Technique and device for non-membrane electrolytic synthesis of butanedioic acid

A technology of electrolytic synthesis and succinic acid, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of anode material consumption and large investment, high content of easy oxides, and difficulty in large-scale production, etc., to improve conversion The effect of high efficiency and anode usage efficiency, high product quality, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

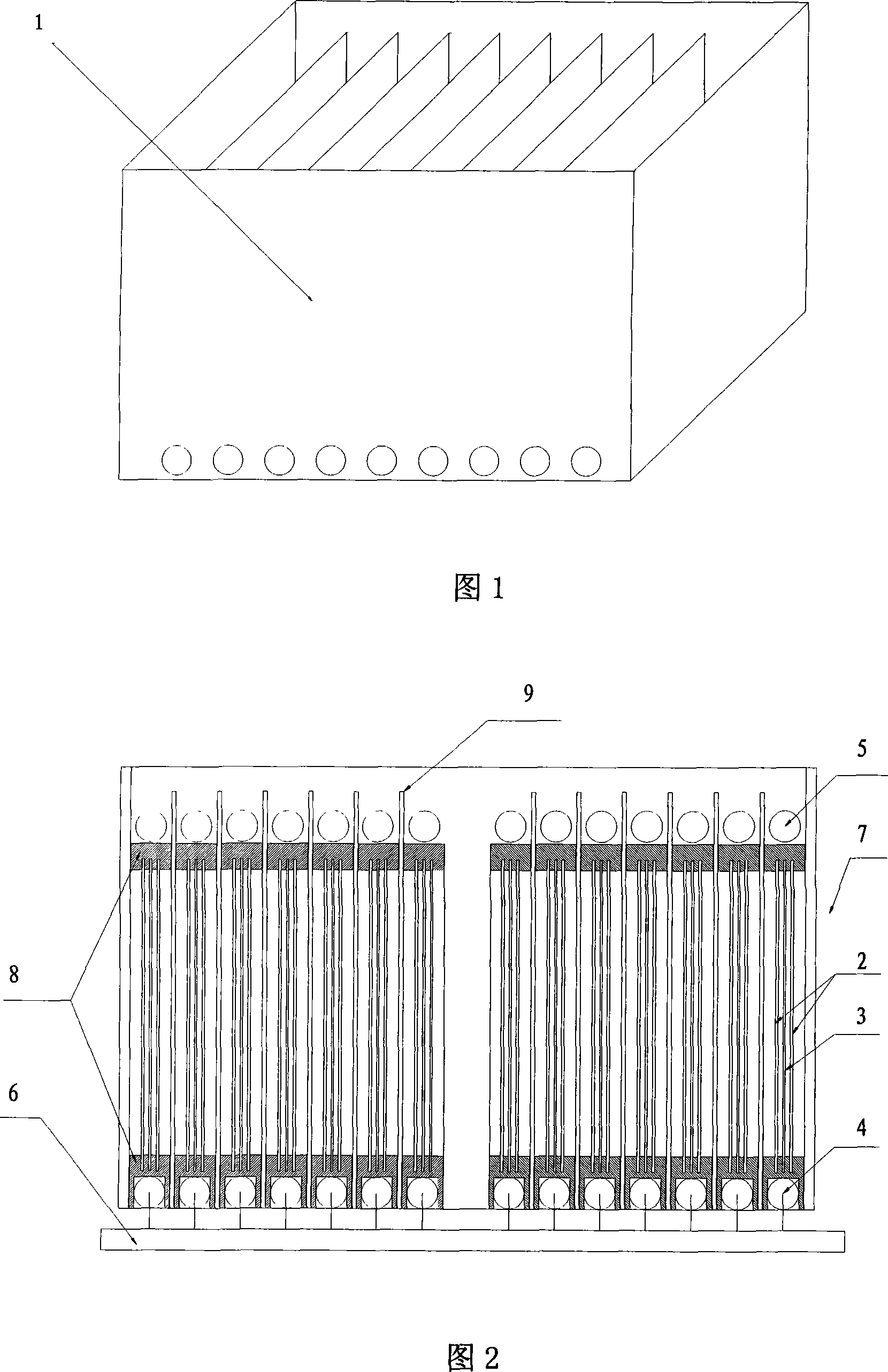

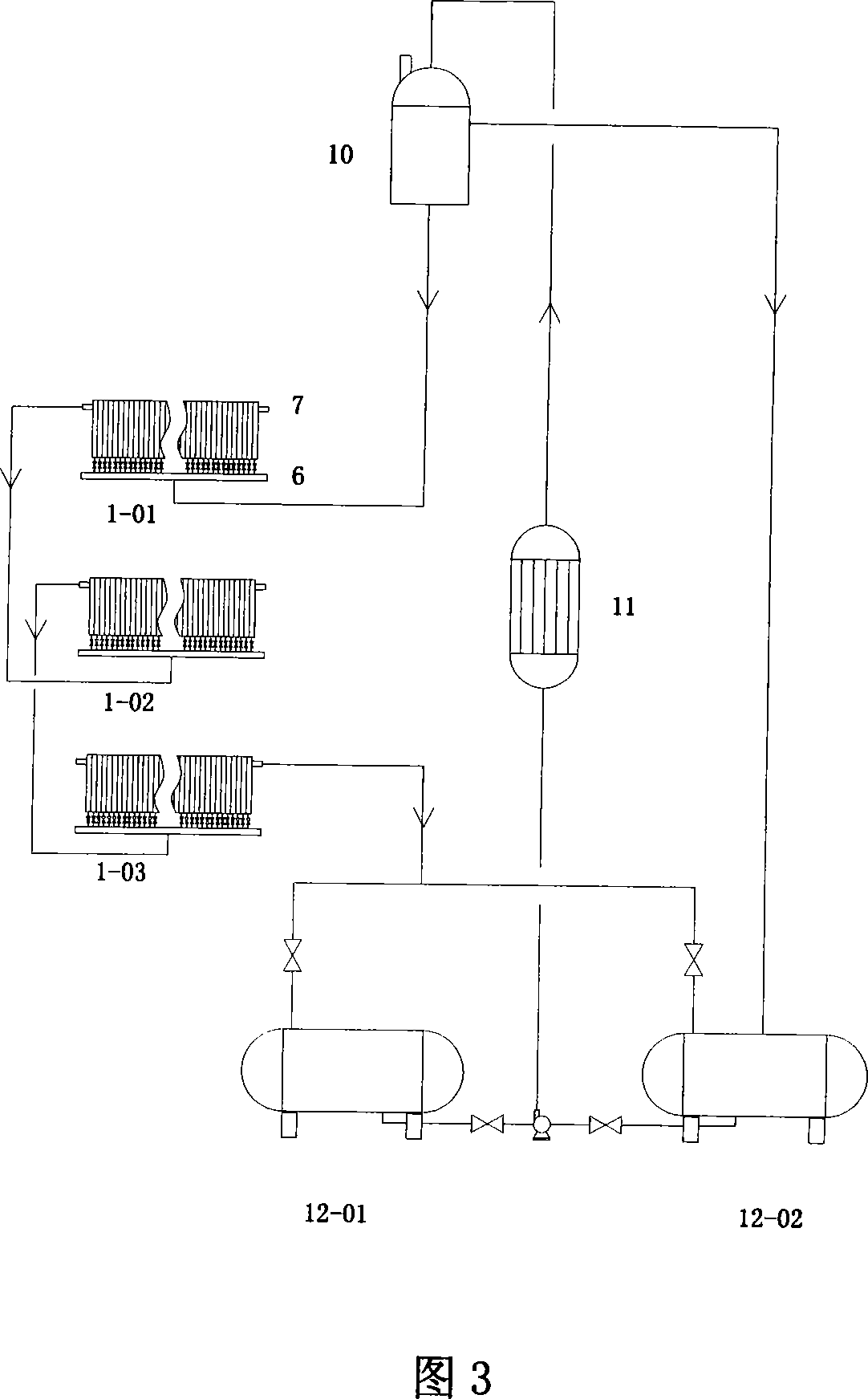

[0038]A device for electrolytically synthesizing succinic acid without a diaphragm: the electrolytic cell includes an electrolytic cell body 1-01 formed by connecting 30 unit cells in series, an electrolytic cell body 1-02 formed by connecting 30 unit cells in series, and 30 units The electrolytic cell body 1-03 formed by connecting the cells in series, and the three sets of electrolytic cell bodies 1-01, 1-02, and 1-03 are connected in series, and the electrolytic cell body is divided into several unit cells by a separator 9 , the unit cell includes a cavity, a lead alloy double cathode 2, a titanium-iridium-tantalum oxide anode 3, and all the unit cells are connected in series; the cell cells of the electrolytic cell group 1-01 pass through their respective The electrolyte inlet 4 is communicated with the electrolyte distribution pipe 6, and the unit cells are communicated with the electrolyte collector 7 through their respective electrolyte outlets 5, and the electrolyte dis...

Embodiment 2

[0041] Replace the electrolytic cell body with 2 groups, each group has 50 unit cells, each unit cell is connected in series, and the electrolytic cell groups are connected in parallel, and other devices are the same as those in the first embodiment. The process steps are the same as in Example 1, 6000L of succinic acid mother liquor (5-10% sulfuric acid), and 600kg of maleic anhydride is added at the beginning of electrolysis, the electrolyte temperature is 50-60°C, and the current density is 300-900A / m 2 electrolysis under conditions. After the electrolysis, the electrolyte was decolorized, cooled and crystallized for 4-8 hours, filtered and dried to obtain 670 kg of colorless succinic acid crystals. The melting point is 185.6-187.2°C, the content of easy oxides is less than 0.06%, the cell voltage is 2.5-3.4V, the electrolytic unit consumption is 895.5kg maleic anhydride / ton succinic acid, and the current efficiency is 90.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com