Patents

Literature

96 results about "Liquid cathode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

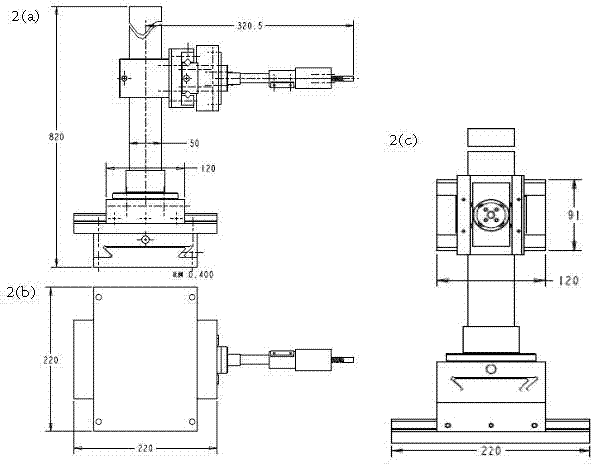

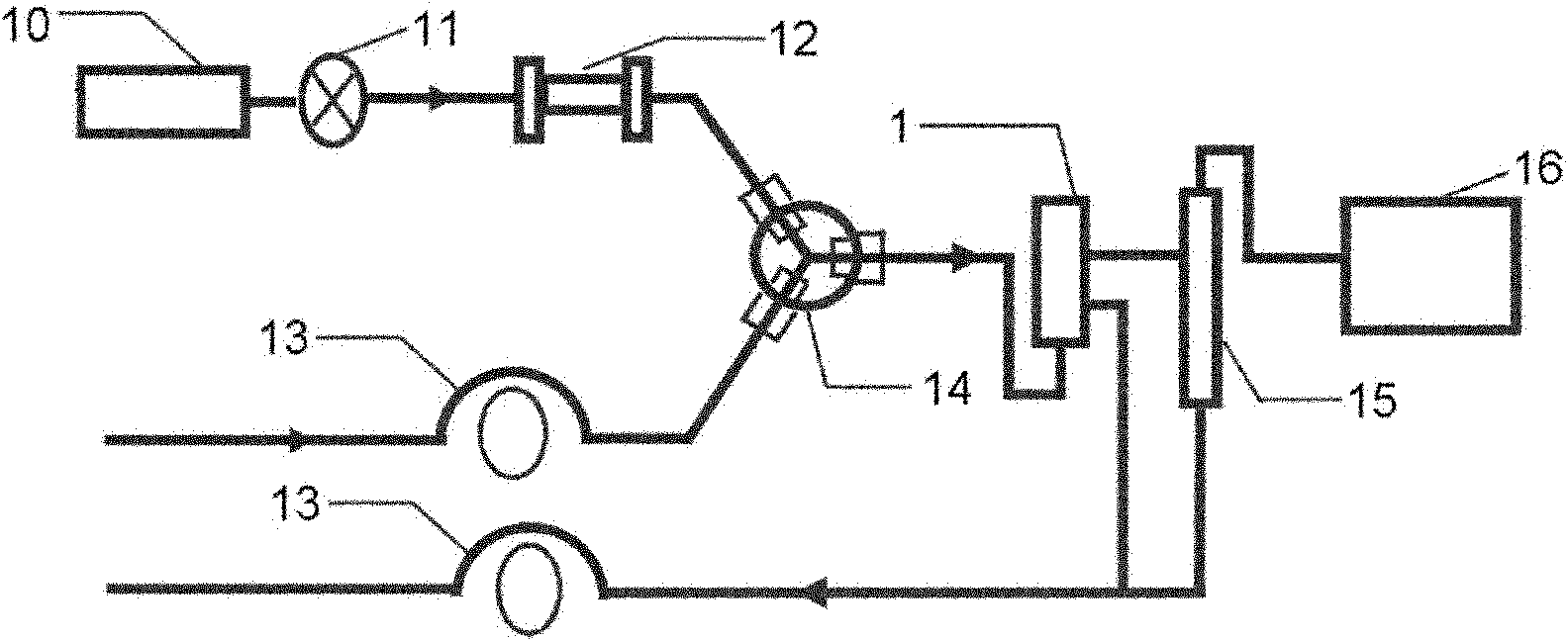

Liquid cathode glow discharge emission spectrum detection metal ion apparatus

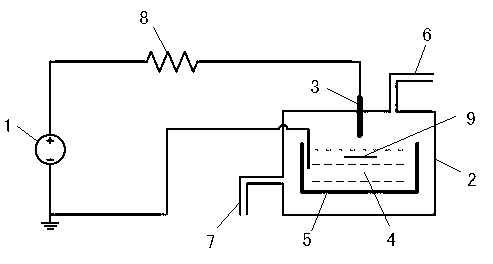

InactiveCN103163116ASimple structureReduce volumeAnalysis by electrical excitationProcess systemsHigh pressure

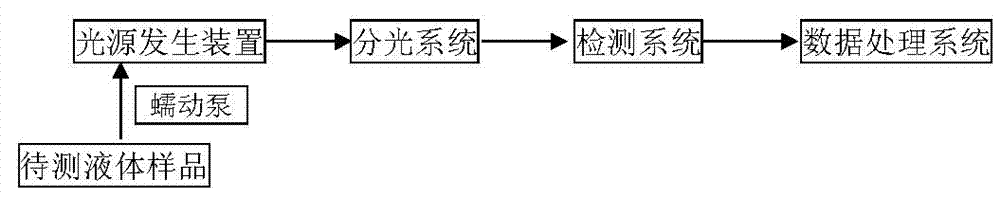

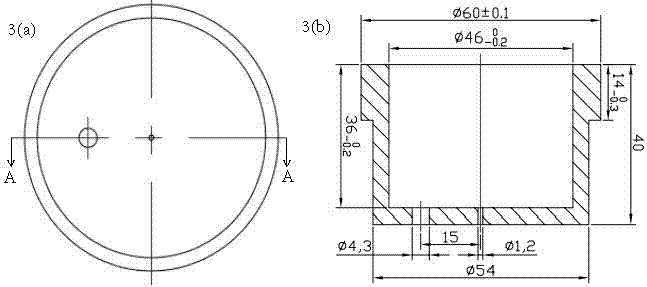

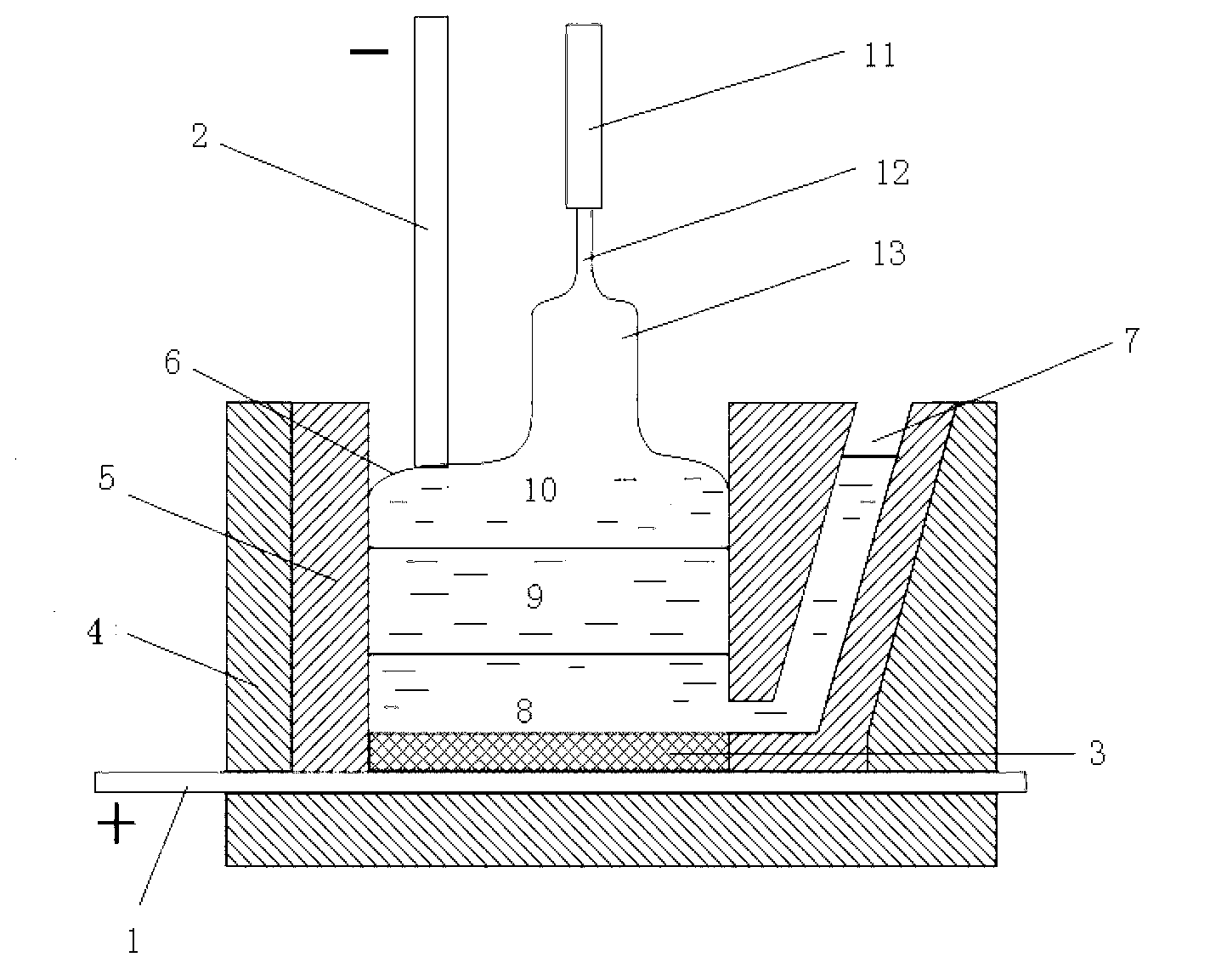

The invention relates to a liquid cathode glow discharge emission spectrum detection metal ion apparatus, which comprises a light source generation part used for generating glow discharge, a splitting system used for performing light splitting treatment on glow discharge emission spectrum generated by the light source generation part, a detection apparatus used for detecting the emission spectrum after light splitting treatment, and a data process system used for analyzing and processing the signals of the detection apparatus; wherein, the light source generation part comprises a metal anode connected to the anode of high voltage supply, a liquid pool filled with an electrolyte connected to the cathode of the high voltage supply; and a sample introduction unit, which comprises a sample introduction pipe which is vertically passed through the liquid pool, and the top of the sample introduction pipe is positioned below the metal anode; the sample introduction unit enables a solution to be measured to escape from the top of the sample introduction pipe, thereby the solution to be measured overflowed from the top of the sample introduction pipe and the metal anode form a glow discharge area.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

