Composite electrolyte for lithium-air battery and preparation method thereof

A composite electrolyte and lithium-air battery technology, which is applied in fuel cell half-cells and secondary battery-type half-cells, secondary batteries, circuits, etc., can solve the problem of limited performance improvement of polymers and liquid electrolytes, liquid electrolytes Volatility, electrolyte drying and other problems, to achieve the effect of widening the working temperature range, reducing overpotential, and alleviating poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.3120g lithium trifluoromethanesulfonate (LiCF 3 SO 3 ) dissolved in 2.0 mL of N-methyl-N-propylpyrrole triflate (PYR 13 CF 3 SO3 ), to get 1.0mol / L PYR 13 CF 3 SO 3 / LiCF 3 SO 3 solution, and add 3wt% hydrophobic nano-silica, mix well, in which the ionic liquid cationic PYR 13 + The structural formula is:

[0029] (wherein R1=CH2CH2CH3, R2=CH3)

[0030] Polyvinyl butyral (PVB) based polymer film has a thickness of 95.0 μm and a density of 0.211 g / cm 3 And the porosity is 65.3%, cut into Φ16 discs, and soaked in 1.0M PYR which is 9 times its weight 13 CF 3 SO 3 / LiCF 3 SO 3 After soaking in the solution for 12 hours at 40° C., take it out, absorb the surface solution with filter paper, and the liquid absorption rate of the polymer film reaches 796%. The structural units of the polymer matrix are:

[0031]

[0032] (where R3=R4=CH2CH2CH3)

[0033] The preparation of electrolyte solution and composite electrolyte is carried out in an argon glove bo...

Embodiment 2

[0041] 0.1519g lithium hexafluorophosphate (LiPF 6 ) dissolved in 2.0 mL of N‐methyl‐N‐butylpyrrole hexafluorophosphate (PYR 14 PF 6 ), to get 0.5mol / L PYR 14 PF 6 / LiPF 6 solution in which the ionic liquid cation PYR 14 + The structural formula is:

[0042] (wherein R1=CH2CH2CH2CH3, R2=CH3)

[0043] Polyvinyl formal (PVFM) based polymer film has a thickness of 113.7 μm and a density of 0.179 g / cm 3 And the porosity is 78.2%, cut into Φ16 discs, and soaked in 0.5M PYR which is 10 times its weight 14 PF 6 / LiPF 6 After soaking in the solution for 10 hours at 80° C., take it out, absorb the surface solution with filter paper, and the liquid absorption rate of the polymer film reaches 854%. The structural units of the polymer matrix are:

[0044]

[0045] (where R3=R4=H)

