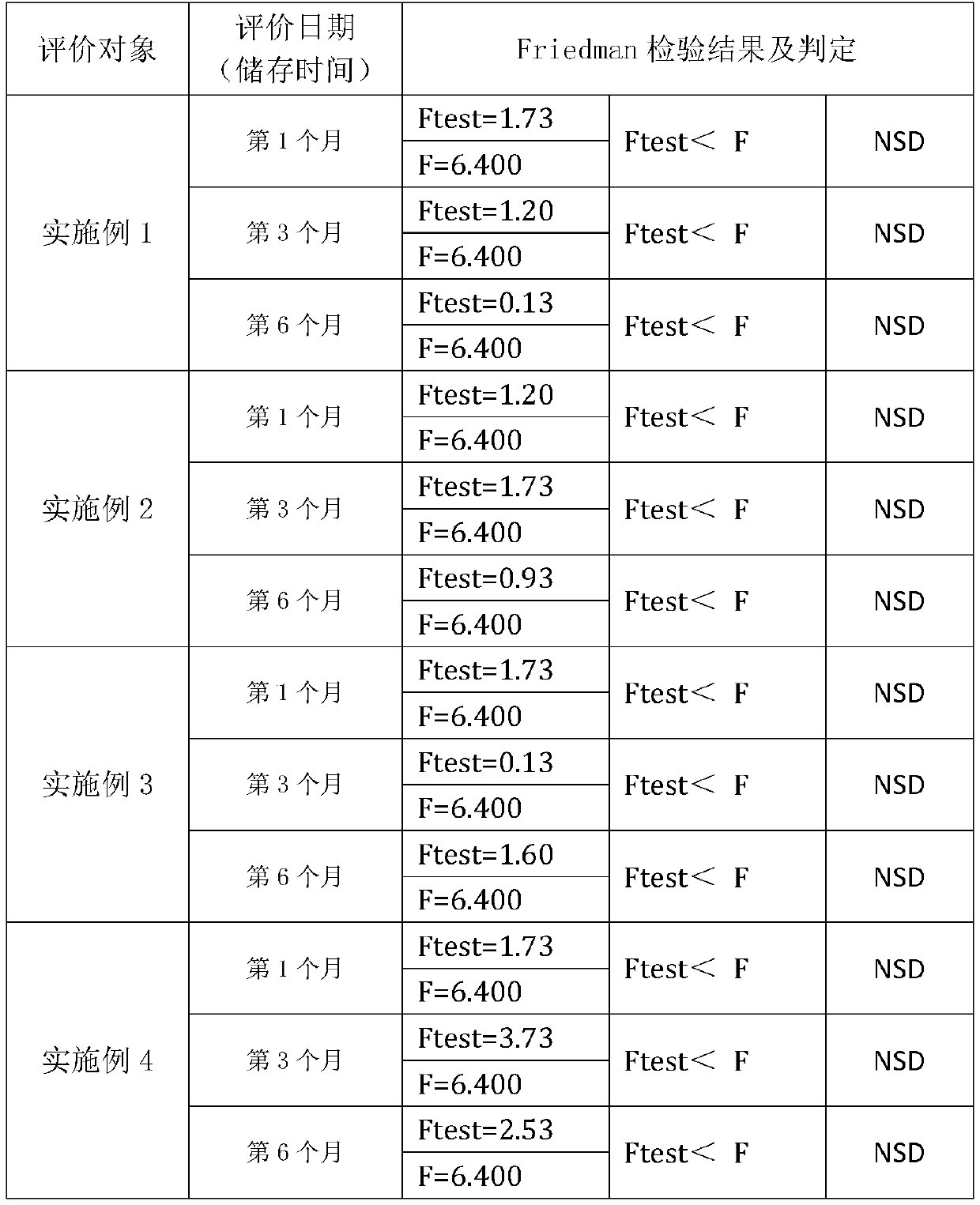

Processing method of pearl milk tea

InactiveCN108719532AUnique tasteEasy to operatePre-extraction tea treatmentTea extractionLiquid ratioSucrose

The invention provides pearl milk tea and a preparation method thereof. The preparation method specifically comprises the steps of preparing tea leaves: selecting green tea leaves or black tea leavesas raw materials, removing impurities, stalks and stems, and then performing reservation and storage for standby application; making tea soup: placing the tea leaves in water in the material-liquid ratio of 1-3%, performing cooking for 5-15 minutes, performing filtration, and storing tea water for standby application; performing blending: adding 4 spoonfuls of non-dairy creamer to the tea soup, and after the non-dairy creamer dissolves, adding an appropriate quantity of ice blocks and an appropriate amount of sweet water, wherein the sweet water is cane sugar water or caramel water; and preparing the milk tea: slowly adding an appropriate quantity of tapioca pearls to an appropriate amount of the tea soup blended in the step (3), and performing uniform stirring so as to obtain the pearl milk tea. The making technology of the pearl milk tea disclosed by the invention is simple and novel, the industrial production quantity and the production efficiency are greatly improved, and the madetapioca pearls are good in elasticity, hardness, tenacity and mouth feel, and are a ideal beverage in summer.

Owner:南京华坤生物技术有限公司

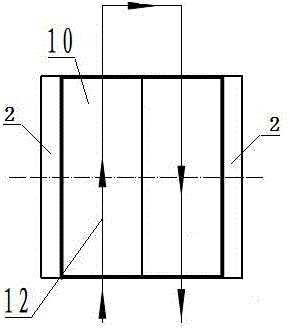

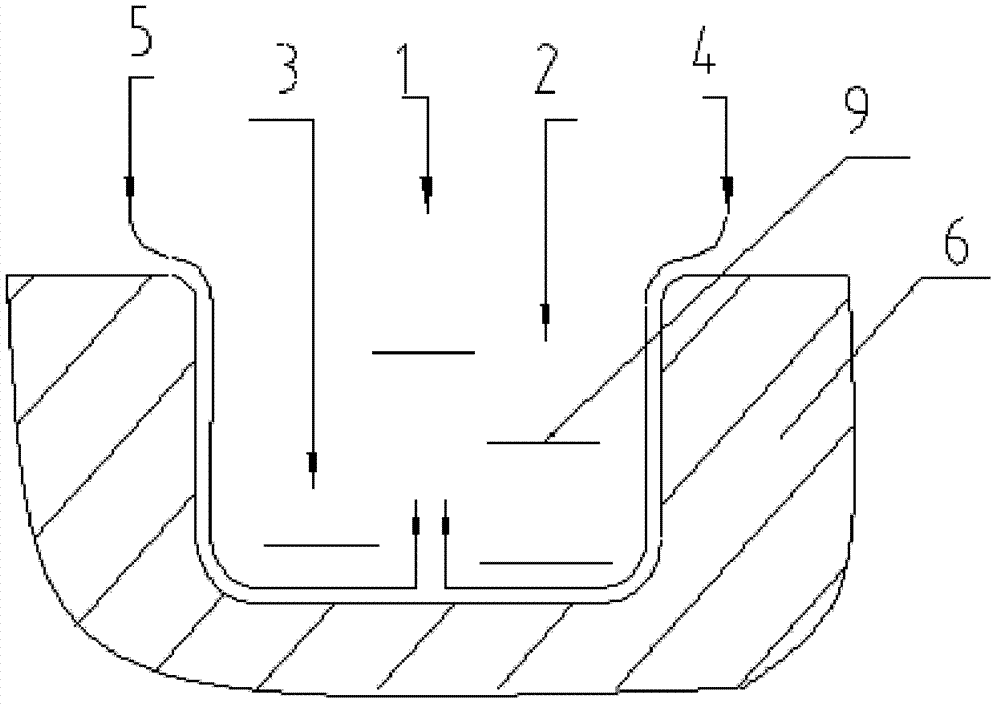

Machining method of H-shaped thin-wall parts

InactiveCN104841990AGood symmetryImprove quality and efficiencyMilling equipment detailsGroove widthNumerical control

The invention provides a machining method of H-shaped thin-wall parts. The machining method includes selecting tri-blade taper-shank rough-machining milling cutters and fine-machining milling cutters according to groove depth, part height and groove width of H-shaped thin-wall parts to be machined, wherein the diameter of the milling cutters ranges from one second of the groove width to the groove width minus two, and roughness of the grinding positions of cutting edges of the fine-machining milling cutters is not higher than Ra 0.4; setting groove depth, groove width and three to eight layers of rough-machining layers on a numerical-control machine tool, setting the thickness of the rough-machining layers at 2-3 millimeters and the fine-machining allowance at 0.5-1 millimeters; setting linear speed and cutting feed of rotation of a spindle of the numerical-control machine tool, wherein linear speed and cutting feed of rough machining are 200-230 m / min and 70-74 mm / min respectively, and those of fine machining are 305-370 m / min and 100 / 115 mm / min respectively. By the machining method of the H-shaped thin-wall parts, machining procedures of parts are simplified.

Owner:LIUZHOU SANNONG TECH

Heat insulation coating and production process thereof

The invention relates to a heat insulation coating and a production process thereof. Raw materials for the heat insulation coating comprise, by weight, 80 to 200 parts of organic hollow microspheres, 50 to 125 parts of alumina silicate, 50 to 135 parts of siliceous lime, 2 to 6 parts of a thickening agent, 1 part to 10 parts of an antifoaming agent, 1 part to 10 parts of a dispersant, 8 to 35 parts of glycol, 3 to 10 parts of a wetting agent, 180 to 500 parts of latex paint emulsion and 100 to 350 parts of water. The heat insulation coating provided in the invention is composed of the organic hollow microspheres suspended in inert latex; microstructure of the microspheres is favorable for reflection and scattering of infrared ray, and the microspheres are enclosed hollow balls, having a low coefficient of heat conductivity; the addition of the microspheres into the coating enables considerable microscopic independent heat insulation cavities to be formed, thereby substantially improving heat insulation of a film.

Owner:DALIAN JINZHOU JINHE CHEM BUILDING MATERIALS FACTORY

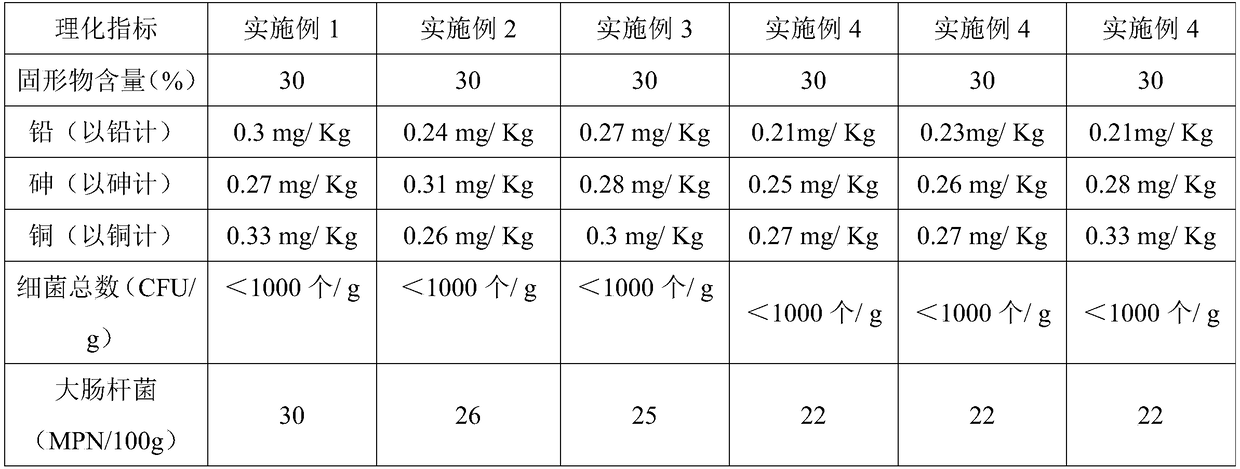

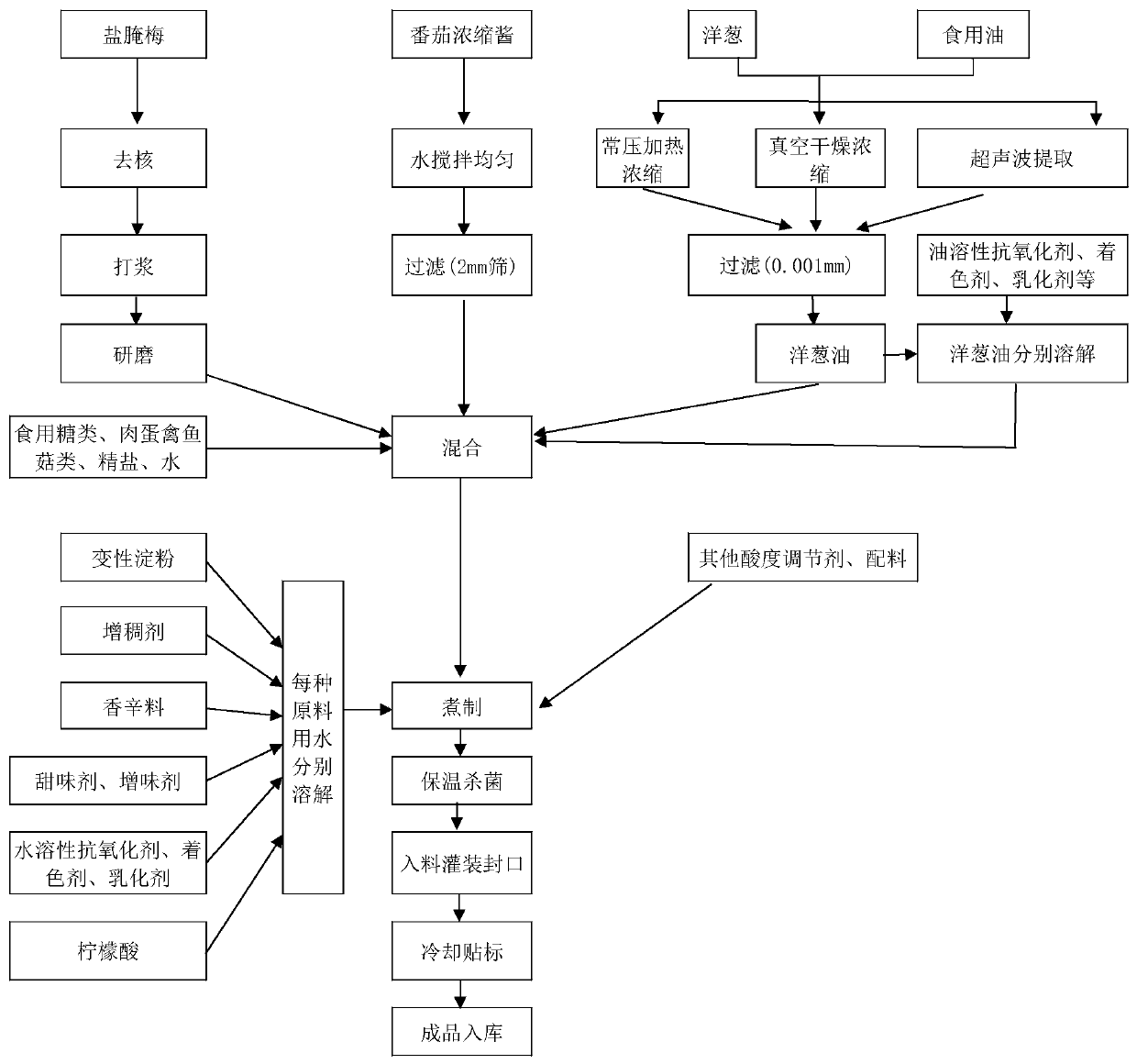

Instant tomato paste rich in lycopene and production method of instant tomato paste

The invention discloses instant tomato paste rich in lycopene and a production method of the instant tomato paste. The instant tomato paste mainly comprises, by weight, 35-55 parts of water, 25-40 parts of concentrated tomato paste, 2-12 parts of edible sugar, 4.5-18.5 parts of meat, egg, fish and mushrooms, 2-10 parts of white vinegar, 1.5-3 parts of salt, 1-10 parts of onion oil, 0.02-0.2 part of emulsifier and 0.0012-0.005 part of antioxidant. The production method includes: pre-producing the onion oil; weighing the raw materials, and pre-dissolving; premixing and preheating the pre-dissolved raw materials, heating and cooking in a staged manner, and performing heat preservation and sterilizing for 20-35 minutes to obtain the instant tomato paste rich in lycopene, wherein the temperature of the materials is 105 DEG C during the heat preservation and sterilizing. The produced instant tomato paste rich in lycopene is convenient to eat, high in nutritional value and good in taste and flavor.

