Laser engraving and faceting compound machine

A technology of laser engraving and compound machine, which is applied in other manufacturing equipment/tools, clothing, jewelry, etc., and can solve the problems of limited process scalability, increased factory production cost, and single processing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This embodiment takes a laser engraving and flower batching compound machine as an example, and the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

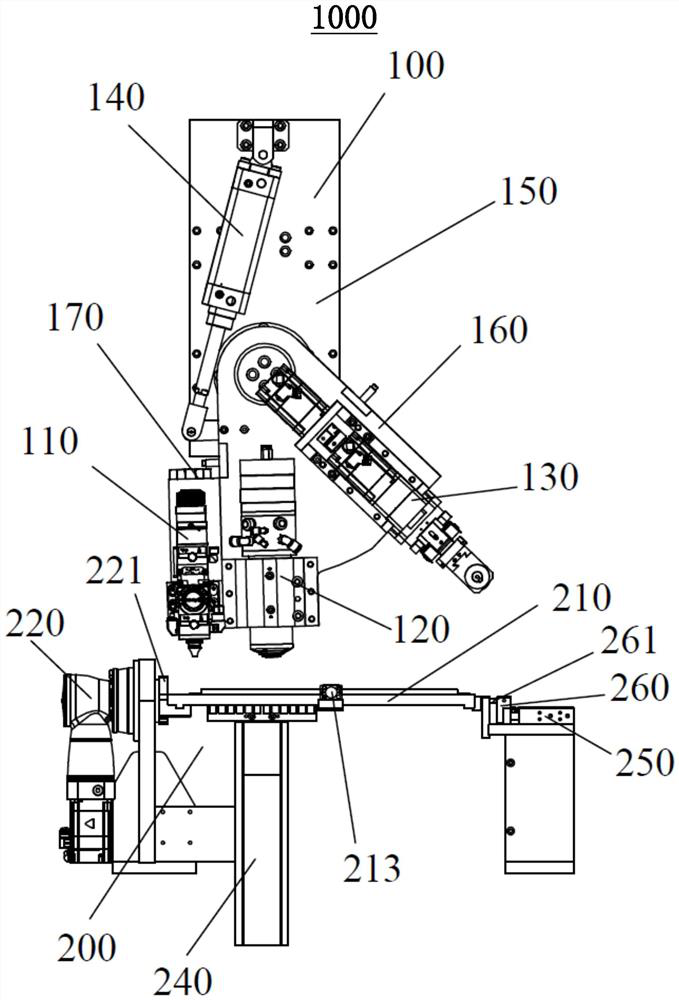

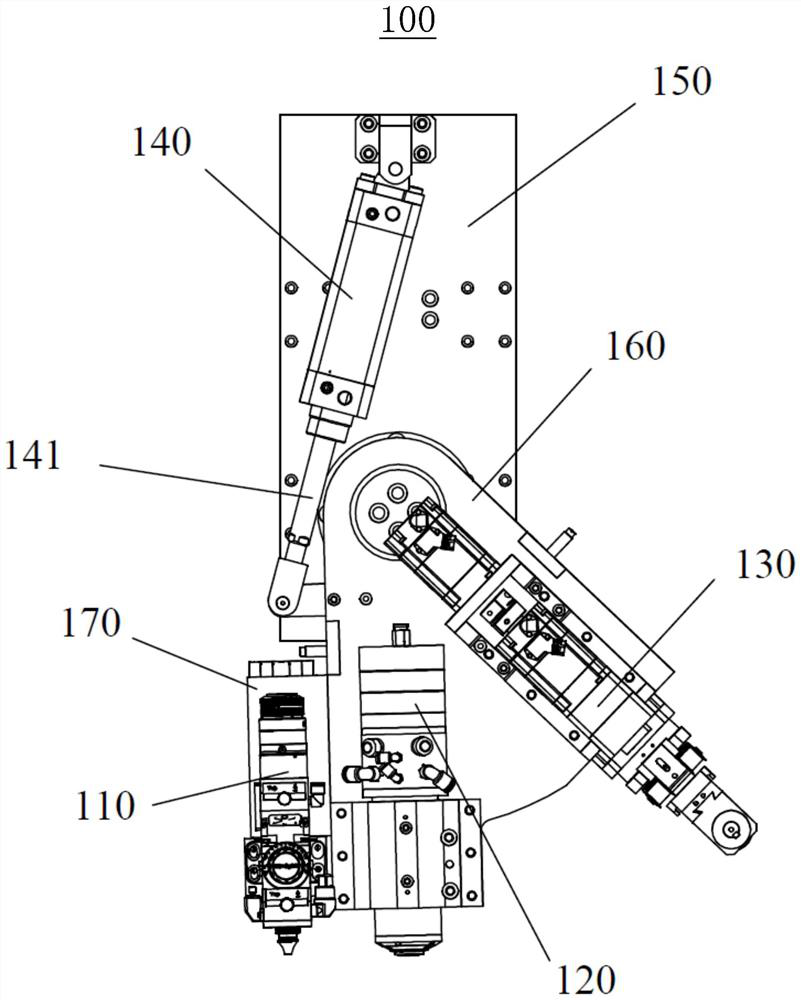

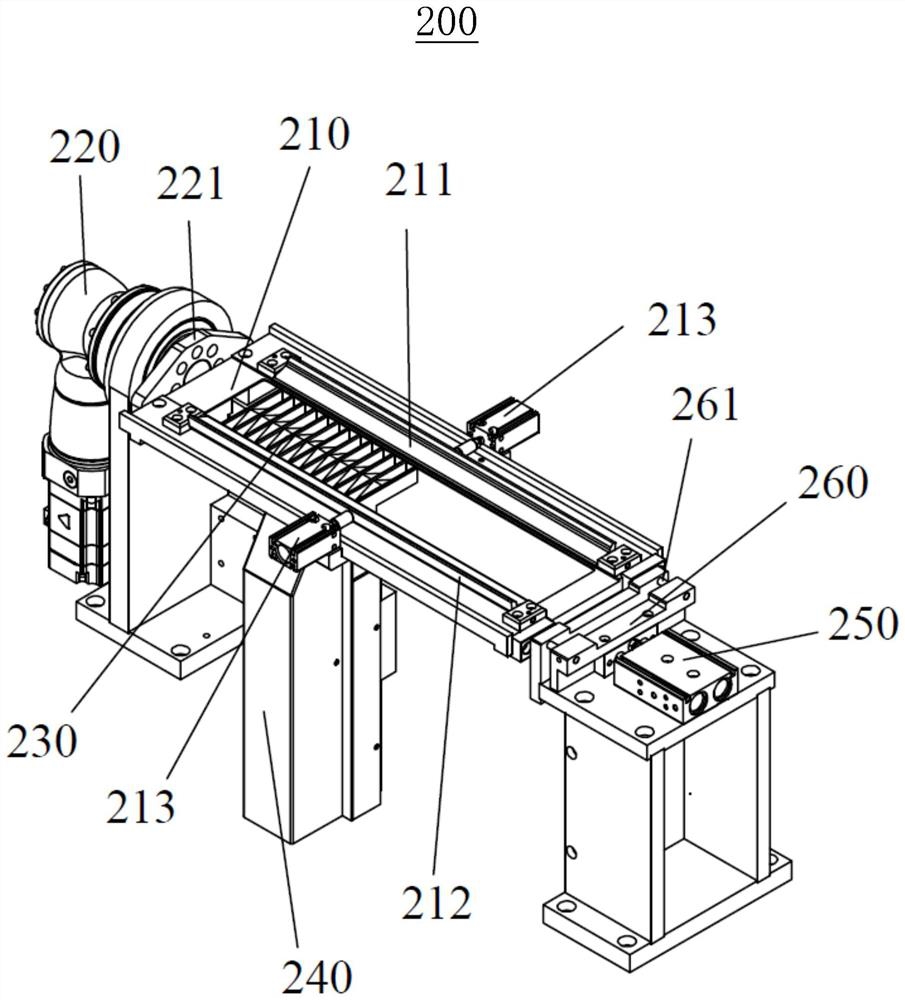

[0022] see figure 1 , figure 2 and image 3 , showing a laser engraving and approving compound machine 1000 provided by the embodiment of the present invention, which is used to process jewelry pieces, including a multifunctional compound mechanism 100 with multiple functional axes for laser cutting, engraving and approving flowers, and a piece of material turning process Mechanism 200, the multifunctional compound mechanism 100 includes a laser cutting shaft assembly 110, an engraving shaft assembly 120, and a batch flower shaft assembly 130, and a spindle switching cylinder 140 that controls the switching between the engraving shaft assembly 120 and the batch flower shaft assembly 130 The sheet material turning mechanism 200 includes a sheet mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com