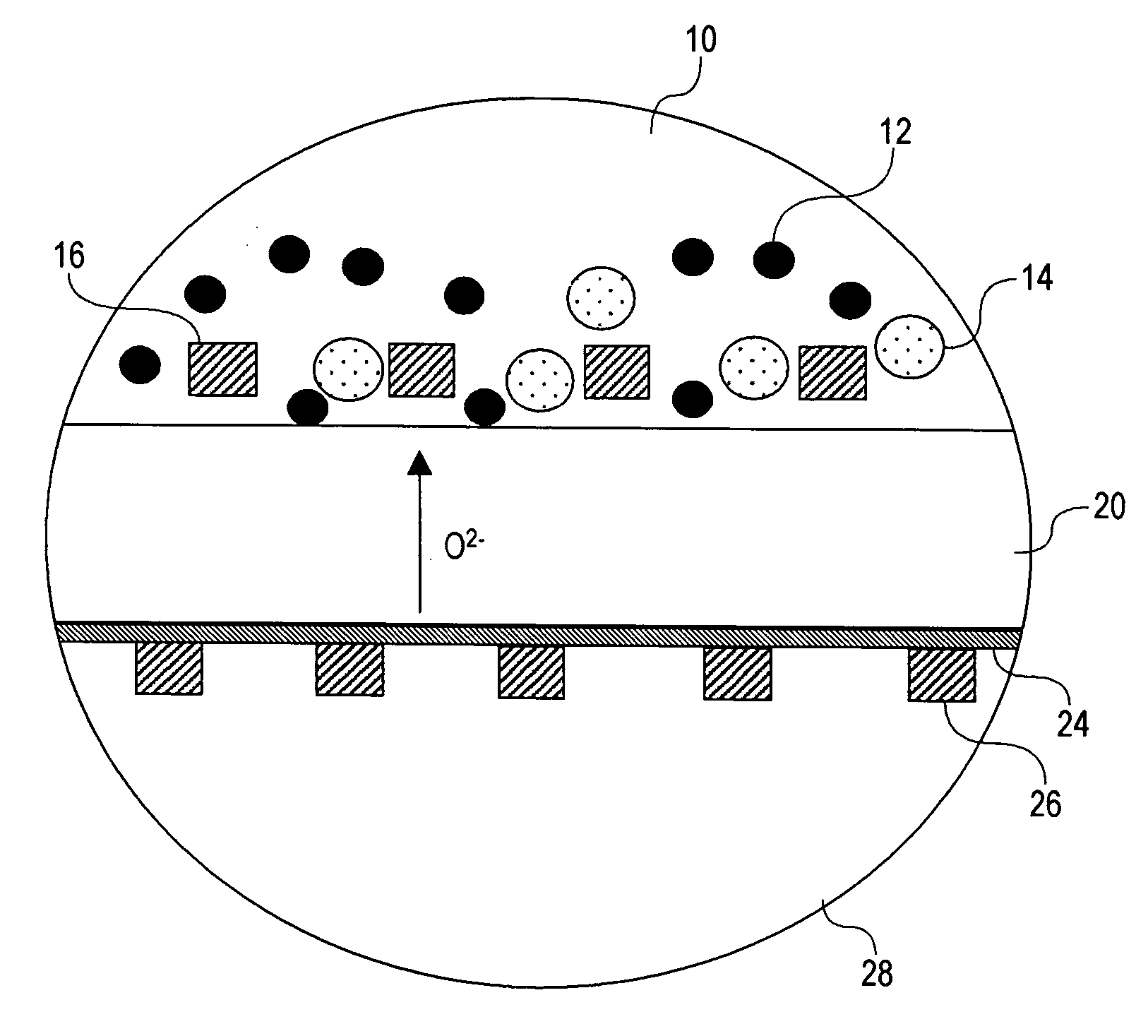

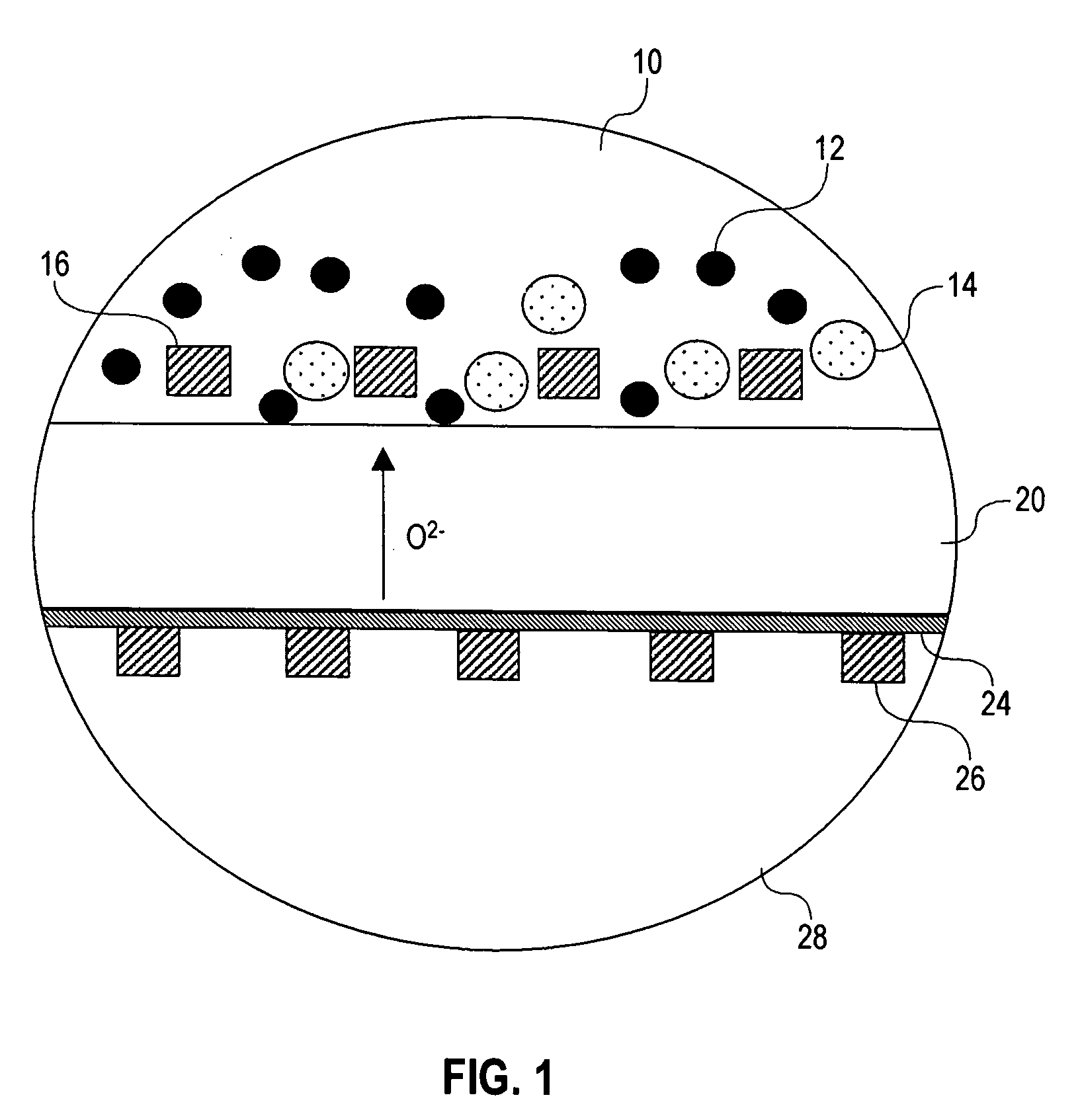

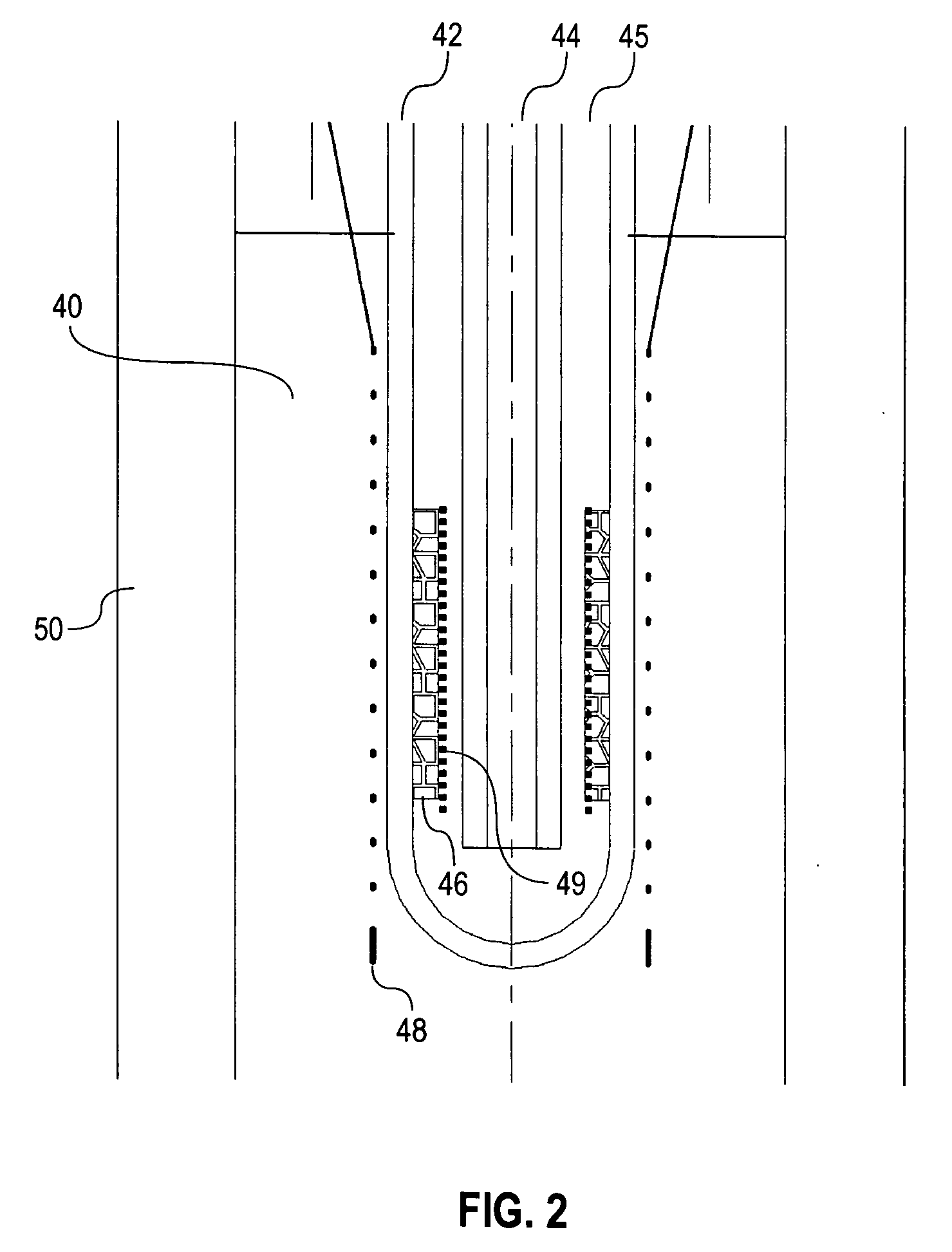

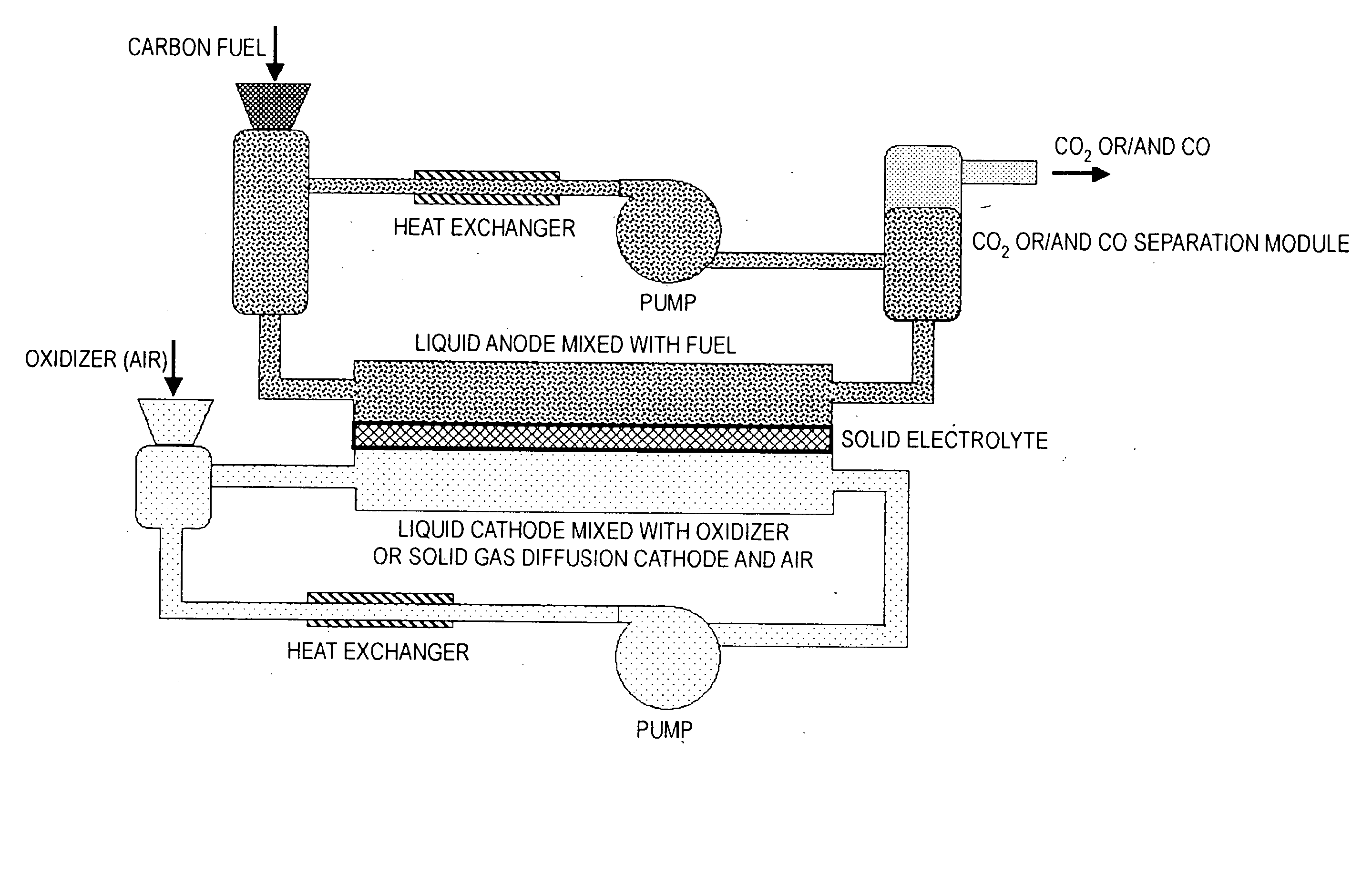

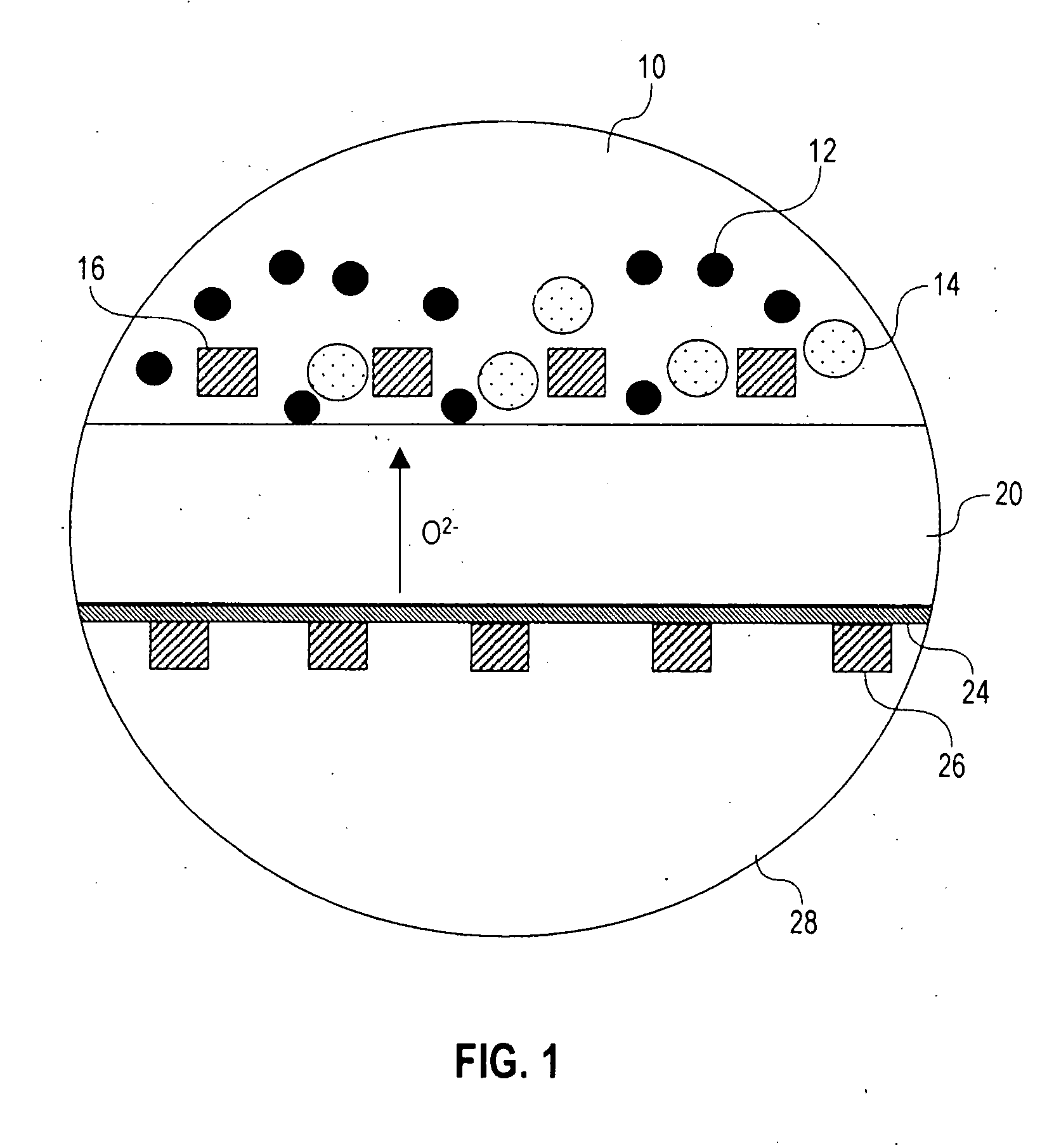

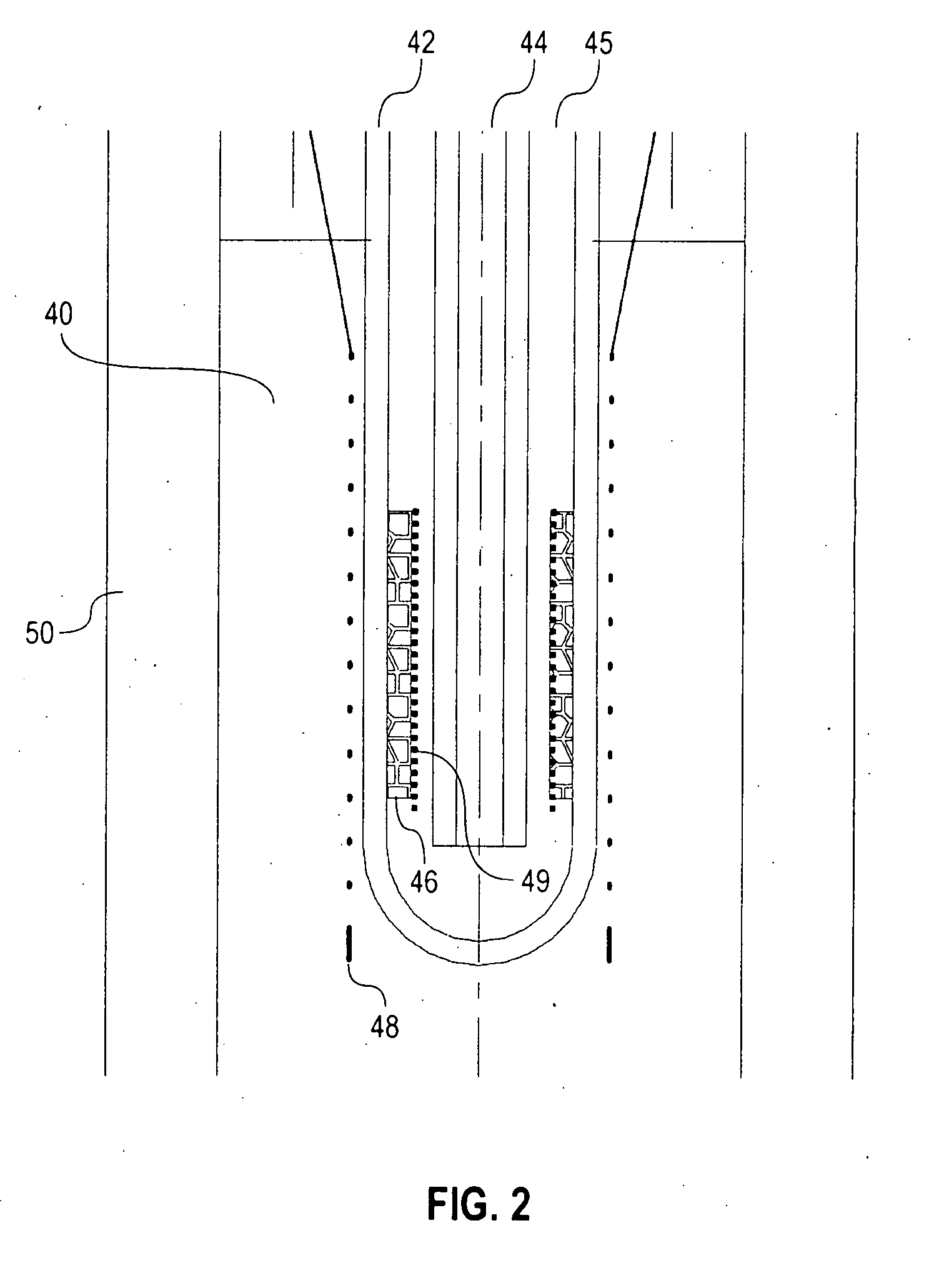

Liquid anode electrochemical cell

InactiveUS20060019132A1High voltageIncrease powerFuel cells groupingCell electrodesFuel cellsLiquid cathode

An electrochemical cell is provided which has a liquid anode. Preferably the liquid anode comprises molten salt and a fuel, which preferably has a significant elemental carbon content. The supply of fuel is preferably continuously replenished in the anode. Where the fuel contains or pyrolizes to elemental carbon, the reaction C+2O2−→CO2+4e− may occur at the anode. The electrochemical cell preferably has a solid electrolyte, which may be yttrium stabilized zirconia (YSZ). The electrolyte is connected to a solid or liquid cathode, which is given a supply of an oxidizer such as air. An ion such as O2− passes through the electrolyte. If O2− passes through the electrolyte from the anode to the cathode, a possible reaction at the cathode may be O2+4e−→2O2−. The electrochemical cell of the invention is preferably operated as a fuel cell, consuming fuel and producing electrical current.

Owner:SRI INTERNATIONAL

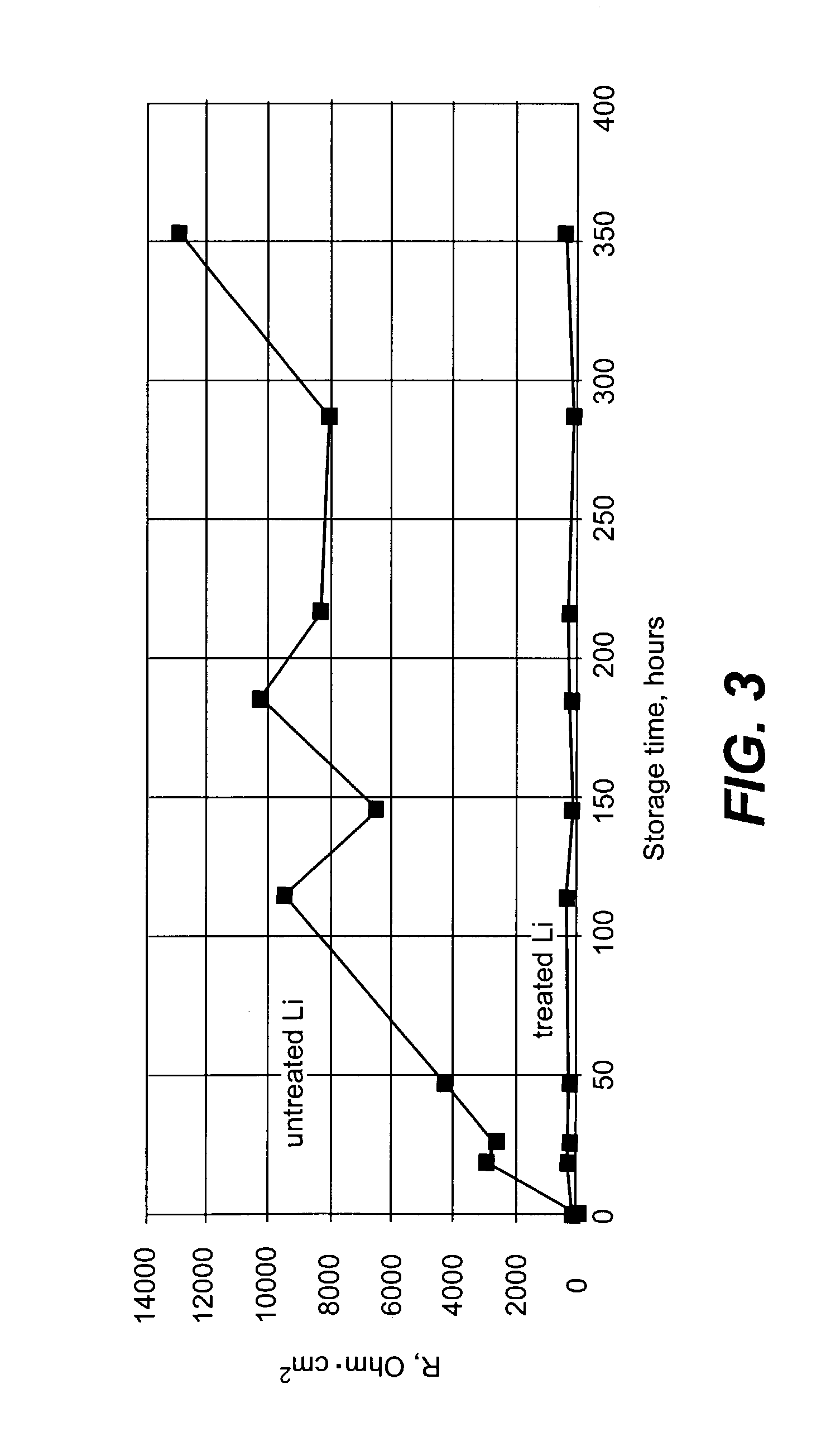

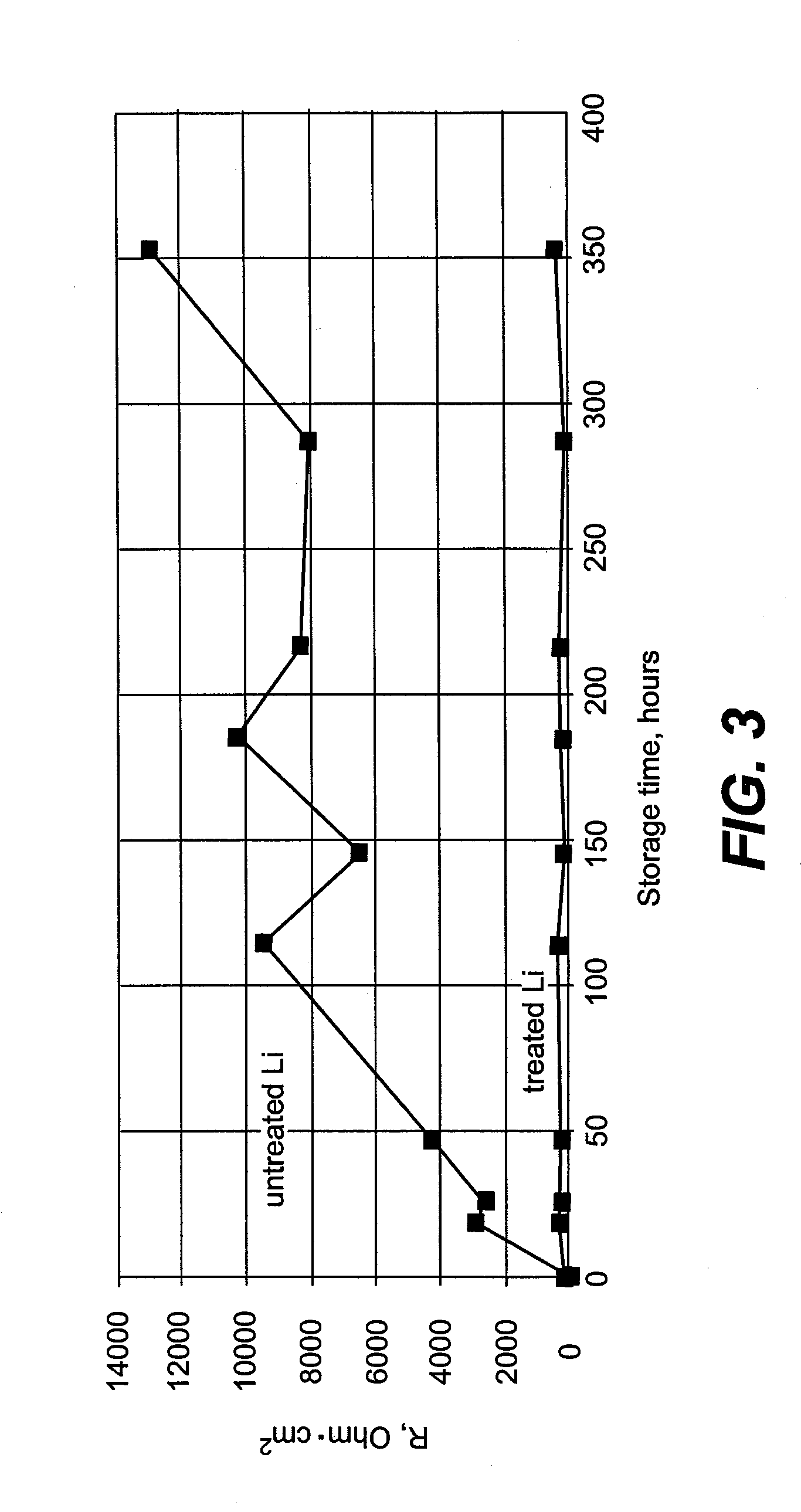

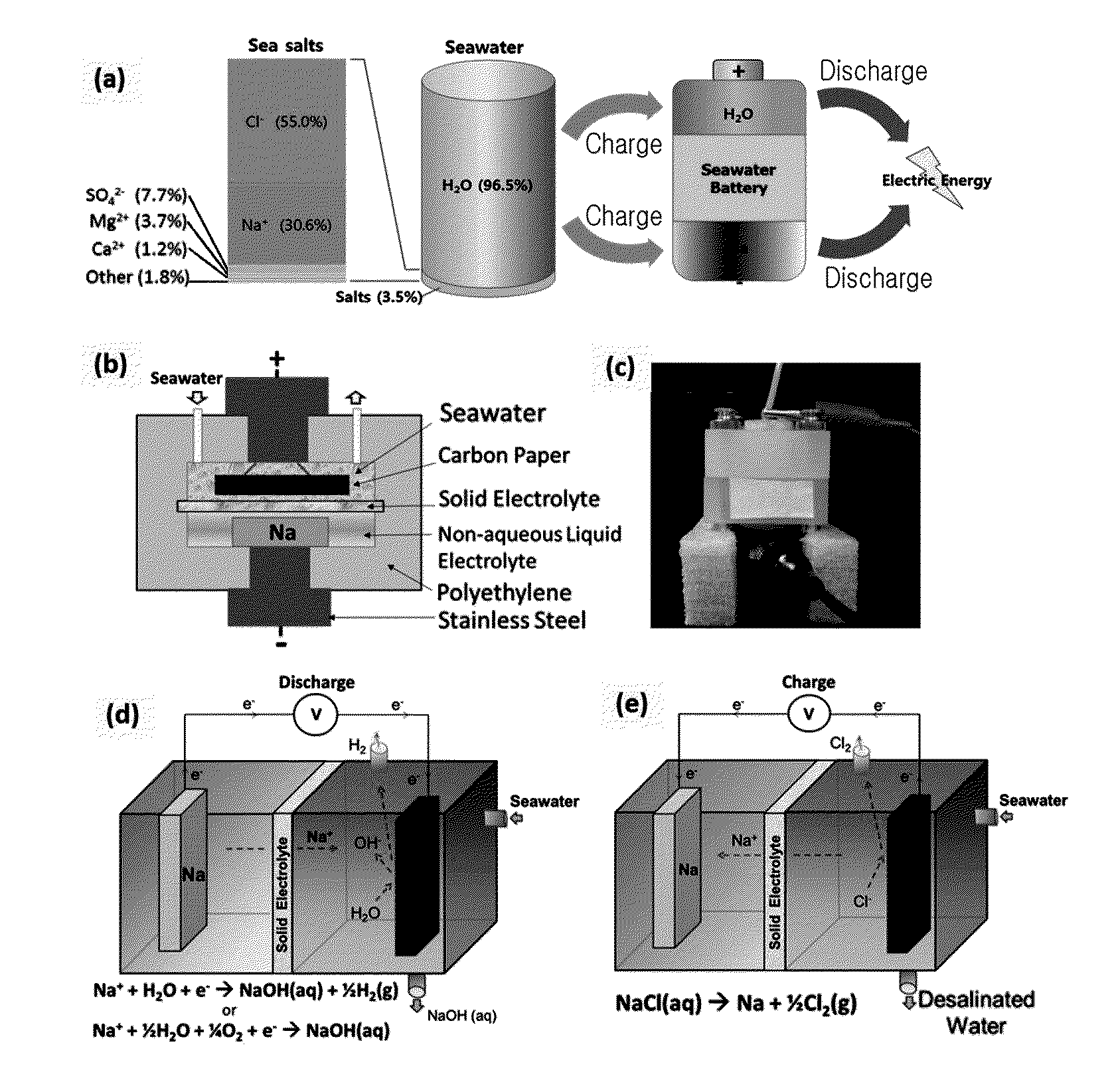

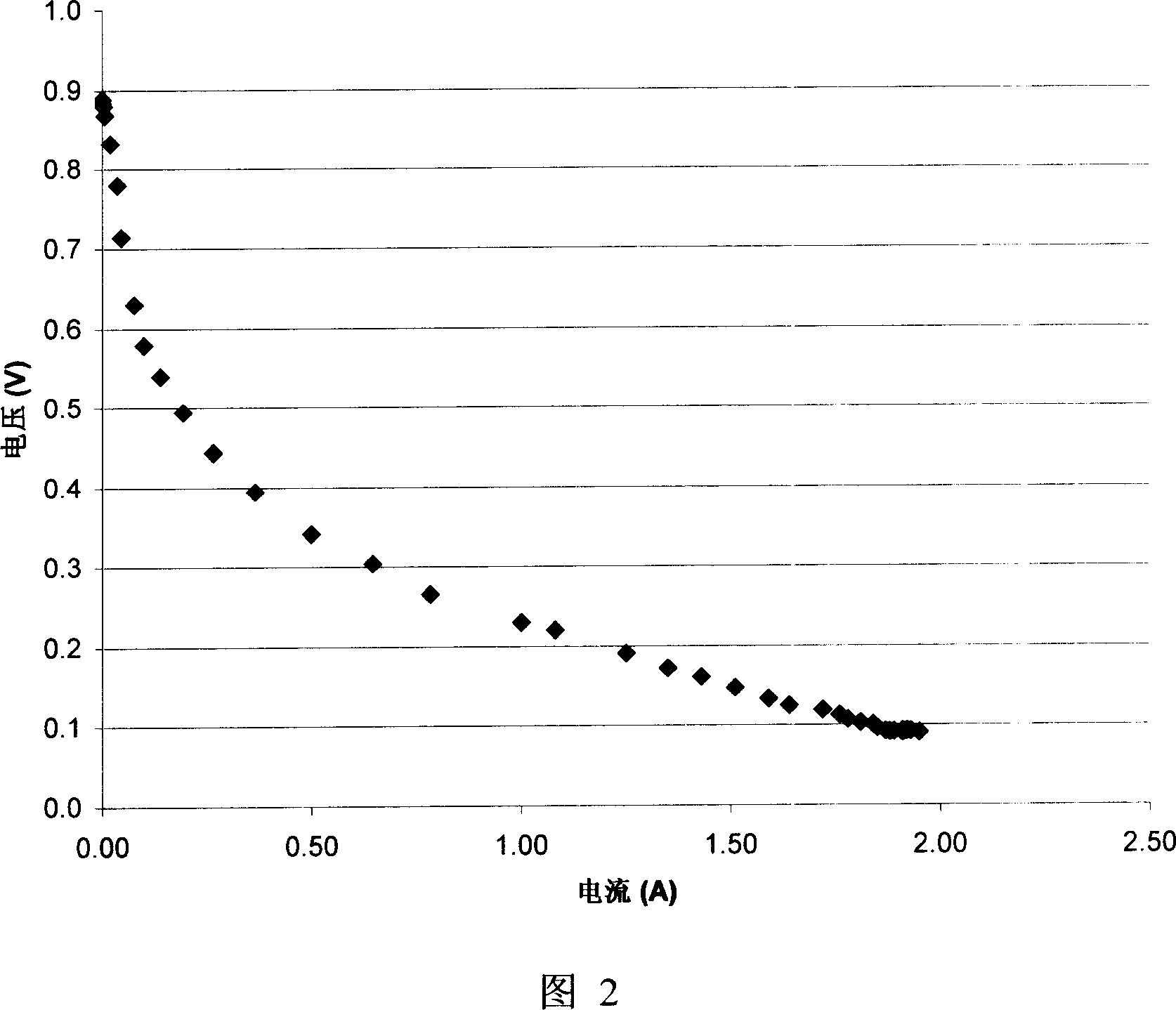

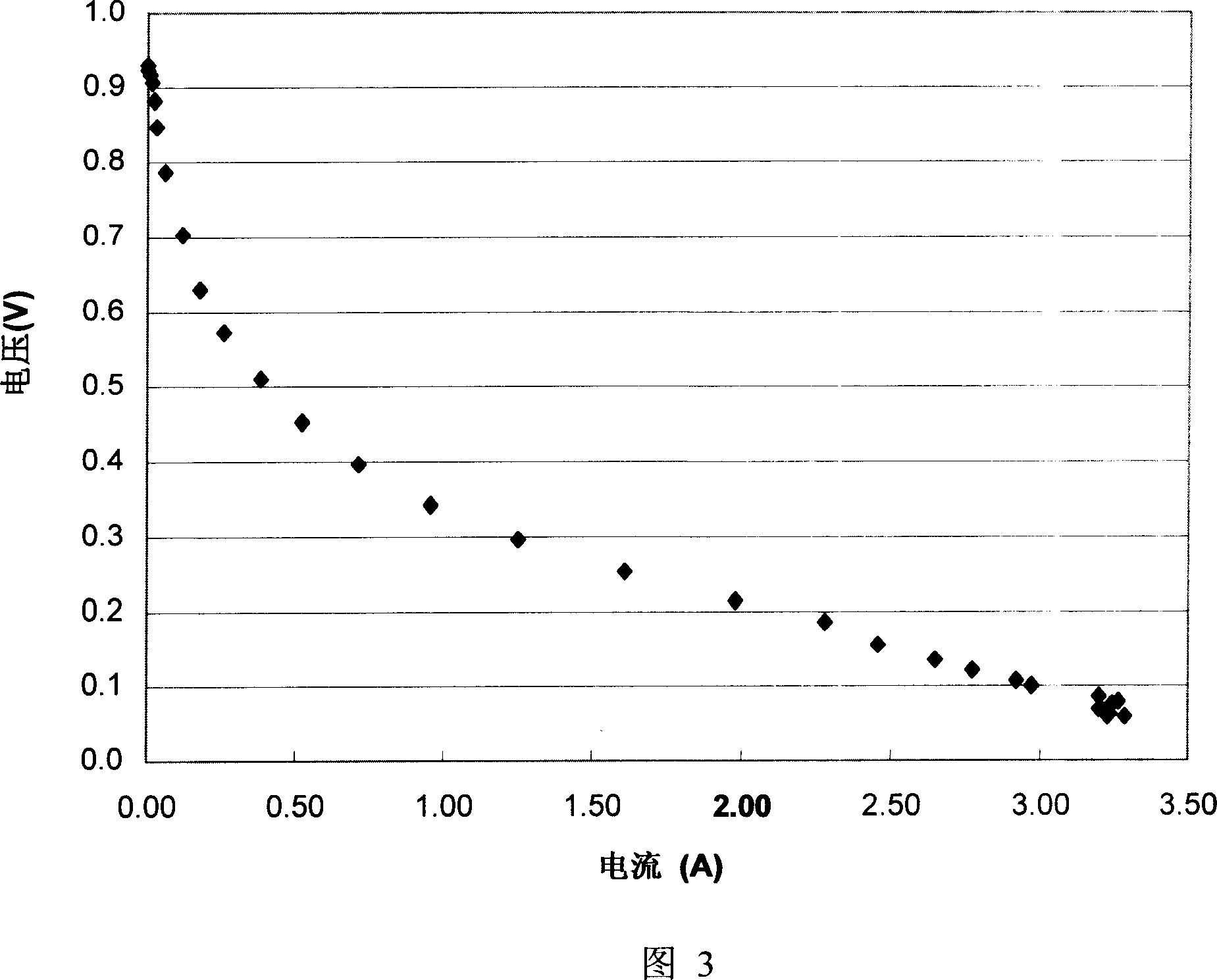

Alleviation of voltage delay in lithium-liquid depolarizer/electrolyte solvent battery cells

InactiveUS7482096B2Reduce degradationImprove stabilityElectrode manufacturing processesSolid electrolyte cellsChemical treatmentInorganic compound

Voltage delay in an active metal anode / liquid cathode battery cell can be significantly reduced or completely alleviated by coating the active metal anode (e.g., Li) surface with a thin layer of an inorganic compound with Li-ion conductivity using chemical treatment of Li surface. Particularly, preferred examples of such compounds include lithium phosphate, lithium metaphosphate, and / or their mixtures or solid solutions with lithium sulphate. These compounds can be formed on the Li surface by treatment with diluted solutions of the following individual acids: H3PO4, HPO3 and H2SO4, their acidic salts, or their binary or ternary mixtures in a dry organic solvent compatible with Li, for instance in 1,2-DME; by various deposition techniques. Such chemical protection of the Li or other active metal electrode significantly reduces the voltage delay due to protected anode's improved stability toward the electrolyte.

