Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

A technology of aluminum-air battery and nanocrystalline aluminum, which is applied in fuel cell-type half-cells and primary battery-type half-cells, battery electrodes, circuits, etc., and can solve the problem that aluminum anodes hinder the development and application of aluminum-air batteries, aluminum-air batteries Problems such as commercial application and unresolved key issues can achieve the effects of good electrochemical activation, improved anode utilization, and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

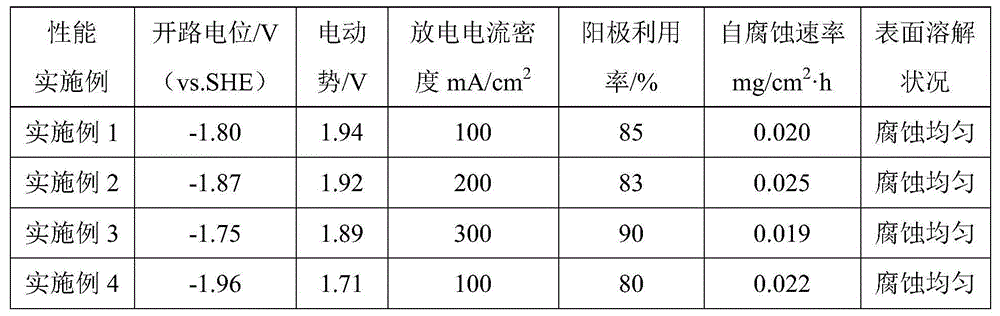

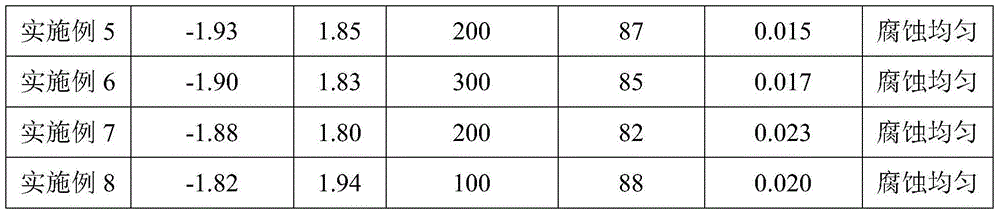

Examples

Embodiment 1

[0029] In this embodiment, the rare earth-containing amorphous / nanocrystalline aluminum anode composite material is composed of the following components in percentage by weight: Mg 0.5%, Sn 2%, Ga 1%, La 0.5%, and the balance is Al, Al Purity≥99.8%.

[0030] The preparation method of the rare earth-containing amorphous / nanocrystalline aluminum anode composite material in this embodiment comprises the following steps:

[0031] (1) Under the protection of argon, when the temperature is 700 ° C, the aluminum ingots are completely melted in the crucible of the ZGJL0.01-40-4 induction melting furnace, and then magnesium ingots, lanthanum-containing aluminum rare earth master alloy (Al-10% La ), tin grains and corn grains, rotate the container while heating to mix the molten metal evenly, continue heating to 760°C, keep warm for 6 minutes, and pour into block-shaped flat ingots;

[0032] (2) After crushing the cast alloy ingot, put it into a quartz tube with a flat opening at the b...

Embodiment 2

[0036] In this embodiment, the rare earth-containing amorphous / nanocrystalline aluminum anode composite material is composed of the following components in percentage by weight: Mg 5%, Sn 0.5%, Ga 0.02%, La 4%, and the balance is Al, Al Purity≥99.8%.

[0037] The preparation method of the rare earth-containing amorphous / nanocrystalline aluminum anode composite material in this embodiment comprises the following steps:

[0038] (1) Under the protection of argon, when the temperature is 710 ° C, the aluminum ingots are completely melted in the crucible of the ZGJL0.01-40-4 induction melting furnace, and then magnesium ingots, lanthanum-containing aluminum rare earth master alloy (Al-10% La ), tin grains and corn grains, rotate the container while heating to mix the molten metal evenly, continue heating to 750°C, keep warm for 10 minutes, and pour into block-shaped flat ingots;

[0039] (2) After crushing the cast alloy ingot, put it into a quartz tube with a flat opening at the...

Embodiment 3

[0043] In this embodiment, the rare earth-containing amorphous / nanocrystalline aluminum anode composite material is composed of the following components in percentage by weight: Mg 1%, Sn 1%, Ga 2%, La 5%, and the balance is Al, Al Purity≥99.8%.

[0044] The preparation method of the rare earth-containing amorphous / nanocrystalline aluminum anode composite material in this embodiment comprises the following steps:

[0045] (1) Under the protection of argon, when the temperature is 670 ° C, all the aluminum ingots are melted in the crucible of the ZGJL0.01-40-4 induction melting furnace, and then magnesium ingots, lanthanum-containing aluminum rare earth master alloy (Al-10% La ), tin grains and corn grains, rotate the container while heating to mix the molten metal evenly, continue heating to 770 ° C, keep warm for 5 minutes, and pour into block-shaped flat ingots;

[0046] (2) After crushing the cast alloy ingot, put it into a quartz tube with a flat opening at the bottom, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com