Owner:LEE KUM KEE XIN HUI FOOD

Processing method for gunpowder tea

InactiveCN103583722ASuitable for large-scale production and processingQuality improvementPre-extraction tea treatmentGunpowderBud

The invention relates to the technical field of tea processing and in particular relates to a processing method for gunpowder tea. The processing method comprises the following steps: raw material screening, rolling and cutting, winnowing, deactivating, rotary sifting, cooling, reciprocating sifting, stem picking, net rotary sifting, net blowing, stack averaging, stack splicing and package. Compared with the conventional gunpowder tea processing technology, the processing method for the gunpowder tea has the advantages that a gunpowder tea product prepared by the processing method is stable in quality, has a round and compact appearance, is granular, is green, is as heavy and solid as pearls, smells fragrance, tastes delicious and is durable in water; leaves are bright olivine; bud-leaves are intact; the gunpowder tea is well received by consumers. The method disclosed by the invention is easy to operate and is suitable for large-scale production and processing of the gunpowder tea.

Owner:贵州铜仁和泰茶业有限公司

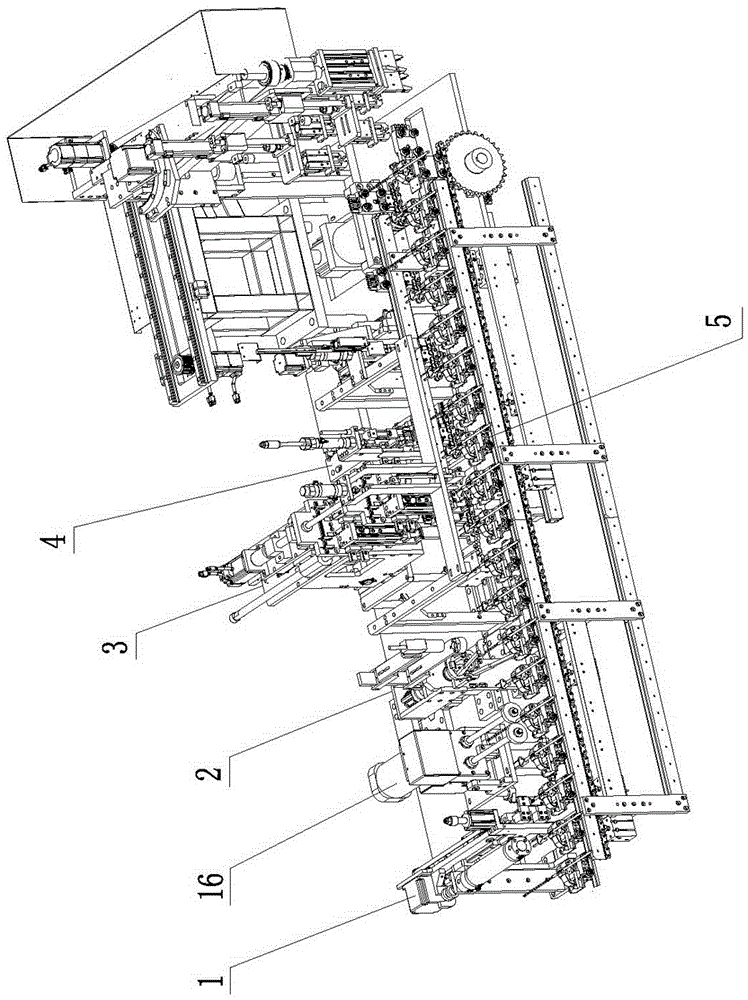

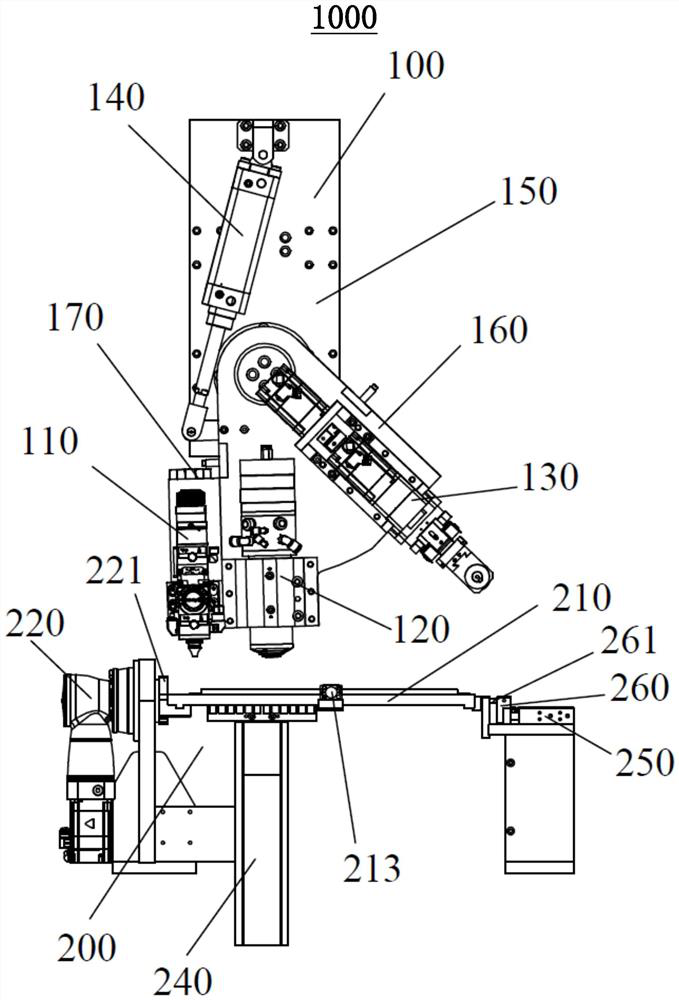

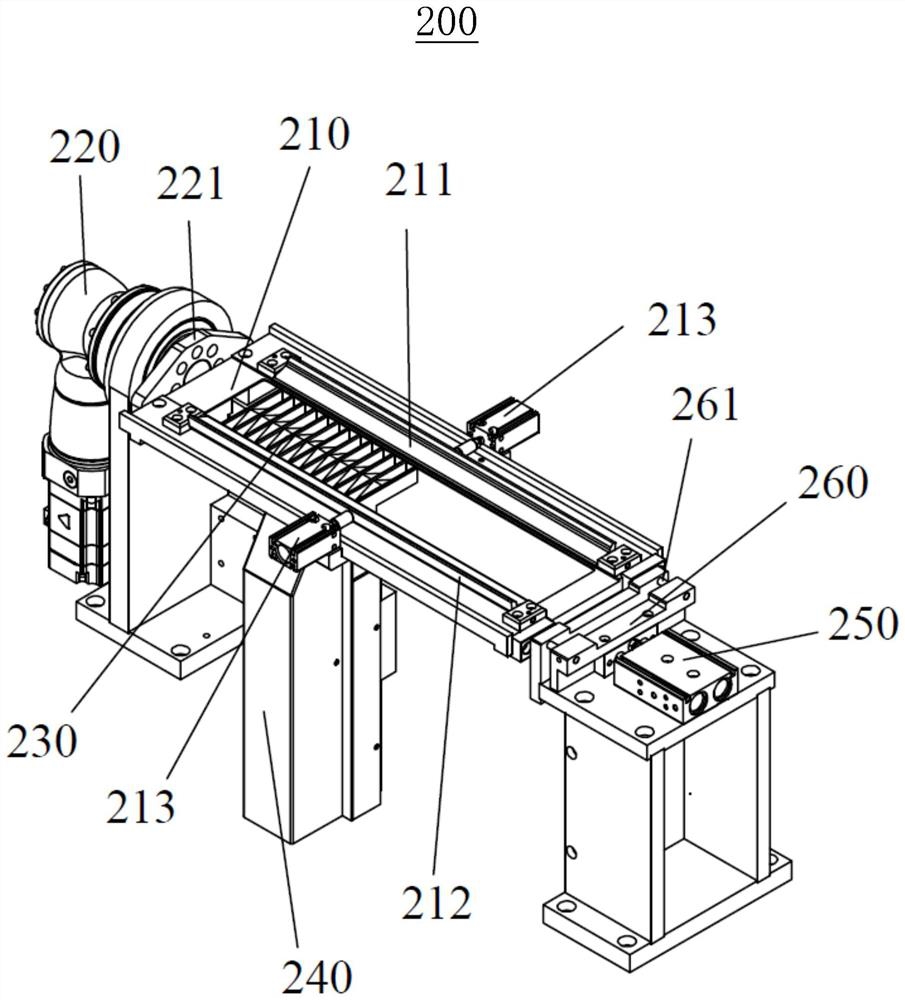

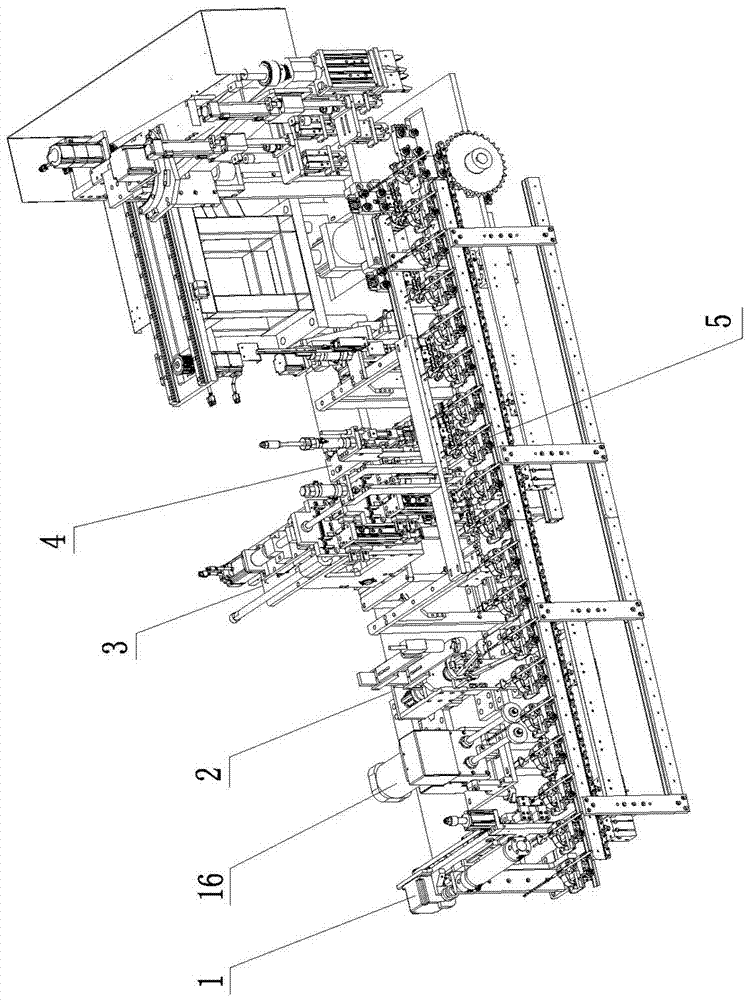

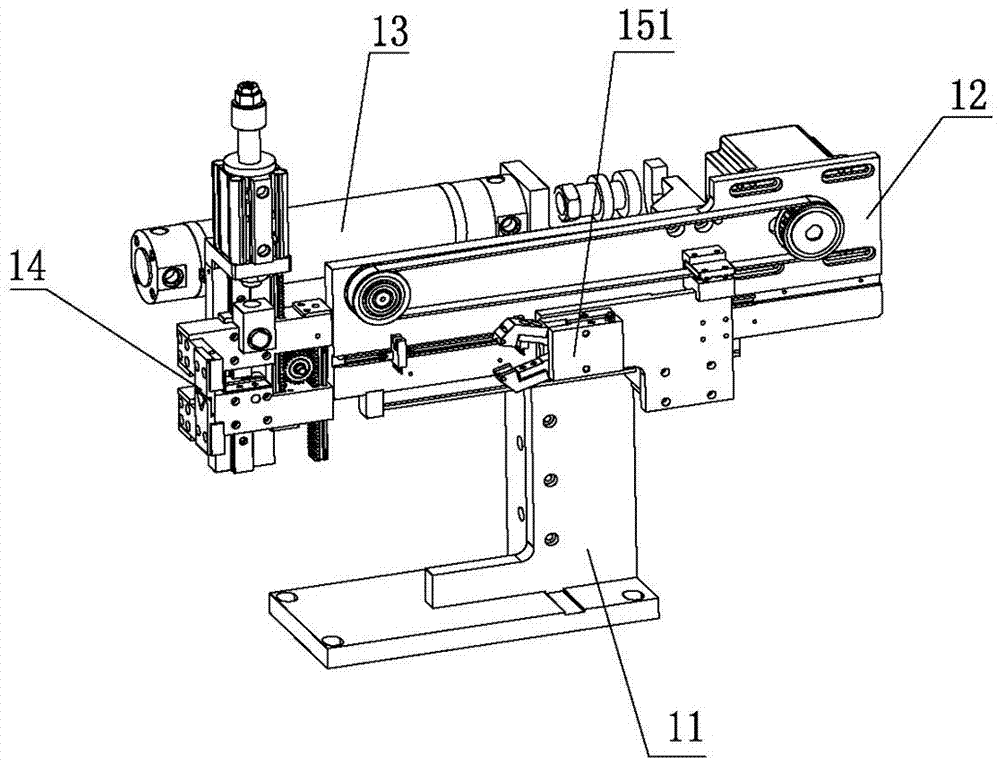

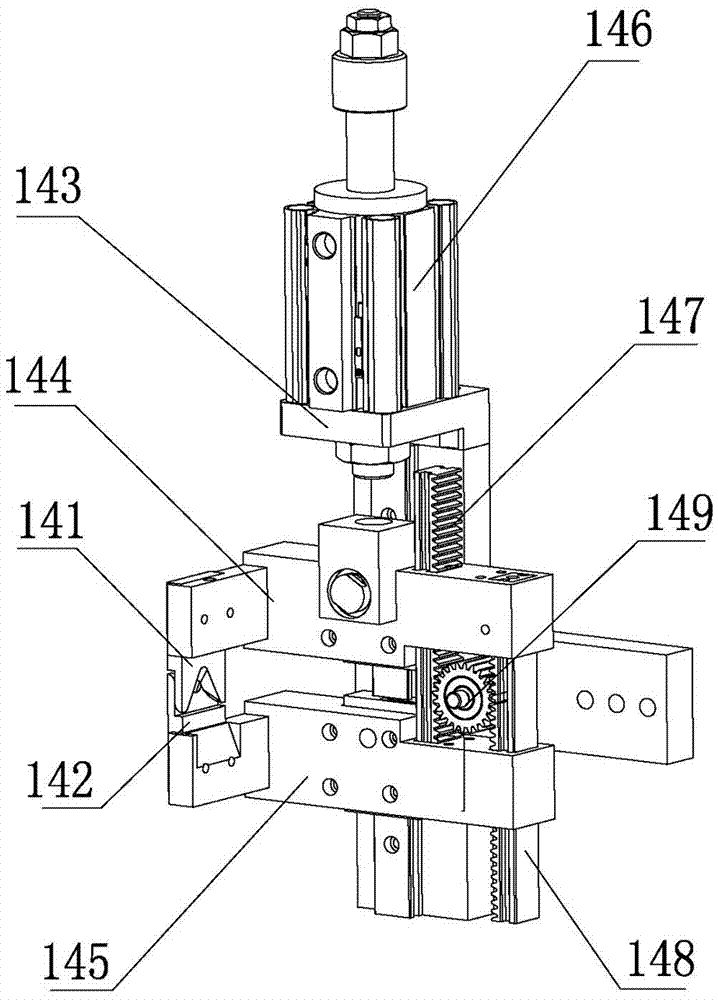

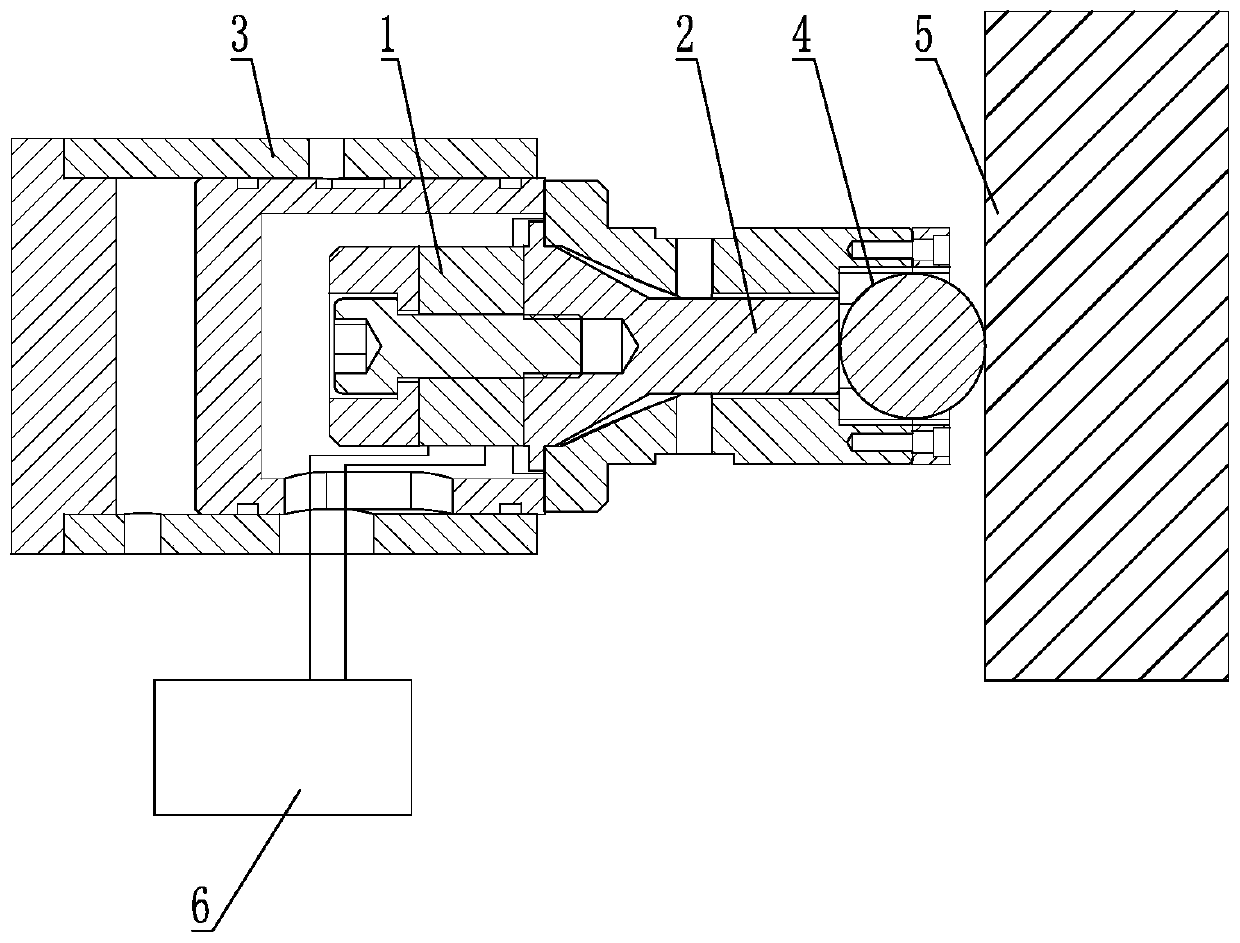

Tail length cutting equipment for three-core original line

ActiveCN106229902ADifferent lengthSuitable for large-scale production and processingApparatus for removing/armouring cablesApparatus for joining/termination cablesIdentification deviceGrounding line

