Sodium ion air battery

An air battery and sodium ion technology, applied in the field of electrochemistry, can solve the problems of reducing battery life, increasing battery safety hazards, and unsatisfactory cycle performance of batteries, achieving long cycle life and improving electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

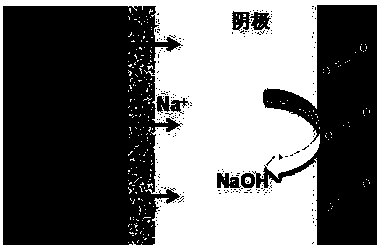

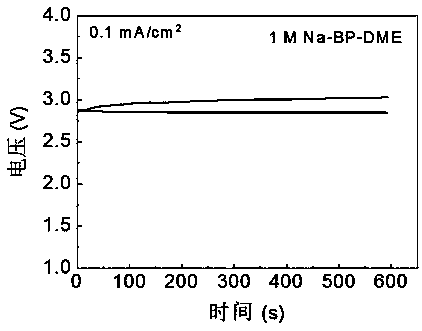

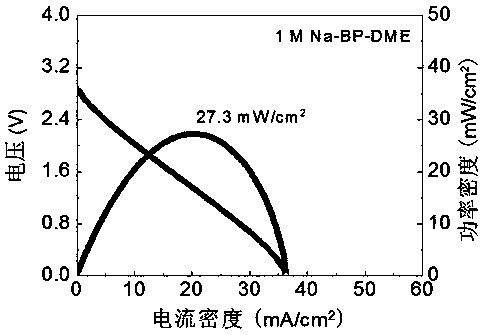

[0024] Such as figure 1 As shown, a new type of sodium-ion-air battery: from the negative electrode to the positive electrode, it includes biphenyl sodium liquid negative electrode, solid electrolyte, aqueous electrolyte, and air positive electrode; wherein, the concentration of sodium in the biphenyl sodium solution is 1 mol / L , the solid electrolyte is a NASICON solid electrolyte diaphragm with a thickness of 1 mm and a diameter of 16 mm, the aqueous electrolyte is a 1 mol / L NaOH aqueous solution, the air positive electrode is made of a catalytic layer and a conductive nickel mesh, and the catalytic layer is made of Pt / C The catalyst, activated carbon, and polytetrafluoroethylene are prepared by mixing and uniformly coating on carbon paper in a solvent of alcohol and water. The mass fraction of Pt in the Pt / C catalyst is 40%, and the Pt / C catalyst, activated carbon, and polytetrafluoroethylene The mass ratio of ethylene is 5:1:1;

[0025] The sodium-ion-air battery assemble...

Embodiment 2

[0027] Such as figure 1 As shown, a new type of sodium-ion-air battery: from the negative electrode to the positive electrode, it includes a biphenyl sodium liquid negative electrode, a solid electrolyte, an aqueous electrolyte, and an air positive electrode; wherein, the concentration of sodium in the biphenyl sodium solution is 5 mol / L ; The solid electrolyte is a NASICON solid electrolyte diaphragm with a thickness of 1 mm and a diameter of 16 mm. The aqueous electrolyte is a 1 mol / L NaOH aqueous solution. The air positive electrode is pressed by a catalytic layer and a conductive nickel mesh; the catalytic layer is made of Pt / C Catalyst, activated carbon, polytetrafluoroethylene are prepared by mixing uniformly in the solvent of alcohol and water and coating on carbon paper. The mass fraction of Pt in the Pt / C catalyst is 40%, and the Pt / C catalyst, activated carbon, polytetrafluoroethylene The mass ratio of ethylene is 5:5:2;

[0028] A new type of sodium-ion-air battery...

Embodiment 3

[0030] Such as figure 1 As shown, a new type of sodium-ion-air battery: from the negative electrode to the positive electrode, it includes a biphenyl sodium liquid negative electrode, a solid electrolyte, an aqueous electrolyte, and an air positive electrode; wherein, the concentration of sodium in the biphenyl sodium solution is 2 mol / L , the solid electrolyte is a NASICON solid electrolyte diaphragm with a thickness of 1 mm and a diameter of 16 mm, the aqueous electrolyte is a 1 mol / L NaOH aqueous solution, the air positive electrode is made of a catalytic layer and a conductive nickel mesh, and the catalytic layer is made of Pt / C The catalyst, activated carbon, and polytetrafluoroethylene are prepared by mixing and uniformly coating on carbon paper in a solvent of alcohol and water. The mass fraction of Pt in the Pt / C catalyst is 40%, and the Pt / C catalyst, activated carbon, and polytetrafluoroethylene The mass ratio of ethylene is 10:1:1; a new type of sodium-ion-air batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com