Machining method of roughness of seal groove

A processing method and sealing groove technology, applied in the field of seal processing, can solve the problems of cumbersome polishing process steps, not suitable for large-scale production and processing, and affecting processing efficiency, so as to reduce human factors, reduce processing costs, and achieve good processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A sealing groove roughness processing method, the steps are as follows:

[0019] (1) Selection of groove cutter: choose a groove cutter with a rake angle of 20° and a concave arc-shaped chip breaker, the elongation of the cutter bar is 4mm, and the cutting edge is ground to Ra0.4;

[0020] (2) Rigid clamping: When machining outer circular grooves, the clamping method of the spindle clamping the top support is adopted; when machining inner hole grooves, the clamping method of center frame support is adopted;

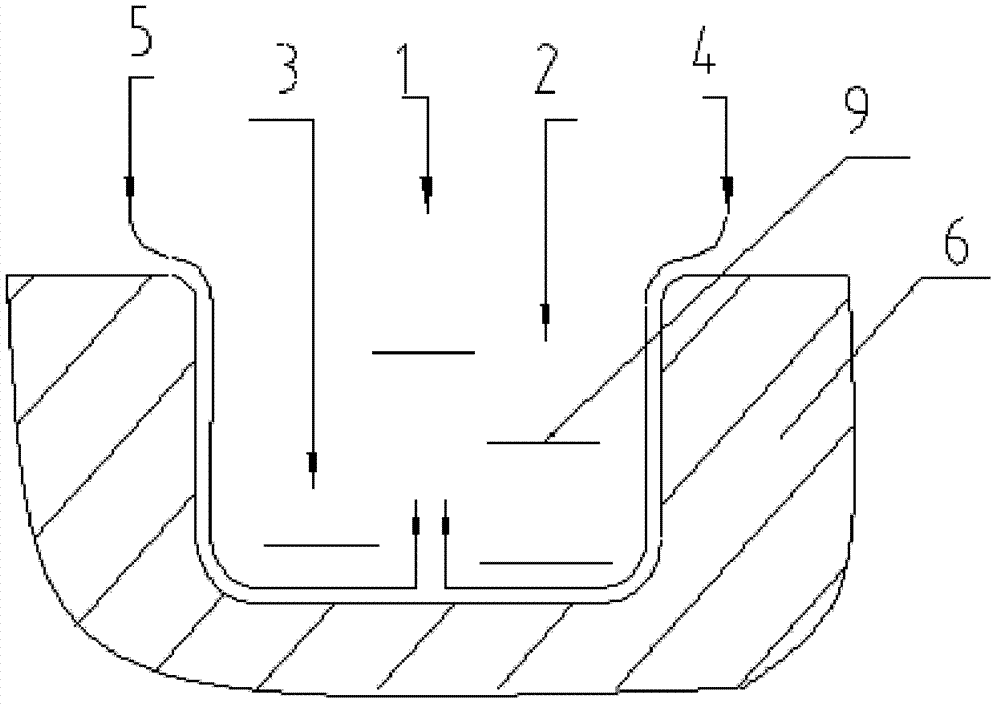

[0021] (3) Rough machining cutting path, the sealing groove 6 is divided into four processing layers 9, the corresponding processing layer 9 is processed with 5 knives, the linear speed is 120m / min, the cutting feed is 0.10mm / r, and the above The cutting speed leaves the part surface; the first to third machining layers (such as figure 1 The processing sequence in 1~3 cuts) occupies 1 / 3 of the groove depth, the fourth processing layer (that is, 4 cuts), and the fi...

Embodiment 2

[0026] A method for processing the roughness of a sealing groove, the steps of which are as follows:

[0027] (1) Selection of groove cutter: choose a groove cutter with a rake angle of 20° and a concave arc-shaped chip breaker, the elongation of the cutter bar is 4mm, and the cutting edge is ground to Ra0.4;

[0028] (2) Clamping: Non-rigid clamping, that is, the parts are clamped by the main shaft without the support of the top or the center frame;

[0029] (3) Rough machining, the sealing groove 6 is divided into four processing layers 9 in depth, and the corresponding processing layer 9 is processed and cut with 5 knives, the line speed is 120m / min, the cutting feed is 0.07mm / r, and the above cutting speed leave the surface of the part;

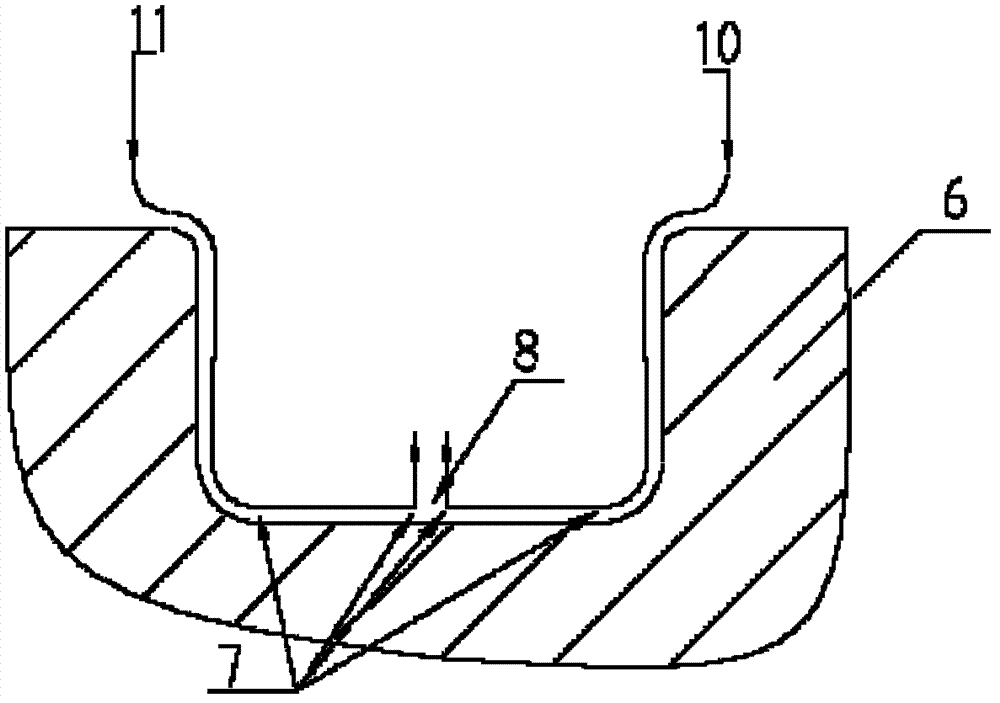

[0030] (4) Finishing, cut into the circular arc on both sides of the sealing groove 6, the linear speed is 120m / min, and the cutting feed is 0.03mm / r; set a cutting pause point 7 on the bottom of the groove bottom arc and the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com