Owner:POLYPLUS BATTERY CO INC

Copper bus bar with high strength, high conductivity and high toughness and preparation method thereof

InactiveCN102034563AImprove conductivityImprove equipment technologySingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesLiquid cathodeLiquid copper

The invention relates to a copper bus bar with high strength, high conductivity and high toughness and a preparation method thereof. The copper bus bar is characterized in that the material comprises 99.96-99.998% of copper and silver, 0.002-0.02% of yttrium rare earth and 0-0.038% of impurities, wherein silver accounts for 0.0005-0.01% of copper and silver; and the copper master alloy containing the yttrium rare earth is used as a modifier. The preparation method comprises the following steps: (1) melting a copper material: heating the cathode copper in a mains frequency core induction furnace to melt the cathode copper into liquid cathode copper; (2) modifying liquid copper: melting the modifier in the liquid cathode copper and fully mixing the modifier with the liquid cathode copper; (3) drawing a continuously cast copper bar upwards: causing a crystallizer of a continuous casting machine to stretch into the liquid cathode copper, condensing the liquid cathode copper into the copper bar in the crystallizer and drawing the copper bar upwards by means of two pairs of drawing roll mechanisms in the continuous casting machine to lead the copper bar to a take-up machine via a wheel frame; (4) continuously extruding the copper bar at medium temperature and carrying out anti-oxidation cooling; and (5) carrying out draw forming: putting copper bus bar blanks on a drawing machine, carrying out draw forming on the copper bus bar blanks.

Owner:福州市广福有色金属制品有限公司

Liquid anode electrochemical cell

Owner:SRI INTERNATIONAL

Method for producing aluminum-magnesium alloy by utilizing liquid aluminum cathode method

The invention discloses a method for producing an aluminum-magnesium alloy by utilizing a liquid aluminum cathode method. The method is used for high-efficiently producing the high-quality aluminum-magnesium alloy. The method comprises the following steps of dissolving the high-purity magnesium oxide (MgO) in an electrolyte system consisting of Na3PO3-MgF2-NaCl in an electrolytic cell under the electrolytic temperature of 850DEG C to 900DEG C, wherein the aluminum liquid which is formed by melting a high-purity aluminum ingot is used as a liquid cathode; and applying a coil magnetic field with the intensity of 30mT to 40mT outside the electrolytic cell so as to enable the aluminum liquid to rotate under the electrolytic conditions that the anode current density is 0.47 to 0.52A / cm<2> and the high-purity graphite is adopted as an anode, reducing the magnesium ions on the rotating aluminum liquid cathode into elemental magnesium under the electromagnetic stirring effect to be uniformly dispersed into the aluminum liquid so as to form the aluminum-magnesium alloy product, and producing CO2 gas on the anode. The alloy prepared through the method is uniform in components and contains no impurity. The production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

Extraction of Liquid Elements by Electrolysis of Oxides

An electrolytic extraction method wins a target element from an oxide feedstock compound thereof. The feedstock compound is dissolved in an oxide melt in contact with a cathode and an anode in an electrolytic cell. During electrolysis the target element is deposited at a liquid cathode and coalesces therewith. Oxygen is evolved on an anode bearing a solid oxide layer, in contact with the oxide melt, over a metallic anode substrate.

Owner:MASSACHUSETTS INST OF TECH

Process for preparing rare earth-magnesium intermediate alloy by compound cathode molten salt electrolysis

InactiveCN1807697AAvoid it happening againIncrease production capacityHigh concentrationElectrolysis

The invention discloses an electrolyzing rare earth-magnesium hardener preparing method, which is characterized by the following: realizing the coexistence of floating upward liquid magnesium cathode, subsidence liquid high concentration rare-earth magnesium cathode and medium density rare-earth magnesium liquid cathode; depositing electrochemistry on the emission surface of three dimensions; Improving productivity with the same ampere density; avoiding producing furnace accretion and improving product quality with the same deliverability; making the dendrite hard to generate on the surface of electrochemical deposition by moving dynamic cathode. The invention simplifies the electrolytic craft, which reduces the cost.

Owner:LINJIANG DONGFENG NON FERROUS METALS

Alleviation of voltage delay in lithium-liquid depolarizer/electrolyte solvent battery cells

InactiveUS20090071835A1Reduce degradationImprove stabilityElectrode manufacturing processesVacuum evaporation coatingChemical treatmentInorganic compound

Voltage delay in an active metal anode / liquid cathode battery cell can be significantly reduced or completely alleviated by coating the active metal anode (e.g., Li) surface with a thin layer of an inorganic compound with Li-ion conductivity using chemical treatment of Li surface. Particularly, preferred examples of such compounds include lithium phosphate, lithium metaphosphate, and / or their mixtures or solid solutions with lithium sulphate. These compounds can be formed on the Li surface by treatment with diluted solutions of the following individual acids: H3PO4, HPO3 and H2SO4, their acidic salts, or their binary or ternary mixtures in a dry organic solvent compatible with Li, for instance in 1,2-DME; by various deposition techniques. Such chemical protection of the Li or other active metal electrode significantly reduces the voltage delay due to protected anode's improved stability toward the electrolyte.

Owner:POLYPLUS BATTERY CO INC

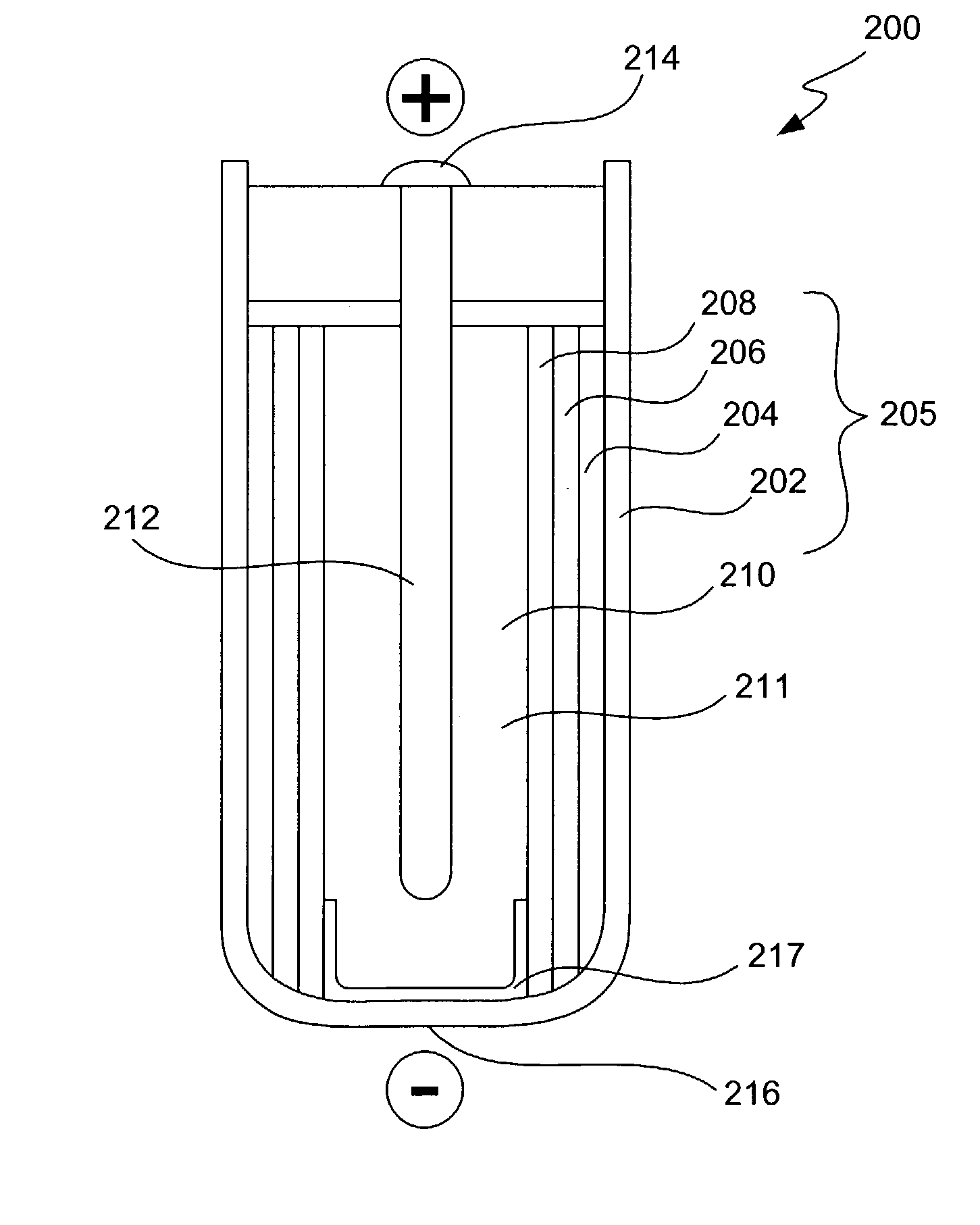

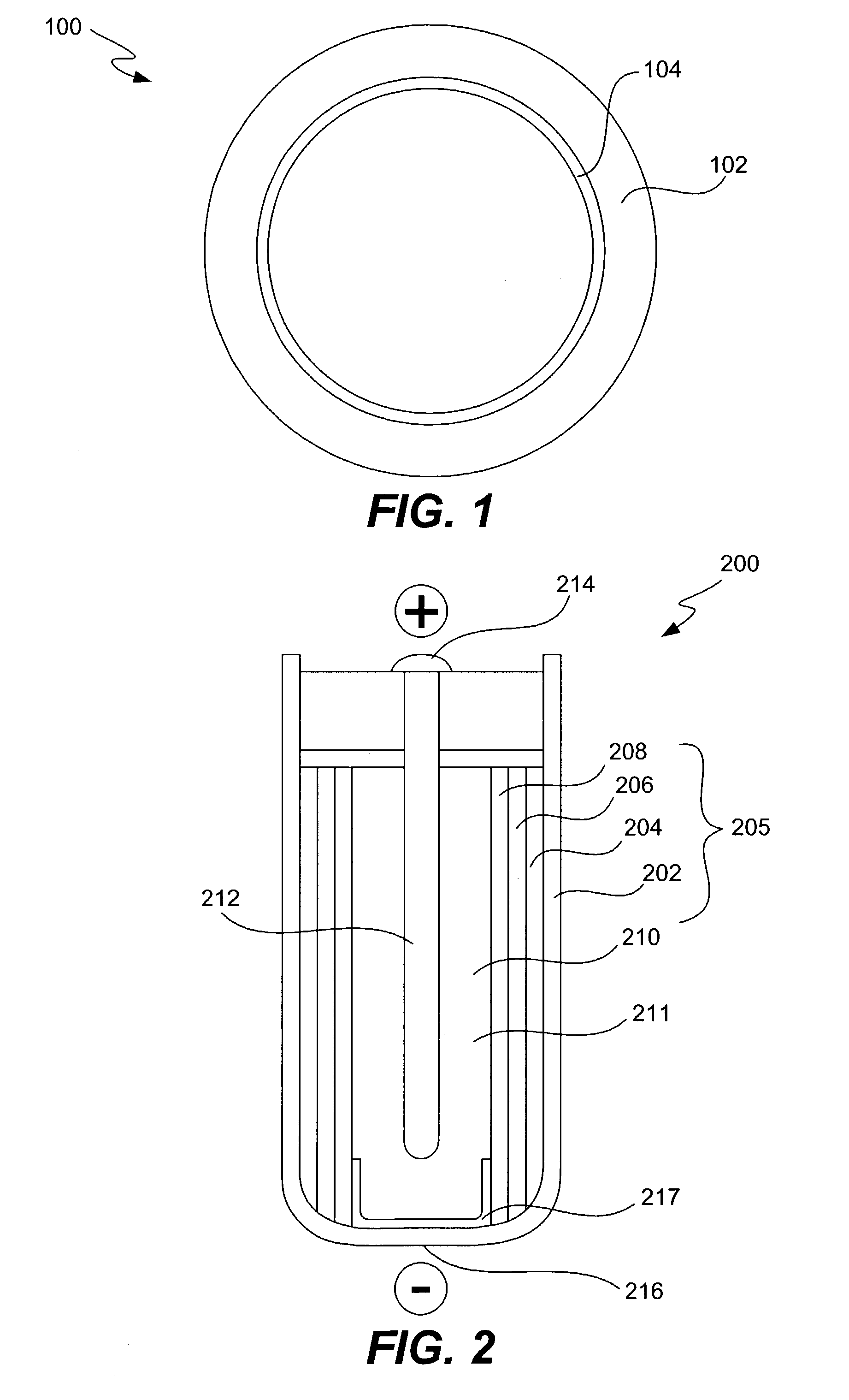

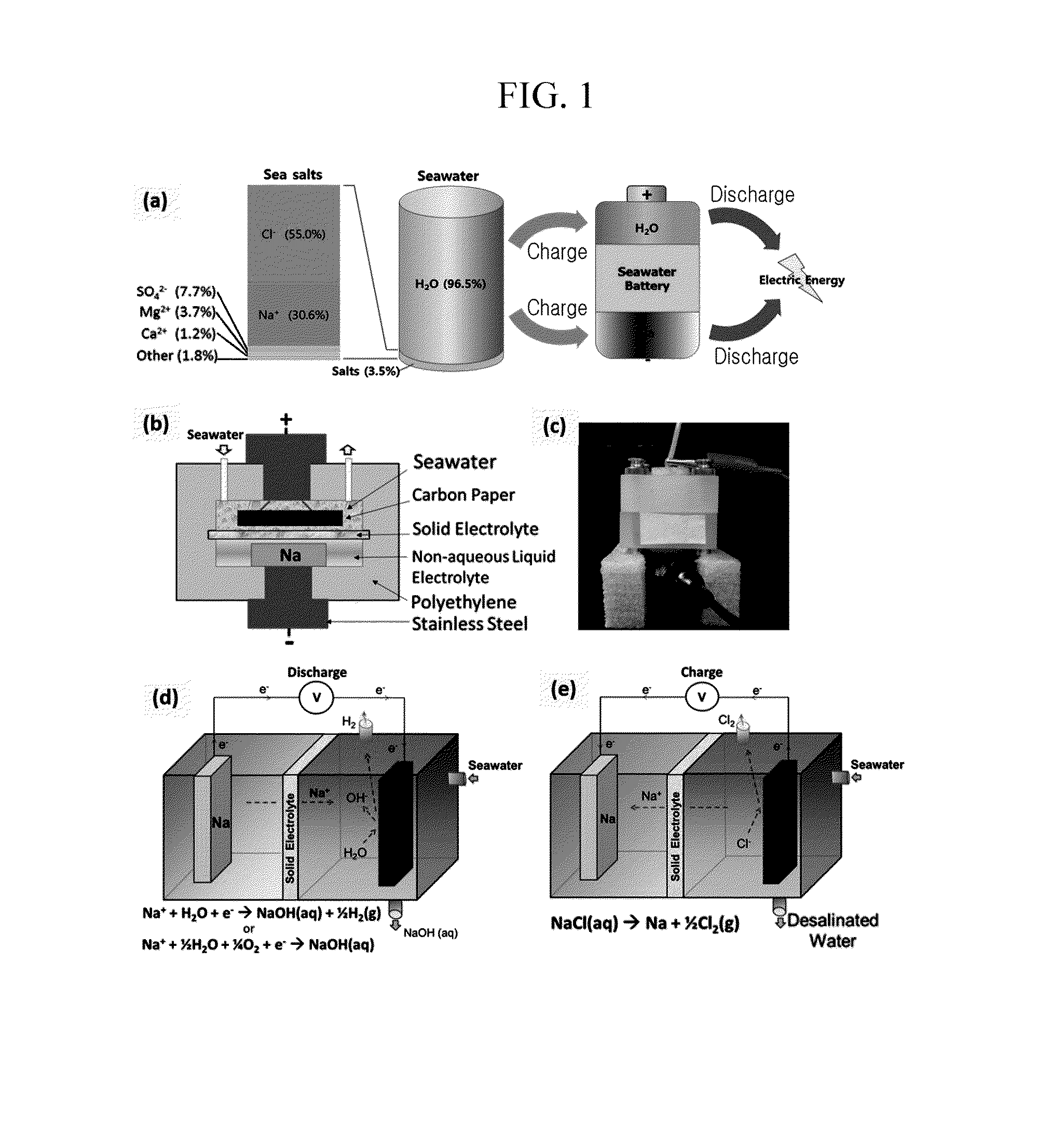

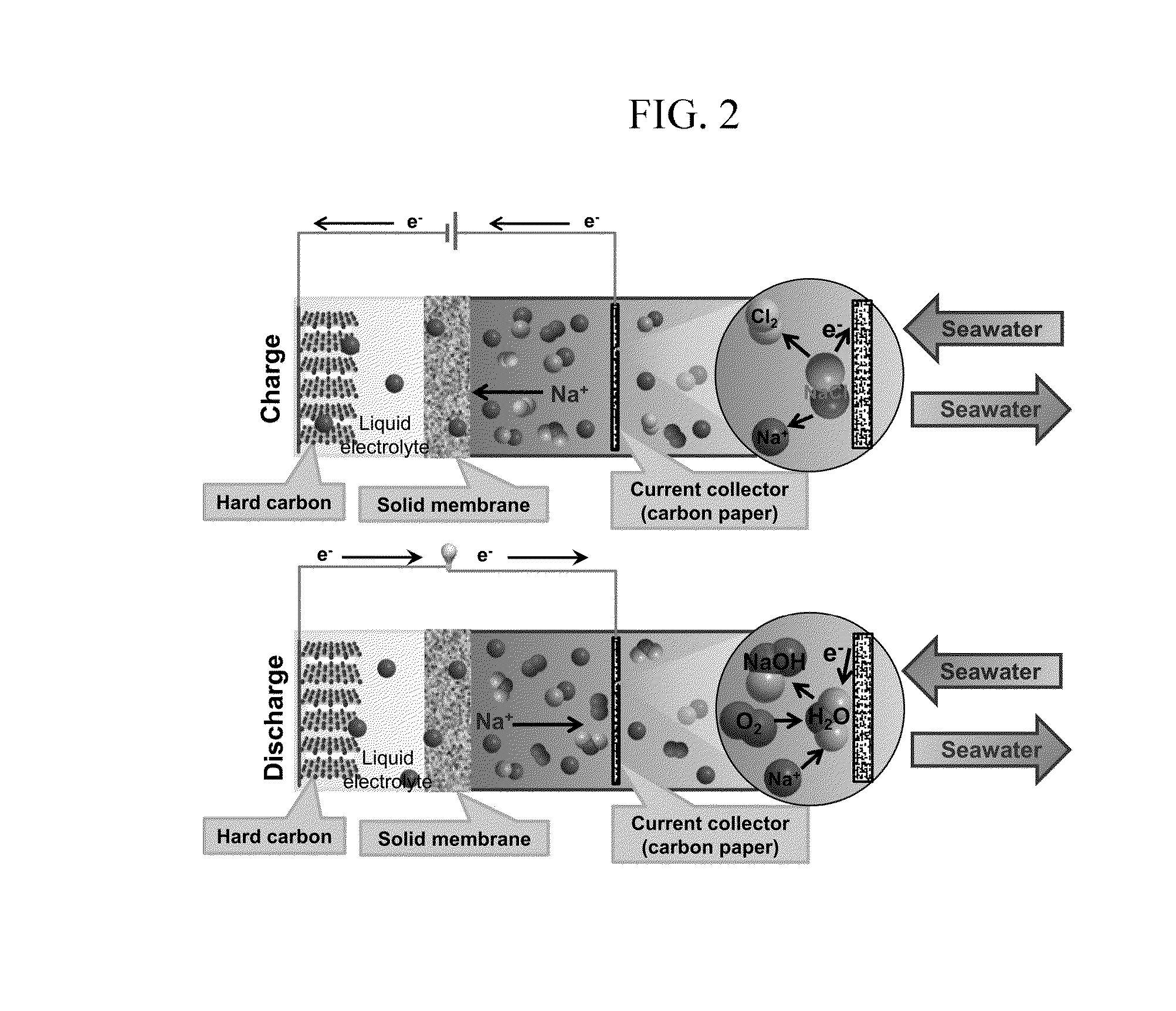

Secondary battery

ActiveUS20160268661A1Fuel and secondary cellsElectrode carriers/collectorsLiquid cathodeElectrical battery

The present invention relates to a rechargeable battery, and a rechargeable battery including: a liquid cathode portion including a sodium-containing solution and a cathode current collector impregnated in the sodium-containing solution; an anode portion including a liquid organic electrolyte, an anode current collector impregnated in the liquid organic electrolyte, and an anode active material provided in the surface of the anode current collector; and a solid electrolyte provided between the cathode portion and the anode portion can be provided.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

