Processing method of pearl milk tea

A processing method and pearl technology, which is applied in the field of beverage processing, can solve problems such as the loss of filling nutrients, poor visual effects, and complicated processes, and achieve the effect of preventing aging and rebirth, avoiding food safety problems, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

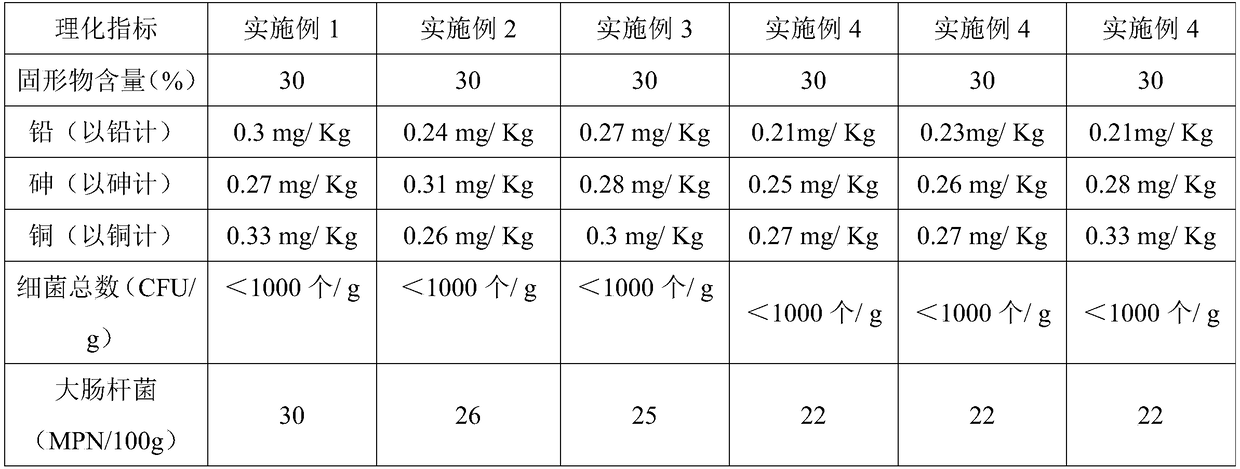

Examples

Embodiment 1

[0046] A processing method of pearl milk tea includes the following steps:

[0047] S1: Tea preparation: select green tea leaves as raw materials, remove impurities and stems, and process them into fine tea powder with D50 ≥ 200 mesh after spreading, steam heating, frying, de-greening, drying, and crushing, and keep it for later use;

[0048] S2: Tea soup making: the above-mentioned tea powder is boiled in water at a material-to-liquid mass ratio of 1%, the cooking temperature is 85°C, and the cooking time is 5 minutes. After filtering, the tea soup is obtained, and the tea soup is kept for later use;

[0049] S3: Preparation of sucrose water: pour 1000g of white granulated sugar into the pan and fry, pour 1000g of hot water to cook after it is coked. After the white sugar is dissolved, the caramel water is obtained;

[0050] S4: Blending: Add 30g of creamer to 200ml of tea soup obtained in step S2 according to the mass-to-volume ratio, stir thoroughly, and then add 200g of ice cubes a...

Embodiment 2

[0059] A processing method of pearl milk tea includes the following steps:

[0060] S1: Tea preparation: select black tea leaves as raw materials, remove impurities and stems, and process them into fine tea powder with D50≥200 mesh after spreading, steam heating, frying, finalizing, drying, and crushing, and keep it for later use;

[0061] S2: Making tea soup: Put the tea powder into water at a ratio of 2% by mass to liquid to cook, the cooking temperature is 90°C, the cooking time is 10 minutes, filtered, and the tea soup is kept for later use;

[0062] S3: Preparation of sucrose water: pour 1000g of white granulated sugar into a pot and fry, and pour it into 1000g of boiling water for cooking after it is coked. After the white sugar is dissolved, the caramel water is obtained;

[0063] S4: Blending: Add 40g creamer to 250ml of tea soup obtained in step 2) according to the mass-to-volume ratio, stir and dissolve, then add 200g ice cubes and 35g sucrose water;

[0064] S5: Preparation o...

Embodiment 3

[0072] A processing method of pearl milk tea includes the following steps:

[0073] S1: Tea preparation: select black tea leaves as raw materials, remove impurities and stems, and process them into fine tea powder with D50≥200 mesh after spreading, steam heating, frying, finalizing, drying, and crushing, and keep it for later use;

[0074] S2: Tea soup making: Put the tea powder in water at a 3% material-to-liquid ratio for boiling, the boiling temperature is 95°C, and the cooking time is 15 minutes, filter, and keep the tea soup for later use;

[0075] S3: Preparation of sucrose syrup: 1000g white granulated sugar is poured into a pot for frying, after the white sugar is caramelized, poured into 1000g of boiling water for cooking, after the white sugar is dissolved, sucrose syrup is obtained;

[0076] S4: Blending: adding 50g creamer into 300ml tea soup obtained in step 2) according to the mass-to-volume ratio, after stirring and dissolving, then adding 200g ice cubes and 35g sucrose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com