A flower batching machine and its automatic tool changing mechanism

A technology for automatic tool change and tool change, applied in metal processing machinery parts, applications, manufacturing tools, etc., can solve problems such as increased production costs in factories, the risk of work-related injuries, and is not suitable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment takes a flower batching machine and its automatic tool changing mechanism as an example, and the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

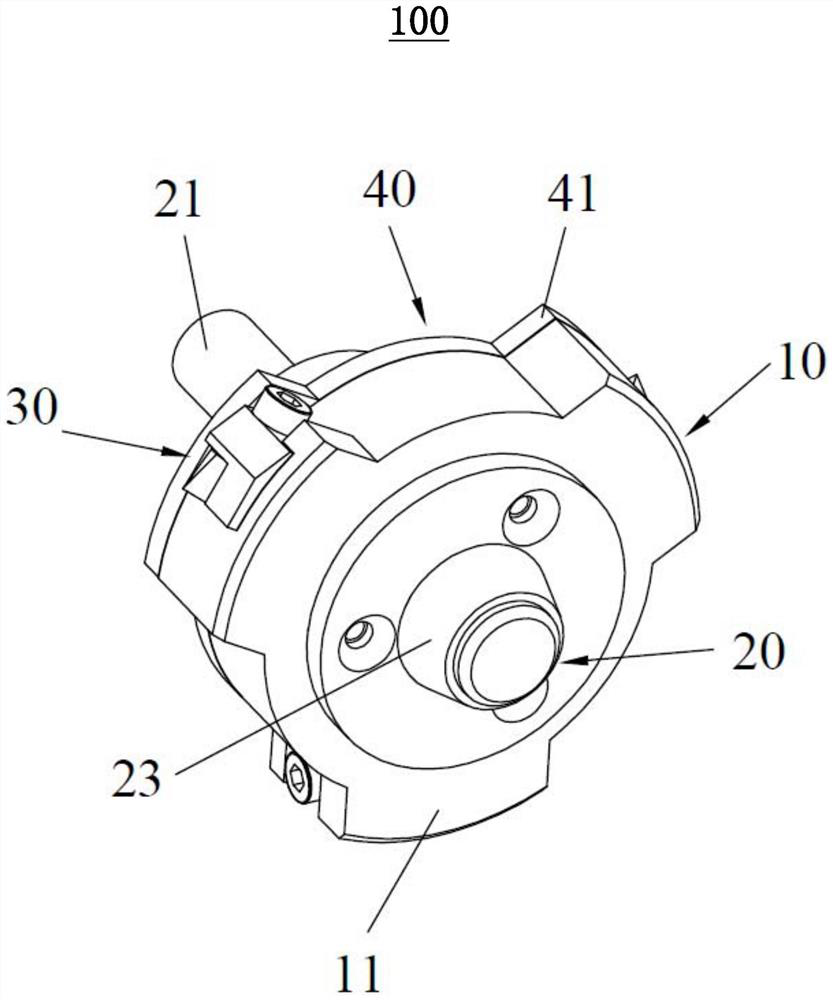

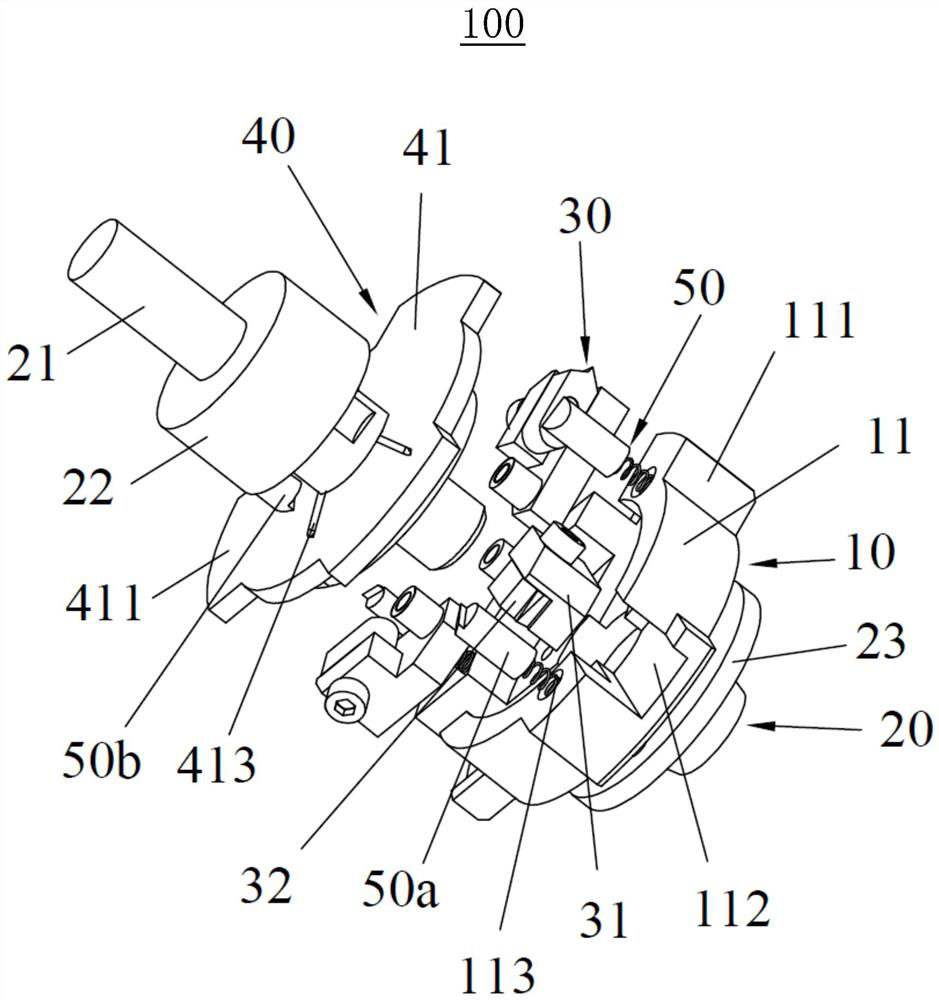

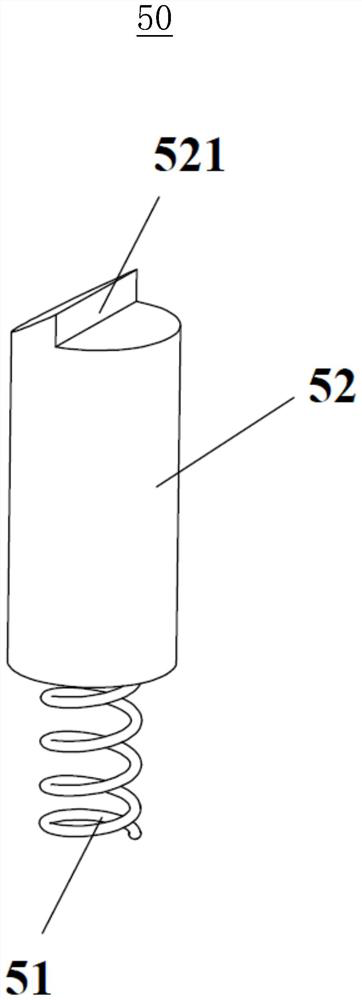

[0024] see Figure 1 to Figure 6 , shows an automatic tool changing mechanism 100 provided by the embodiment of the present invention, which is used for jewelry processing, and includes a tool guide assembly 10, a cutterhead rotating shaft assembly 20, a tool fixing assembly 30, a cam transmission assembly 40 and a spring pin positioning assembly 50, The cam transmission assembly 40 includes a cam, and the cam has a convex point. The tool guide assembly 10 is fastened to the cam transmission assembly 40, and multiple A set of said cutter fixing assemblies 30, multiple sets of said cutter fixing assemblies 30 are wound around the periphery of said cam, and one of said cutter fixing assemblies 30 is pushed out by a convex point of said cam; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com