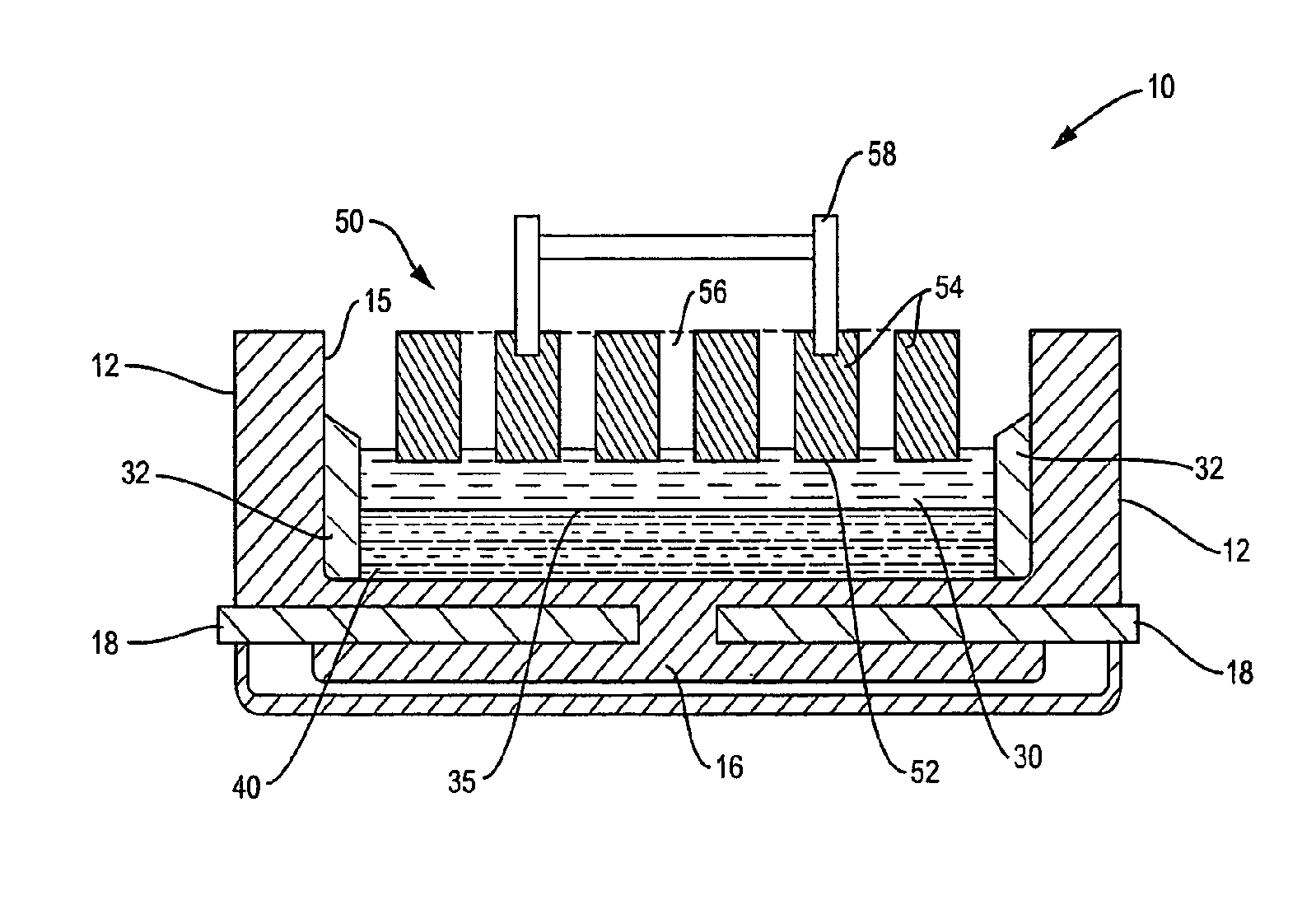

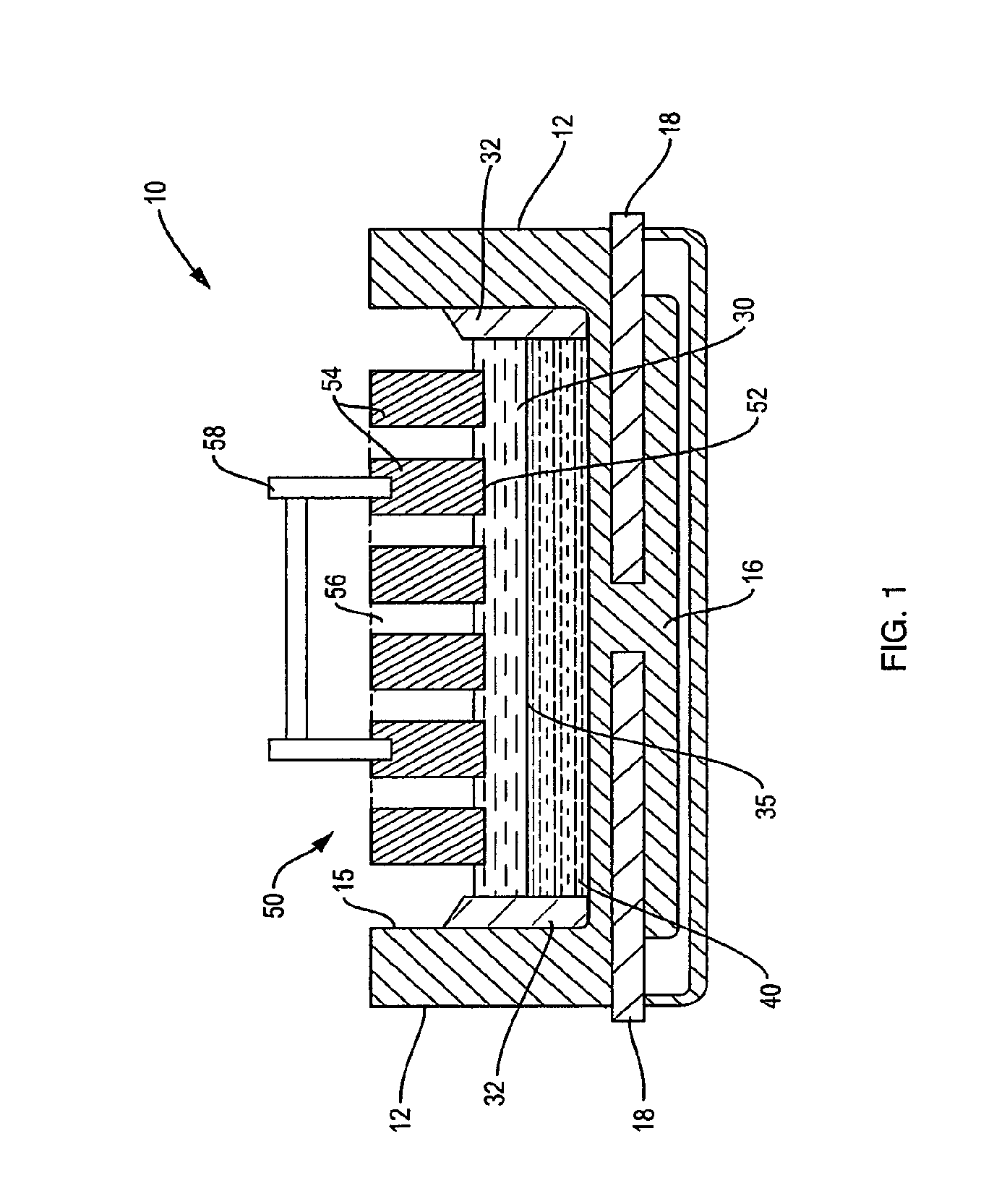

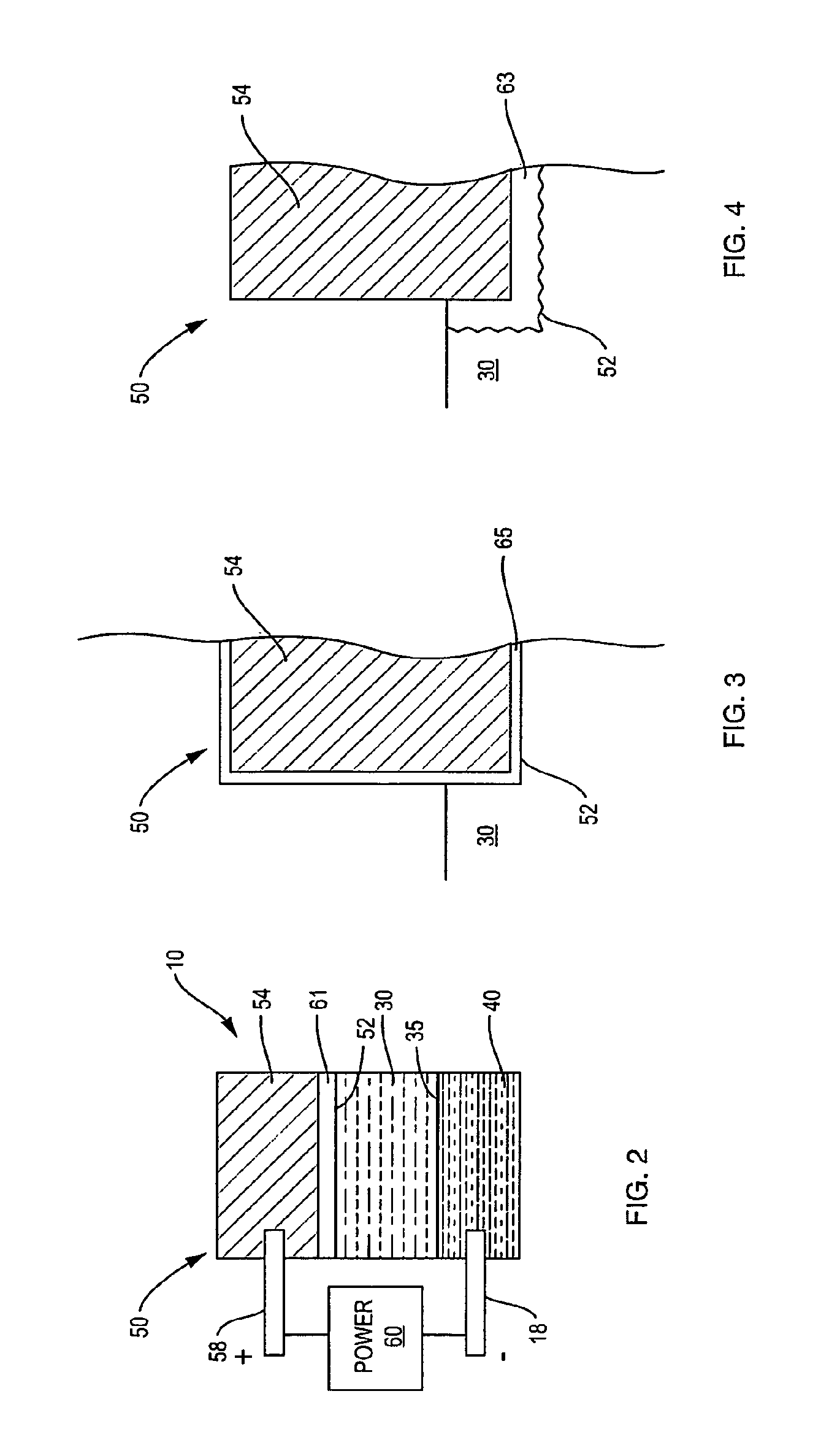

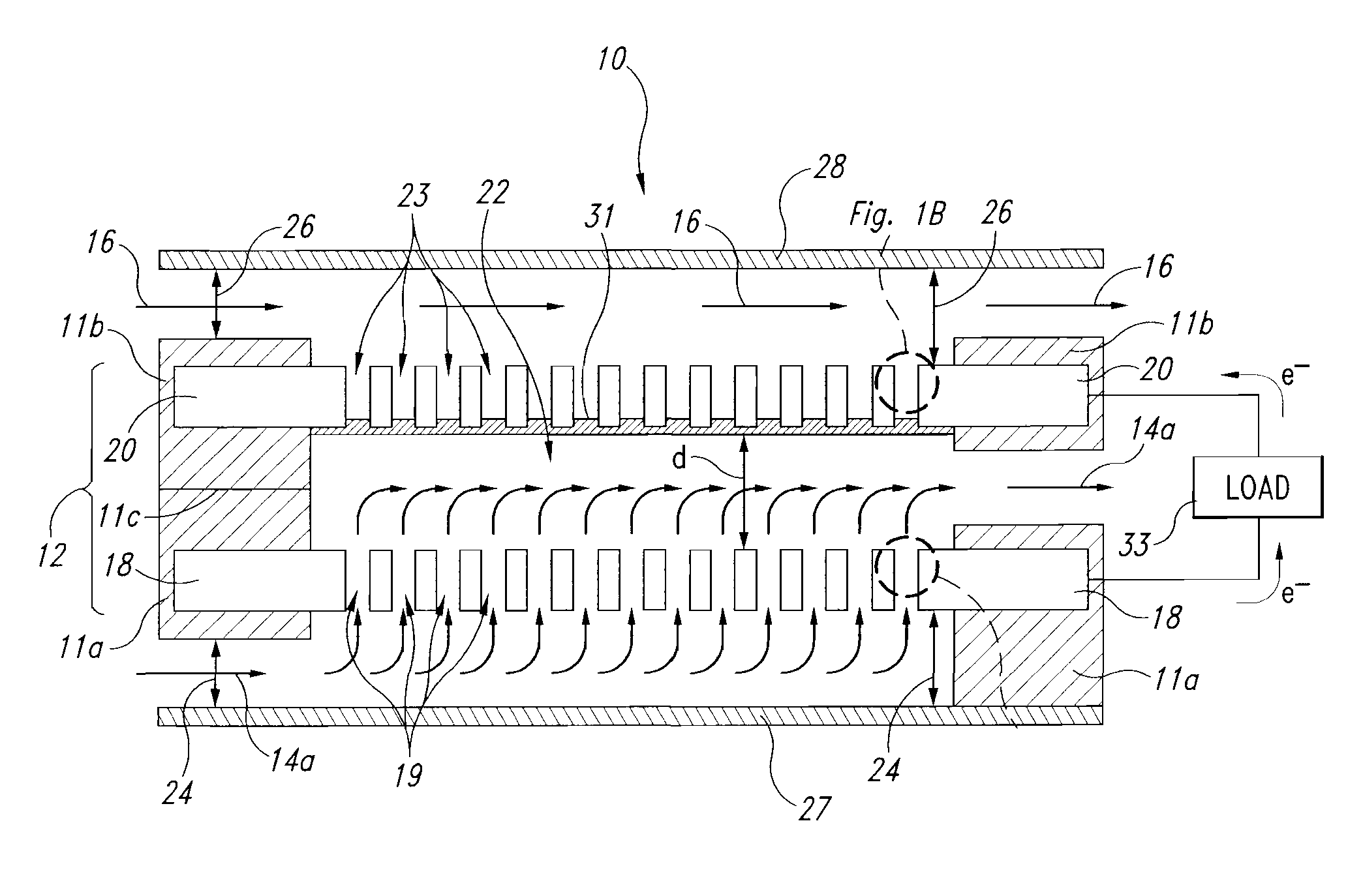

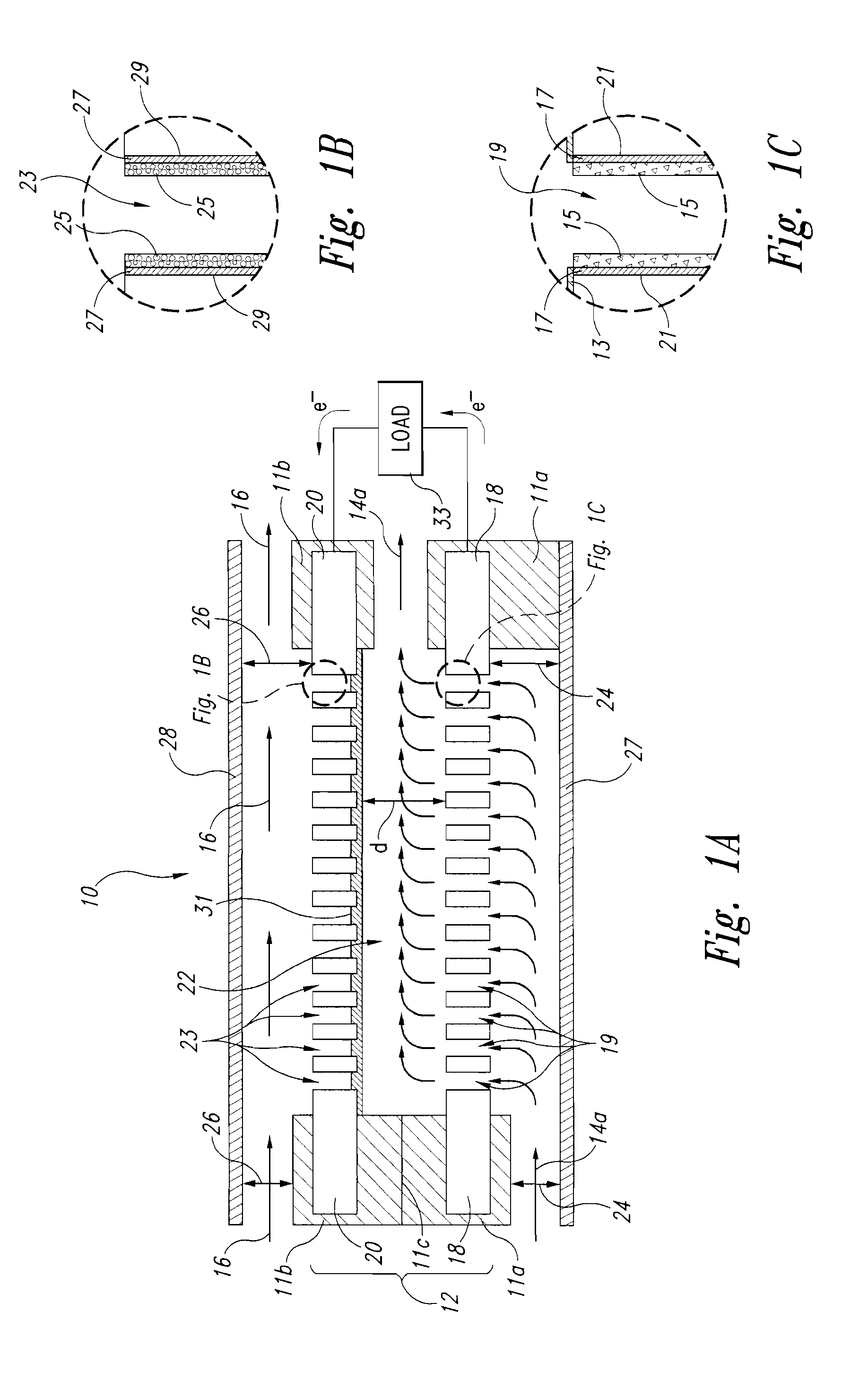

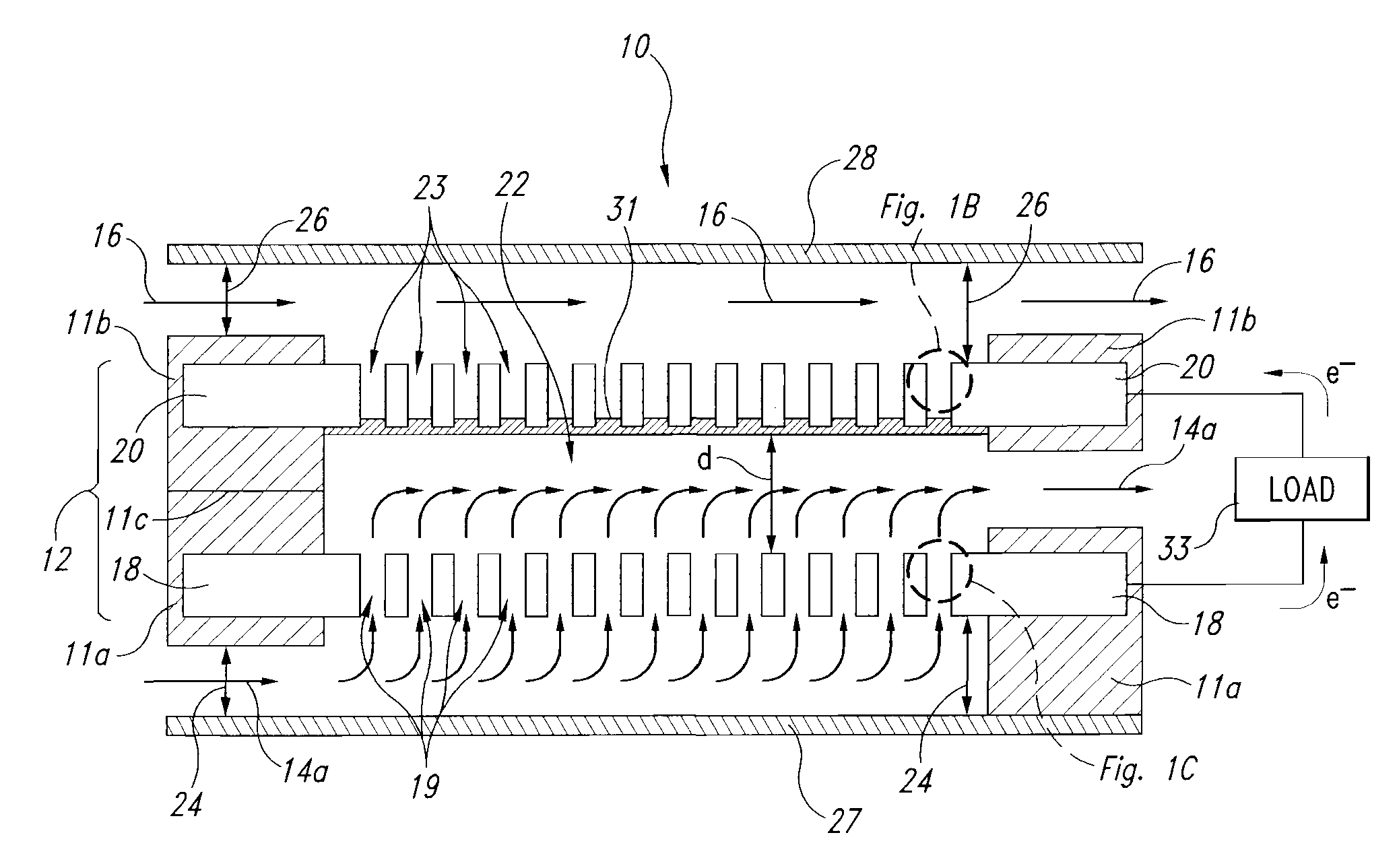

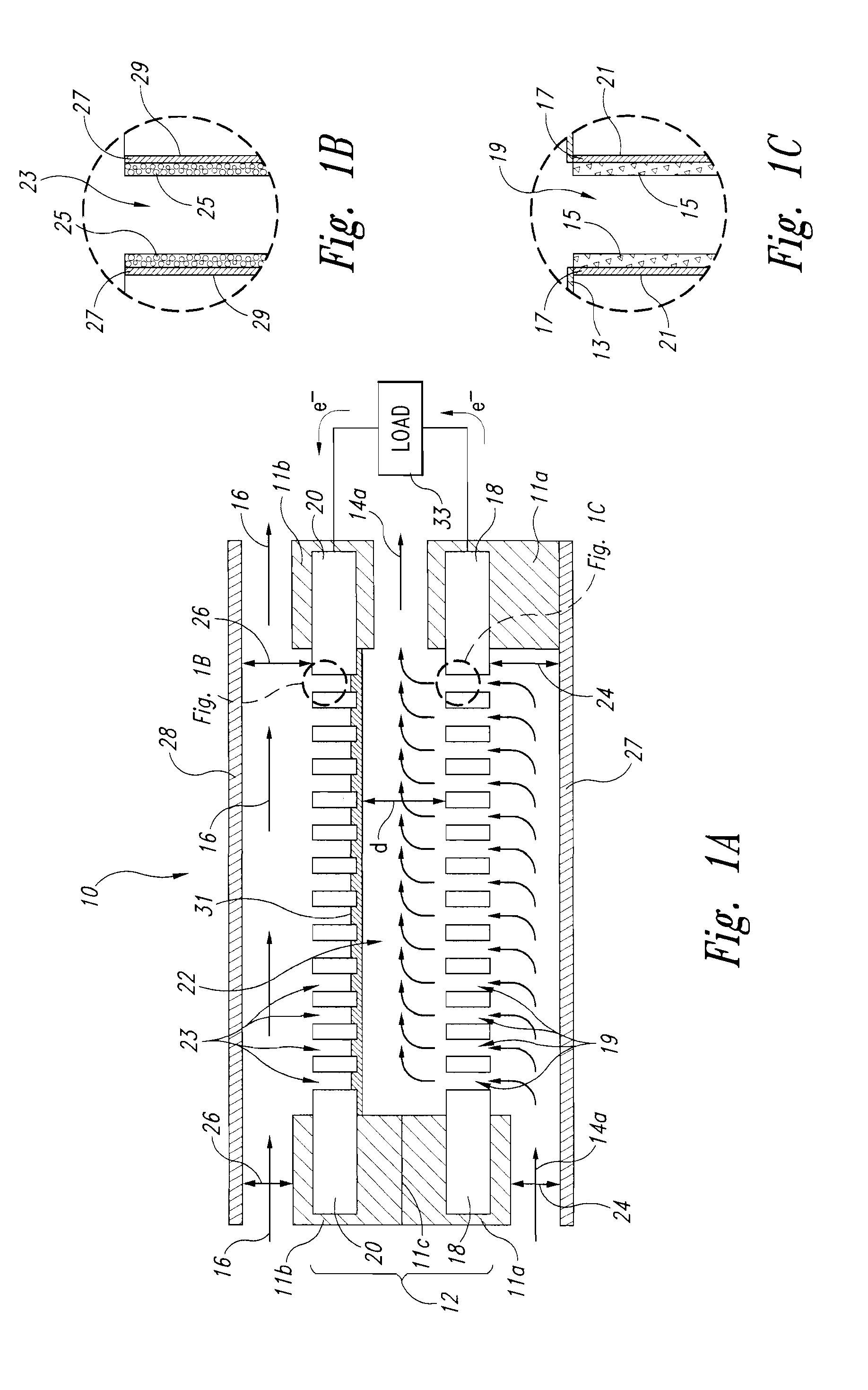

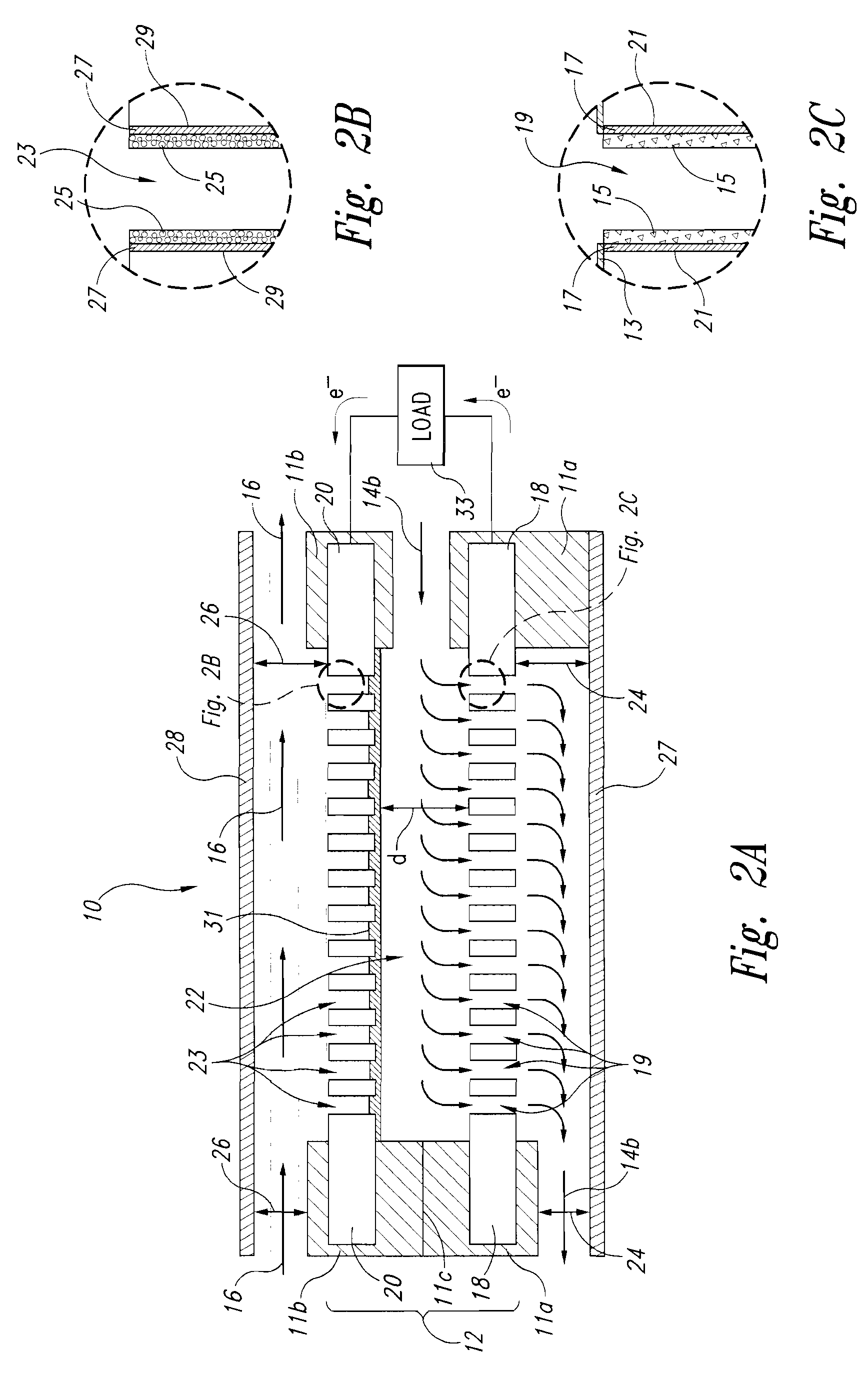

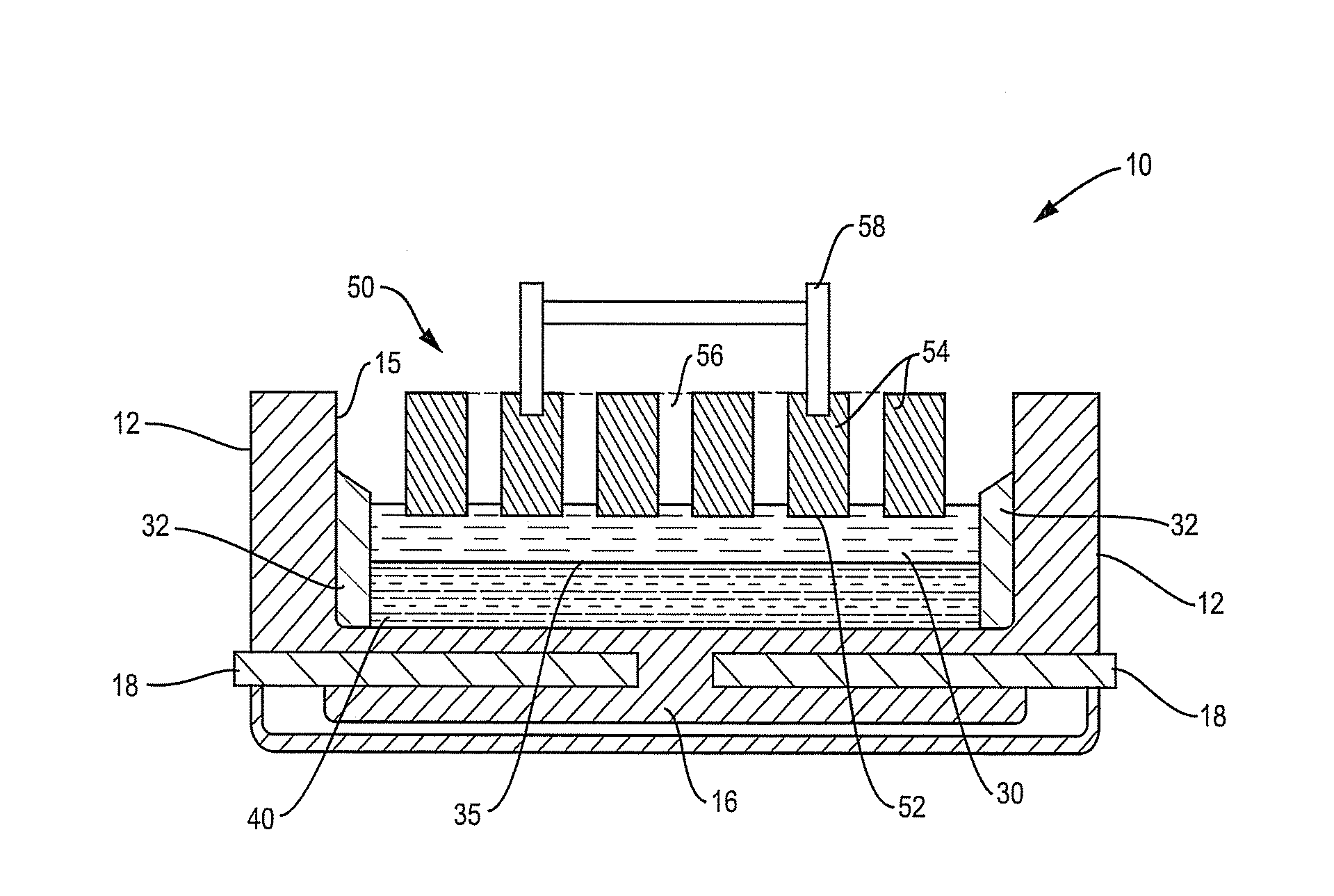

Liquid-liquid fuel cell systems having flow-through anodes and flow-by cathodes

The invention disclosed herein relates to fuel cell electrode pair assemblies, not having interposing proton exchange membranes, configured to receive and react with liquid anolyte and liquid catholyte microfluidic flowstreams. In one embodiment, the present invention is directed to a fuel cell electrode pair assembly, not having an interposing proton exchange membrane, configured to receive and react with a liquid microfluidic anolyte flowstream (e.g., laminarly flowing methanol solution) and a liquid microfluidic catholyte flowstream (e.g., laminarly flowing nitric acid solution), wherein the fuel cell electrode pair assembly comprises: a porous flow-through anode; a porous flow-by cathode confronting and spaced apart from the anode; and a central plenum interposed between and connected to the anode and the cathode.

Owner:EPD INVESTMENT CO

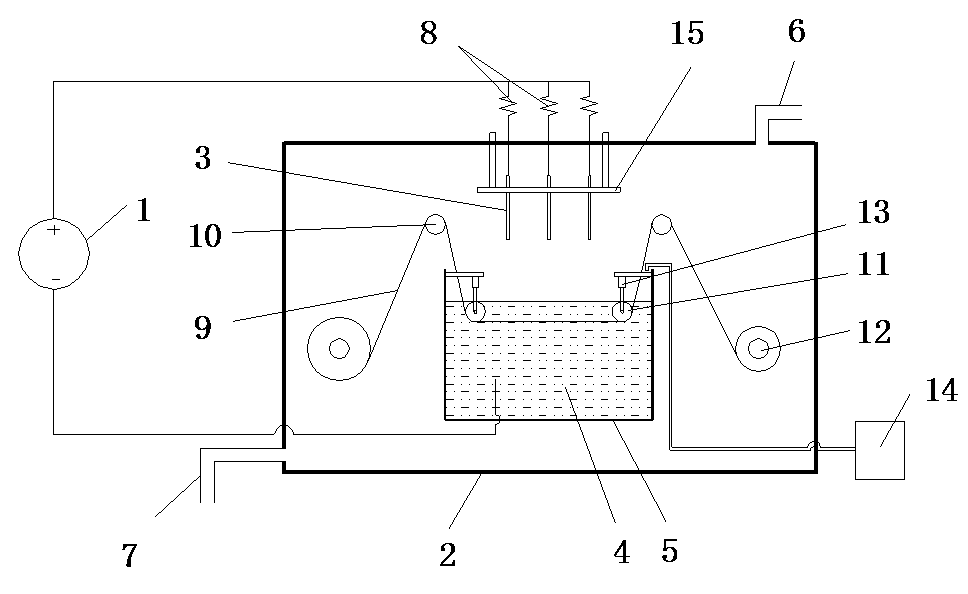

Plasma treatment device and plasma treatment method for polymer material surface modification

ActiveCN103194001ASimple and fast operationLow costUltrasonic/sonic fibre treatmentLiquid mediumLiquid cathode

The invention discloses a plasma treatment device for polymer material surface modification. The plasma treatment device comprises a direct-current power supply and a reaction chamber, wherein a metal anode and a liquid cathode which are connected with the direct-current power supply are arranged in the reaction chamber correspondingly; a liquid-medium container used for containing the liquid cathode is arranged in the reaction chamber; the metal anode is arranged right above a liquid level of the liquid cathode; and the reaction chamber is internally provided with a gas inlet system for circulating gas media. The invention further discloses a plasma treatment method for the polymer material surface modification. The plasma treatment method comprises the following steps of 1) placing a polymer material to be treated below the liquid level of the liquid cathode; 2) starting the gas inlet system to conduct gas inlet on the reaction chamber; 3) turning on the direct-current power supply, adjusting a space between the metal anode and the liquid cathode to allow discharge plasma to generate between the metal anode and the liquid cathode, and beginning to conduct plasma treatment on the polymer material; and 4) turning off the direct-current power supply after the treatment, and taking out the polymer material.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Process for producing Mg rare earth intermediate alloy by Submerged Liquid Cathode electrolysis under low-temperature

