A three-core primary wire tail length cutting equipment

A kind of equipment and cutting technology, applied in the direction of dismantling/armoring cable equipment, connecting/terminating cable equipment, cable installation device, etc., can solve the problems that are not suitable for large-scale assembly production lines, and the efficiency of manual operation is slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Attached below figure 1 to attach Figure 12 , and specific embodiments will further illustrate the present invention.

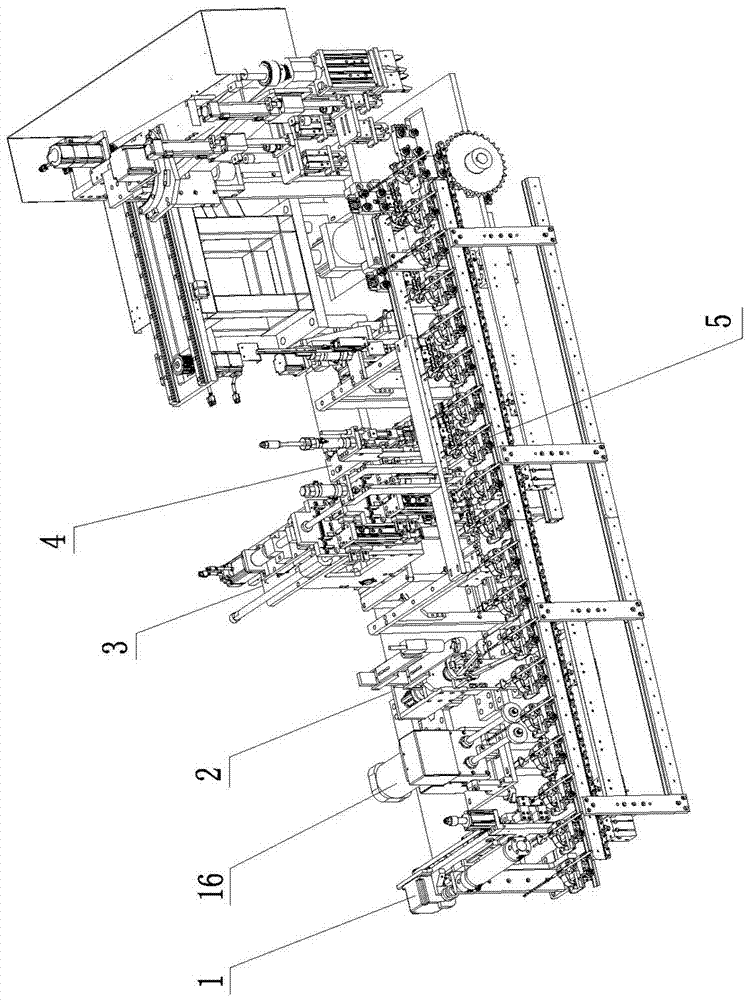

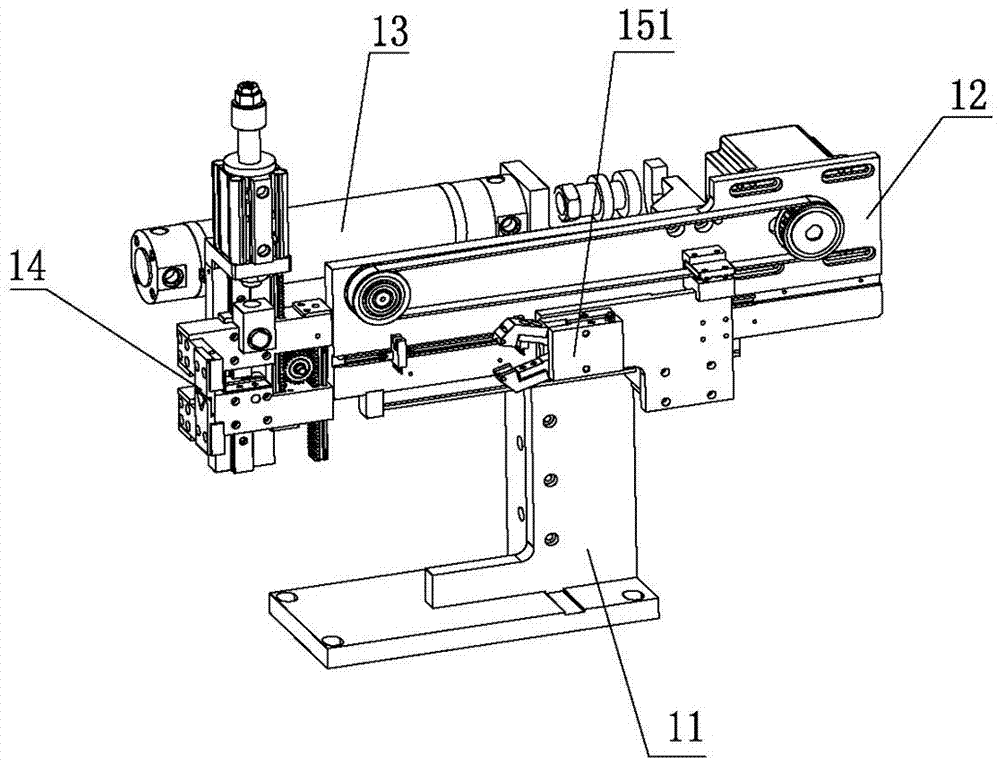

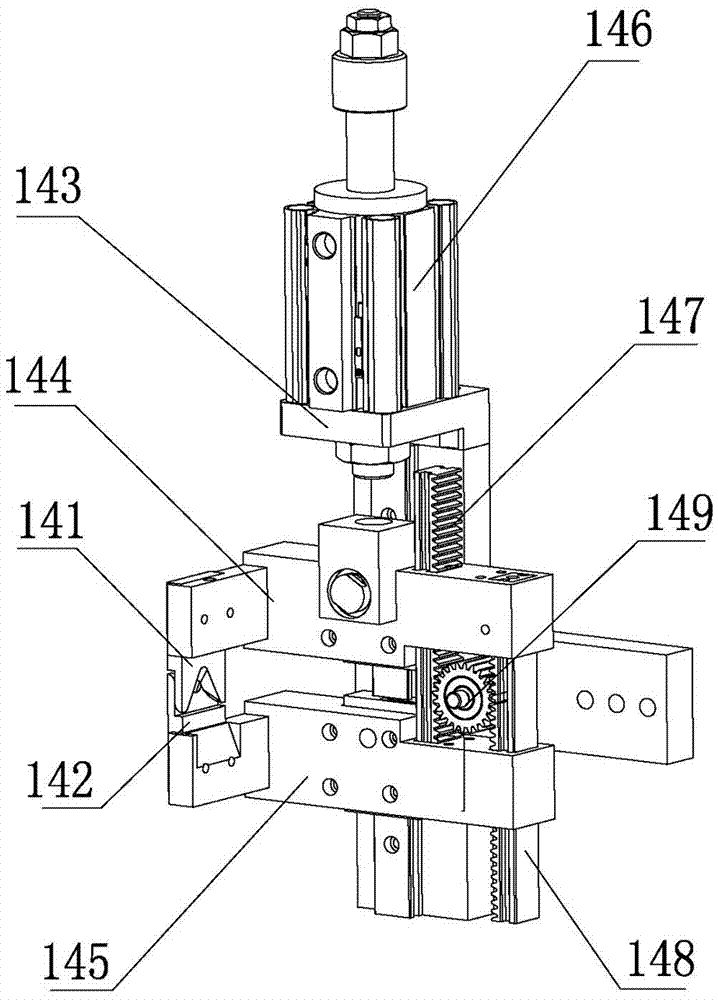

[0030] Such as figure 1 As shown, a three-core original wire tail length cutting equipment includes a power cord sheath stripping device 1 for stripping the power cord sheath in sequence according to the process; CCD color distinguishing device 2; After the position of neutral wire, ground wire and live wire is determined, a branching device 3 for separating the three inner core wires; and an inner wire for adjusting the lengths of the ground wire, live wire and neutral wire respectively The core wire length adjustment device 4; the device also includes a transfer device 5 for transferring the power cord between the various devices.

[0031] In this embodiment, at first the transmission device 5 sends the power cord to the power cord sheath stripping device 1 to peel off the sheath of the power cord. After the sheath is peeled off, the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com