A high-safety, high-energy quasi-solid-state lithium secondary battery based on lithium sulfide positive electrode and its preparation method

A lithium secondary battery, quasi-solid-state technology, applied in the direction of secondary batteries, positive electrodes, battery electrodes, etc., can solve problems that plague the creation and application of secondary batteries, battery leakage, flatulence, and electrode dissolution, etc., to achieve improved battery performance. Safety, ensuring battery performance, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of cathode material

[0040] 1.1 Dissolve lithium sulfide in ethanol to form a homogeneous solution with a concentration of 10mg mL -1 ;

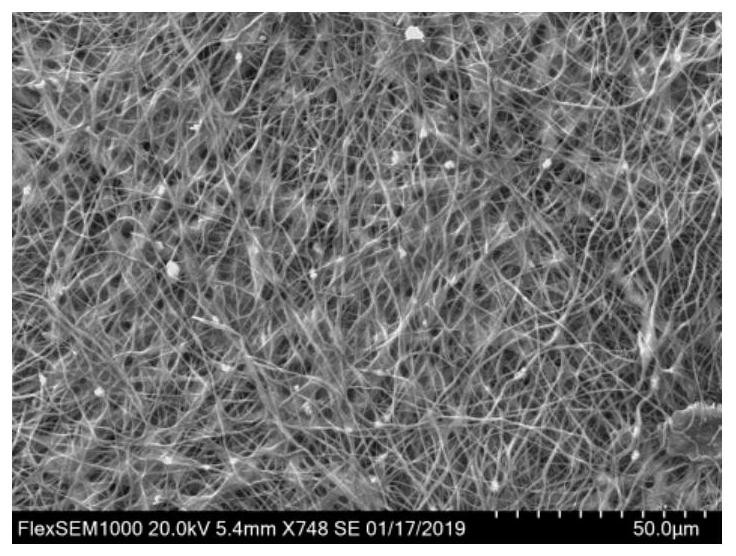

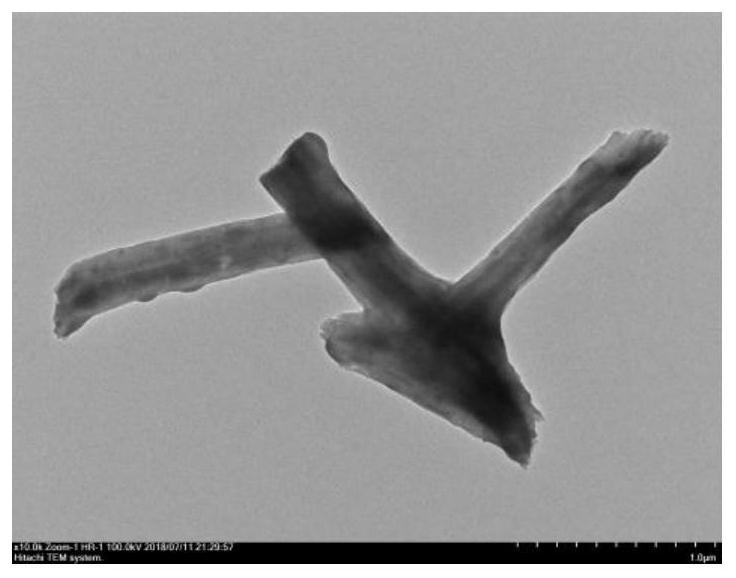

[0041] 1.2 In the glove box (water content <0.1ppm, oxygen content <0.1ppm), slowly drop the lithium sulfide solution obtained in step 1.1 on the porous carbon fiber to form a composite positive electrode material. The lithium sulfide loading in the obtained positive electrode material is 60wt.%.

[0042] 2. Preparation of negative electrode materials

[0043] Si nanoparticles, porous carbon fibers and binders are formulated into a slurry at a ratio of 7:2:1, coated on metal copper foil, and dried to obtain a composite positive electrode material. The binder is polyvinylidene fluoride. The positive electrode material loading is 50wt.%.

[0044] 3. Preparation of gel polymer-based electrolyte

[0045] Polyethylene oxide and lithium bistrifluoromethanesulfonimide are dissolved in a mixed solvent of 1,3 dioxolane an...

Embodiment 2

[0050] 1. Preparation of cathode material

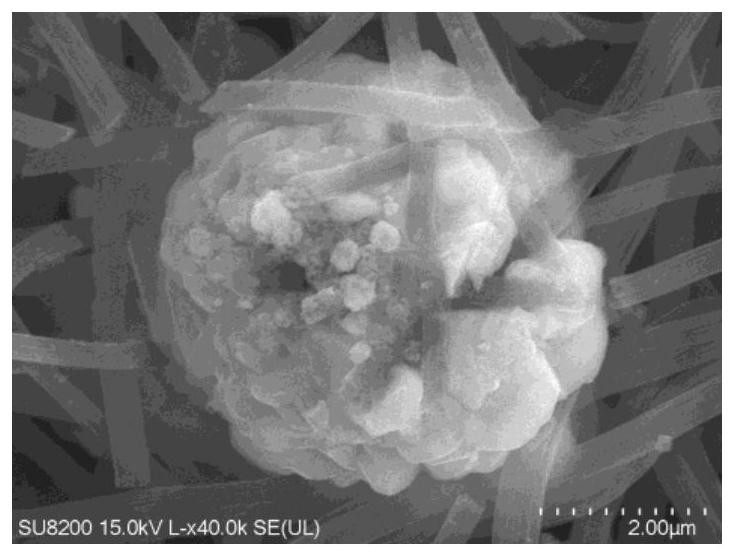

[0051] 1.1 Dissolve lithium sulfide in ethanol to form a homogeneous solution with a concentration of 25mg mL -1 ;

[0052] 1.2 In a glove box (water content <0.1ppm, oxygen content <0.1ppm), slowly drop the lithium sulfide solution obtained in step 1.1 onto acetylene black to form a composite positive electrode material. The lithium sulfide loading in the obtained positive electrode material is 67.5wt.%.

[0053] 2. Preparation of negative electrode materials

[0054] The silicon nanoparticles, acetylene black and binder are formulated into a slurry at a ratio of 7:2:1, coated on metal copper foil, and dried to obtain a composite positive electrode material. The binder is polyvinylidene fluoride. The positive electrode material loading is 62.5wt.%.

[0055] 3. Preparation of gel polymer-based electrolyte

[0056] Polyethylene oxide and lithium bistrifluoromethanesulfonimide are dissolved in a mixed solvent of 1,3 dioxolane and...

Embodiment 3

[0061] 1. Preparation of cathode material

[0062] 1.1 Dissolve lithium sulfide in ethanol to form a homogeneous solution with a concentration of 40mg mL -1 ;

[0063] 1.2 In a glove box (water content <0.1ppm, oxygen content <0.1ppm), slowly drop the lithium sulfide solution obtained in step 1.1 onto acetylene black to form a composite positive electrode material. The lithium sulfide loading in the obtained positive electrode material is 75wt.%.

[0064] 2. Preparation of negative electrode materials

[0065] Prepare ferric oxide nanoparticles, porous carbon fibers and binders in a ratio of 7:2:1 to make a slurry, coat the metal copper foil, and dry to obtain a composite positive electrode material. The binder is polyvinylidene fluoride. The positive electrode material loading is 75wt.%.

[0066] 3. Preparation of gel polymer-based electrolyte

[0067] Polyethylene oxide and lithium bistrifluoromethanesulfonimide are dissolved in a mixed solvent of 1,3 dioxolane and eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com