The present invention belongs to a preparation process of magnesium-rare earth intermediate alloy, belonging to the field of fused salt electrolysis metallurgical technology. It is characterized by that it uses the lanthanum-praseodymium-cerium chloride (LPC) cl3 which is residual after neodymium extraction and whose content is 8-30 wt% after it is dehydrated as raw material, its electrolyte system is Kcl (50-40)% : NaCl (42-30) %: (8-30%) of (LPC) Cl3, and its solvent is Kcl and Nacl, and (LPC) Cl3 is solute. Said invention adopts magnesium-lanthanum-praseodymium-cerium intermediate alloy whose rare earth content is 5-8 wt% as initial subsidence liquid cathode, and the mass ratio of said intermediate alloy and total electrolyte is 1:4-5, under the condition of 700-900 deg.C said invention utilizes the electrolysis process to prepare magnesium-(8-30) wt% lanthanum-praseodymium-cerium intermediate alloy with high rare earth content.

Owner:白山市天安金属镁矿业有限公司

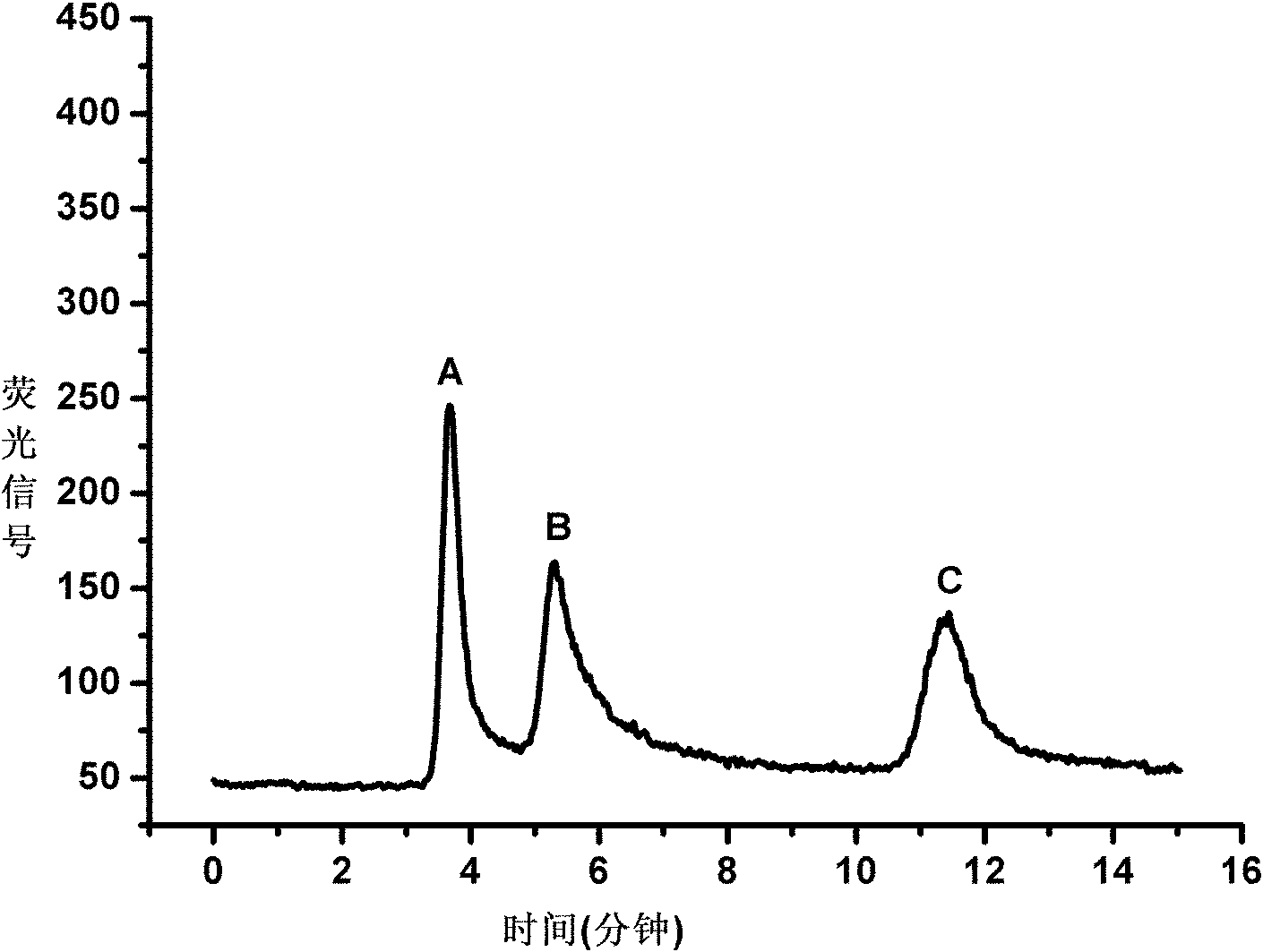

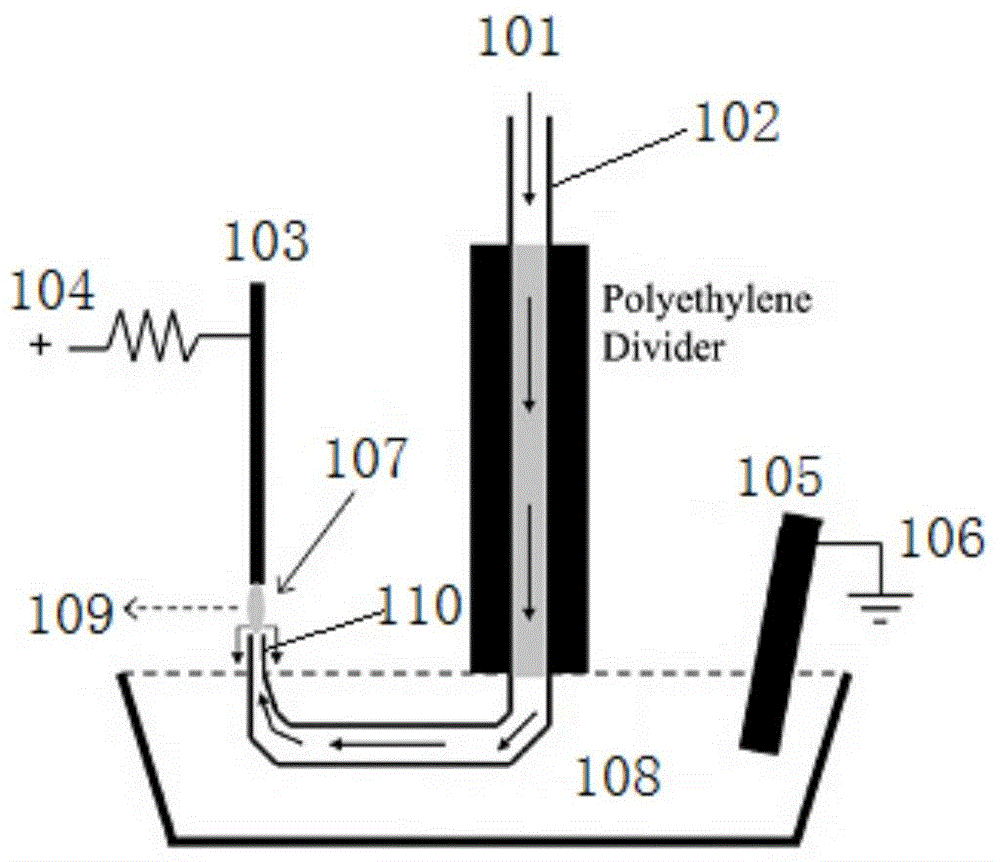

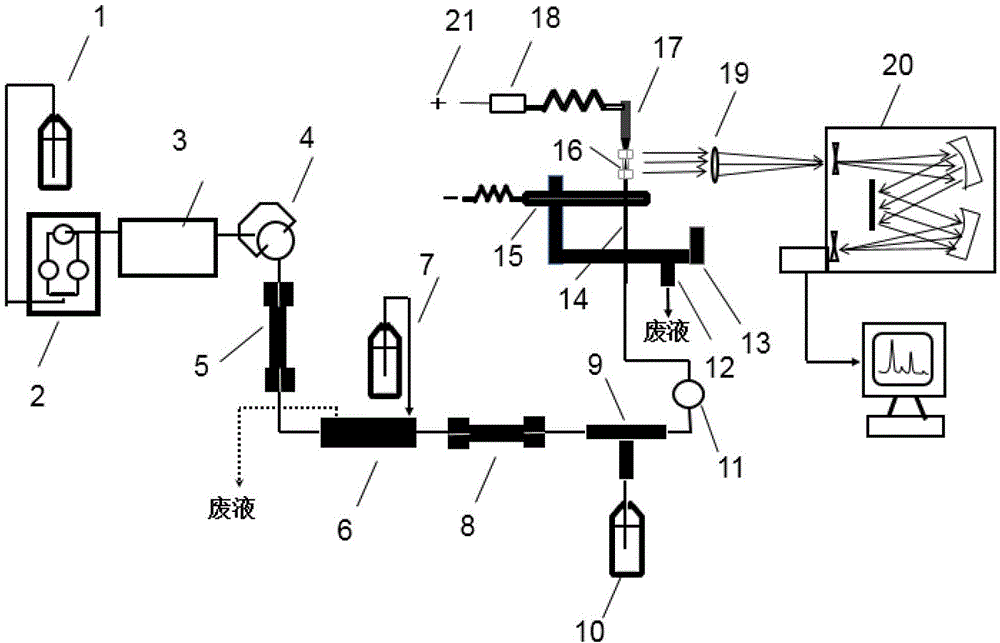

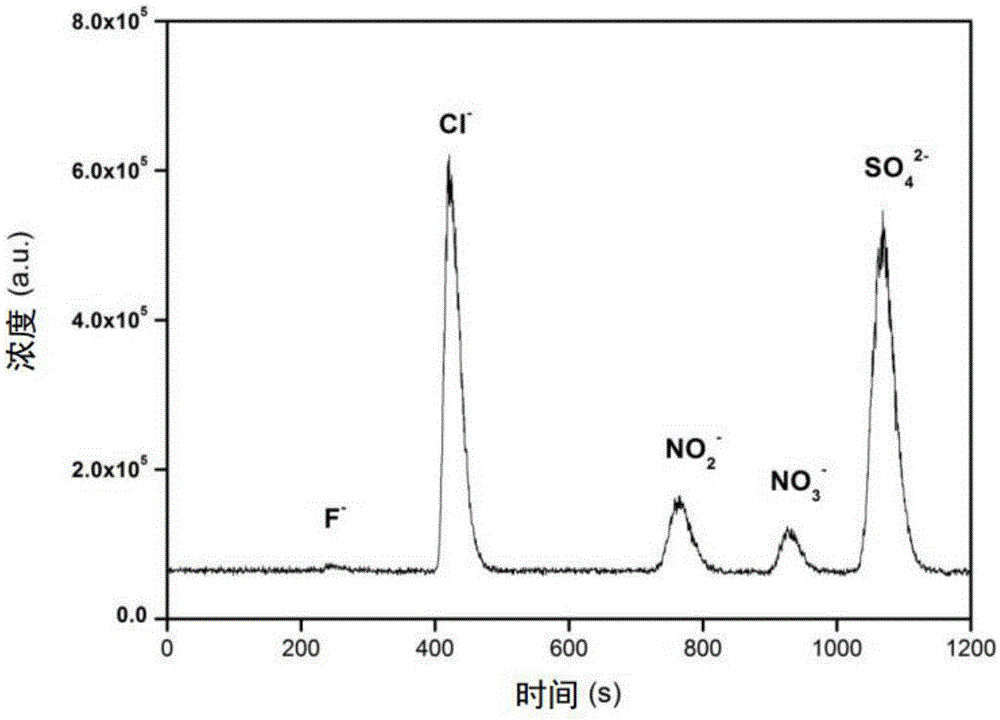

Mercury morphological analysis method based on liquid cathode discharge and mercury vapor generating device

InactiveCN102033103AAchieve steamEfficient separationComponent separationAnalysis by electrical excitationFluorescenceINTRODUCTION device

The invention discloses a mercury morphological analysis method based on liquid cathode discharge and a mercury vapor generating device. The method comprises: a mercury-containing sample solution is introduced into a chromatographic column of a liquid chromatograph; a discharge medium carrier flow passes through a sample introduction device and is introduced into a sample introduction capillary tube of a discharge pool with the effluence of the chromatographic column through a tee joint; by taking a metal electrode as an anode, and graphite, platinum or a stainless steel material as a cathode, liquid cathode discharging is carried out to generate vapor which is carried by a carrier gas into a gas-liquid separator; and finally the separated gas is detected by an atomic fluorescence spectrometer to obtain the morphology of mercury. Through the method provided by the invention, organic mercury and inorganic mercury in an object to be detected are effectively separated and detected; and the method has the advantages of small volume, low energy consumption, high mercury vapor generation efficiency and low matrix interference, is simple in operation and can be used for analyzing the morphology of mercury in a biological sample.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

