Anode material for high-power aluminum air battery at low temperature and preparation method of anode material

An aluminum-air battery and anode material technology, which is applied in battery electrodes, fuel cell-type half-cells and primary battery-type half-cells, circuits, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The above-mentioned preparation method for the high-power aluminum-air battery anode material at low temperature includes:

[0024] The batching method adopted is as follows: Mg, Mn, Bi and 997 industrial pure aluminum are added in block form, and Sn is added in the form of Al-50% Sn master alloy. Wrap with aluminum foil when adding to avoid burning phenomenon.

[0025] Put the cut 997 industrial pure aluminum block into the preheated graphite crucible and heat it with an intermediate frequency furnace. When the temperature rises to 710-740°C, add an intermediate alloy containing Mg, Mn, Bi and Al-50%Sn Elements of aluminum foil, and stir slowly to combine. At this time, the temperature will drop to 710-730°C, hold the temperature for 5-8 minutes, remove the slag, and cast it in a water-cooled copper mold to make an ingot.

[0026] The obtained ingot is placed in a suspension furnace, kept at 420-650°C for 1-3 hours, then water-cooled, the surface scale is milled off ...

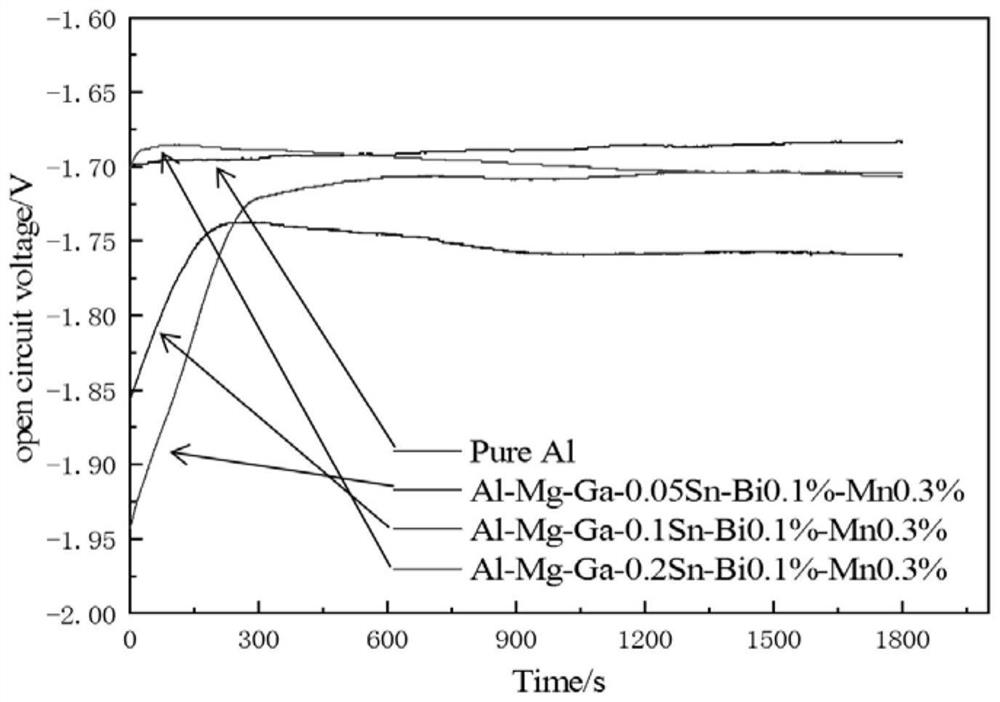

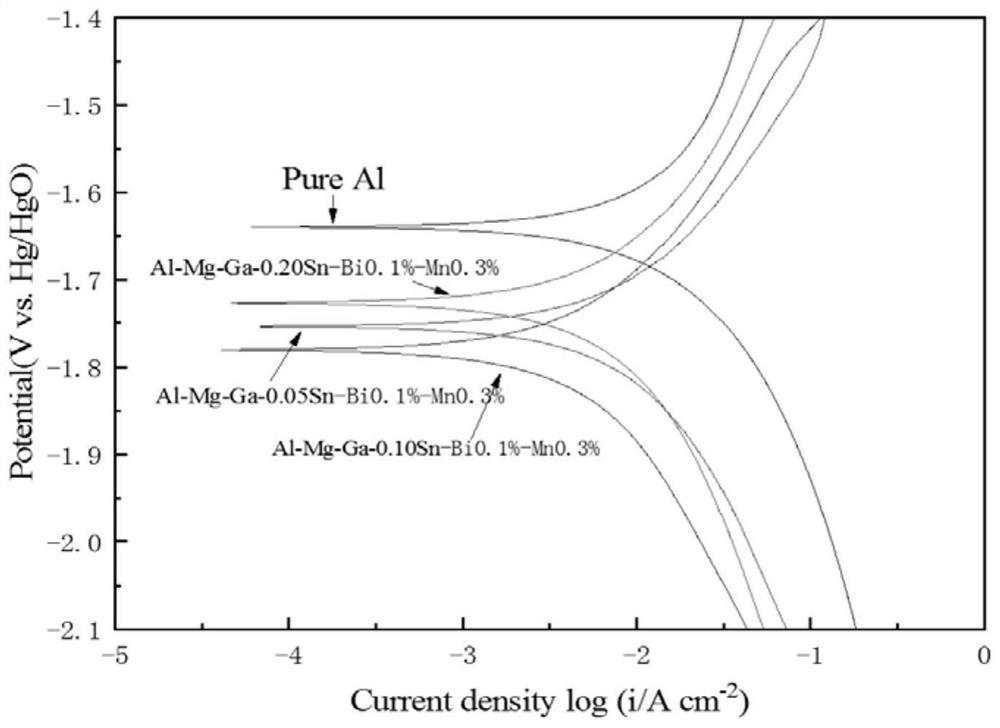

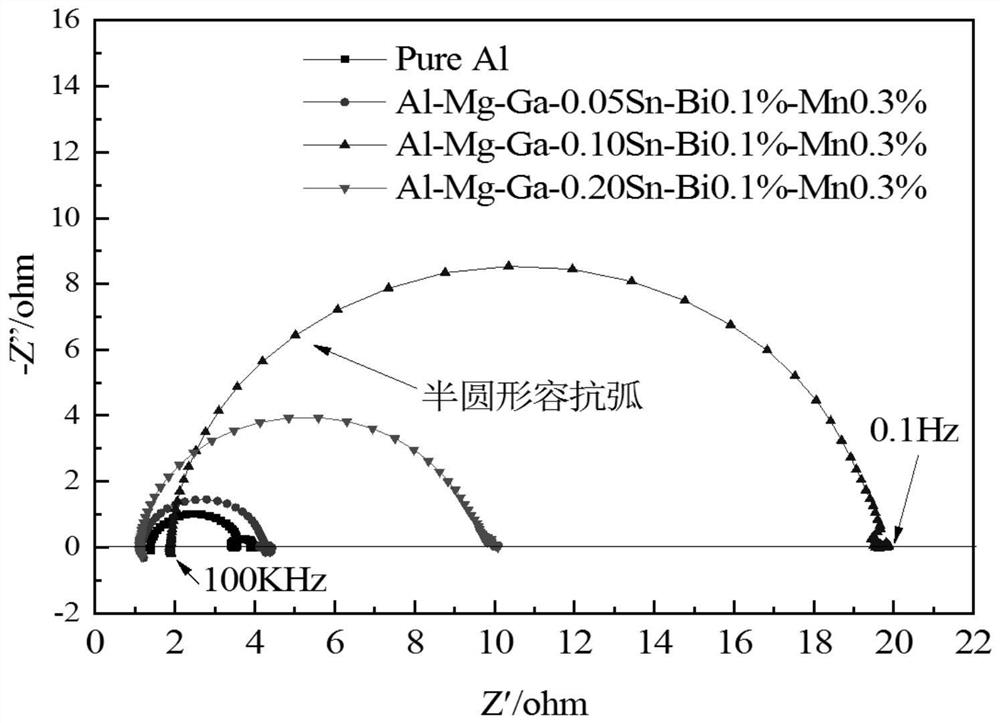

Embodiment 1

[0029] A high-power aluminum-air battery anode material for low temperature, including: Mg0.4%, Sn0.05%, Bi0.1%, Mn0.3%, and the rest is 997 industrial pure aluminum.

[0030] The above-mentioned preparation method for the high-power aluminum-air battery anode material at low temperature comprises the following steps:

[0031] Put the 997 industrial pure aluminum block into the preheated graphite crucible, put the graphite crucible into the heating furnace and heat until all the pure aluminum is melted to form an aluminum melt;

[0032] Add Mg, Sn (Al-50% Sn intermediate alloy form), Bi, Mn aluminum foil to the molten aluminum melt at 720°C, and stir until the material is completely melted to obtain a mixed melt; The body contains 0.4% Mg, 0.05% Sn, 0.1% Bi, 0.3% Mn by mass percentage, and the rest is 997 industrial pure Al;

[0033] Heat at 720°C for 5 minutes and stir evenly;

[0034] After the heat preservation is over, remove the slag, and then cast it into a copper wate...

Embodiment 2

[0038] A high-power aluminum-air battery anode material for low temperature, including: Mg0.4%, Sn0.1%, Bi0.1%, Mn0.3%, and the rest is 997 industrial pure Al.

[0039] The above-mentioned preparation method for the high-power aluminum-air battery anode material at low temperature comprises the following steps:

[0040] Put the 997 industrial pure aluminum block into the preheated graphite crucible, put the graphite crucible into the heating furnace and heat until all the pure aluminum is melted to form an aluminum melt;

[0041] Add Mg, Sn (Al-50% Sn intermediate alloy form), Bi, Mn aluminum foil to the molten aluminum melt at 720°C, and stir until the material is completely melted to obtain a mixed melt; The body contains 0.4% Mg, 0.1% Sn, 0.1% Bi, 0.3% Mn by mass percentage, and the rest is 997 industrial pure Al;

[0042] Heat at 720°C for 5 minutes and stir evenly;

[0043] After the heat preservation is completed, remove the slag, and then cast it into a copper water-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com