The invention relates to the technical field of processing of power lines, and in particular relates to tail length cutting equipment for a three-core original line. The tail length cutting equipment comprises a power line jacket stripping device, a CCD colour distinguishing device, a line dividing device and an inner core line length adjusting device; the power line jacket stripping device is used for stripping the jacket of a power line; the CCD colour identification device is used for distinguishing positions of a zero line, a ground line and a live line after the jacket is stripped; the line dividing device is used for dividing three inner core lines after the positions of the zero line, the ground line and the live line are determined; the inner core line length adjusting device is used for respectively adjusting the lengths of the ground line, the live line and the zero line; and the equipment further comprises a transmission device for transmitting the power line among the various devices. By means of the equipment disclosed by the invention, the power line can be automatically stripped; line dividing and length adjusting of the three inner core lines do not need to be manually operated; and thus, the equipment disclosed by the invention is simple to operate and high in working efficiency, and is suitable for large-scale production and processing in factories.

Owner:DONGGUAN SENJIA MACHINERY

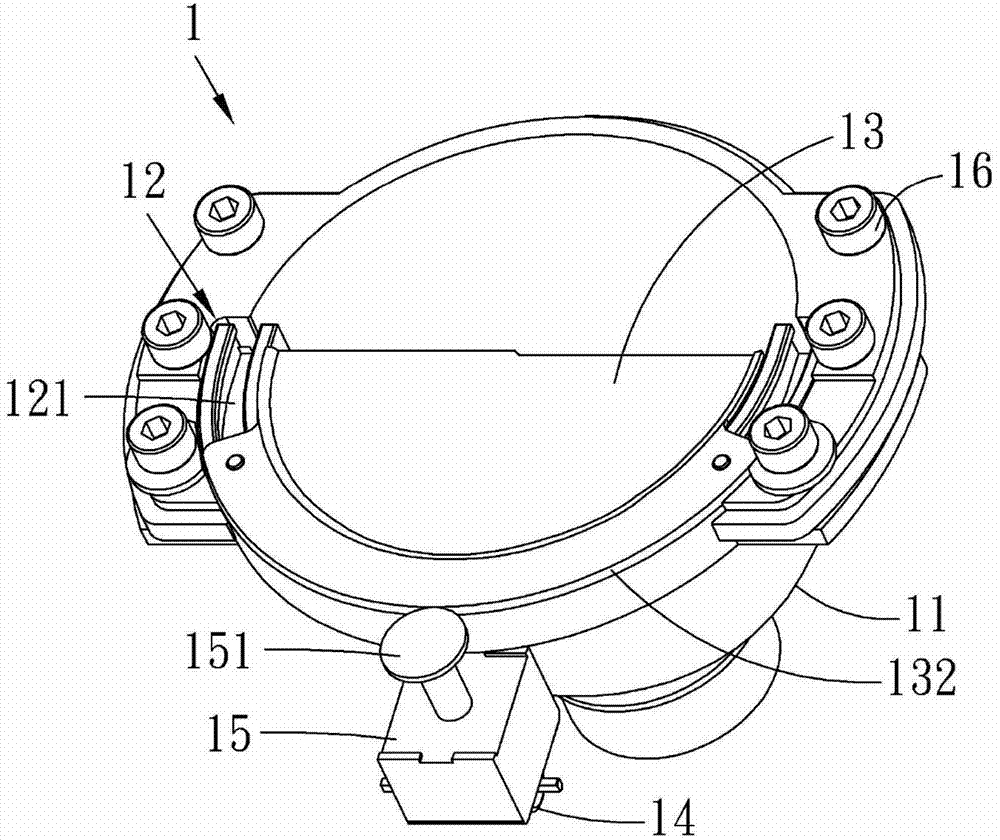

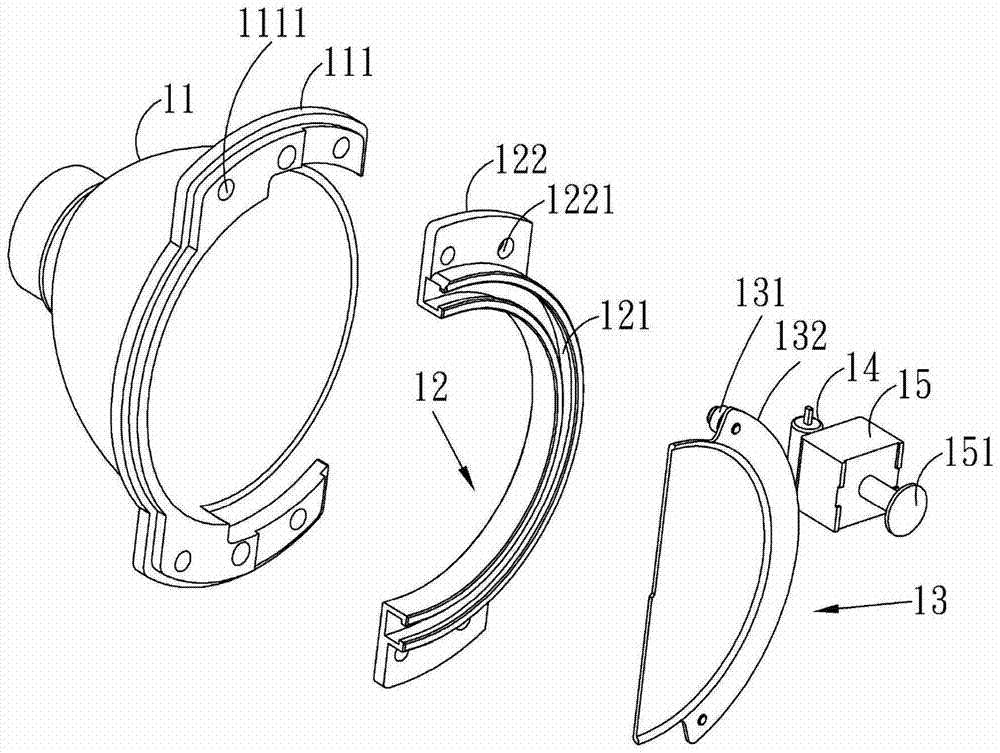

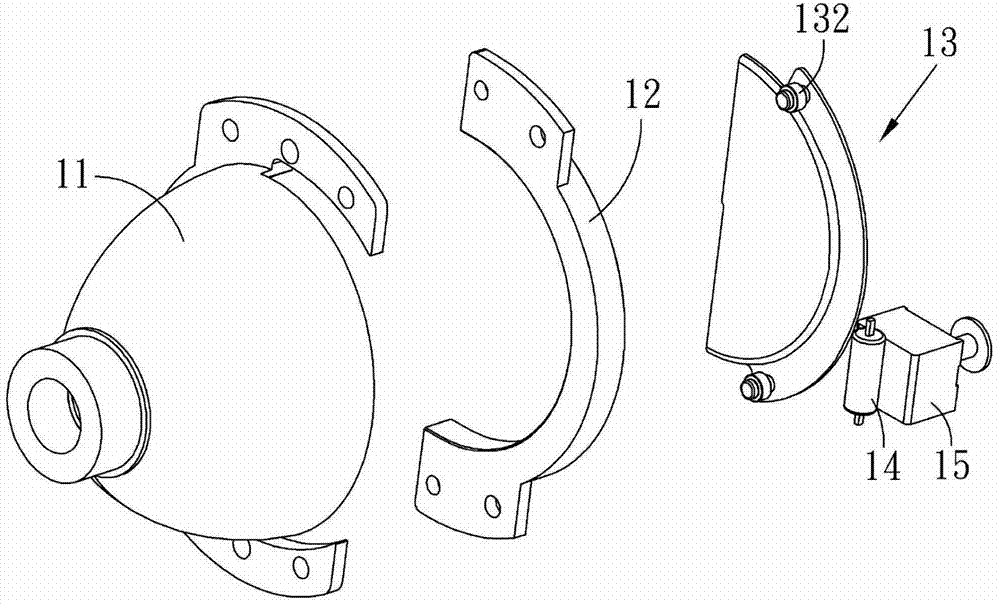

Illuminator of two-wheeled vehicle

InactiveCN103574472ASimple structureLow costLighting support devicesElectric circuit arrangementsInductorEngineering

The invention discloses an illuminator of a two-wheeled vehicle. The illuminator of the two-wheeled vehicle is characterized by comprising a base, a fastening body, a moving plate, an inductor and a power unit. A light emitting element is arranged in the base; the fastening body corresponds to an opening of the base and is fixedly arranged on the edge of the opening of the base, and a groove is formed in the front end of the fastening body; the moving plate is provided with a moving part and a first gear, the moving part is arranged on the face, corresponding to the base, of the moving plate and is arranged in the groove in a sliding mode, and the first gear is arranged on the edge of the moving plate; the inductor is used for inducting driving conditions of a vehicle body and generates induction signals corresponding to the driving conditions; the power unit is provided with a second gear, the second gear is connected with the first gear, the power unit sequentially drives the second gear and the first gear in corresponding to the induction signals, and then the moving plate move corresponding to the opening of the base. The illuminator of the two-wheeled vehicle can achieve unshaded illumination and is simple in structure, low in cost and suitable for mass production.

Owner:ANHUI HUAIHUA

Multifunctional coating and productive technology thereof

InactiveCN102391748AIncrease reflectionEasy to scatterAntifouling/underwater paintsPaints with biocidesInfraredPolymer science

The invention relates to a multifunctional coating and a productive technology thereof. The multifunctional coating comprises the following raw material in parts by weight: 50-190 parts of hollow borsal microspheres, 44-125 parts of aluminium silicate, 44-135 parts of siliceous lime, 2-5 parts of thickening agent, 1-10 parts of deforming agent, 1-7 parts of dispersing agent, 8-35 parts of ethylene glycol, 3-10 parts of wetting agent, 180-450 parts of latex paint emulsion and 100-350 parts of water. The multifunctional coating is formed by the hollow borsal microspheres suspended in inertia latex; the microstructures of the microspheres are beneficial to the reflection and scattering of infrared rays; in addition, the microspheres of the invention are hollow closed spheres and have very low coefficient of heat conductivity; the microspheres added to the coating can form a number of independent microscopic heat insulation cavities, thereby greatly increasing the thermal insulation of a paint film; and meanwhile, the multifunctional coating of the invention can supply enough negative ions to ensure indoor air to be good and simultaneously has very good anti-bacterium effect.

Owner:DALIAN JINZHOU JINHE CHEM BUILDING MATERIALS FACTORY

Paint and its preparation method

InactiveCN102344732AIncrease reflectionEasy to scatterReflecting/signal paintsInfraredPolymer science

The invention relates to a paint and a preparation method, the paint comprises the following raw materials by weight part: 100-200 parts of polystyrene hollow microballoons, 30-125 parts of alumina silicate, 30-135 parts of kaolin, 2-5 parts of thickening agent, 1-10 parts of antifoaming agent, 1-10 parts of dispersant, 8-38 parts of glycol, 3-10 parts of wetting agent, 180-550 parts of emulsion paint emulsion and 100-350 parts of water. The paint of the invention is composed of polystyrene hollow microballoons suspended in an inert latex, a microstructure of the microballoons is in favor of reflection and diffraction of the infrared ray, in addition, the microballoons of the present invention are enclosed hollow balls with low heat conduction coefficient, and are added in the paint to form a plurality of the isolated heat insulation cavities, so that heat insulation performance is substantially raised.