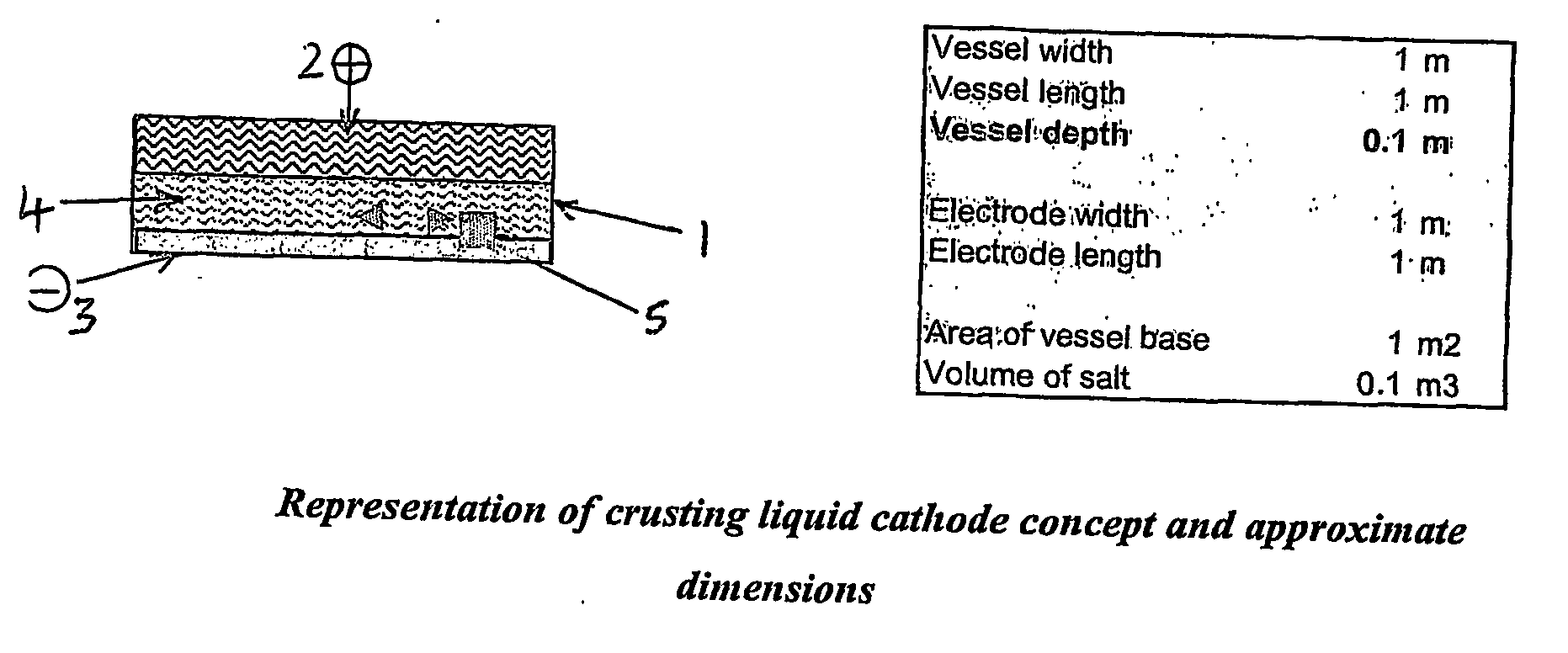

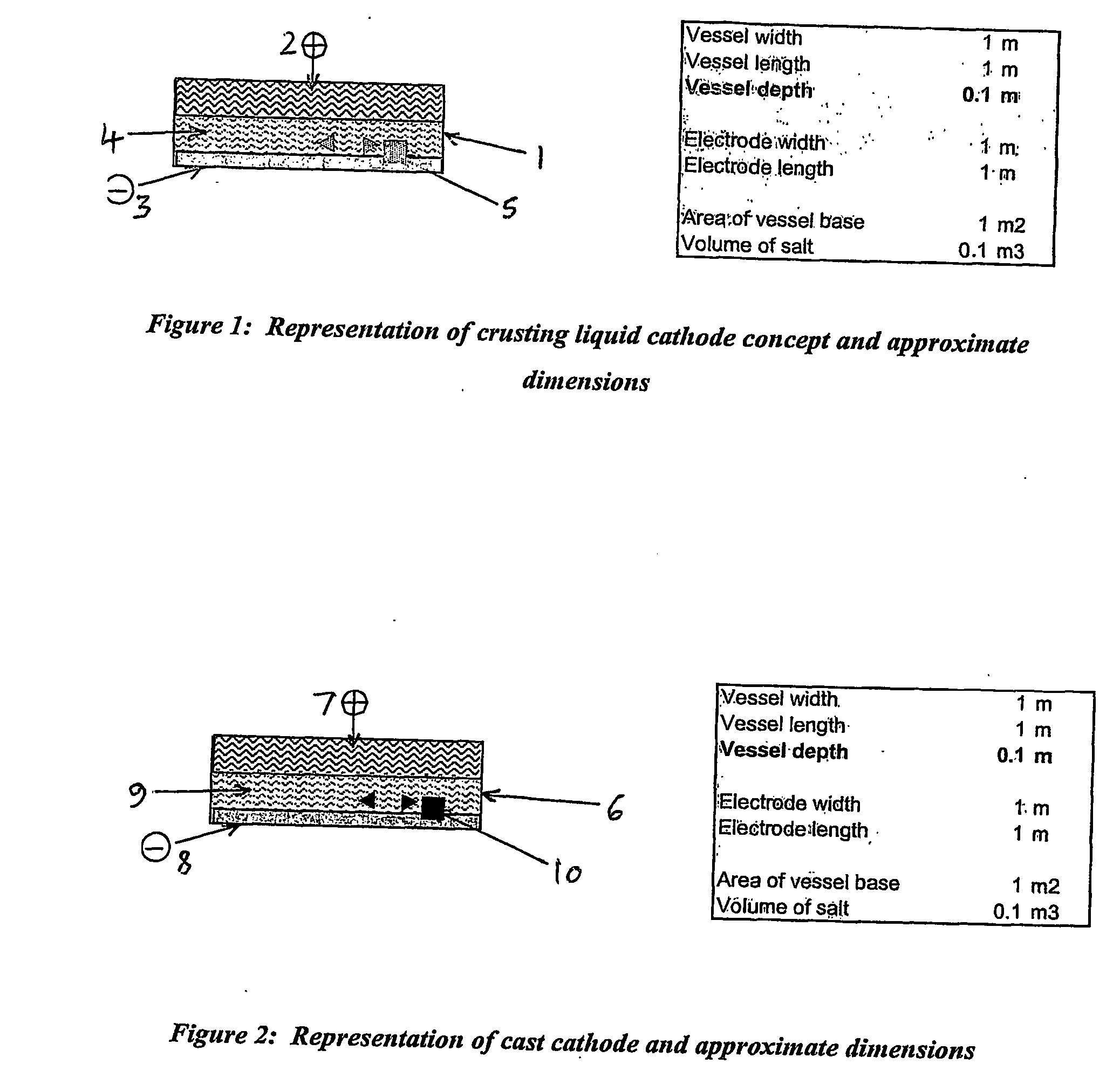

Process for separating metals

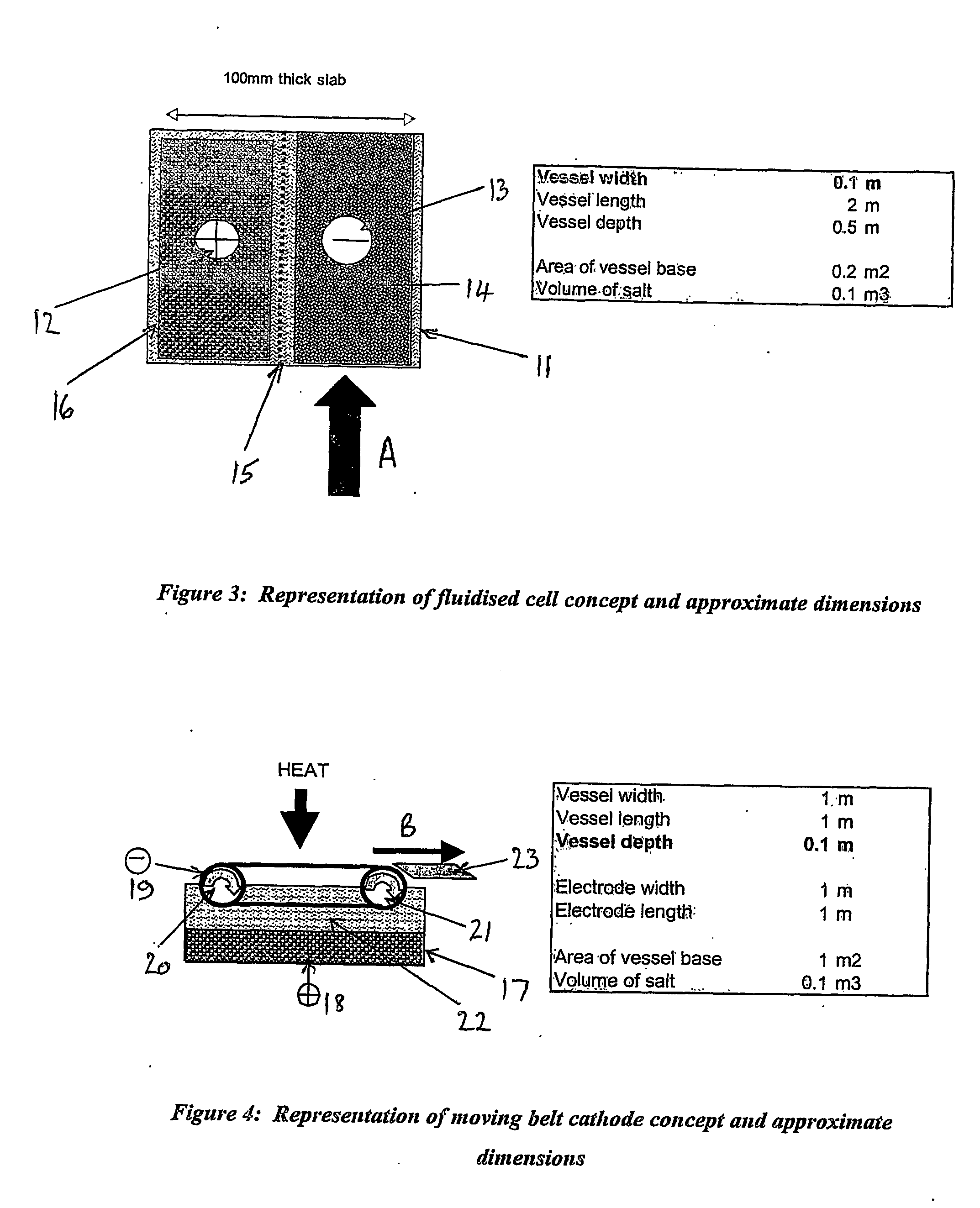

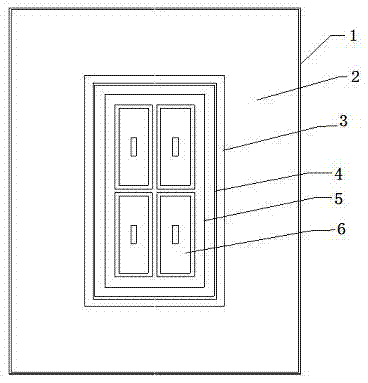

An electrorefining apparatus is capable of operating in continuous mode, and includes a criticality control mechanism, preferably a geometric criticality control mechanism, for example, to control the dimensions of the apparatus. Electrochemical cells include a large surface area per unit volume, preferably in the form of thin, flat plates. Cells include a crusting liquid cathodes, a cast cathode, a fluidised cell or pulsed bed, a moving belt cathode, a consolidating cathode, or a liquid anode and a plate cathode. A continuous process for the isolation of metals, typically uranium, from spent nuclear fuels includes electrochemically treating the spent nuclear fuels in the apparatus.

Owner:NUCLEAR DECOMMISSIONING AUTHORITY

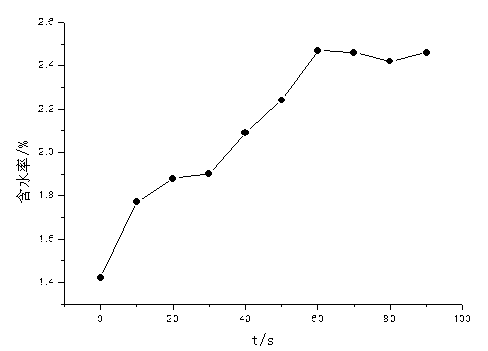

Method for fast forming plasma in liquid cathode glow discharge atomizer

ActiveCN103712973ASimple and fast operationAnalysis by electrical excitationPeristaltic pumpLiquid cathode

The invention discloses a method for fast forming a plasma in a liquid cathode glow discharge atomizer. The method comprises the steps of: controlling the initial flow velocity of a peristaltic pump at 1.5-3.5mL.min<1>, and the interval between a metal anode and a glass capillary tube to be 3mm; when the voltage applied between the metal anode and the glass capillary tube is direct-current high voltage of 950-1050V, regulating the flow velocity of a peristaltic pump at 4.2-8.5mL.min<1>, or increasing the flow velocity to be 4.2-8.5mL.min<1> through a fast pump button in the peristaltic pump; after the current is stable, restoring the flow velocity of a peristaltic pump to be the initial flow velocity. The method for fast forming plasma in the liquid cathode glow discharge atomizer has the advantages of being safe, fast, simple and convenient to operate, and the like, can be widely popularized and applied, and is applicable to plasma in a liquid cathode glow discharge emission spectrometer or similar devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

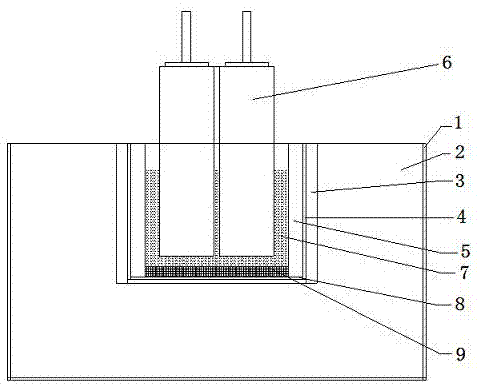

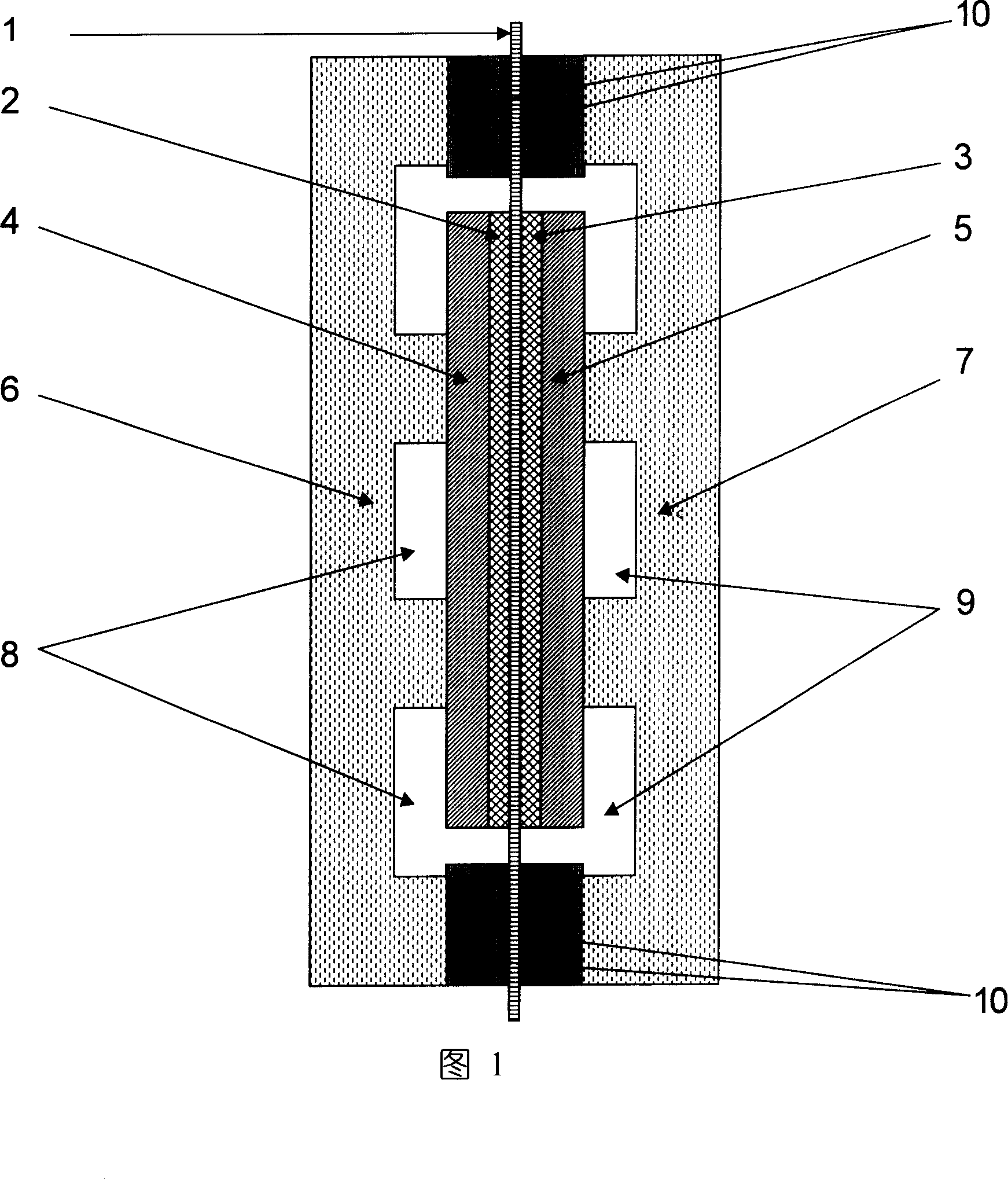

Rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using liquid cathode

InactiveCN105441987AImprove current efficiencyExtended service lifeCellsElectrodesRadiative heat lossRare-earth element

The invention discloses a rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using a liquid cathode. The rare earth fused-salt electrolysis cell mainly comprises an electrolysis cell body, an anode and the liquid cathode; the anode and the cathode are provided with horizontal planes parallel to and facing each other; the anode is vertically inserted in the electrolysis cell body; the liquid cathode is a liquid metal electrolyzed at the bottom; a tungsten plate is inlaid in the internal bottom of the electrolysis cell body; a molybdenum plate or a niobium plate can be taken as a cathode bottom plate or a rare earth metal catcher for an electrolytic product separated out on the cathode. The rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using the liquid cathode has the advantages of high current efficiency, low radiant heat losses, high anode utilization rate, long electrolysis cell service life and low investment of the electrolysis cell body; the single plant capacity can reach above 100 KA, the energy consumption per unit product is greatly reduced, and produced products are stable in quality, low in production cost and relatively closed.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

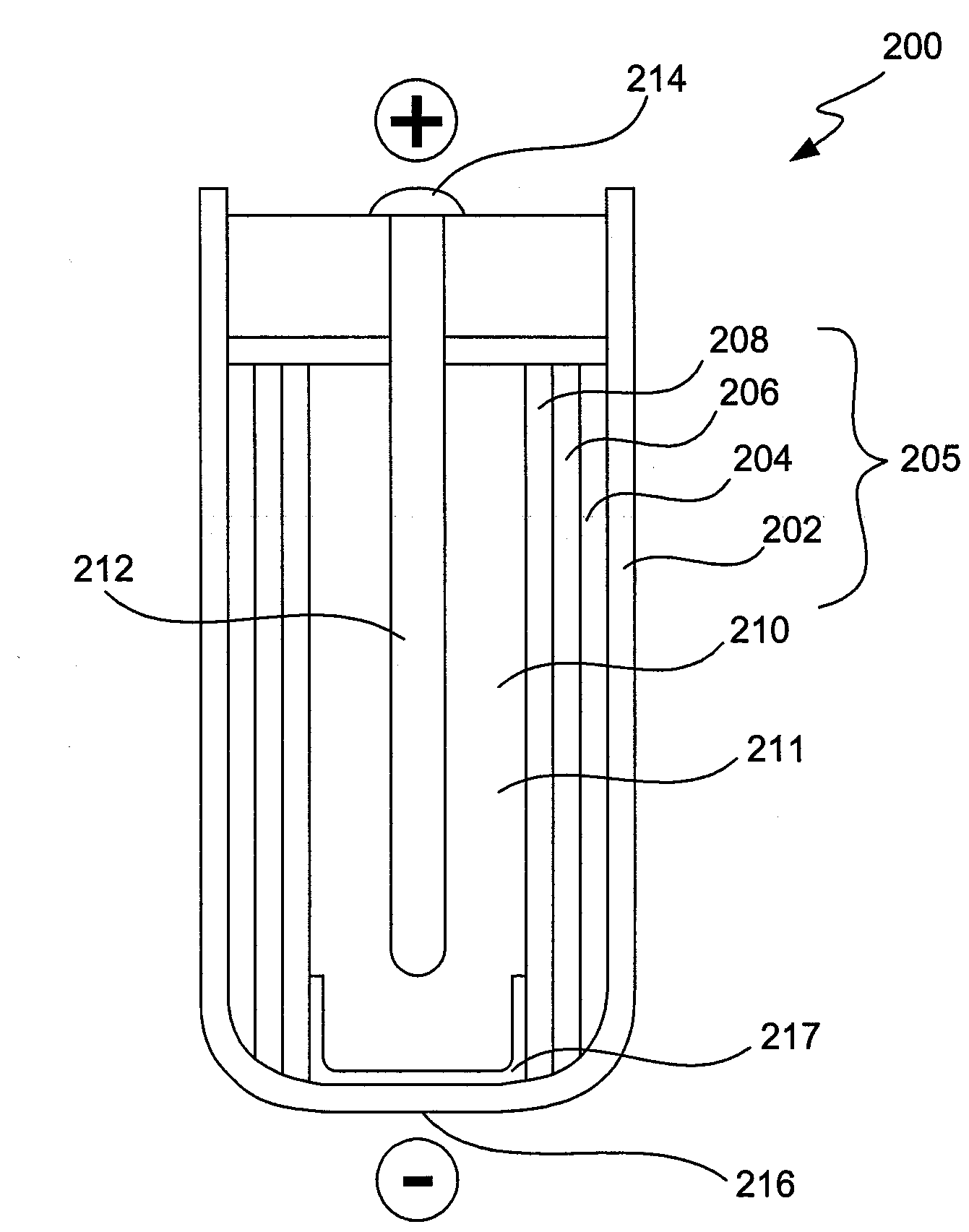

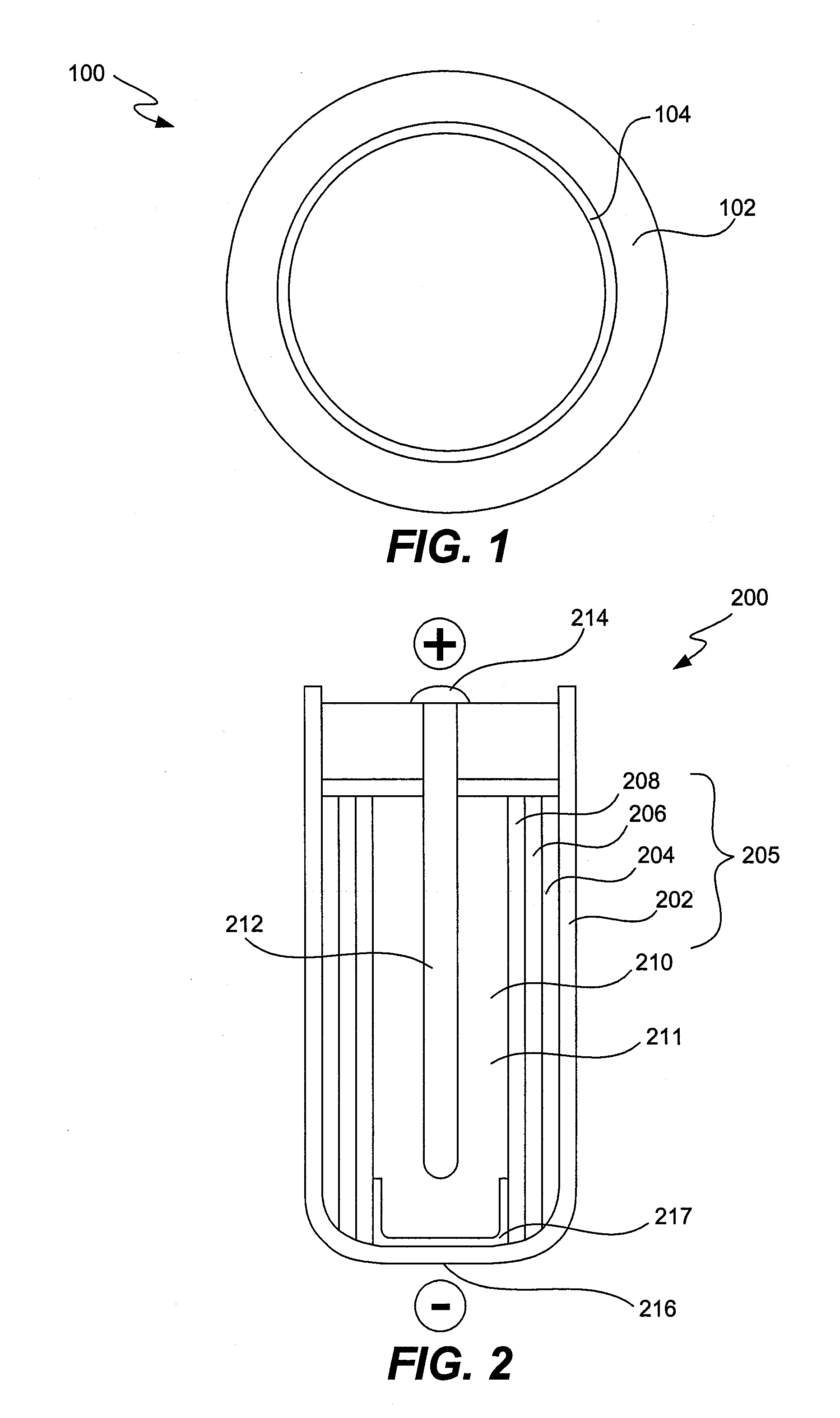

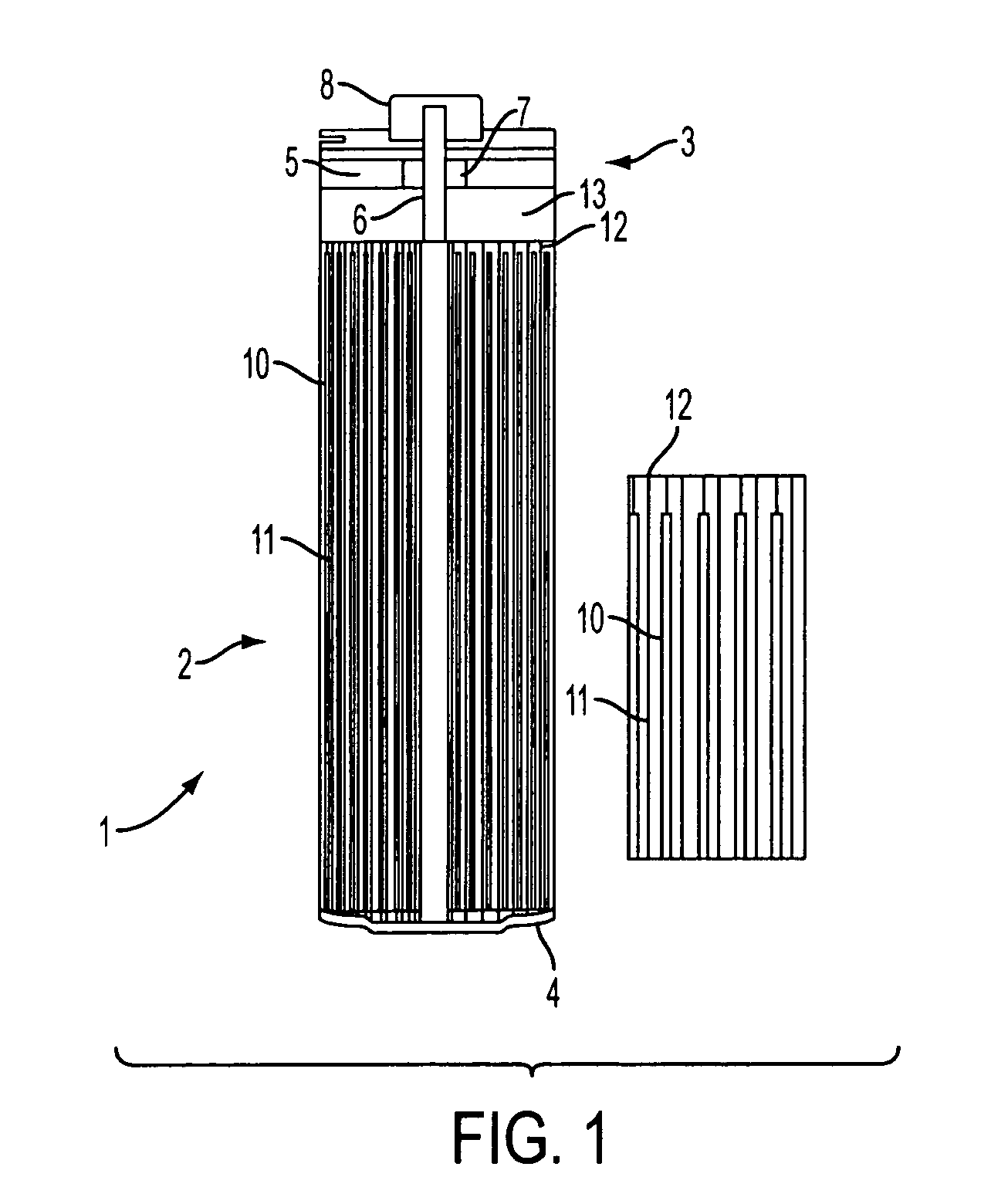

Current collector for the anode of a primary lithium electrochemical generator

InactiveUS20100055571A1Non-aqueous electrolyte cellsElectrode carriers/collectorsMetallic lithiumLiquid cathode

