Annular thin-wall parts fixture and method for processing thin-wall outer surface of parts

A technology for processing thin-walled parts and parts, which is applied in the field of fixtures for annular thin-walled parts and the thin-walled outer surface of the parts, which can solve problems such as deformation of annular thin-walled parts, reduce production cycle and processing costs, and simplify the processing technology , Eliminate the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

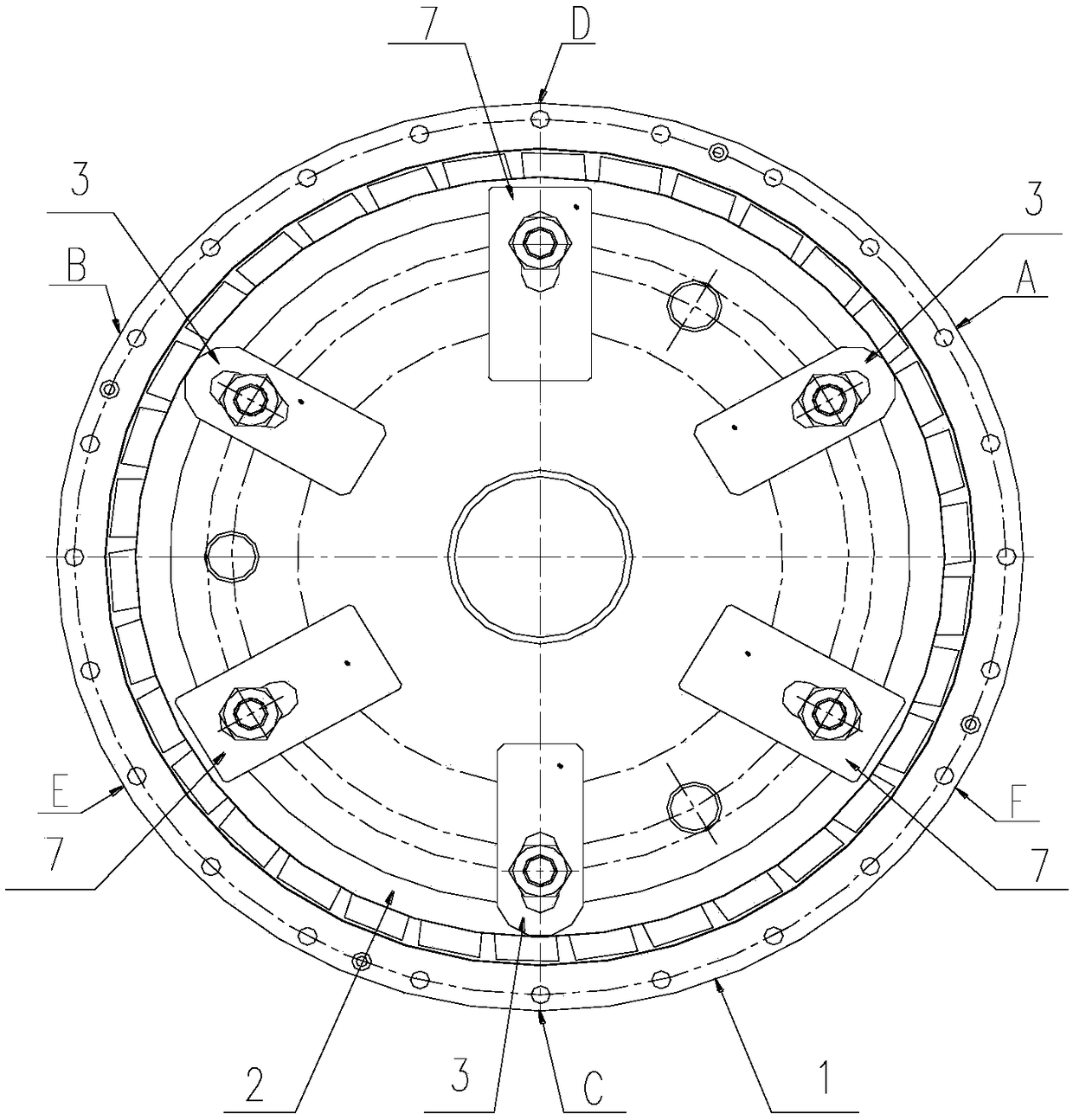

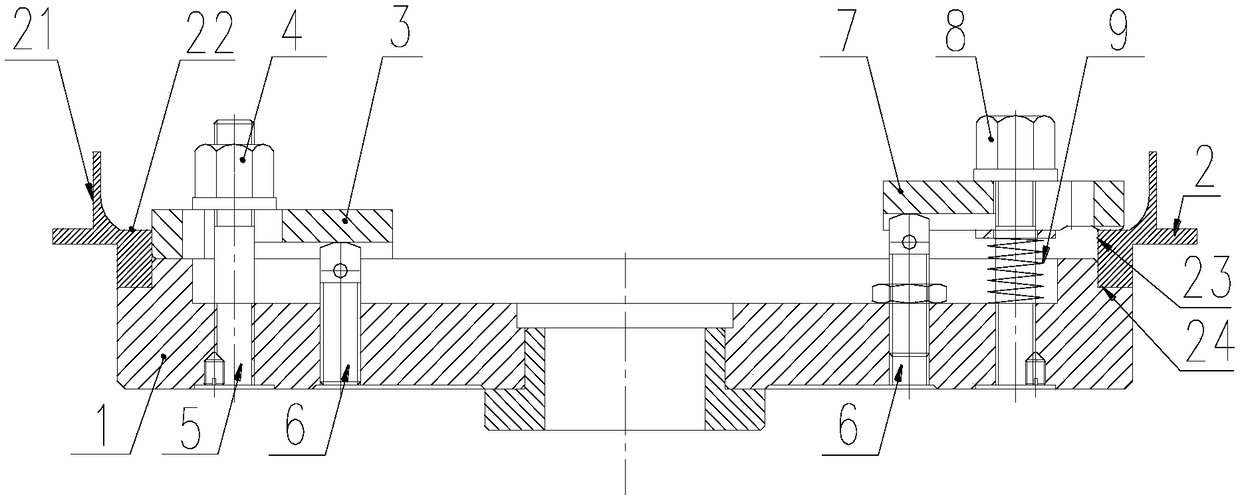

[0028] Reference as figure 1 and figure 2 , a fixture for an annular thin-walled part, which includes a circular fixture support 1 for supporting an annular thin-walled part 2; three stoppers 3 evenly distributed on the fixture support 1 for limiting