Owner:DALIAN JINZHOU JINHE CHEM BUILDING MATERIALS FACTORY

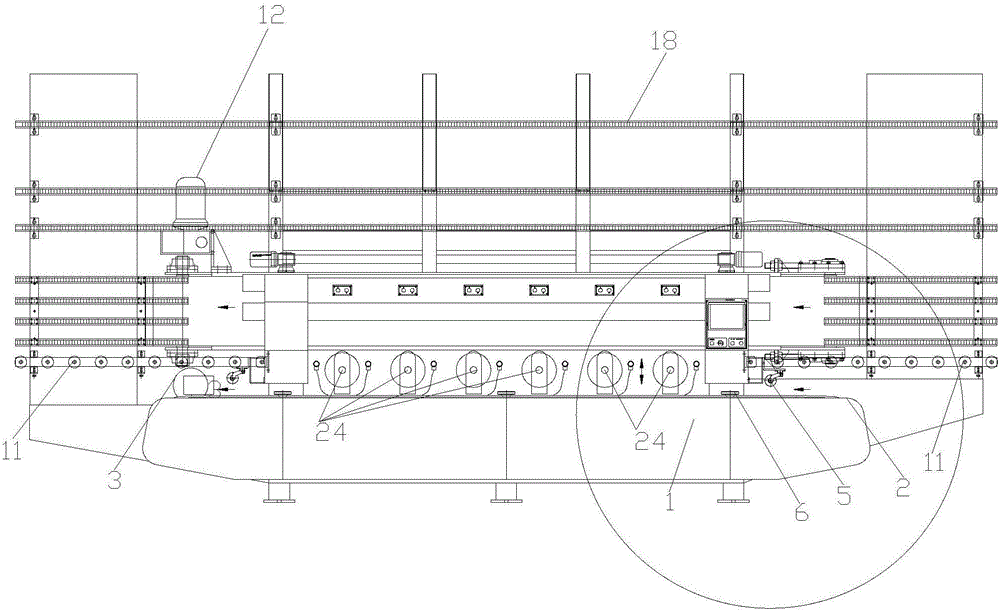

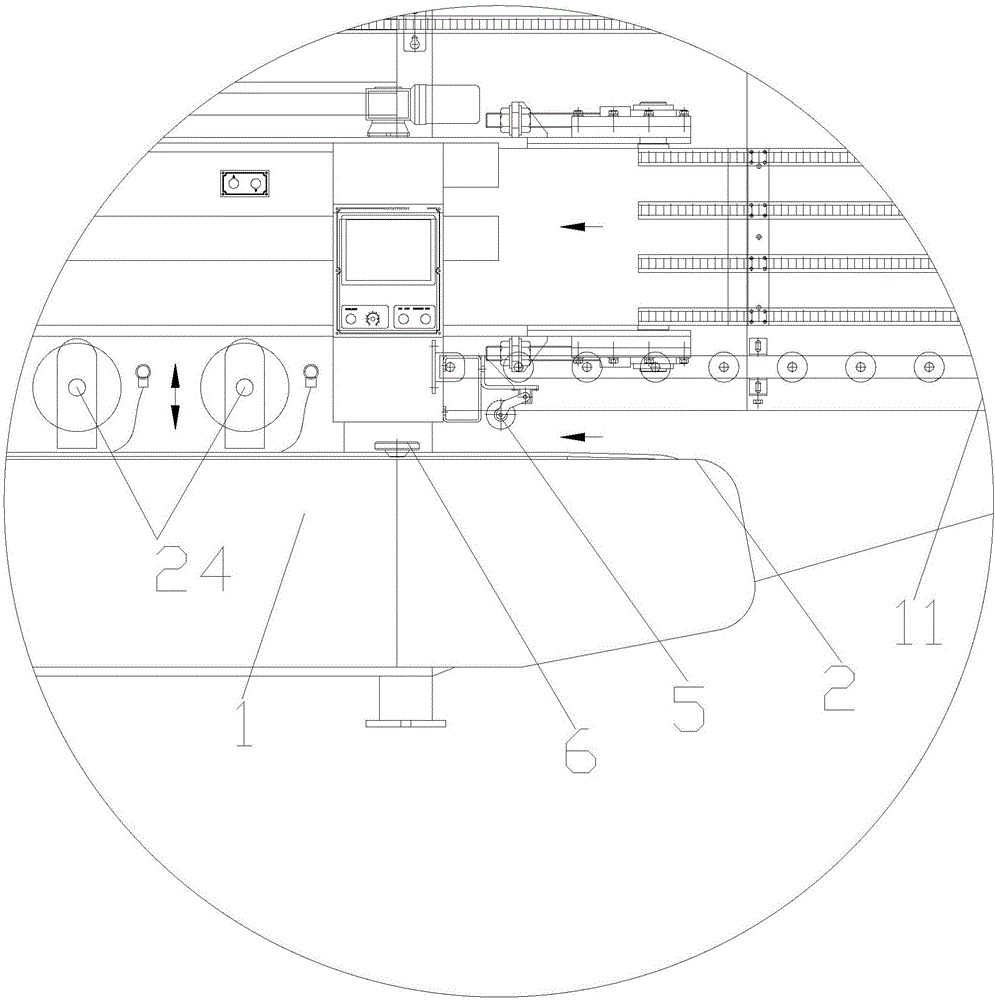

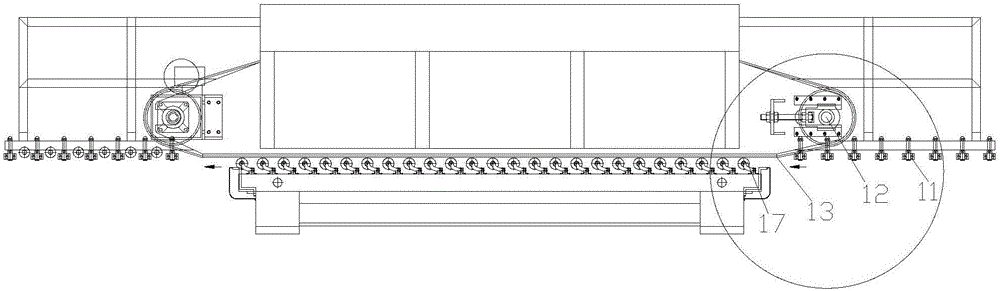

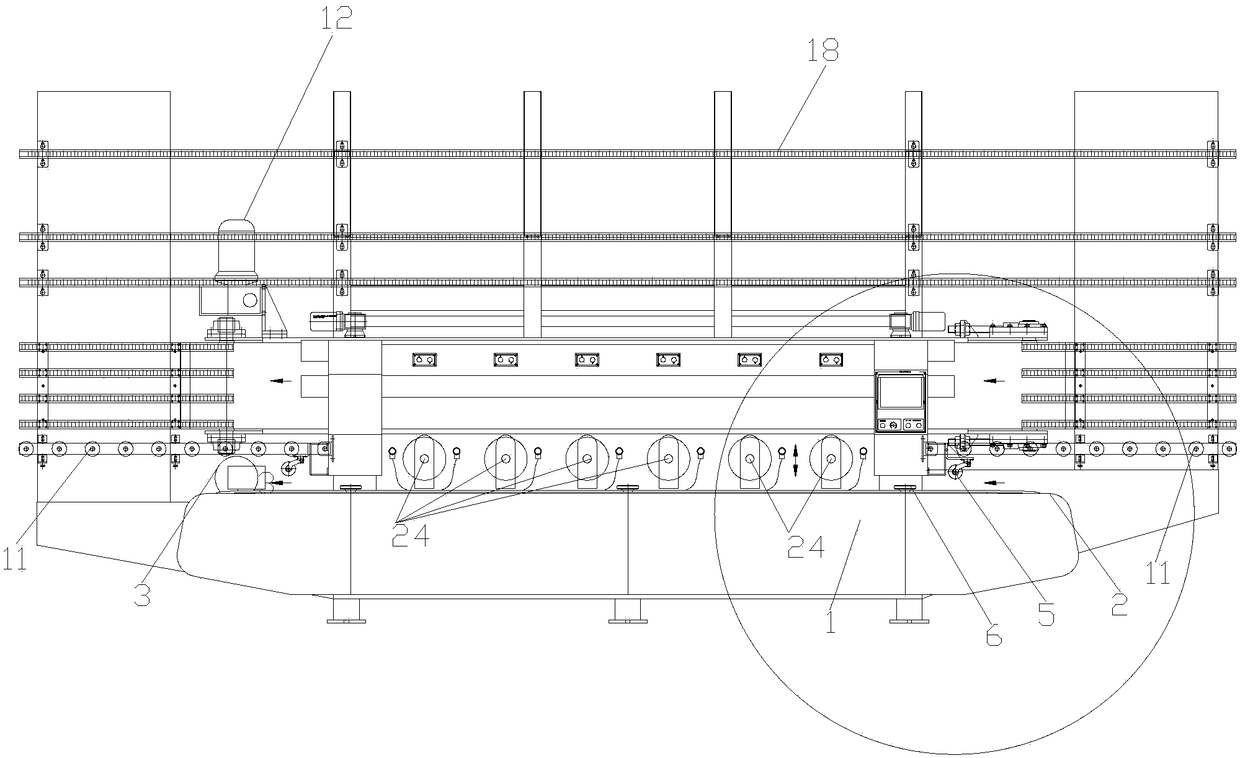

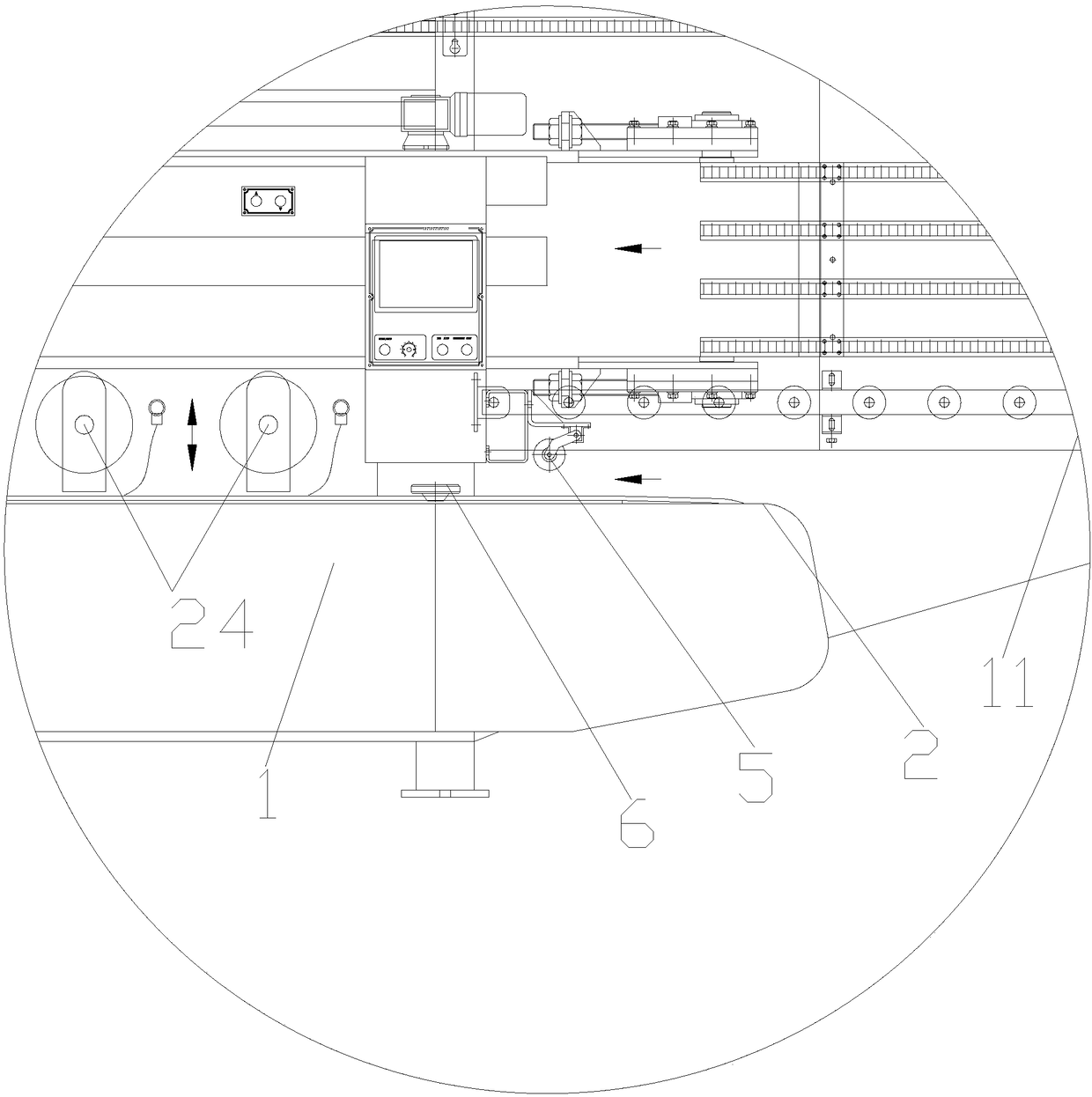

Full-automatic stone material line and edge grinding integrated machine

ActiveCN106181704ACompact structureSmall footprintEdge grinding machinesGrinding carriagesEngineeringMachining

The invention discloses a full-automatic stone material line and edge grinding integrated machine. The full-automatic stone material line and edge grinding integrated machine comprises a rack, an edge grinding conveying mechanism, a line grinding conveying mechanism and grinding head mechanisms. The rack is provided with the edge grinding conveying mechanism and the line grinding conveying mechanism which are arranged up and down. The multiple grinding head mechanisms are distributed between the edge grinding conveying mechanism and the line grinding conveying mechanism in sequence. When conducting upward compensation, the grinding head mechanisms are matched with the edge grinding conveying mechanism to conduct edge grinding machining on a stone material; and when conducting downward compensation, the grinding head mechanisms are matched with the line grinding conveying mechanism to conduct line grinding machining on the stone material. According to the full-automatic stone material line and edge grinding integrated machine, the structure is compact; one device can achieve the two functions of line grinding and edge grinding without rotating the angle of grinding heads; the occupied space is small; the working efficiency is improved; the labor force of workers is reduced; and meanwhile, the grinding heads can further be rapidly replaced through conical cutter bars, so that the full-automatic stone material line and edge grinding integrated machine is high in practicality and suitable for large-scale production and machining for enterprises.

Owner:苏州广隆富机械设备有限公司

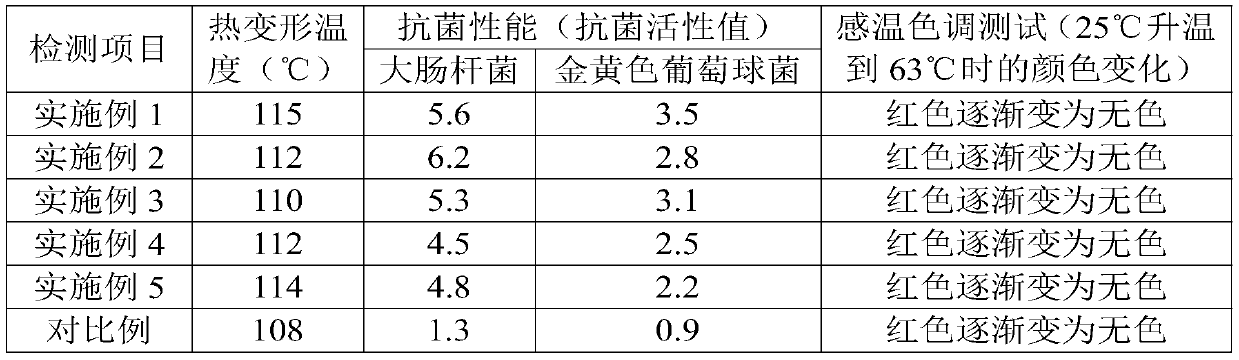

Antibacterial temperature-sensitive straw material and preparation method thereof

InactiveCN111253678AIncreased strength and temperature resistanceImprove biodegradabilityPolypropyleneAnti bacterial

The invention discloses an antibacterial temperature-sensitive straw material and a preparation method thereof. The antibacterial temperature-sensitive straw material is prepared from the following raw materials in parts by weight: 100 parts of polypropylene resin, 12-28 parts of TPE, 10-25 parts of hemp stalk fibers, 0.5-2 parts of thermochromic powder, 8-14 parts of an antibacterial composition,0.8-1.5 parts of hydroxy propyl cellulose, 4-8 parts of calcium carbonate, 1-3 parts of polyethylene wax and 0.1-0.4 parts of polycaprolactam. The melt flow rate of the polypropylene resin is 20-32 g / 10 min, and the vicat softening point is greater than or equal to 145 DEG C. The prepared antibacterial temperature-sensitive straw material is good in antibacterial performance, long in antibacterial time, sensitive to temperature induction and simple in preparation method, has certain biodegradability, and is suitable for large-scale production and processing, and the preparation process is easy to operate.