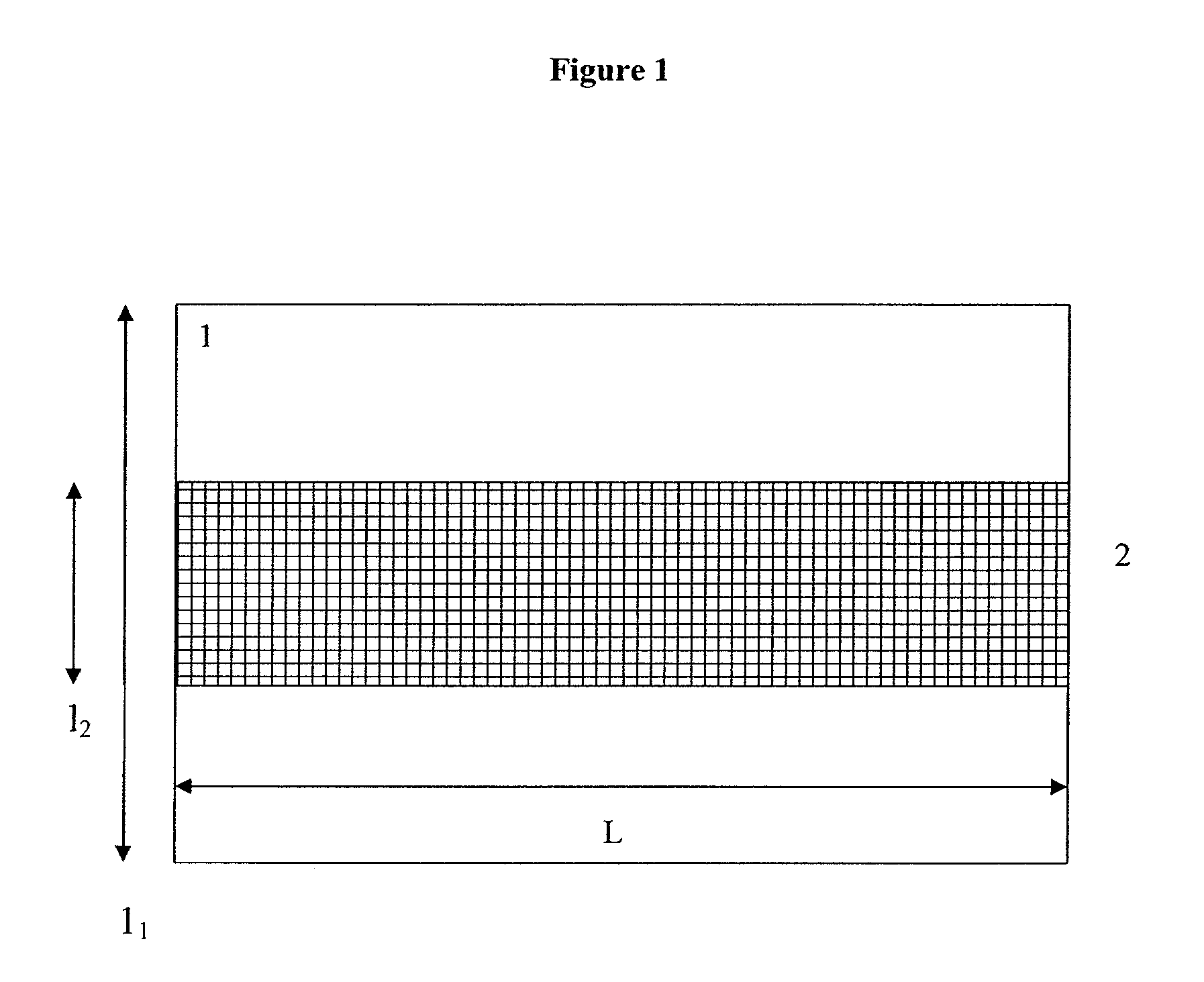

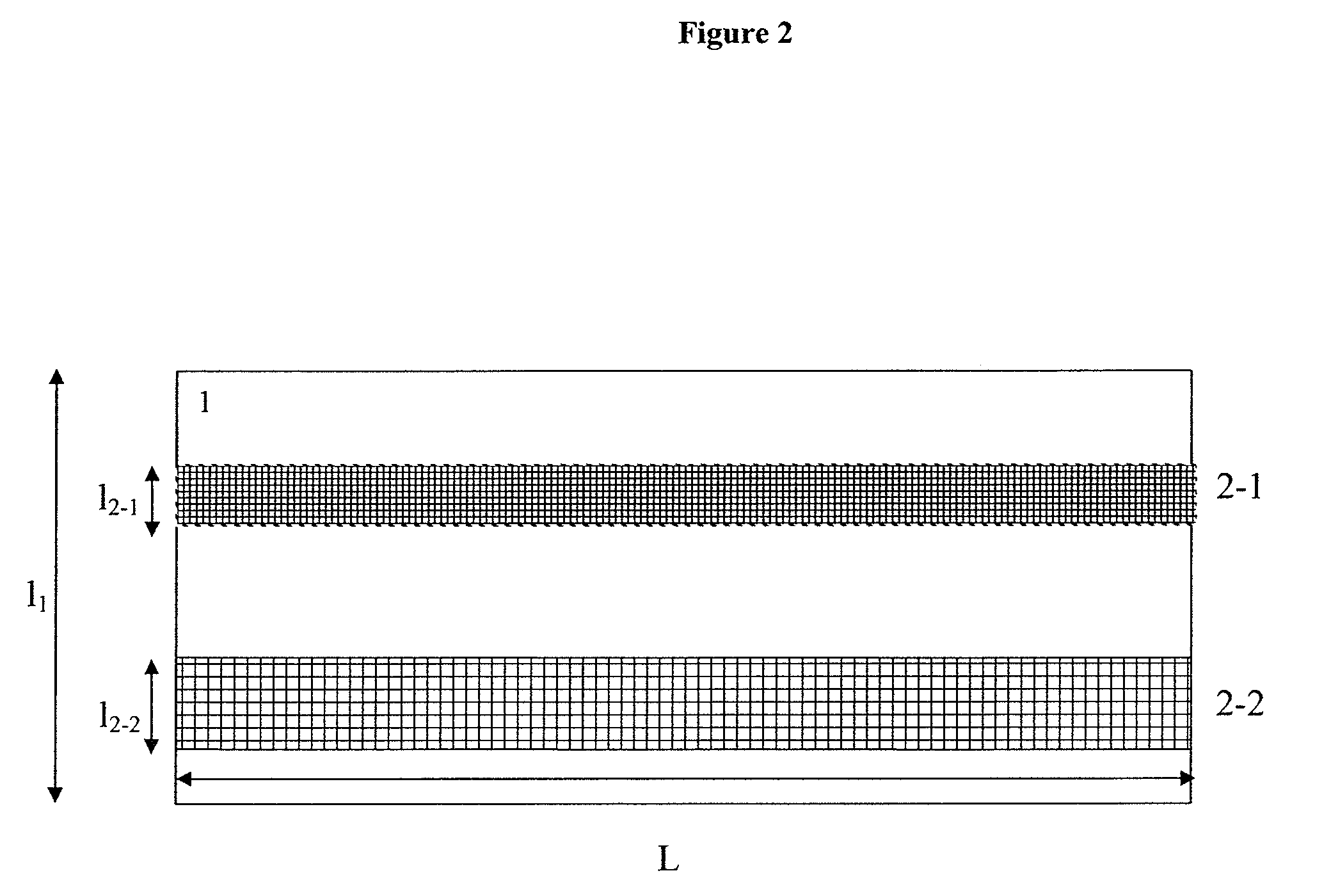

An electrode comprising a metallic lithium strip (1) and on at least one of its surfaces, at least one open-worked current collector strip (2), the ratio of the widths of the current collector strip(s) to the width of the metallic lithium strip ranging from 0.3 to 0.8, the proportion of openwork of each current collector strip ranging from 30 to 95%, the metallic lithium strip and the at least one current collector strip(s) being of substantially identical lengths.This electrode is advantageously used as the anode of a primary lithium electrochemical generator for example of the liquid cathode type such as Li / SO2, of the Li / MnO2 type or of the Li / CFx type with x comprised between 0.5 and 1 in order to reduce the quantity of non-discharged residual lithium.

Owner:SAFT GRP SA

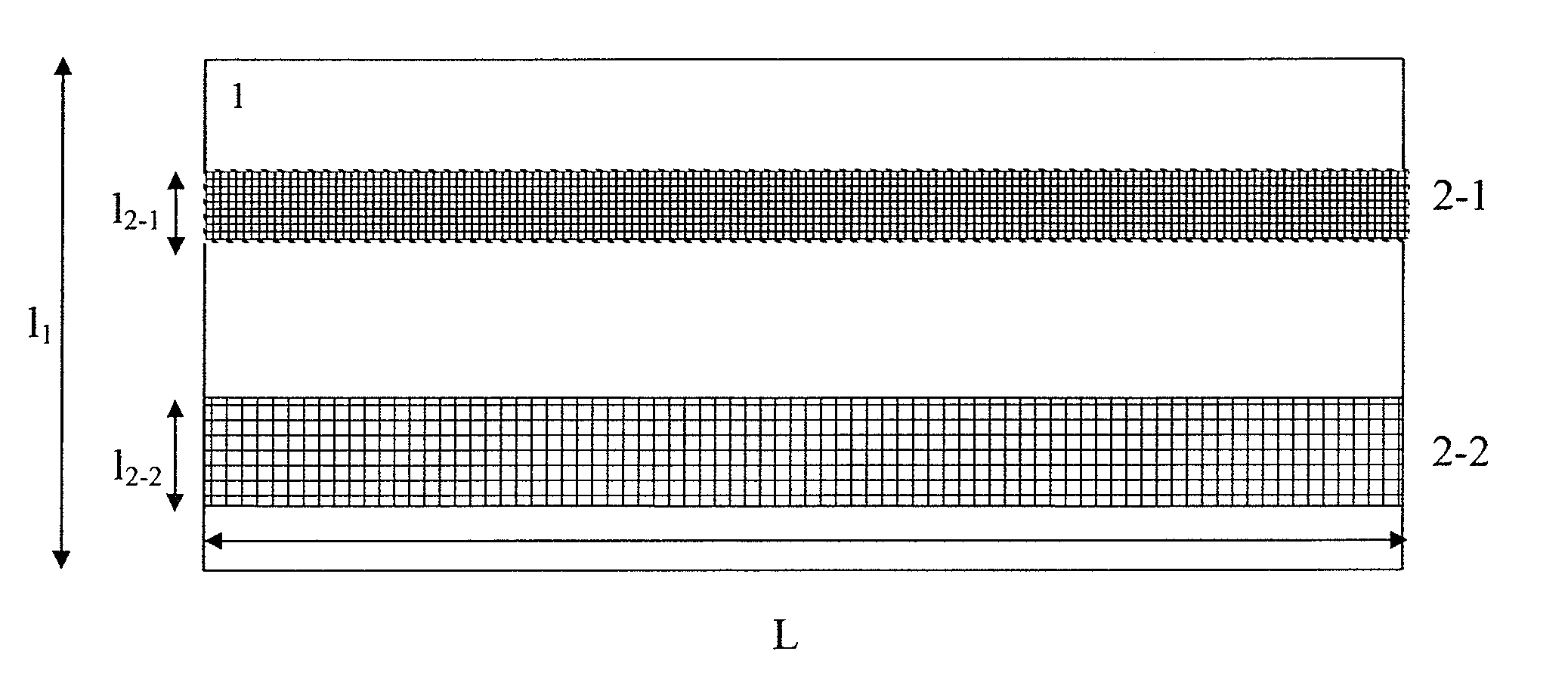

Method for preparing high-purity monocrystalline silicon through electrolytic refining-liquid cathode in-situ directional solidification

ActiveCN103243385AShort manufacturing processSolve the problem of high costPolycrystalline material growthFrom melt solutionsMolten siliconLiquid cathode

The invention relates to a method for preparing high-purity monocrystalline silicon through electrolytic refining-liquid cathode in-situ directional solidification. The method disclosed by the invention comprises the steps of: taking a molten silicon-containing alloy as the anode of an electrolytic cell, placing fluoride electrolyte at the middle layer and placing molten high-purity silicon at the uppermost layer to serve as the cathode so as to form a three-layer liquid electrolytic tank with the molten silicon alloy, the molten electrolyte and the molten high-purity silicon from bottom to top, carrying out constant current electrolytic refining, carrying out in-situ czochralsk directional solidification on the cathode liquid high-purity silicon in the electrolytic refining process to further purify and directly preparing high-purity silicon into the high-purity monocrystalline silicon. The method has the advantages that the polycrystalline silicon is deposited in a liquid form, so that the problems that in the process of preparing solar grade polycrystalline silicon by using a molten salt electrolysis method, the silicon is deposited in a solid form, the product is easy in dendrite forming, the electrical conductivity is poor, the cathode solid-liquid interface is unstable, the deposition speed is low and the current efficiency is low are solved; the preparation flow of the monocrystalline silicon is shortened; and the manufacturing cost of solar grade polycrystalline silicon and monocrystalline silicon batteries can be reduced.

Owner:UNIV OF SCI & TECH BEIJING

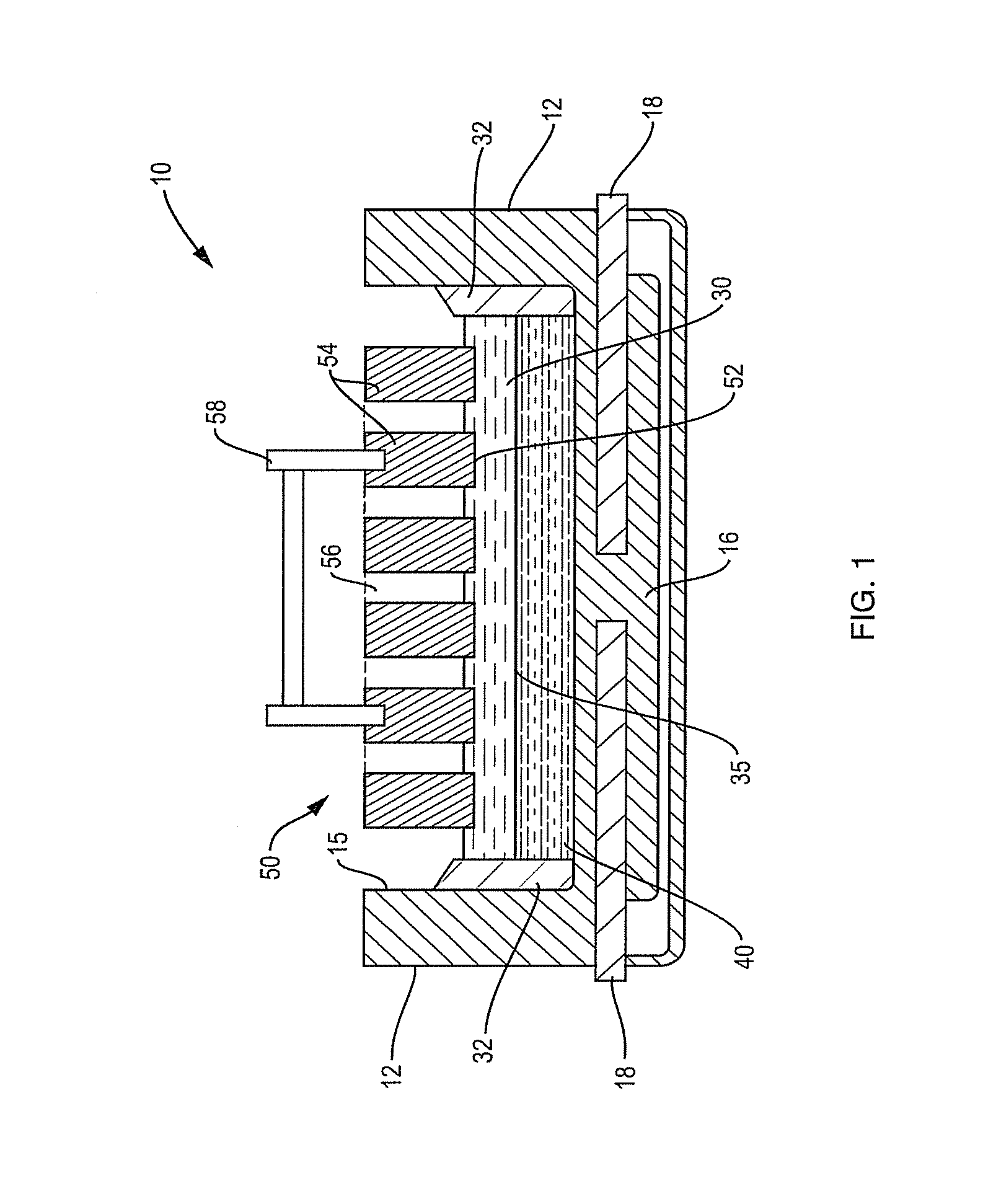

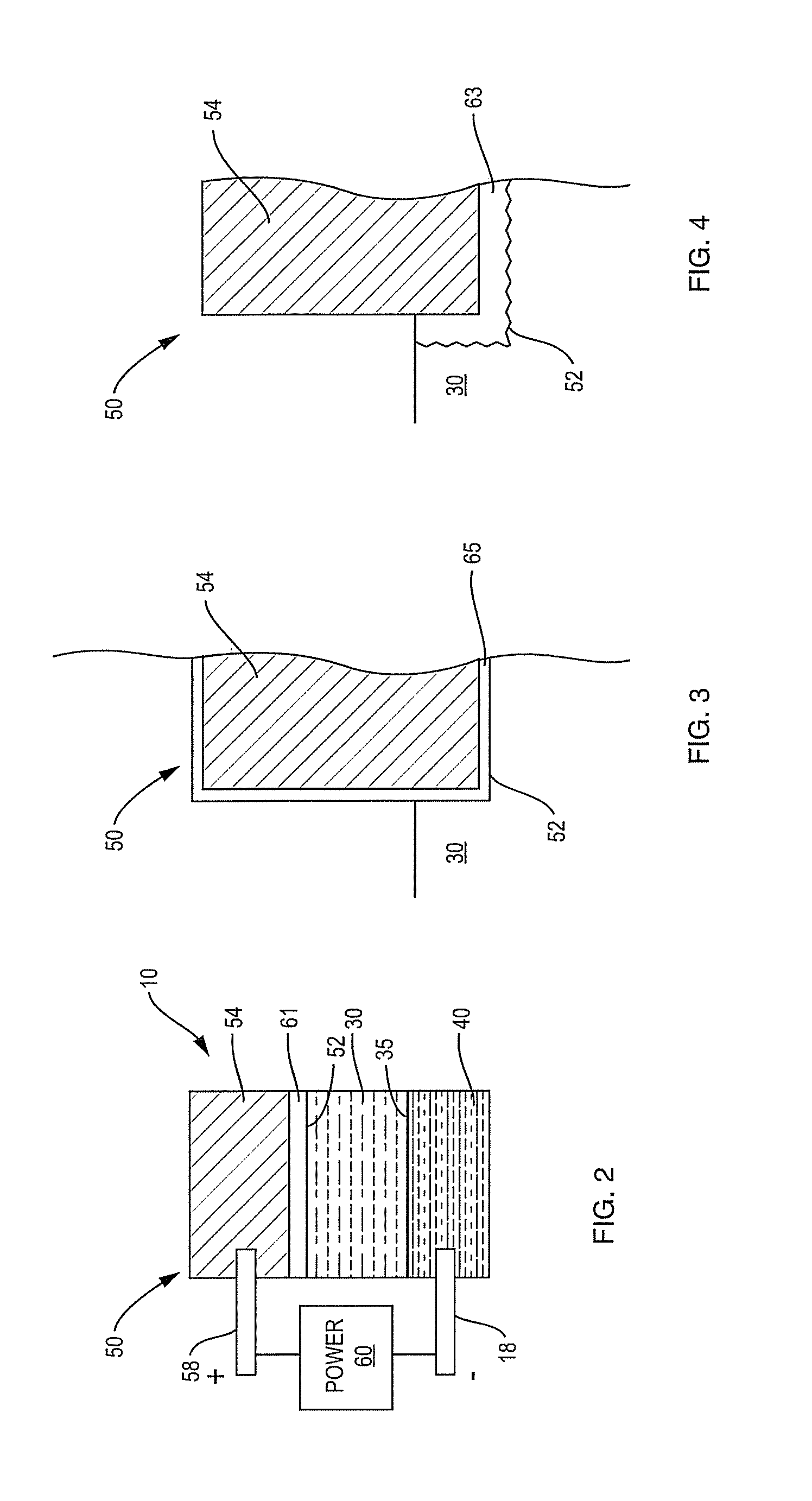

Liquid-liquid fuel cell systems having flow-through anodes and flow-by cathodes

The invention disclosed herein relates to fuel cell electrode pair assemblies, not having interposing proton exchange membranes, configured to receive and react with liquid anolyte and liquid catholyte microfluidic flowstreams. In one embodiment, the present invention is directed to a fuel cell electrode pair assembly, not having an interposing proton exchange membrane, configured to receive and react with a liquid microfluidic anolyte flowstream (e.g., laminarly flowing methanol solution) and a liquid microfluidic catholyte flowstream (e.g., laminarly flowing nitric acid solution), wherein the fuel cell electrode pair assembly comprises: a porous flow-through anode; a porous flow-by cathode confronting and spaced apart from the anode; and a central plenum interposed between and connected to the anode and the cathode.

