Strand winding mechanical device

A technology of mechanical device and raw silk, applied in transportation and packaging, transportation of filamentous materials, textiles and papermaking, etc., can solve problems such as poor functionality, low product qualification rate, affecting production efficiency, etc., and achieve good product quality and production. The effect of low equipment cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

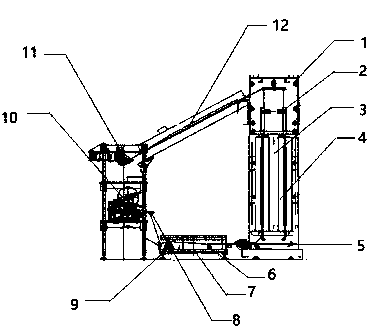

[0012] This embodiment provides a mechanical device for collecting raw silk, which is characterized in that: the mechanical device for collecting raw silk includes a main frame (1), a deformation preheating box (2), a raw silk groove (3), a shape-setting Heat box (4), first wire guide wheel (5), wire detector (6), oil tank (7), lower wire groove (8), oiling part (9), wire receiving drum (10), the first Two raw silk guide wheels (11), deformation heating box (12);

[0013] Among them: the device is mainly composed of a wire receiving device and a raw wire deformation device. The wire receiving device is composed of a wire receiving drum (10) and a second raw wire guide wheel (11) arranged above the wire receiving drum (10). The wire deformation device consists of the main frame (1), the deformation preheating box (2) set on the upper part of the main frame (1) and the setting heating box (4) set on the lower part, and the upper part set between the main frame (1) and the sub-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com