Owner:泉州市华创园智能研究有限公司

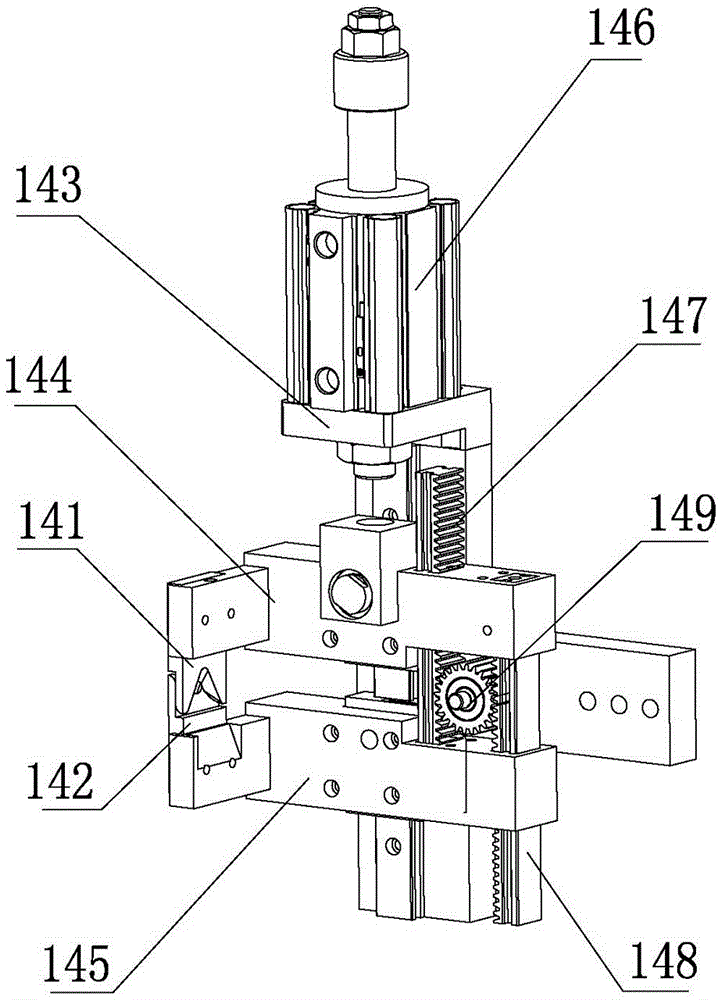

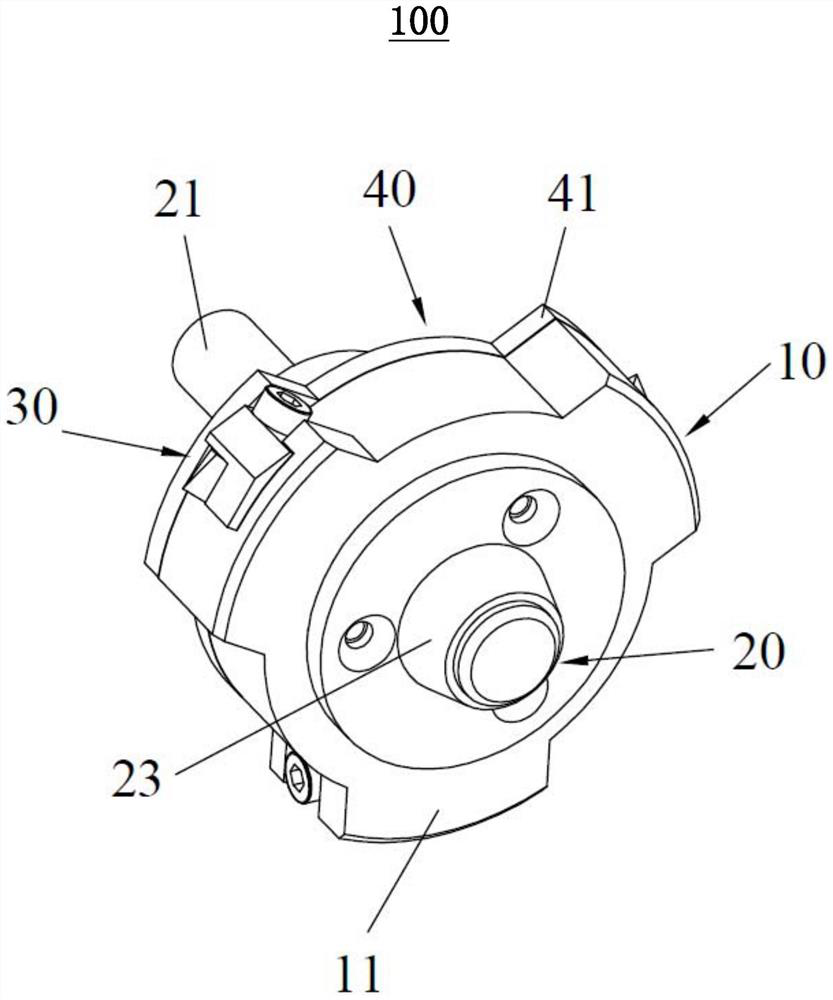

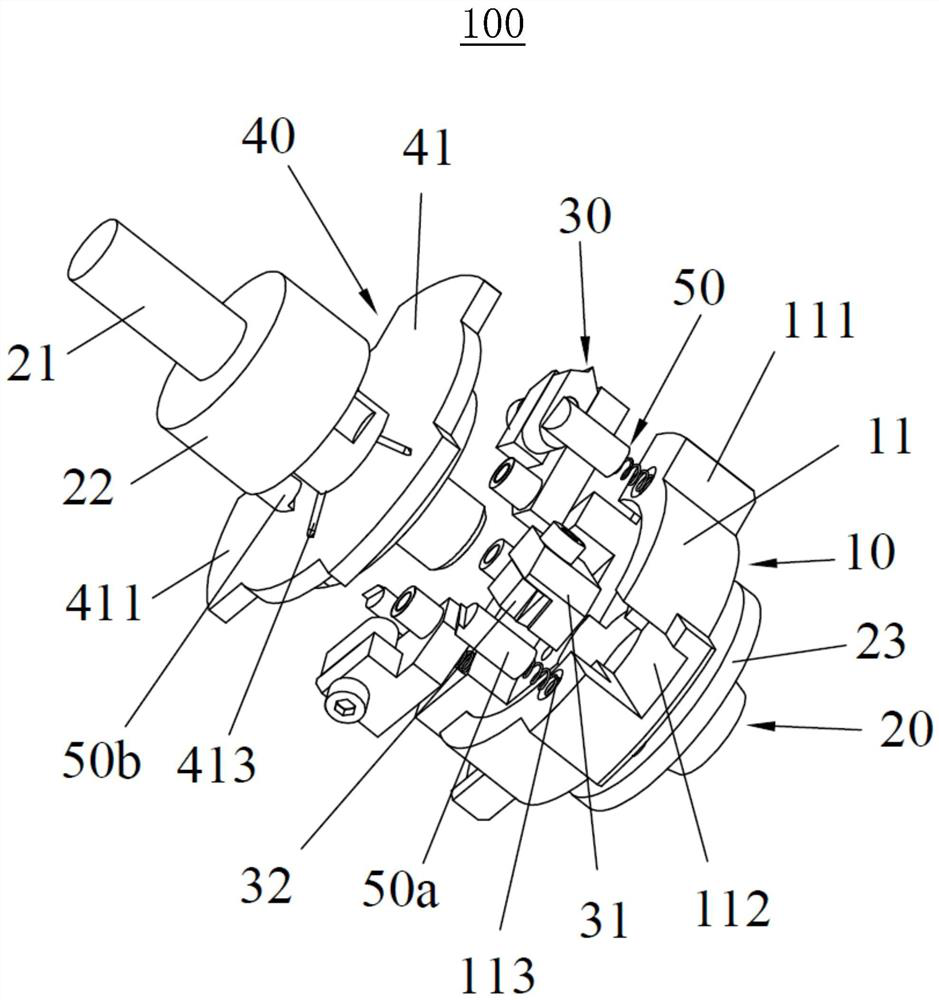

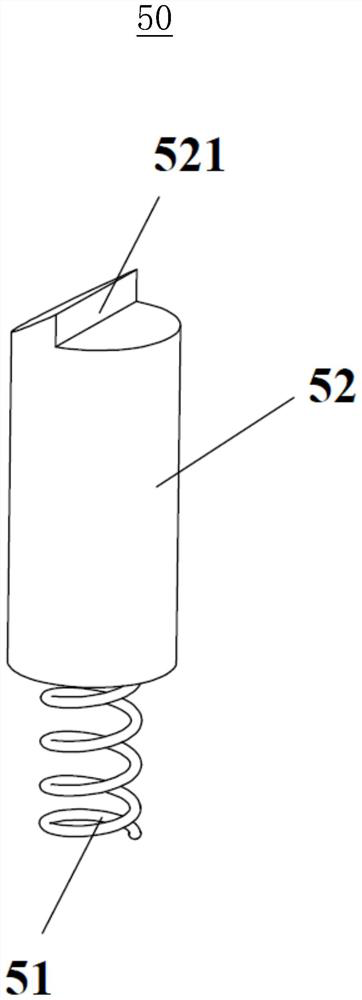

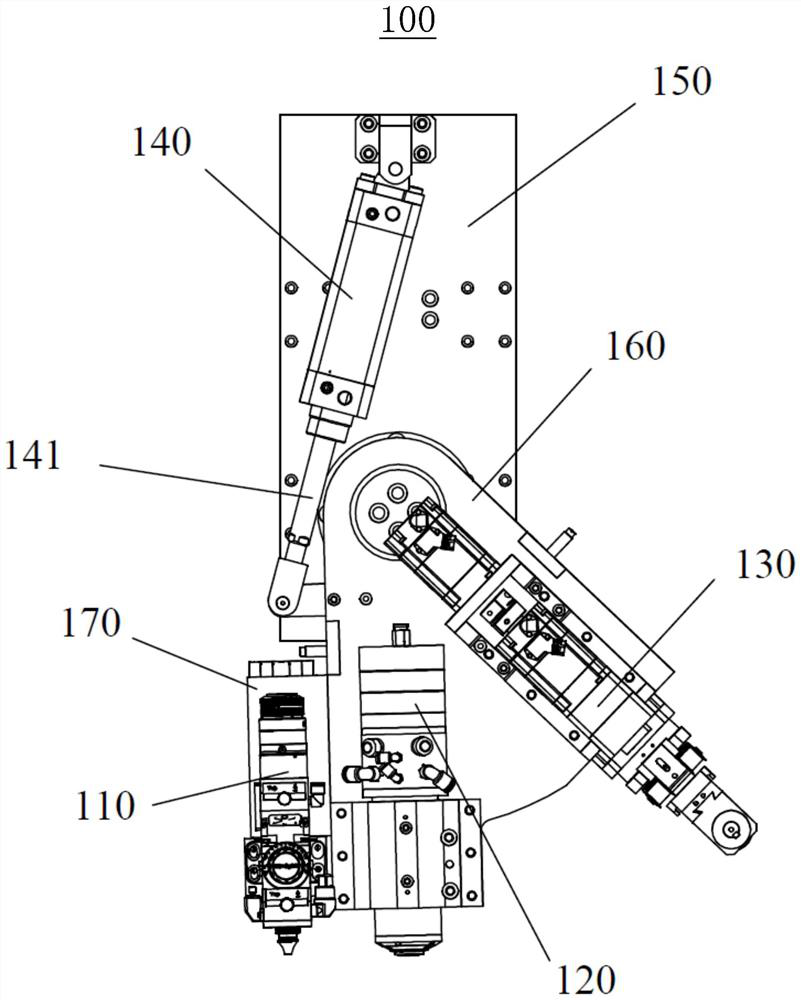

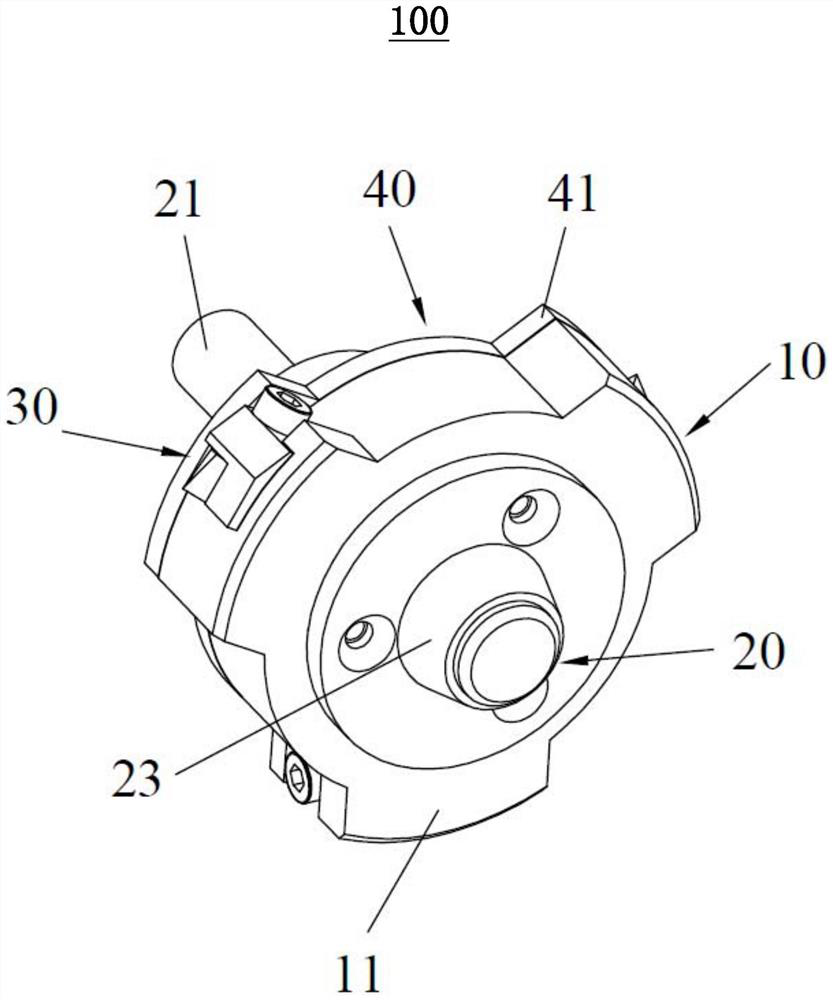

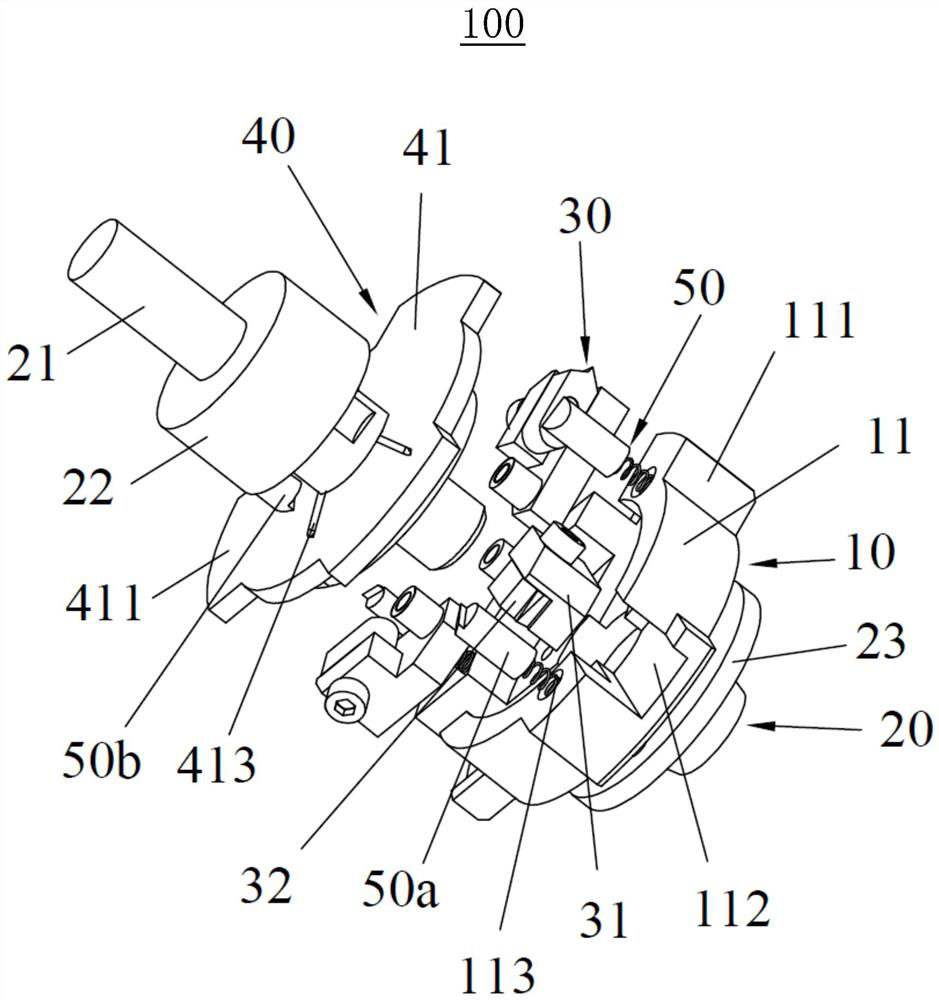

Faceting machine and automatic tool changing mechanism thereof

ActiveCN112475952AAvoid reverse rotationNo human intervention requiredJewelleryPositioning apparatusNumerical controlRotational axis

The invention discloses a faceting machine and an automatic tool changing mechanism thereof. The automatic tool changing mechanism is used for jewelry processing, a plurality of sets of tool fixing assemblies are clamped between a tool guiding assembly and a cam transmission assembly, a tool disc rotating shaft assembly drives the tool guiding assembly and the tool fixing assemblies to rotate, a cam of the cam transmission assembly ejects a tool fixing assembly and a tool which rotate to a protruding point out of the outer edge of a tool installation wheel and the outer edge of the transmission wheel, other tool fixing assemblies and tools are contracted in the tool installation wheel and the transmission wheel, and a spring bolt positioning assembly is arranged between the tool guiding assembly and the cam transmission assembly so as to prevent the tool guiding assembly from rotating reversely. The tool guiding assembly is rotated, so that tools required for machining work on an operation surface, and as each group of tool fixing assemblies is provided with different types of tools, different types of tools can be used for finishing different requirements of faceting operation, and multiple faceting machining operation functions can be finished on the same numerical control mechanism.

Owner:SHENZHEN GUANG LI JIN TECH CO LTD

Extraction method of longan seed polyphenol

InactiveCN102961486BReduce oxidase activityReduce pollutionCosmetic preparationsToilet preparationsPregnant leach solutionEconomic benefits

The invention relates to an extraction method of longan seed polyphenol, relating to a processing method of a longan. The extraction method of the longan seed polyphenol can enhance the economic benefit of a longan industry and increase the income of fruit growers. The extraction method of the longan seed polyphenol comprises the following steps of: drying cleaned longan seeds; smashing raw material longan seeds to obtain longan seed powder; adding a sodium phosphate buffer solution to the longan seed powder to obtain a leach solution; pouring out the leach solution, filtering, removing leaching residues, and recovering immersion liquid; concentrating obtained filter liquor to obtain a concentrated solution; adding hydrochloric acid to the concentrated solution, stirring, and then standing for precipitation to obtain a precipitation solution; centrifugalizing the precipitation solution, removing a supernatant, washing precipitates by using the hydrochloric acid, and then drying to obtain fine longan seed polyphenol powder.

Owner:XIAMEN UNIV

Laser engraving and faceting compound machine

ActiveCN112475915ANo human intervention requiredReduce manufacturing costOther manufacturing equipments/toolsJewelleryNumerical controlLaser engraving

The invention discloses a laser engraving and faceting compound machine which is used for processing jewelry sheets. The laser engraving and faceting compound machine comprises a multifunctional compound mechanism with a plurality of functional shafts for laser cutting, engraving and faceting and a sheet turnover processing mechanism arranged below the multifunctional compound mechanism. A laser cutting shaft assembly, an engraving shaft assembly and a faceting shaft assembly of the multifunctional compound mechanism are used for processing the sheets clamped by the sheet turnover processing mechanism; and a sheet clamping assembly is used for clamping a to-be-machined sheet, a turnover motor is used for controlling the sheet clamping assembly to turn over by 180 degrees, machining operation of the front face and the back face of the to-be-machined sheet is achieved, multiple machining operation functions are achieved on the same numerical control mechanism, manual intervention is notneeded in the production and machining process, the production cost is reduced, the production efficiency is improved, and the laser engraving and faceting compound machine is more suitable for large-scale production and machining.