Owner:EPD INVESTMENT CO

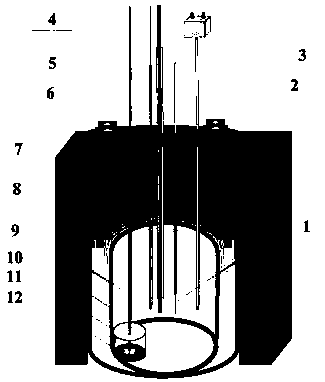

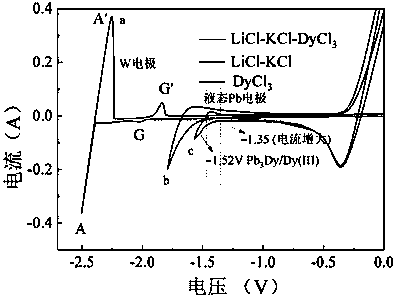

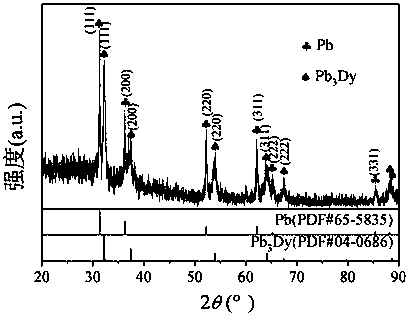

Method for electrolytically extracting rare earth through liquid cathode molten salt and preparing lead rare earth alloy

ActiveCN110195243AHigh extraction rateSolve the problem of reciprocating cycle idle currentElectrodesLithium chlorideElectrolysis

The invention discloses a method for electrolytically extracting rare earth through liquid cathode molten salt and preparing lead rare earth alloy, and belongs to the technical field of nuclear fuel reprocessing. According to the technical scheme, lithium chloride, potassium chloride, and rare earth chloride are put into an alumina crucible, a mixture is subjected to temperature rise and is meltedto molten salt, a small crucible containing a lead ingot is put into the alumina crucible, and heat preservation is carried out; a cathode, a reference electrode and an auxiliary electrode are inserted into the molten salt to be connected with an electrochemical workstation; electrochemical workstation cyclic voltamogram and timing potential are used for measuring rare-earth reduction peak potential and alloy forming current; according to the reduction peak potential of the rare earth on the liquid-state lead electrode and the forming current of the lead rare earth alloy, constant potential electrolysis and constant current electrolysis are carried out for extracting the rare earth; the small crucible is cooled under the argon protection, an electrolysate is taken out, ethyl alcohol and deionized water are used for flushing, low-temperature drying is carried out, and the lead rare earth alloy is obtained. Compared with a method for extruding the rare earth through a solid electrode and obtaining the lead rare earth alloy, the method is short in flow process, and high in extraction rate, and the rare earth extraction rate is up to 97.2%.

Owner:EAST CHINA UNIV OF TECH

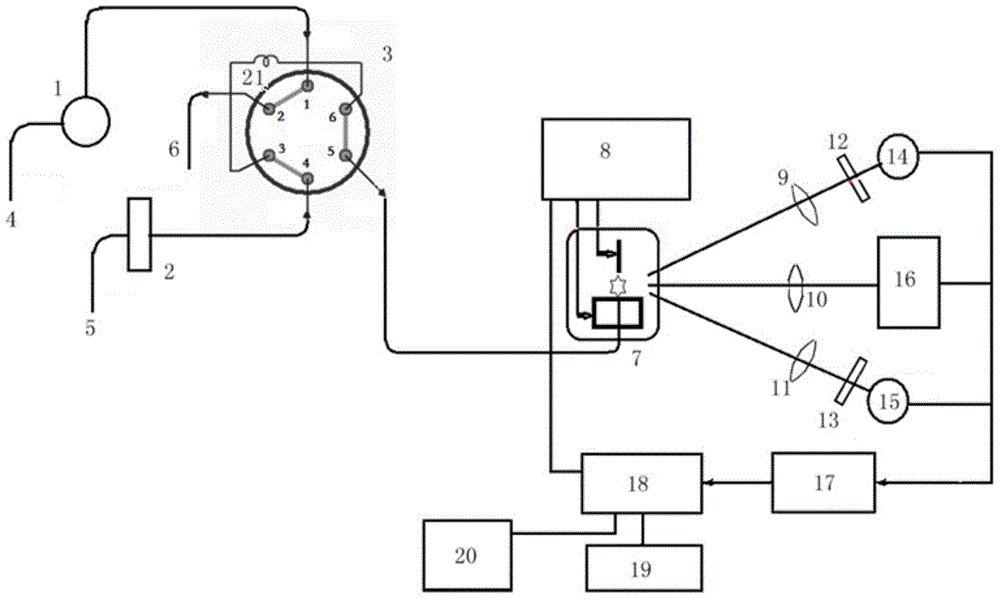

Portable liquid cathode glow discharge element analyzer

InactiveCN104964965ASimple structureEasy to implementAnalysis by electrical excitationLiquid cathodeLiquid state

The present invention discloses a portable liquid cathode glow discharge element analyzer, which comprises a sample injection system, a liquid-state cathode glow discharge system, an optical system, and a microprocessor and data processor, wherein the sample injection system is connected with a sample and the sample inlet of the liquid-state cathode glow discharge system, the liquid-state cathode glow discharge system performs electrical arc discharge atomization on the entering sample, the optical system collects the emission spectrum lines generated during the atomization of the liquid-state cathode glow discharge system and transmits to the microprocessor and data processor, and the microprocessor and data processor controls the sample injection system and the liquid-state cathode glow discharge system in a coordinated manner, and performs sample element determination according to the signal transmitted by the optical system. The portable liquid cathode glow discharge element analyzer of the present invention has characteristics of simple structure, easy achieving, reliable performance, accurate determination, and great market potential.

Owner:NAT RESERACH CENT OF GEOANALYSIS +1

Liquid cathode fuel battery

InactiveCN1921198AIncrease volumetric energy densityEasy to carryCell electrodesFuel cellsState of artFuel cells

The invention relates to a liquid cathode fuel battery to solve the problems of present technique that low energy density and transportation. Wherein, the invention is characterized in that: the fuel battery comprises halide oxy acid at 1-100 mass% or the acid liquid with halide oxy acid as cathode fuel, to directly or indirectly discharge at cathode. The fuel battery has high volume energy density and better discharge property.

Owner:崔骥 +1

Analysis device and method for detecting multiple anions simultaneously

InactiveCN105628854ASimple structureImprove performanceComponent separationAnalysis by electrical excitationIon chromatographyData treatment

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

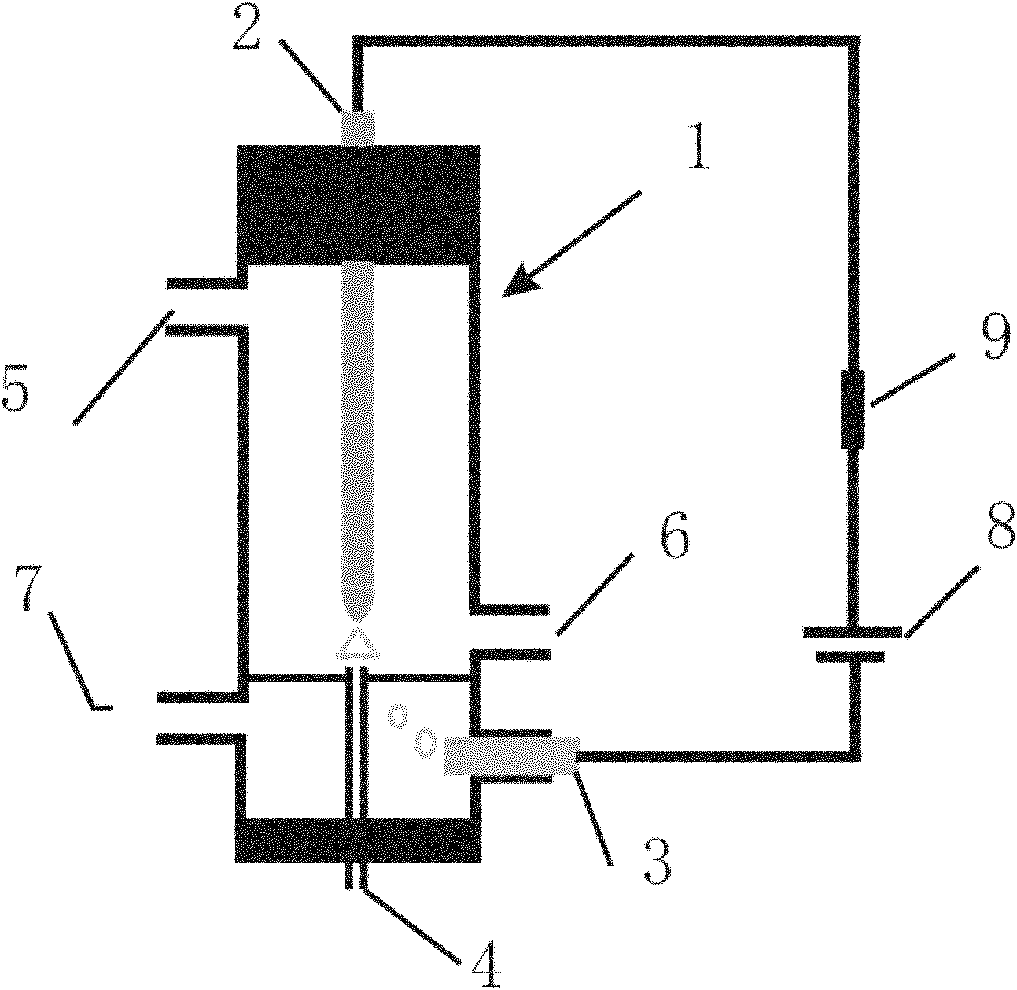

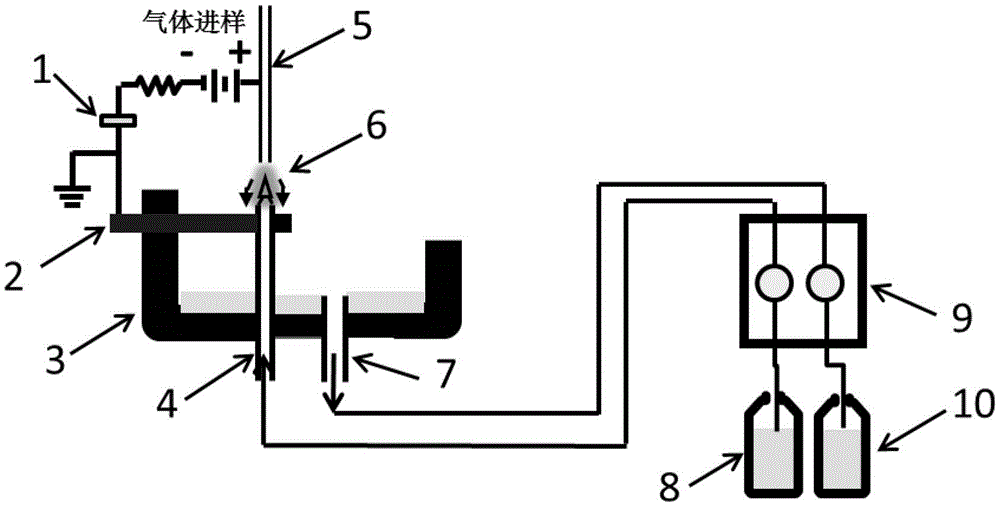

Microplasma apparatus suitable for metallic element analysis in gas

ActiveCN105651760AEnables direct injectionHigh sensitivitySamples introduction/extractionAnalysis by electrical excitationElement analysisHigh pressure

The invention relates to a microplasma apparatus suitable for metallic element analysis in gas. The apparatus comprises a high-voltage power supply, a buffer resistor, a hollow metal anode, and a liquid cathode, wherein the hollow metal anode is connected to a positive electrode of the high-voltage power supply through the buffer resistor, and the liquid cathode is connected to a negative electrode of the high-voltage power supply through a graphite electrode. The microplasma apparatus has such a structure that a discharging area is formed between the hollow metal anode and the liquid cathode, and the hollow metal anode is taken as a sampling pipe to enable to-be-detected gas to enter the discharging area and to be excited. The apparatus is simple in structure, small in size, simple to operate, and low in cost. Gas can be directly sampled without affecting stability of microplasma; the metallic element analysis is high in sensitivity; and a base is established for combination of the apparatus and other instruments.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

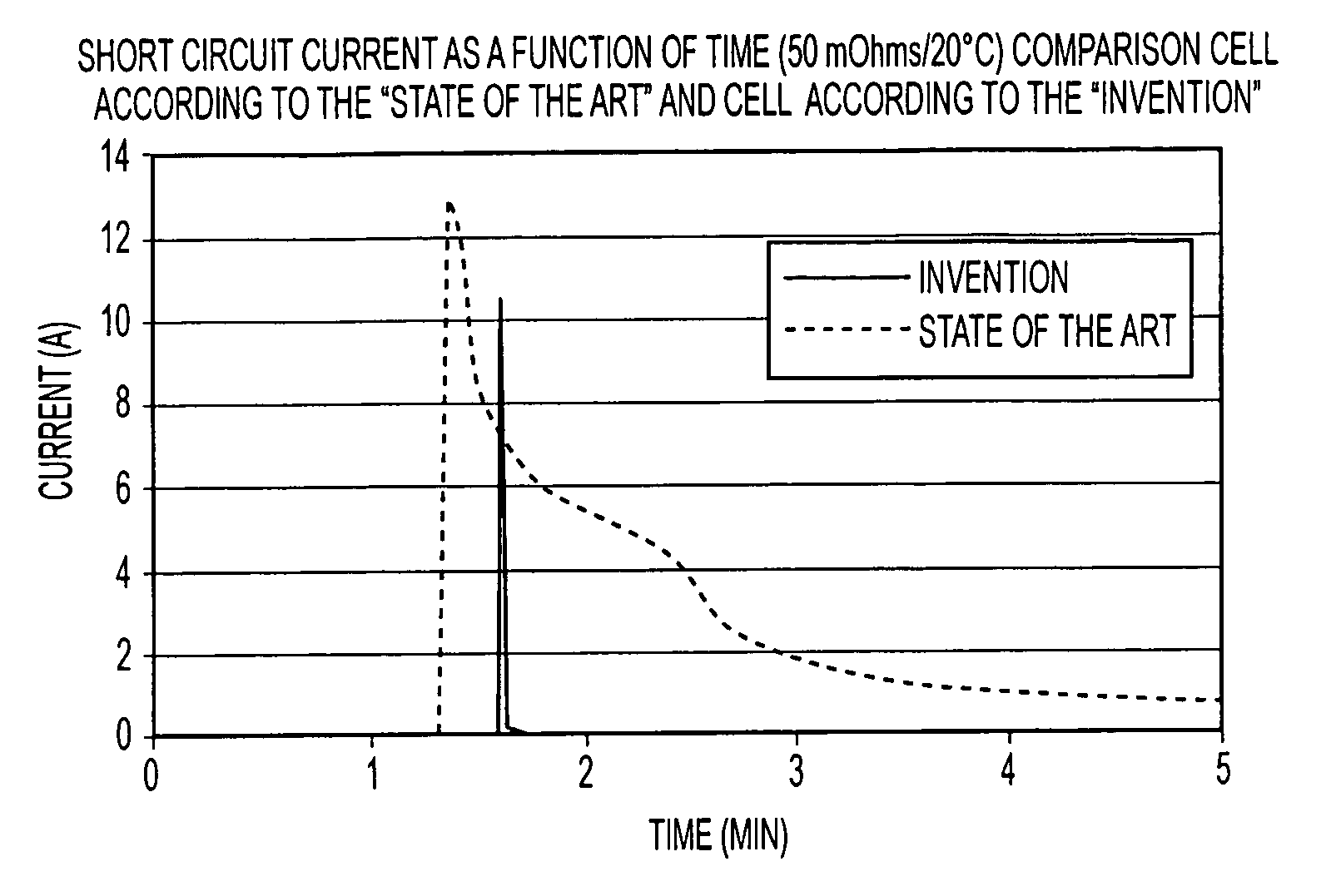

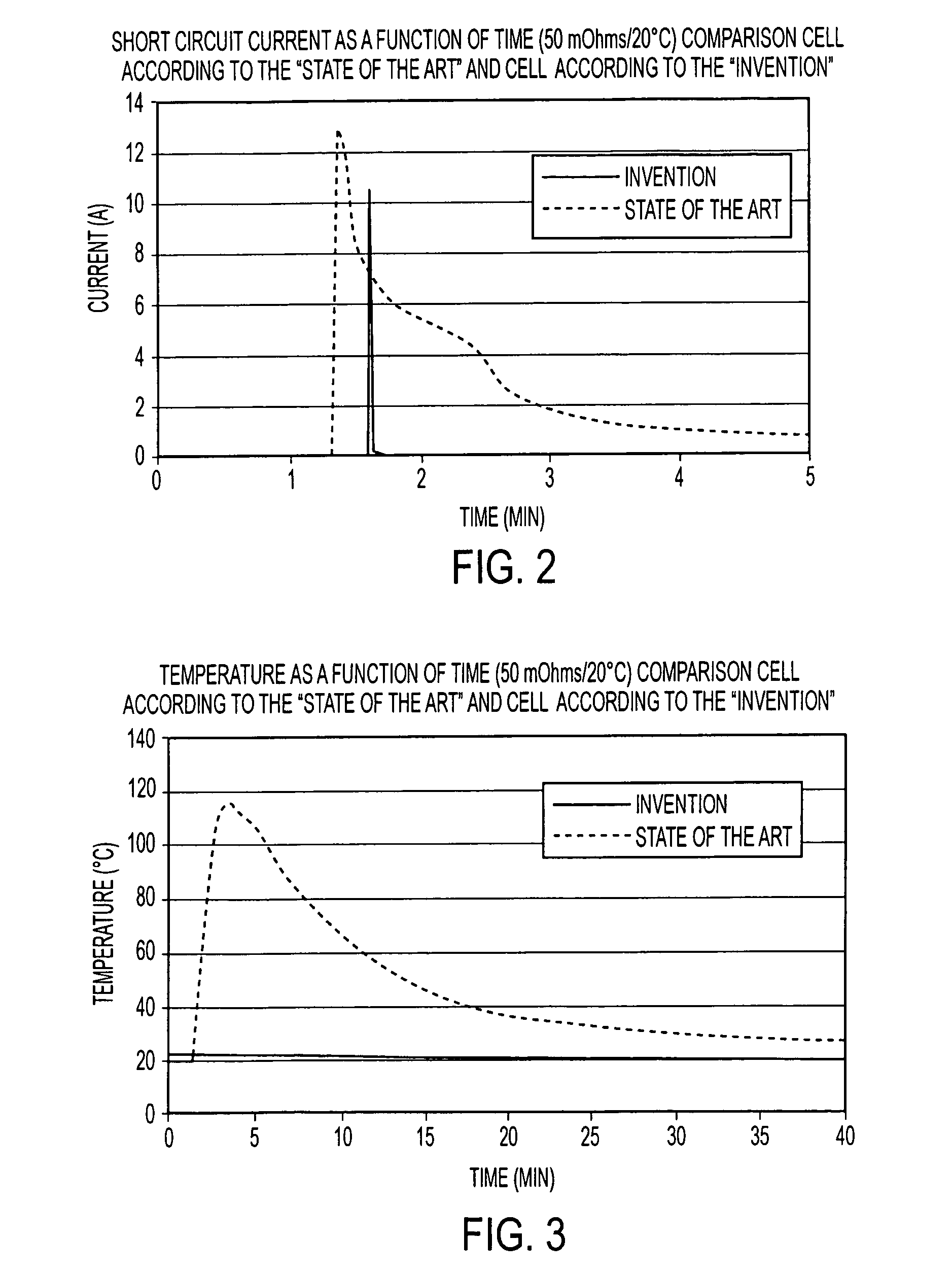

Electrochemical generator with a liquid cathode

InactiveUS20060166084A1Reduce riskReduce porosityNon-aqueous electrolyte cellsActive material electrodesPorosityLiquid cathode

The subject of the invention is an electrochemical generator with a liquid positive material comprising at least one metal anode and at least one cathode, characterized in that the cathode has a very low porosity, less than 0.1. A subject of the invention is also the use of a conductive element chosen from Mo, C, Ni, W and Ta for the production of a cathode with a porosity of less than 0.1.

Owner:SAFT GRP SA

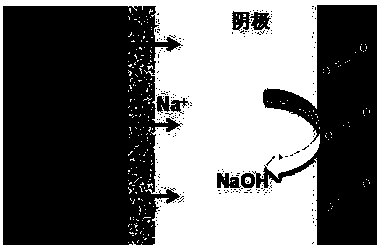

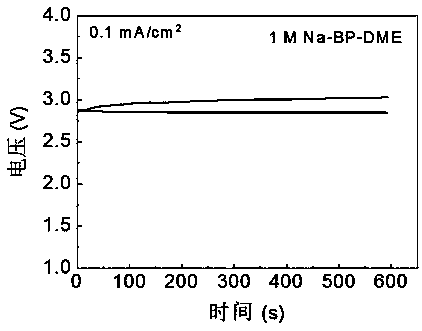

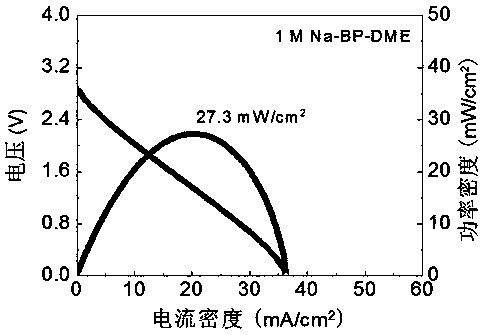

Sodium ion air battery

InactiveCN108258243AHigh theoretical energy densityHigh theoretical capacityFuel and secondary cellsCell electrodesLiquid cathodePhysical chemistry

The invention discloses a sodium ion air battery, and belongs to the technical field of electrochemistry. The sodium ion air battery disclosed by the invention comprises a liquid cathode, solid electrolyte, aqueous electrolyte solution and an air anode; the liquid cathode is separated from the aqueous electrolyte solution by using the solid electrolyte; NaOH solution is used as the aqueous electrolyte solution; biphenyl sodium (Na-PB-DME) solution is used as the liquid cathode; the concentration of the sodium in biphenyl sodium solution is 1 to 5 mol / L, wherein the proportion of water in the biphenyl sodium solution is not greater than 6 mg / L. The battery disclosed by the invention has high discharge voltage, high specific discharge capacity and output power density; moreover, the sodium ion air battery disclosed by the invention has high stability and safety.

Owner:KUNMING UNIV OF SCI & TECH

Extraction of liquid elements by electrolysis of oxides

An electrolytic extraction method wins a target element from an oxide feedstock compound thereof. The feedstock compound is dissolved in an oxide melt in contact with a cathode and an anode in an electrolytic cell. During electrolysis the target element is deposited at a liquid cathode and coalesces therewith. Oxygen is evolved on an anode bearing a solid oxide layer, in contact with the oxide melt, over a metallic anode substrate.

Owner:MASSACHUSETTS INST OF TECH

Method for directly preparing liquid cathode of lithium-sulfur battery through potential control

ActiveCN111564602AExcellent rate performanceImprove uniformityElectrochemical processing of electrodesPositive electrodesLiquid cathodeLithium–sulfur battery

The invention discloses a method for directly preparing a liquid cathode of a lithium-sulfur battery through potential control. Liquid active substances are directly prepared through potential control, and the types of the liquid active substances are subjected to reaction regulation and control of accurate potentials. The substances are directly added to a positive electrode current collector toprepare a battery pole piece for a positive electrode of the lithium-sulfur battery. The liquid active substance prepared by utilizing potential control is easy to realize uniform distribution of theliquid substance in the current collector, and the electrode prepared from the liquid active substance can enable the lithium-sulfur battery to have the advantages of high rate capability, high sulfurutilization rate, low capacity attenuation rate and the like. According to the method, the liquid active substance can be directly added to the positive electrode current collector to prepare the battery pole piece, such as a current collector selectable carbon nanotube, graphene, conductive fiber, conductive carbon cloth and the like, and the method for directly preparing the liquid positive electrode of the lithium-sulfur battery by using the potential control method is provided. The problems of non-uniform sulfur distribution, low active substance utilization rate, poor rate capability, high capacity attenuation rate and the like of an existing lithium-sulfur battery positive plate are effectively solved, the manufacturing method is simple and rapid, and large-scale commercial production is easy to realize.

Owner:JIANGXI UNIV OF SCI & TECH

Method for preparing mixed intermediate alloy of magnesium and light rare earth with double-cathode method

The invention provides a method for preparing a mixed intermediate alloy of magnesium and light rare earth with a double-cathode method, and belongs to the technical field of thermometallurgy. A graphite crucible is taken as an anode, magnesium lanthanum praseodymium cerium with low concentration is taken as a liquid cathode and forms double cathodes with a molybdenum rod; an electrolyte is added to the graphite crucible for electrolyzing, and the mixed intermediate alloy of magnesium and light rare earth is obtained; the electrolyte is formed by mixing magnesium chloride, lanthanum praseodymium cerium chloride and potassium chloride; and lanthanum praseodymium cerium chloride and magnesium chloride are added in an electrolyzing process. According to the method, a large number of low-price surplus mixed light rare earth materials are taken as raw materials, metal magnesium and rare earth metal are not used, chlorides of mixed light rare earth and magnesium are used, rare earth ions and magnesium ions are electrolyzed and deposited under the action of double electrodes, so that the intermediate alloy with a melting point close to magnesium-mixed light rare earth eutectic temperature is generated. The method is low in cost and high in operability. The prepared mixed intermediate alloy of magnesium and light rare earth is a basic material for preparing a high-strength and corrosion-resistant magnesium alloy.

Owner:扬州宏福铝业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com