A device for extracting brazing and cutting materials for insulating crepe paper tubes

A technology of insulating crepe paper and material rack, which is applied in the direction of cardboard winding articles, etc., can solve the problems of continuous drawing and blanking, contusion of paper tube at the tail end, high production cost, etc., and achieve stable and rapid extraction, small operation difficulty, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

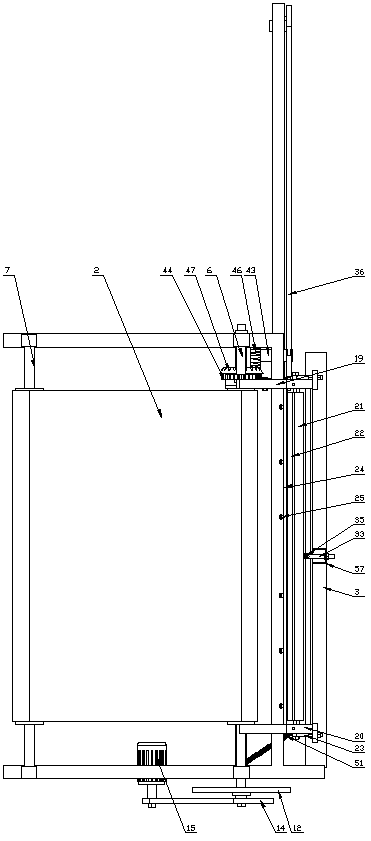

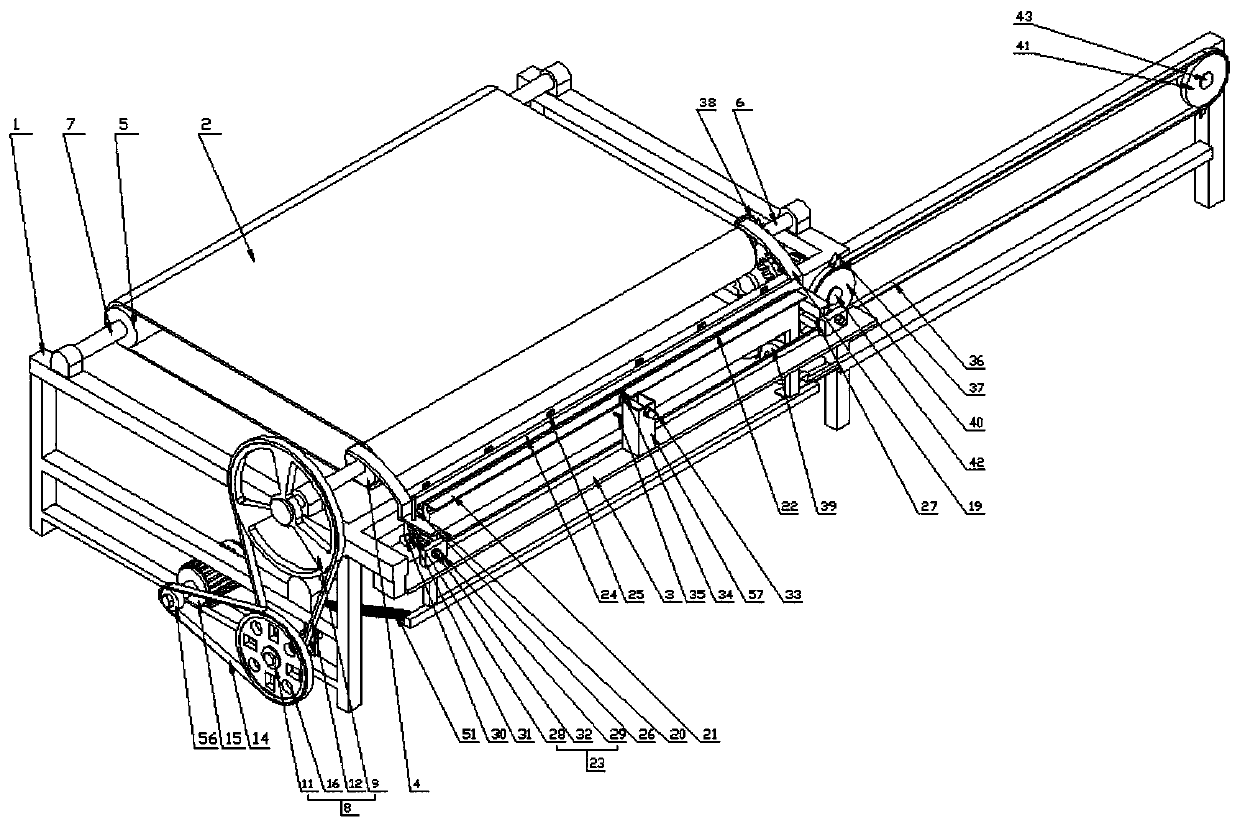

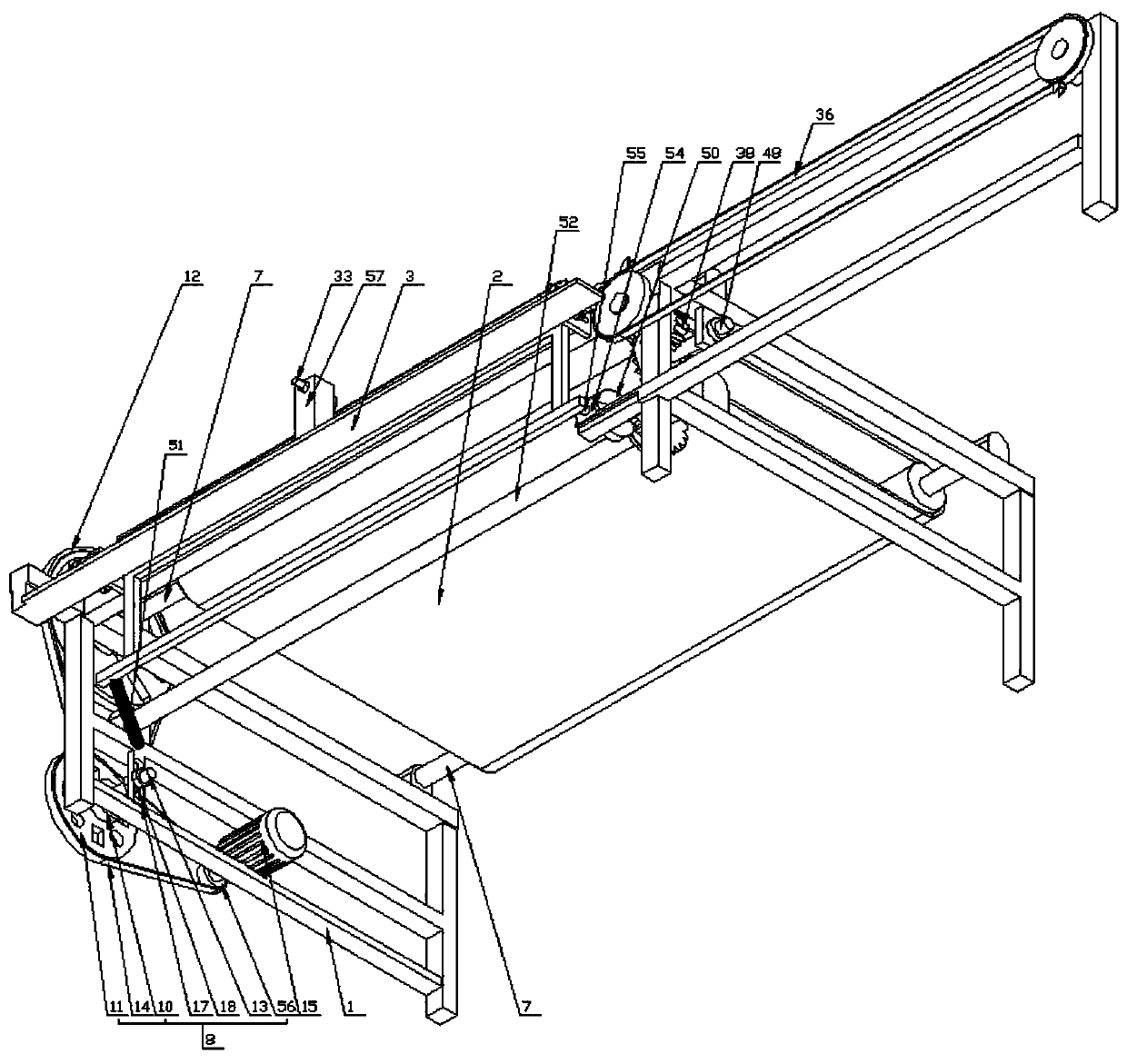

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] An insulating crepe paper tube brazing and blanking device, comprising a frame 1, wherein, the frame 1 is provided with a conveyor belt 2 and a support frame 3, and the conveyor belt 2 is provided with a driving roller 4 and a driven roller 5, The driving roller 4 and the driven roller 5 are respectively provided with a driving shaft 6 and a driven shaft 7, and a rotating drive mechanism 8 is arranged between the driving shaft 6 and the frame 1;

[0019] The rotary driving mechanism 8 includes a first pulley 9, a second pulley 10, a third pulley 11 and a fourth pulley 56. The first pulley 9 is arranged outside the driving shaft 6 and connected to the second pulley. The first belt 12 is arranged between the pulleys 10, the first shaft body 13 is arranged between the third pulley 11 and the second pulley 10 and the frame 1, the fourth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com