Owner:SHENZHEN GUANG LI JIN TECH CO LTD

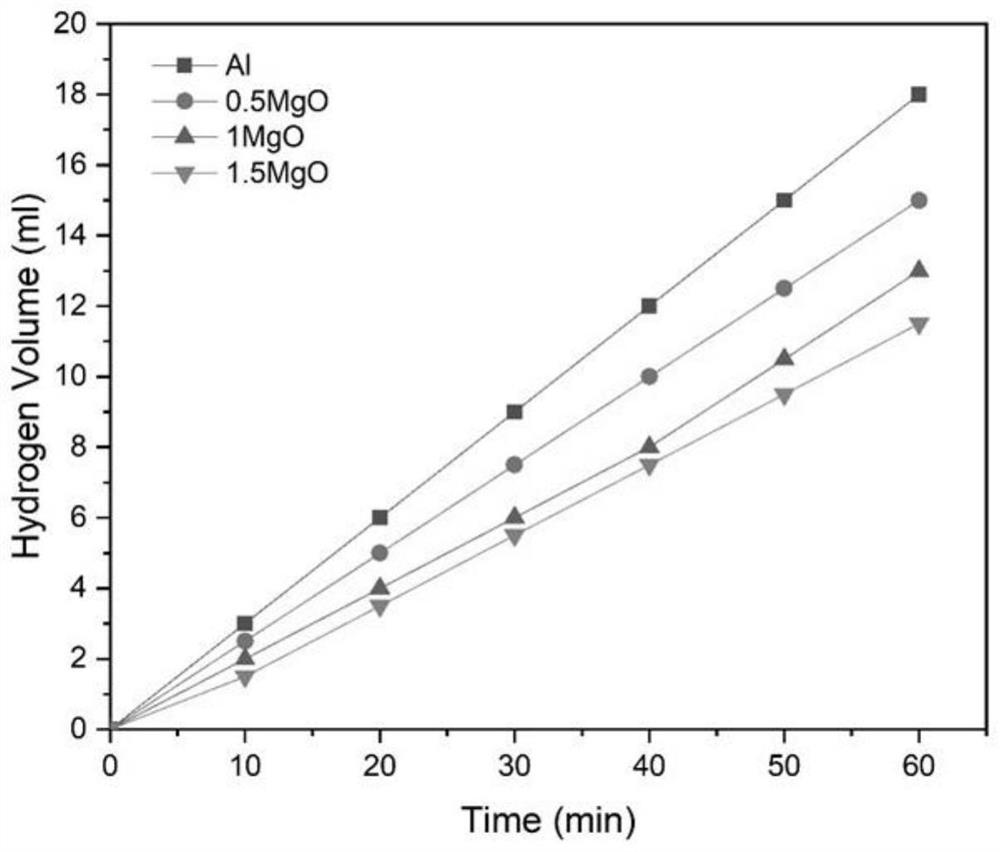

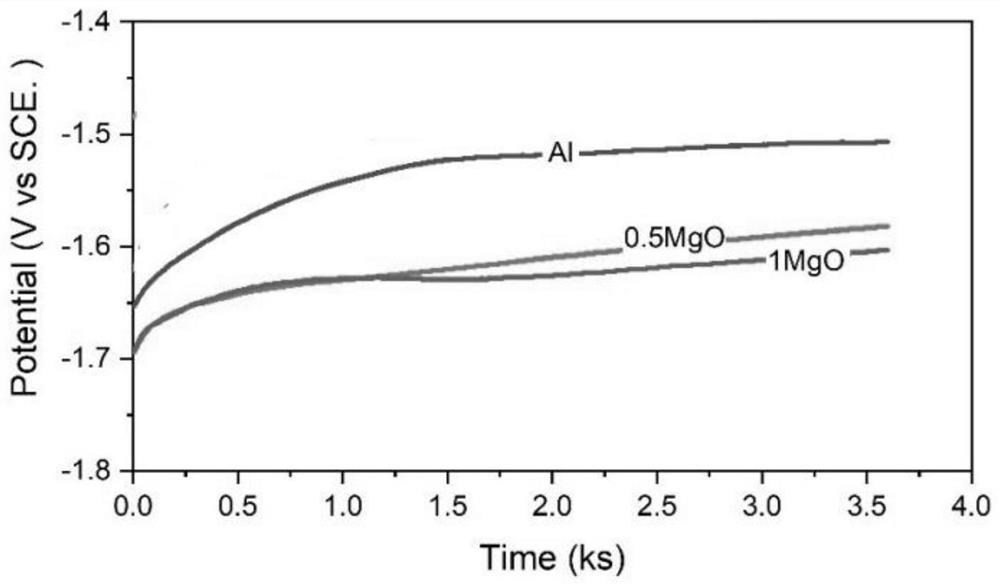

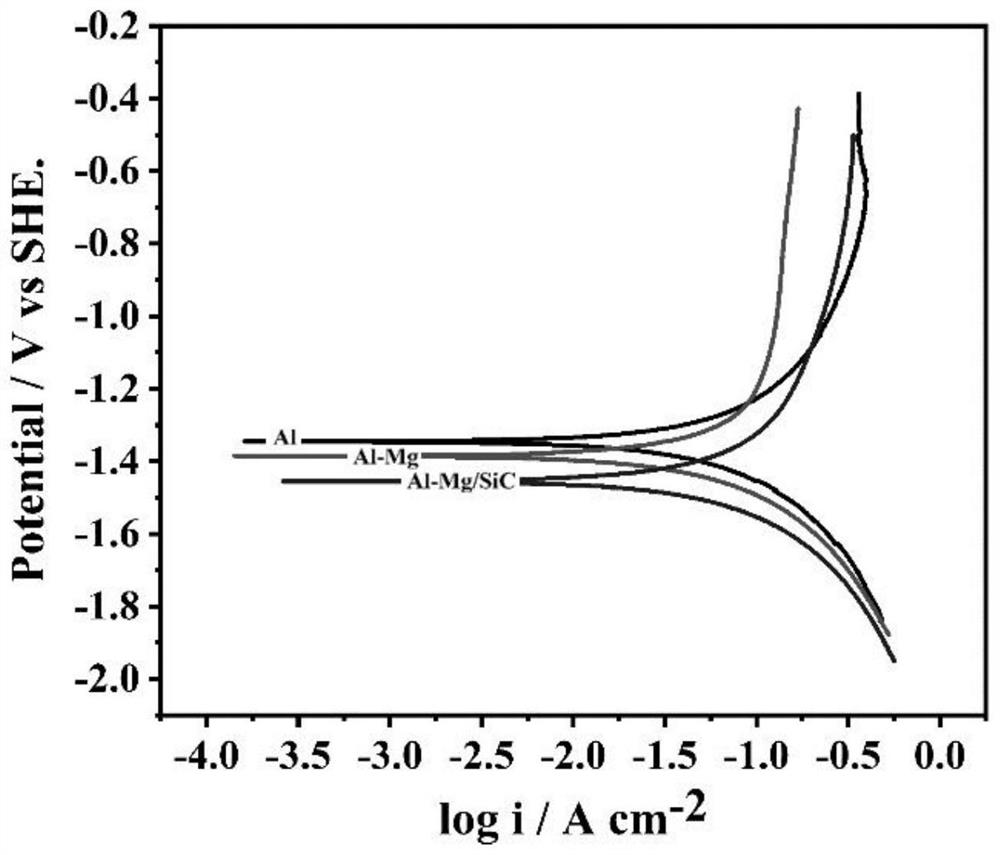

A kind of aluminum-air battery ceramic particle composite anode material and preparation method thereof

ActiveCN112921201BHigh anode utilizationIncrease profitFuel and primary cellsCell electrodesElectrolytic agentMetallic materials

The invention relates to an aluminum-air battery ceramic particle composite anode material and a preparation method thereof, belonging to the field of metal materials. The preparation method provided by the invention includes: preheating the ceramic particles first, and mixing them with heated and melted pure aluminum or aluminum alloy, and then adopting ordinary aluminum melting furnace + mechanical stirring or vacuum semi-solid stirring technology to obtain evenly dispersed particles Composite anode material, the granular composite material obtained by casting is directly cut, or further press processed to make composite anode for aluminum-air battery. Because the preparation method provided by the invention is simple, the cost is low, the obtained composite anode material has good electrochemical activity in alkaline electrolyte, low self-corrosion rate, and high battery anode utilization, so the preparation method provided by the invention is suitable for large-scale Chemical production and processing.

Owner:TONGJI UNIV

Preparation method of metal ceramic material

InactiveCN112760546AWell mixedImprove toughnessTransportation and packagingMetal-working apparatusEpoxyParaffin wax

The invention provides a preparation method of a metal ceramic material. The method comprises the steps that S1, metal raw materials are prepared, and Ti powder, Co powder, Fe powder and Cu powder are taken, specifically, the metal raw materials comprise the following components of, in parts by weight, 30 parts of Ti powder, 30 parts of Co powder, 30 parts of Fe powder and 10 parts of Cu powder; S2, adhesive raw materials including paraffin, ethylene-vinyl acetate copolymer, high-density polyethylene, epoxy resin, carnauba wax and stearic acid are prepared, specifically, the adhesive raw materials comprise the following components of, in parts by weight, 30 parts of paraffin, 10 parts of ethylene-vinyl acetate copolymer, 10 parts of high-density polyethylene, 10 parts of epoxy resin, 30 parts of carnauba wax and 10 parts of stearic acid. According to the preparation method of the metal ceramic material, the purpose of improving the toughness and plastic deformation resistance of metal ceramic is achieved, and the production method is reasonable, easy to operate and suitable for large-scale production and processing.

Owner:SUZHOU OUMEIKE CARBIDE TOOL

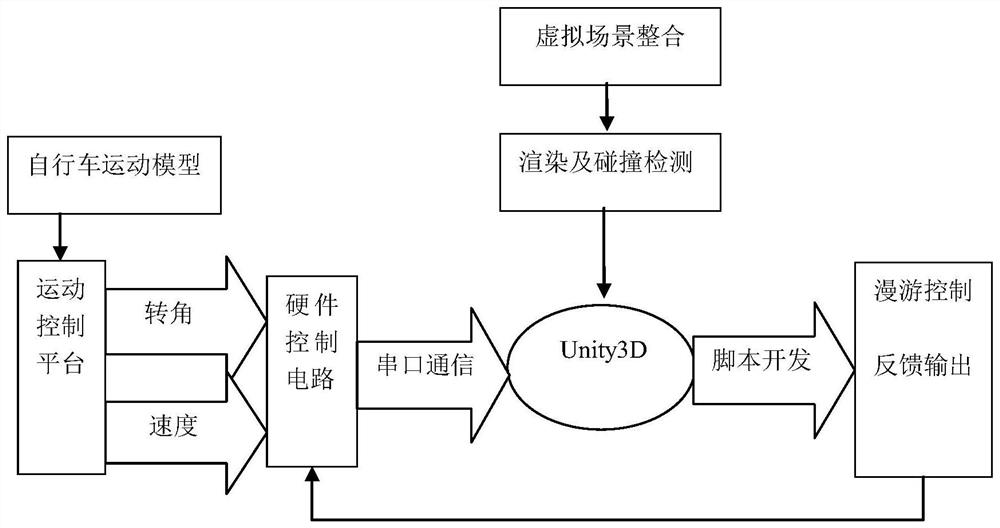

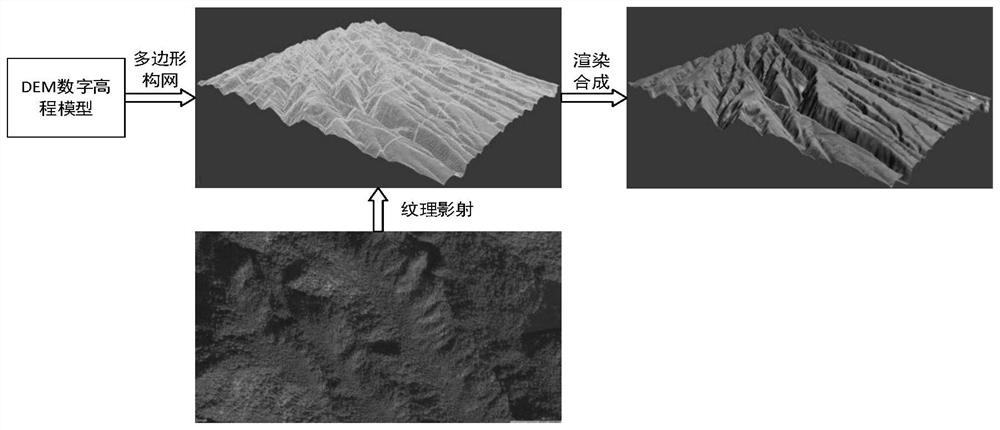

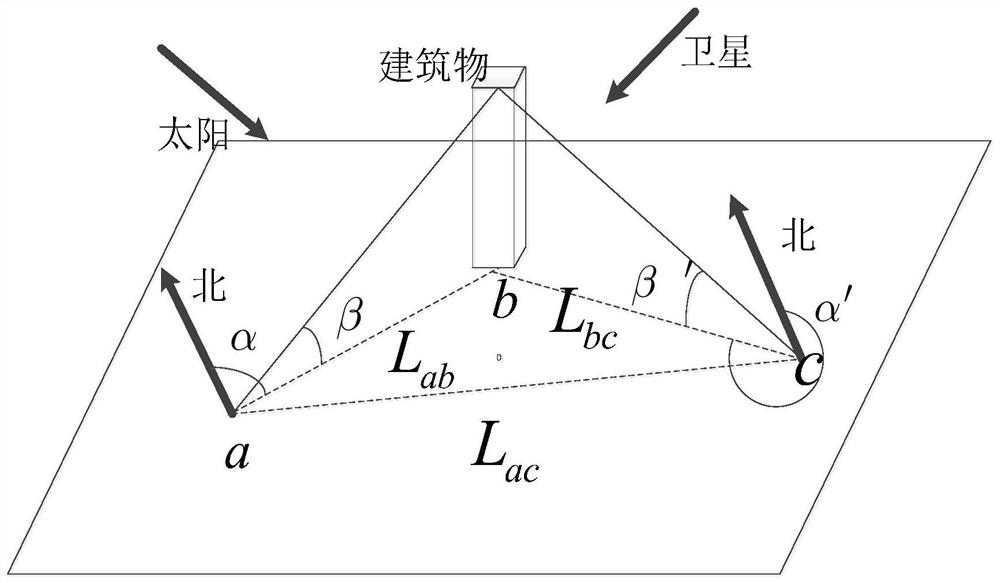

Interactive Virtual Walkthrough Exercise Bike

ActiveCN109011516BImprove scalabilityRoaming display optimizationMovement coordination devicesCardiovascular exercising devicesSimulationInteraction interface

The invention provides an interactive virtual roaming body building vehicle which relates to the field of computer interaction applications. The vehicle disclosed in the invention comprises a front wheel steering floating support platform, a rear wheel dynamic resistance support platform and a motion control hardware circuit. External data acquisition parts are respectively installed at data collection positions of the front wheel steering floating support platform and the rear wheel dynamic resistance support platform. During simulated bicycle riding, the front wheel steering floating supportplatform and the rear wheel dynamic resistance support platform are respectively used for collecting data so as to finally realize virtual simulation. Via the interactive virtual roaming body building vehicle, roaming display effect of virtual scenes can be optimized, innovative design of a hardware control circuit and a bicycle motion platform helps reduce complexity of equipment while interactivity and practicality are improved, a system is provided with a good man-machine interaction interface, software and hardware of equipment are high in expansibility, and the vehicle is suitable for large scale production and processing operation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

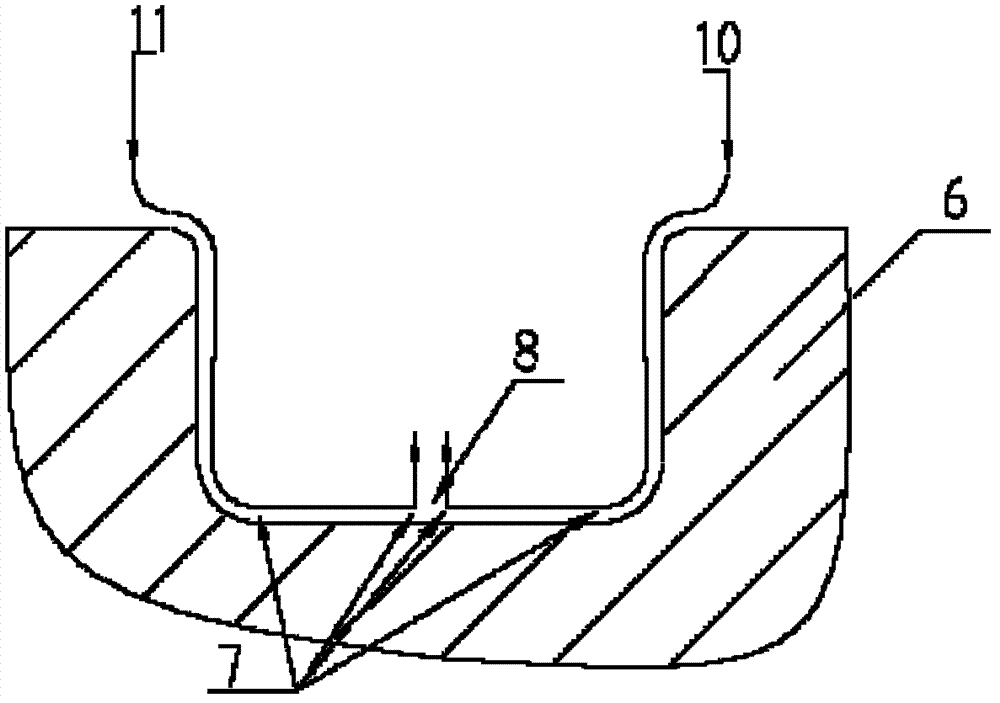

A processing method for T-shaped thin-walled parts

ActiveCN104526030BGood symmetryImprove quality and efficiencyMilling equipment detailsPositioning apparatusEngineeringLoading unloading

The invention relates to a processing method for T-shaped thin-walled parts. The main point lies in that: a low feed layer-by-layer processing method adopting cushion block supporting and vice paired clamping, and combining rough machining and finish machining is employed to process the T-shaped thin-walled parts. The processing method is convenient to load and unload parts, simplifies loading-unloading and processing procedure, and reduces the labor intensity of part loading and unloading, the processing process is simple, and parts are difficult to deform during loading-unloading processing. The method employs a low feed layered milling and rigid clamping mode, and rough machining and finish machining combined stepwise layer-by-layer processing, reduces the vibration of cutting tools and parts, improves the processing efficiency of T-shaped thin-walled parts, has stable processing quality stable and good reliability, lowers the loss and processing cost of cutting tools, and is suitable for large-scale production and processing.

