A processing method for T-shaped thin-walled parts

A processing method and technology of thin-walled parts, applied in the field of parts processing, can solve the problems of time-consuming and laborious loading and unloading of parts, unstable parts quality, easy deformation of thin-walled parts, etc., to reduce loss and processing costs, good symmetry, eliminate Effects of deformation of thin-walled parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

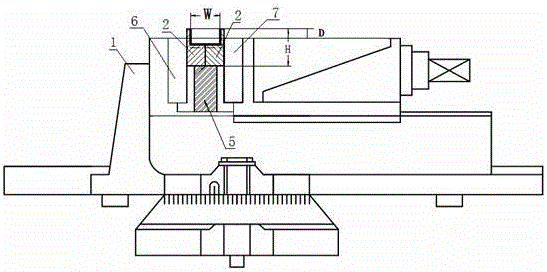

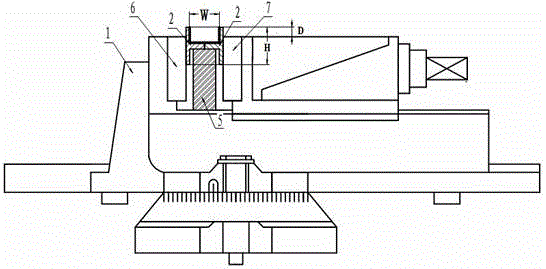

[0023] The processing method of T-type thin-walled part of the present invention, processing step is as follows:

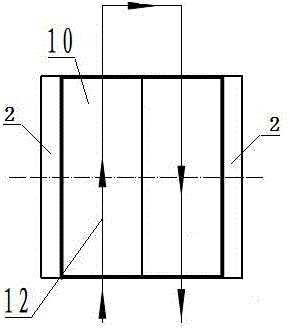

[0024] a. Select the cutting tool: According to the groove depth C of the T-shaped thin-walled part to be processed is 12.5mm, the part height H is 30mm, the groove width W is 24mm, and the diameter of the milling cutter is 22mm, choose a three-edged tapered shank for rough machining Milling cutter and finishing milling cutter, the roughness of the cutting edge of the finishing milling cutter is Ra0.3.

[0025] b. On the CNC machine tool, set the groove depth C of the part to 12.5 mm, the thickness of the rough machining layer to 2 mm, the number of rough machining layers to 6 layers, the groove width W to 24 mm and the finishing allowance to 0.5 mm.

[0026] c. Set the linear speed and cutting feed speed of the CNC machine tool spindle rotation. The linear speed and cutting feed speed of rough machining are 200m / min and 70mm / min respectively, and the linear speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com