Antibacterial temperature-sensitive straw material and preparation method thereof

An antibacterial and straw technology, which is applied in the field of antibacterial and temperature-sensing straw materials and its preparation, can solve the problems that transparent drinking straws do not have a temperature-sensing function, cannot predict the temperature of drinks, and have poor antibacterial performance. Long duration and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

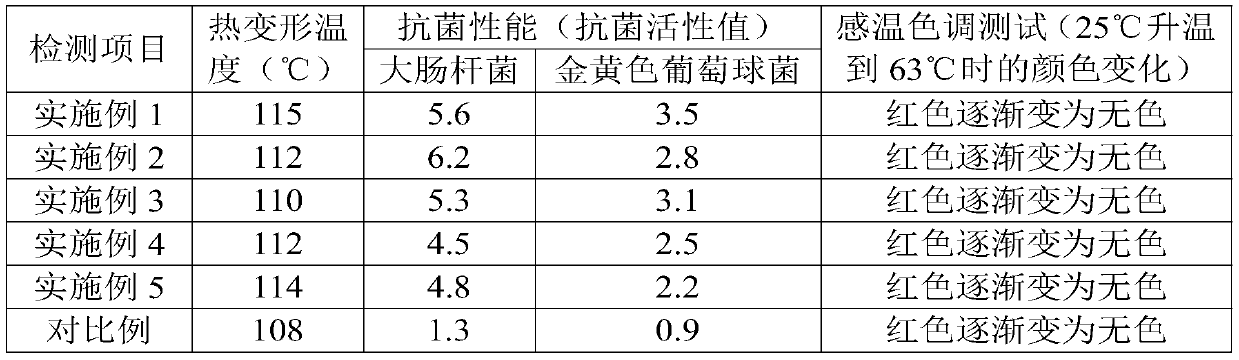

Examples

Embodiment 1

[0029] A kind of antibacterial temperature-sensitive straw material and preparation method thereof

[0030] The raw materials for preparing antibacterial and temperature-sensitive straw materials include: 100kg of polypropylene resin, 20kg of TPE, 18kg of hemp stalk fiber, 1.2kg of temperature-sensitive discoloration powder, 11kg of antibacterial composition, 1.2kg of hydroxypropyl cellulose, 6kg of calcium carbonate, and 2kg of polyethylene wax , polycaprolactam 0.25kg; the melt flow rate of polypropylene resin is 20g / 10min~32g / 10min, and the Vicat softening point is ≥145°C; polypropylene resin can be selected from R520Y polypropylene produced by SK in South Korea; temperature-sensitive color-changing powder The particle size of the hemp fiber is between 6 microns and 9 microns, and the discoloration temperature range is 58 ° C ~ 63 ° C. You can choose the temperature-sensitive powder of Juliang Optical brand; the preparation of hemp fiber includes: first peeling the hemp stem...

Embodiment 2

[0041] A kind of antibacterial temperature-sensitive straw material and preparation method thereof

[0042] The raw materials for preparing antibacterial and temperature-sensitive straw materials include: 100kg of polypropylene resin, 12kg of TPE, 12kg of hemp stalk fiber, 0.5kg of temperature-sensitive discoloration powder, 8kg of antibacterial composition, 1.2kg of hydroxypropyl cellulose, 7kg of calcium carbonate, and 1kg of polyethylene wax , polycaprolactam 0.4kg; the melt flow rate of polypropylene resin is 20g / 10min~32g / 10min, and the Vicat softening point is ≥145°C; polypropylene resin can be selected from R520Y polypropylene produced by SK in South Korea; temperature-sensitive color-changing powder The particle size of the hemp fiber is between 6 microns and 9 microns, and the discoloration temperature range is 58 ° C ~ 63 ° C. You can choose the temperature-sensitive powder of Juliang Optical brand; the preparation of hemp fiber includes: first peeling the hemp stem, ...

Embodiment 3

[0053] A kind of antibacterial temperature-sensitive straw material and preparation method thereof

[0054] The raw materials for preparing antibacterial and temperature-sensitive straw materials include: polypropylene resin 100kg, TPE 15kg, hemp stalk fiber 20kg, temperature-sensitive discoloration powder 2kg, antibacterial composition 10kg, hydroxypropyl cellulose 0.8kg, calcium carbonate 8kg, polyethylene wax 1.5kg , polycaprolactam 0.3kg; the melt flow rate of polypropylene resin is 20g / 10min~32g / 10min, and the Vicat softening point is ≥145°C; polypropylene resin can be selected from R520Y polypropylene produced by SK in South Korea; thermochromic powder The particle size of the hemp fiber is between 6 microns and 9 microns, and the discoloration temperature range is 58 ° C ~ 63 ° C. You can choose the temperature-sensitive powder of Juliang Optical brand; the preparation of hemp fiber includes: first peeling the hemp stem, shaving it, and breaking it into small particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com