Owner:中国航发湖南南方宇航工业有限公司

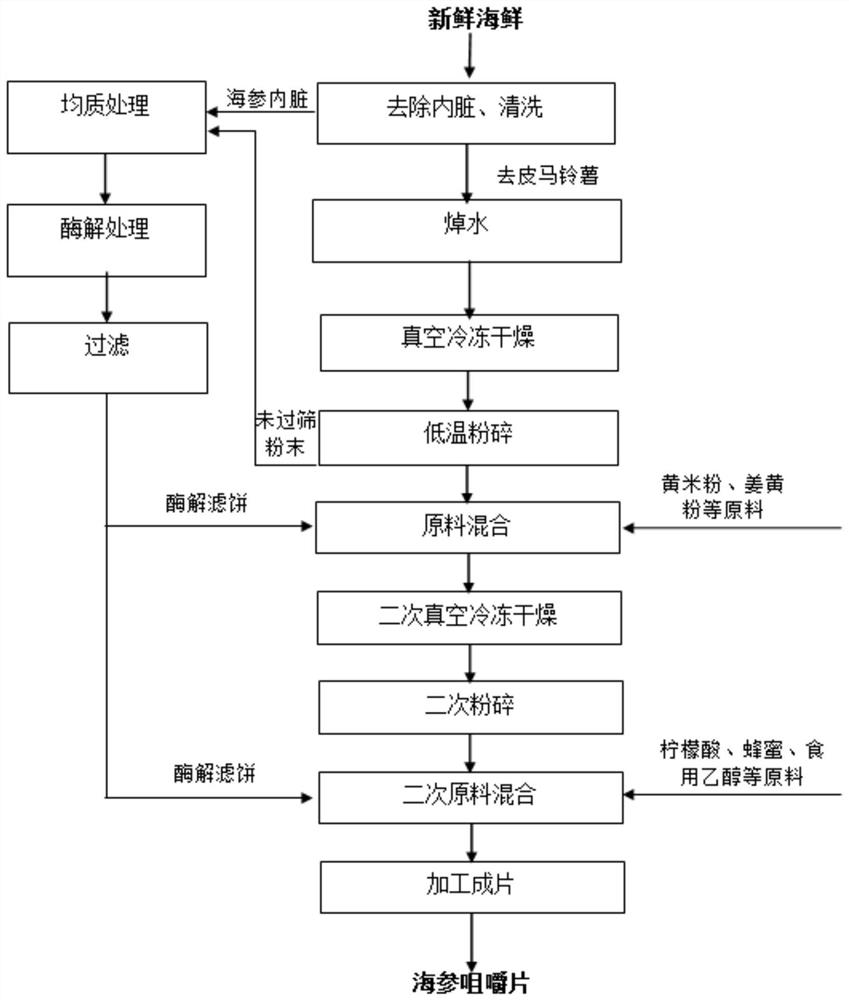

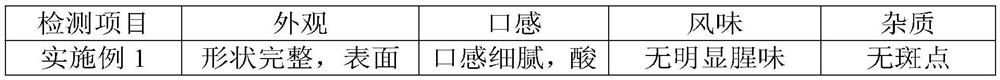

Sea cucumber chewable tablets and preparation method thereof

PendingCN112385798ACompletely brokenPromote absorptionProtein composition from fishFood ingredient as taste affecting agentFreeze-dryingNutrition

The invention discloses sea cucumber chewable tablets and a preparation method thereof. The preparation method comprises the following steps: removal of internal organs; blanching; vacuum freeze drying; low-temperature crushing; raw material mixing; secondary vacuum freeze drying; secondary crushing; secondary raw material mixing; and processing into tablets: carrying out wet granulation, drying,grain shaping, total mixing and tabletting treatment on an obtained soft material to obtain the sea cucumber chewable tablets. According to the prepared sea cucumber chewable tablets, waste sea cucumber internal organs obtained by treating sea cucumbers and primary unscreened powder are subjected to enzymolysis treatment, colloid components in the internal organs and the sea cucumber powder are decomposed into the polypeptide easier to dissolve and absorb through biological fermentation treatment, waste is turned into wealth while nutrition of the sea cucumber chewable tablets is enriched, andthe utilization effect of the raw materials is improved.

Owner:福建御蓝记水产食品有限公司

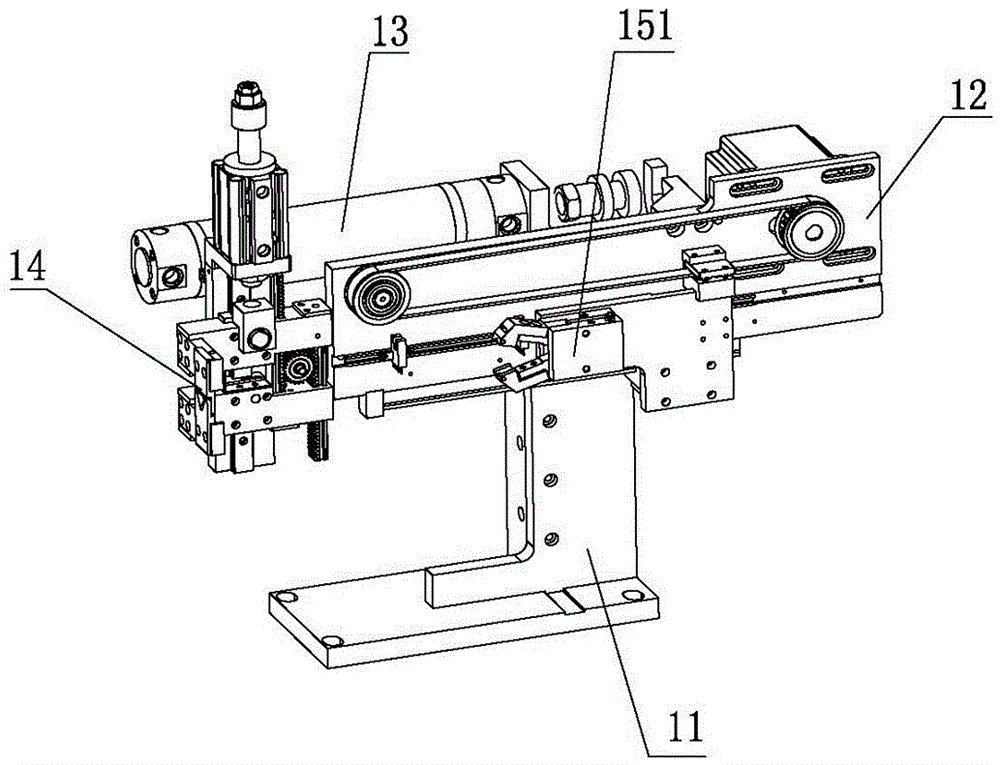

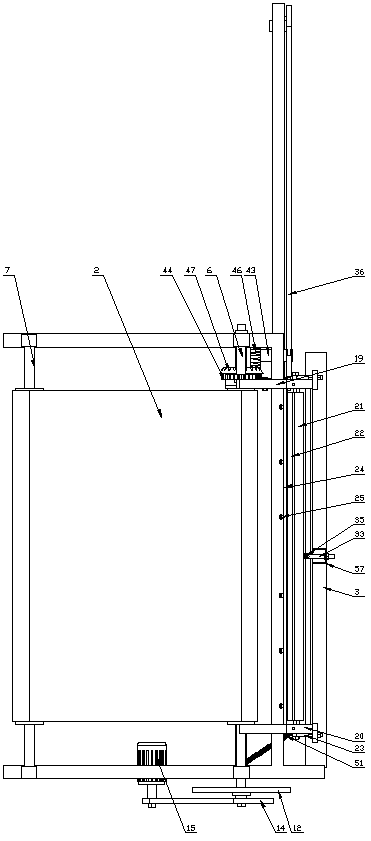

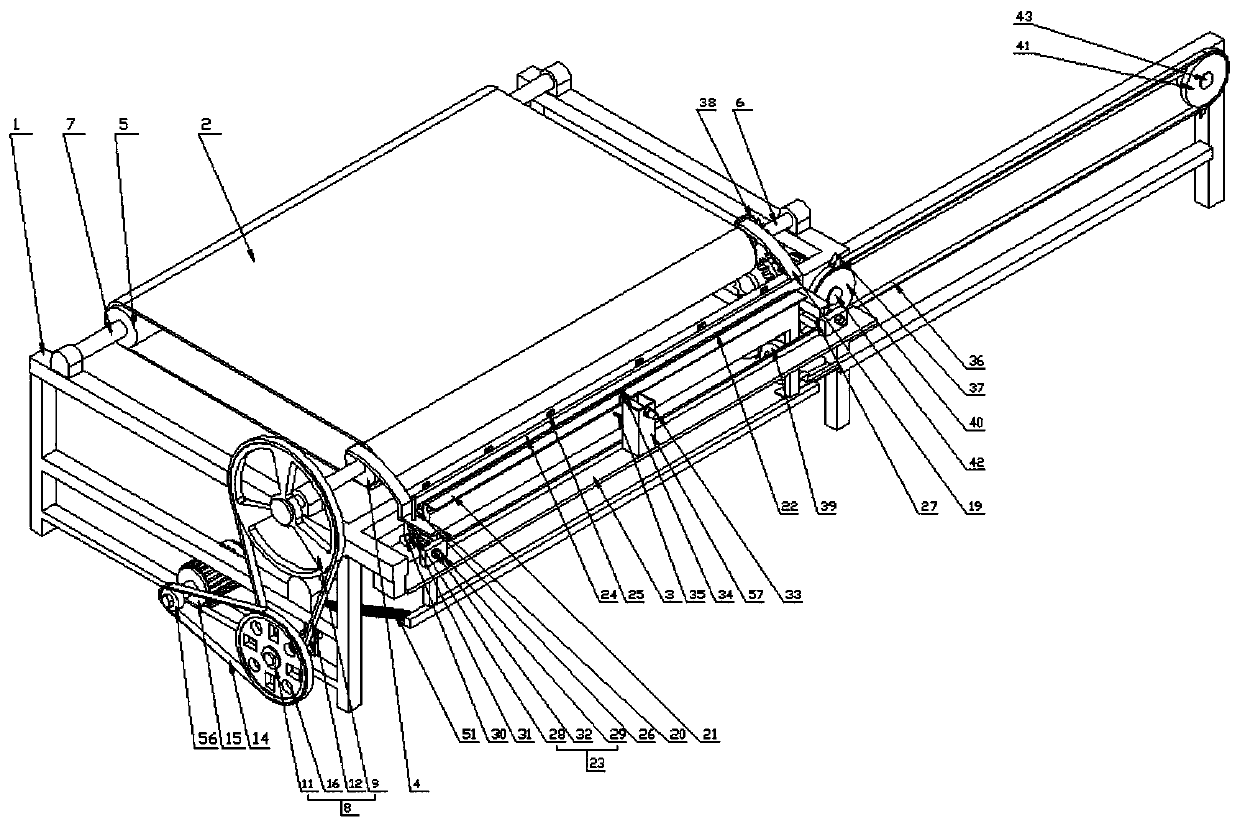

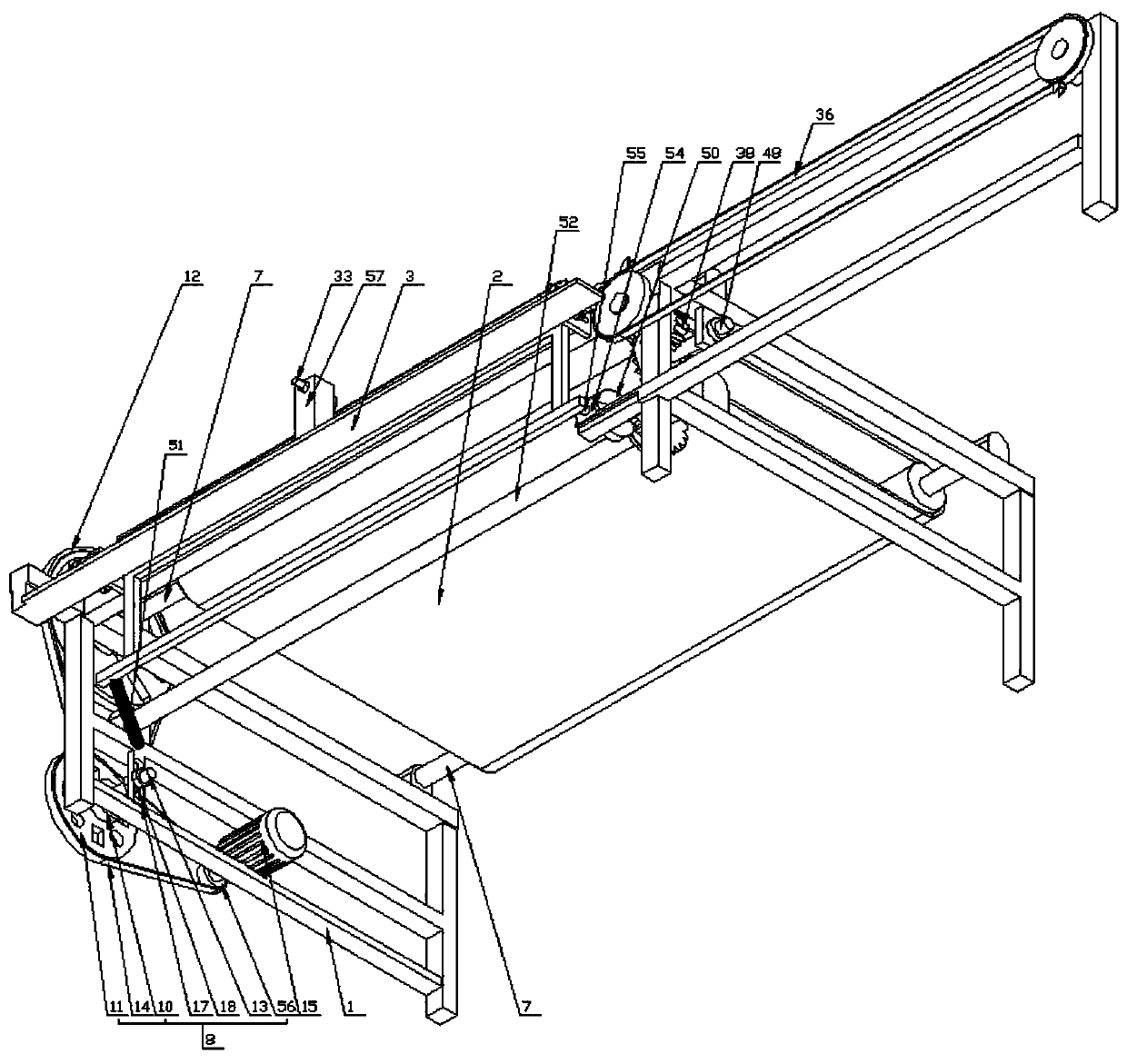

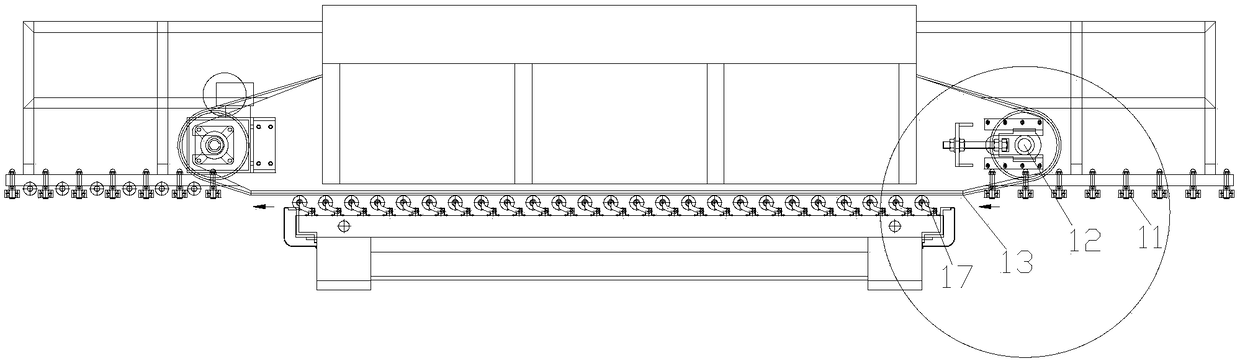

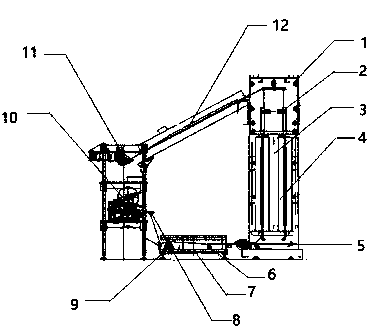

A device for extracting brazing and cutting materials for insulating crepe paper tubes