the The horizontal position of the part 2; three pressure plates 7 that are evenly distributed on the fixture support 1 and spaced from the limit block 3.

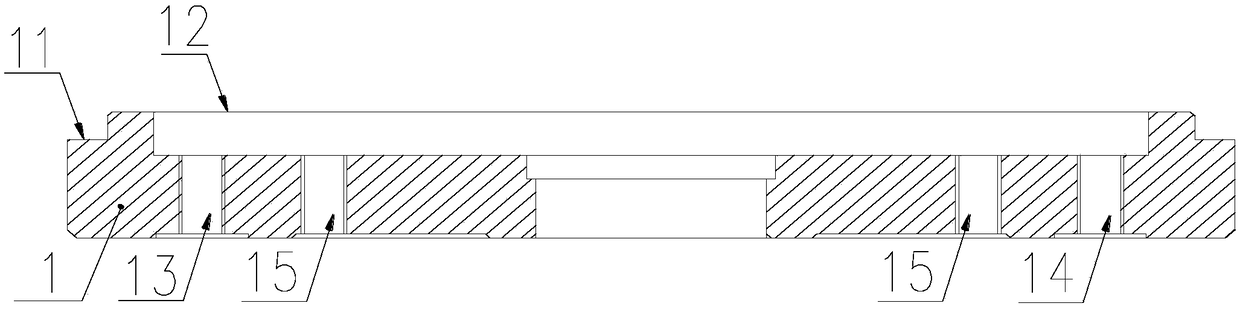

[0029] Its structure diagram is as follows image 3 As shown, a circle of steps 11 is arranged on the outermost side of its upper end surface along the circumferential direction, and the step 11 is arranged lower than the upper end surface 12. The bottom end surface 24 and the inner ring surface 23 are positioned; a circular groove is arranged on the upper end surface of the fixture support 1 on the inner side of the step 11, and three thirds are evenly distributed on the circumference of the main body of the fixture support 1 at the lower part of the groove. A threaded h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com