Extraction of Liquid Elements by Electrolysis of Oxides

a technology of oxide ores and liquid elements, which is applied in the direction of electrolysis components, instruments, optics, etc., can solve the problems of pig iron further consuming energy, iron produced conventionally in a blast furnace entails significant process emissions, and the need for replacement technologies for basic metal smelting operations is becoming critical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

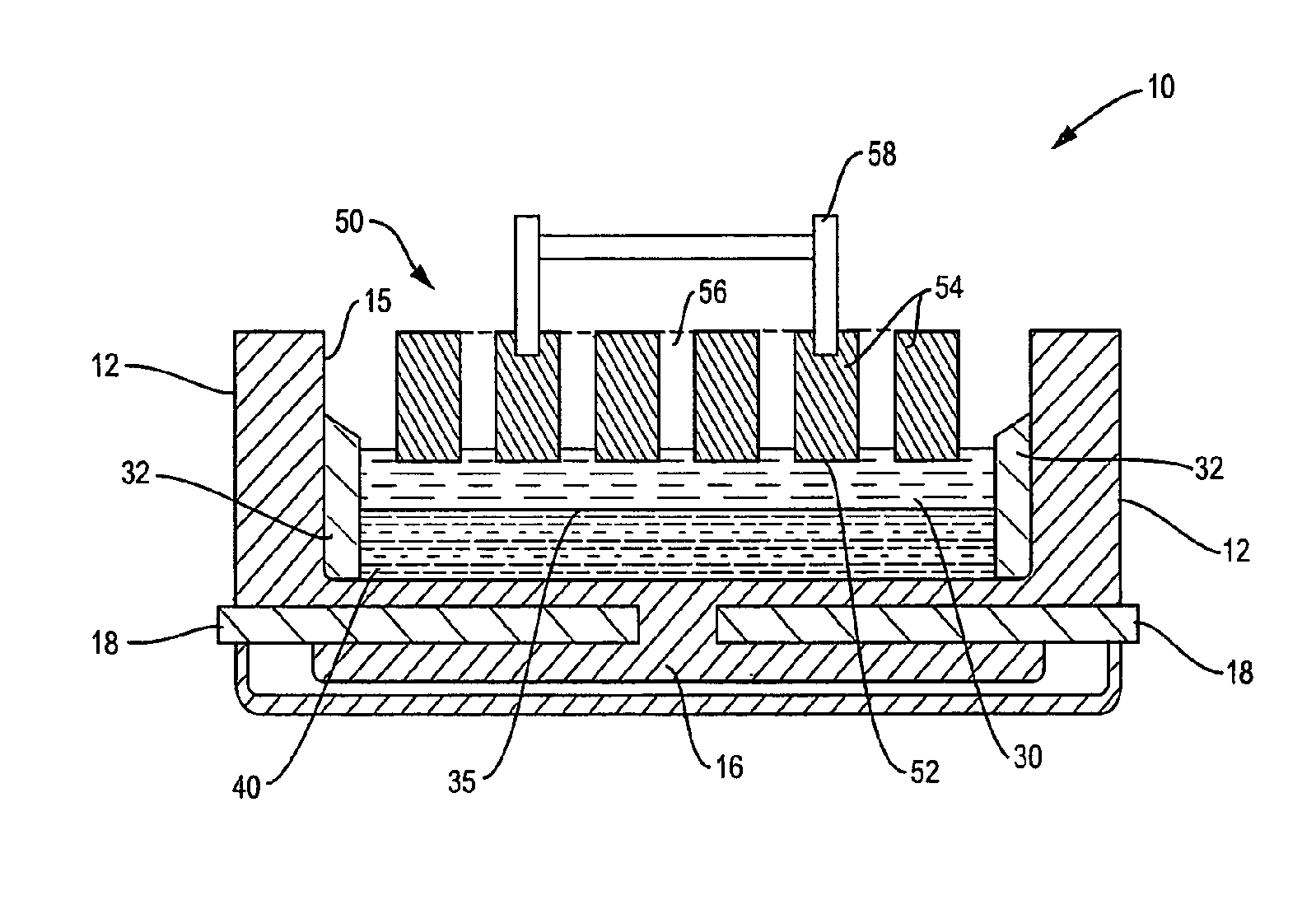

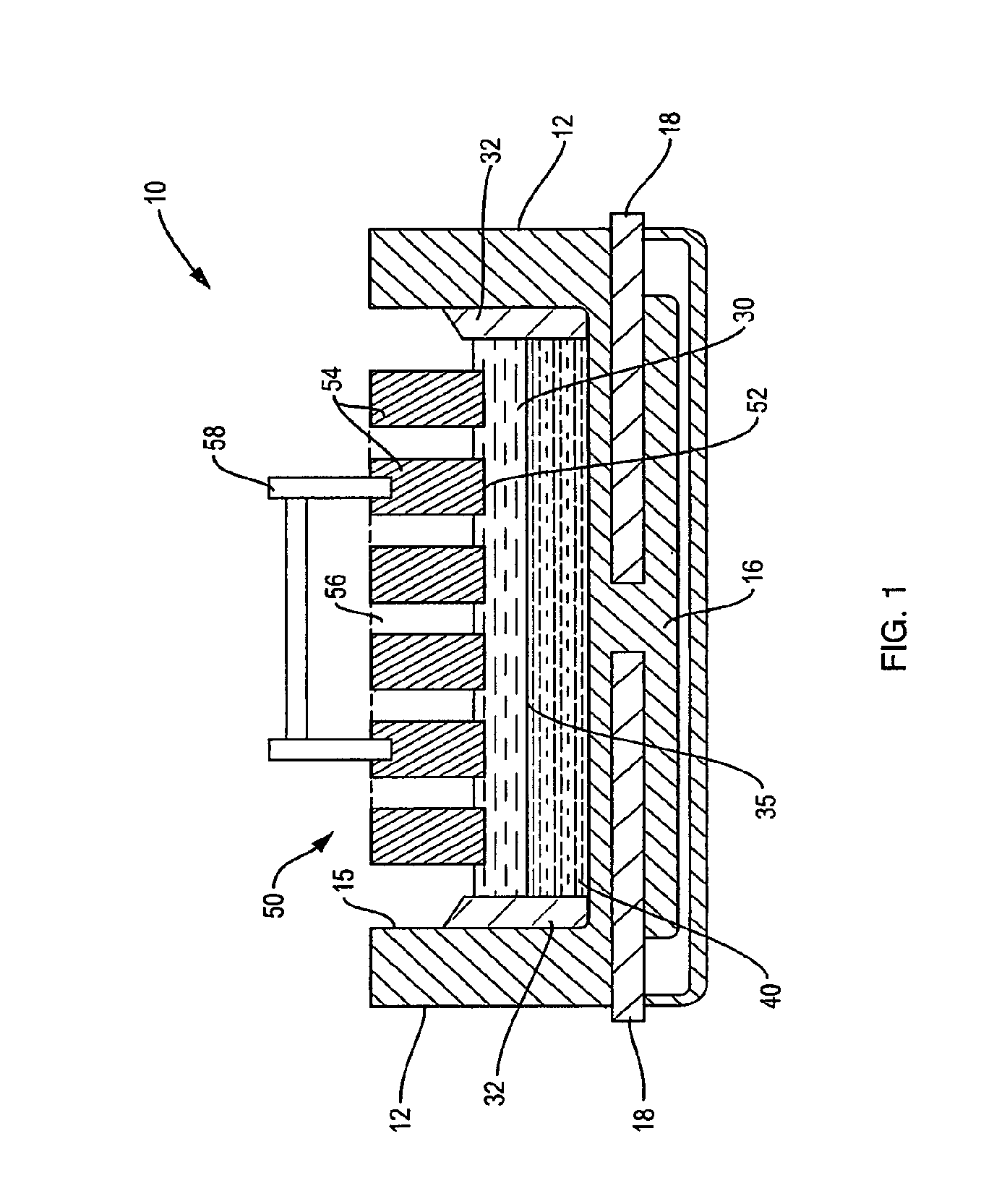

[0019]Molten oxide electrolysis (“MOE”) entails the direct electrolysis of an oxide feedstock compound to extract a target element therefrom. MOE wins the target metal with production of gaseous oxygen and without, or with reduced, release of carbon dioxide or other objectionable fugitive species. Because the target metal is reduced directly from oxide, preparatory processing of source compounds is much cleaner and simpler than for conventional extraction techniques in the case of many metals. MOE has the potential to produce metal of exceptional purity, especially with regard to so-called interstitial elements, namely carbon and nitrogen. Since MOE may produce a target element in liquid form, difficulties associated with dendritic deposits are avoided. MOE is furthermore energy efficient for extraction of an element in its liquid state in that irreversibilities necessarily accompanying the flow of electric current through components of an electrolytic cell also serve to maintain ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| Tm | aaaaa | aaaaa |

| Tm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com