ActiveCN109278360BSuitable for large-scale production and processingNovel and compact structurePaper/cardboard wound articlesNumerical controlDrive shaft

The invention relates to a brazing and discharging device of insulating wrinkle paper tubes. The brazing and discharging device comprises a machine frame, wherein a conveying belt and a supporting frame are arranged on the machine frame, a rotating driving mechanism is arranged between the driving shaft of the conveying belt and the machine frame; and the rotating driving mechanism comprises a first belt wheel, a second belt wheel, a third belt wheel and a fourth belt wheel, arc-shaped guide plates are arranged on the two sides of the tail end of the conveying belt, a material frame is arranged between supporting plates of the supporting frame, a concave opening and a supporting arm are arranged on the material frame, a chain is arranged on one side of the concave opening, a transmission mechanism is arranged between a first gear shaft and a driving shaft of a chain driving gear, the transmission mechanism is used for driving the chain to rotate, and a deflection mechanism used for driving the material frame to deflect and discharge is arranged between the transmission mechanism and the material frame. According to the brazing and discharging device, the whole machine can be drivento link by only one rotating motor, continuous conveying, brazing and discharging can be realized without numerical control, the efficiency is high, the energy consumption is low, the operation difficulty is low, the production cost is effectively reduced, and the device is suitable for large-scale production and processing of insulating wrinkle paper tubes.

Owner:镇江市鑫泰绝缘材料有限公司

Fully automatic stone line edging machine

ActiveCN106181704BCompact structureSmall footprintEdge grinding machinesGrinding carriagesEngineeringMachining

The invention discloses a full-automatic stone material line and edge grinding integrated machine. The full-automatic stone material line and edge grinding integrated machine comprises a rack, an edge grinding conveying mechanism, a line grinding conveying mechanism and grinding head mechanisms. The rack is provided with the edge grinding conveying mechanism and the line grinding conveying mechanism which are arranged up and down. The multiple grinding head mechanisms are distributed between the edge grinding conveying mechanism and the line grinding conveying mechanism in sequence. When conducting upward compensation, the grinding head mechanisms are matched with the edge grinding conveying mechanism to conduct edge grinding machining on a stone material; and when conducting downward compensation, the grinding head mechanisms are matched with the line grinding conveying mechanism to conduct line grinding machining on the stone material. According to the full-automatic stone material line and edge grinding integrated machine, the structure is compact; one device can achieve the two functions of line grinding and edge grinding without rotating the angle of grinding heads; the occupied space is small; the working efficiency is improved; the labor force of workers is reduced; and meanwhile, the grinding heads can further be rapidly replaced through conical cutter bars, so that the full-automatic stone material line and edge grinding integrated machine is high in practicality and suitable for large-scale production and machining for enterprises.

Owner:苏州广隆富机械设备有限公司

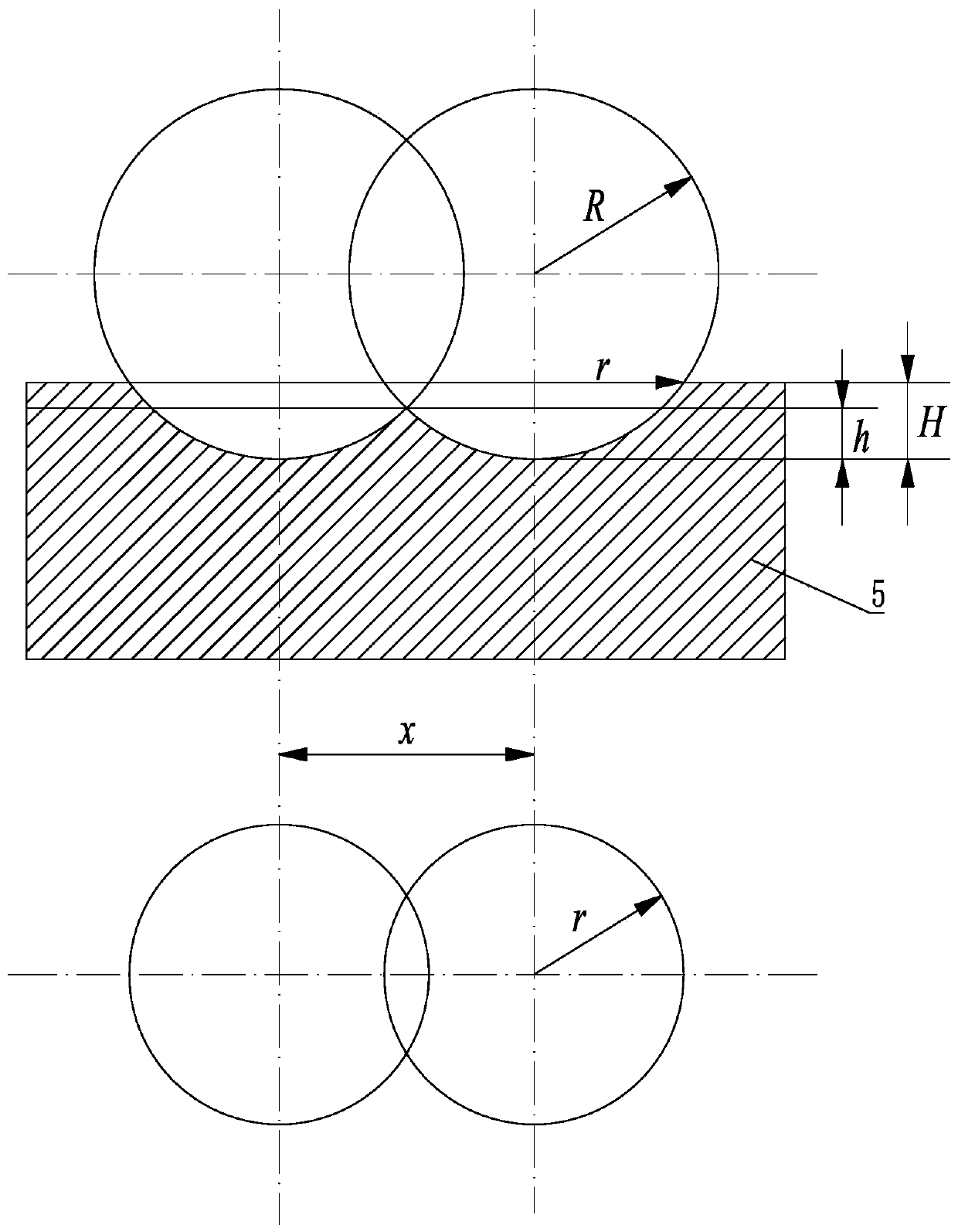

Machining method of roughness of seal groove

The invention relates to a machining method of the roughness of a seal groove. The machining method comprises the following steps of: selecting a slotting cutter with a knifepoint front angle of 15-25 degrees and a concave-arc-shaped chip breaker groove; carrying out rigid clamping; carrying out rough machining; dividing the groove depth of the seal groove into four machining layers; carrying out slitting and layering on the corresponding machining layers and machining and cutting in a linear speed of 100-120m / min and a cutting feeding speed of 0.07-0.15mm / r; carrying out fine machining; and carrying out circular-arc cutting-in at two edges of the seal groove, setting cutting breakpoints on the circular-arc bottom of the groove bottom and the cutting path center of the groove bottom, and cutting according to 2-4s of cutting feeding stop. The machining method disclosed by the invention is convenient and simple to operate; the vibration of the cutter and parts is reduced because a low feeding amount and rapid clamping way is adopted, and thus the machining quality is good; the cutting paths of rough machining and fine machining are adjusted, and thus the roughness of the machined parts of the seal grooves is good; manual polishing is not required, and thus personal factors during machining are reduced; the machining efficiency is increased; and the machining cost is reduced.

Owner:中国航发湖南南方宇航工业有限公司

Explosion-proof agent for methanol fuel and preparation method thereof

InactiveCN111635791AStrong explosion-proof performanceGood miscibilityLiquid carbonaceous fuelsFuel additivesMethylanilinePOLYETHYLENE WAX

The invention discloses an explosion-proof agent for methanol fuel and a preparation method thereof. The explosion-proof agent for methanol fuel is prepared from the following raw materials by weight:2-8.5 parts of glyceryl stearate, 1-25 parts of dimethyl carbonate, 1.5-6.8 parts of N-methylaniline, 2-8.5 parts of 2, 6-di-tert-butyl-p-cresol, 8-25 parts of ethyl tert-butyl ether, 0.2-3.6 parts of modified kaolin, 0.2-0.8 part of polyethylene wax and 0.5-1.8 parts of isobutanol. The prepared explosion-proof agent for methanol fuel is compounded by adopting different high-octane-number substances, a good synergistic effect is formed among the raw materials, the explosion-proof performance is high, the preparation method is simple, the preparation process is easy to operate, the economic benefit is high, and the explosion-proof agent is suitable for large-scale production and processing.

Owner:保蓝行福建环保技术研究院有限责任公司

A three-core primary wire tail length cutting equipment

ActiveCN106229902BDifferent lengthSuitable for large-scale production and processingApparatus for removing/armouring cablesApparatus for joining/termination cablesIdentification deviceGrounding line

The invention relates to the technical field of processing of power lines, and in particular relates to tail length cutting equipment for a three-core original line. The tail length cutting equipment comprises a power line jacket stripping device, a CCD colour distinguishing device, a line dividing device and an inner core line length adjusting device; the power line jacket stripping device is used for stripping the jacket of a power line; the CCD colour identification device is used for distinguishing positions of a zero line, a ground line and a live line after the jacket is stripped; the line dividing device is used for dividing three inner core lines after the positions of the zero line, the ground line and the live line are determined; the inner core line length adjusting device is used for respectively adjusting the lengths of the ground line, the live line and the zero line; and the equipment further comprises a transmission device for transmitting the power line among the various devices. By means of the equipment disclosed by the invention, the power line can be automatically stripped; line dividing and length adjusting of the three inner core lines do not need to be manually operated; and thus, the equipment disclosed by the invention is simple to operate and high in working efficiency, and is suitable for large-scale production and processing in factories.

Owner:DONGGUAN SENJIA MACHINERY

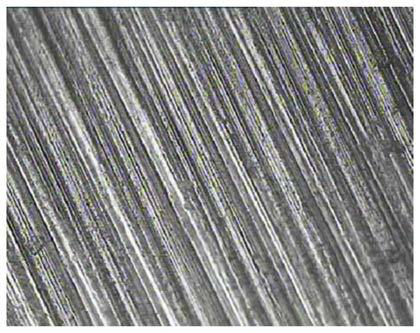

Processing method for optimizing metal surface performance by using high-frequency impact technology

InactiveCN110358992AImprove roughness qualityChange microscopic morphologyTransformerMaterials science

The invention discloses a processing method for optimizing metal surface performance by using a high-frequency impact technology. High-frequency vibration is generated by adopting a high-frequency vibration generator, and transmitted to a ball through a transducer and an amplitude transformer, so that the ball generates high-frequency mechanical vibration, the ball impacts the surface of a processed workpiece at a high speed under the action of the high-frequency mechanical vibration, and after continuous impact, the metal surface of the processed workpiece undergoes severe plastic deformation, thereby changing the microscopic appearance of the metal surface; and through high-frequency impact on the metal surface, a metal surface crystal is reshaped, the metal surface crystal defect is eliminated, the lubricating property and the wear resistance of the friction working surface are improved, the running-in period is shortened, the lubricating oil loss is reduced, and the service life ofa product is prolonged. The method also has the advantages of convenient operation, simple process and the like, the processed metal surface roughness quality is high, the processing efficiency is improved, and the method is suitable for large-scale production and processing.

Owner:山东聚亿能智能科技有限公司

A flower batching machine and its automatic tool changing mechanism

ActiveCN112475952BAvoid reverse rotationNo human intervention requiredJewelleryPositioning apparatusNumerical controlRotational axis

The invention discloses a flower batching machine and its automatic tool changing mechanism, which are used for jewelry processing. Multiple sets of tool fixing components are interposed between the tool guiding component and the cam transmission component, and the cutter head rotating shaft component drives the tool guiding component and the tool fixing component. Rotate, the cam of the cam transmission assembly will rotate to the convex point of the tool fixing assembly and the tool to push out the outer edge of the tool installation wheel and the transmission wheel, other tool fixing components and tools shrink in the tool installation wheel and the transmission wheel, and the spring latch positioning assembly It is located between the tool guide assembly and the cam drive assembly to prevent the tool guide assembly from rotating in reverse. Rotate the tool guide assembly to make the tools required for processing work on the operating surface. Since each group of tool fixing components is equipped with different types of tools, different types of tools can be used to complete the batching operation of different requirements, realizing the same numerical control mechanism. Complete a variety of batch flower processing operation functions.

Owner:SHENZHEN GUANG LI JIN TECH CO LTD

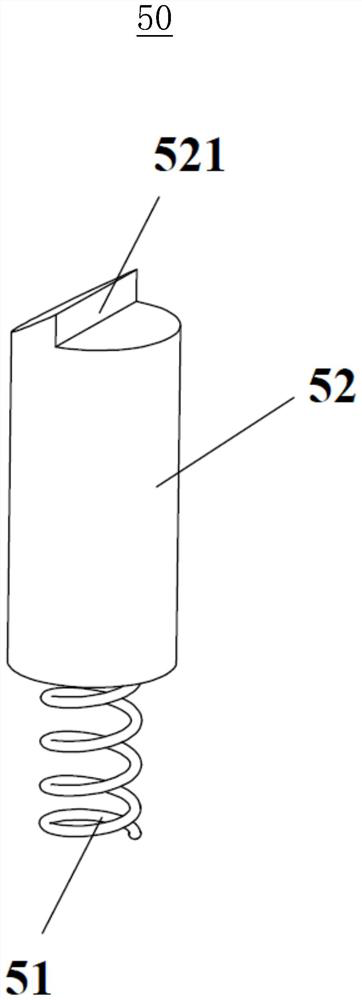

Strand winding mechanical device

The invention discloses a strand winding mechanical device. The strand winding mechanical device is characterized in that the strand winding mechanical device comprises a main rack, a deformation preheating box, one or two strand grooves, a shaping hot box, a first strand guiding wheel, a strand detector, an oil tank, a strand feeding groove, an oiling part, a strand winding cylinder, a second strand guiding wheel and a deformation hot box. The strand winding mechanical device is mainly composed of a strand winding device and a strand deformation device, the strand winding device is composed of the strand winding cylinder and the second strand guiding wheel arranged on the upper part of the strand winding cylinder, the strand deformation device is composed of the main rack, the deformationpreheating box arranged on the upper part of the main rack, the shaping hot box arranged on the lower part of the main rack, and a deformation hot box arranged on the upper part between the main rackand an auxiliary rack, the one or two strand grooves are formed in the shaping hot box, the oil tank is arranged on the lower side between the main rack and the auxiliary rack, and the oiling part and the strand detector are arranged in the oil tank. The strand winding mechanical device has the advantages and characteristics that the structure is simple, the principle is simple, production equipment is low in cost, performance is stable, the production efficiency is high, the production variety is wide, the quality of produced products is good, and the strand winding mechanical device is suitable for large-scale production and processing.

Owner:李月鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com