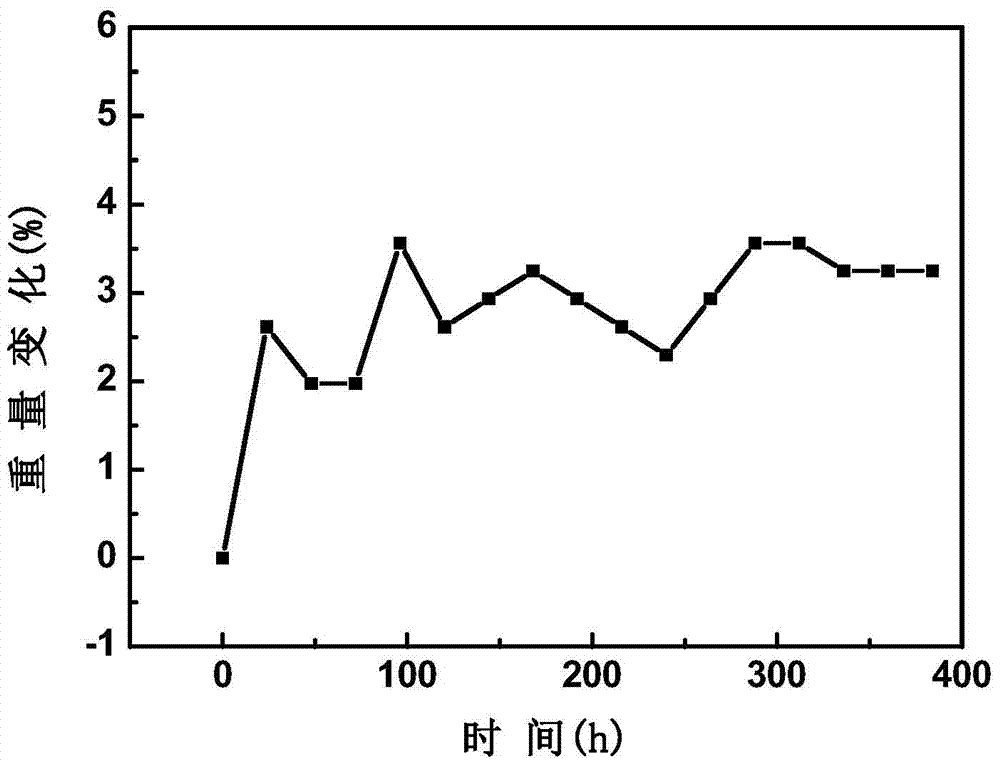

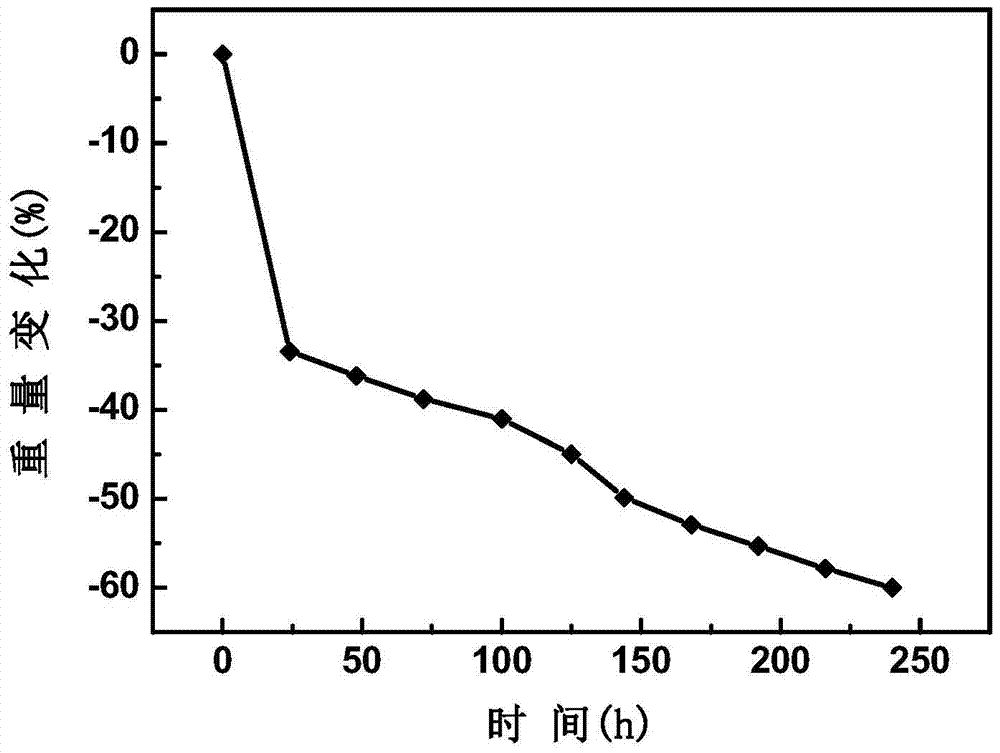

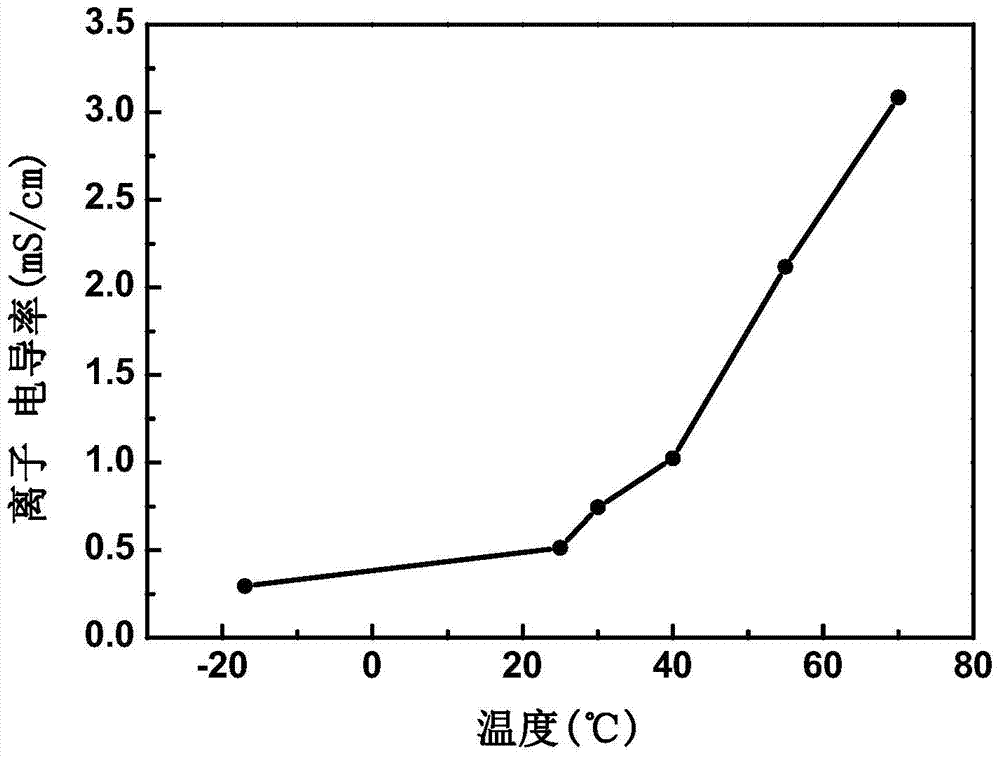

[0046] The preparation of electrolyte solution and composite electrolyte is carried out in an argon glove box with water content and oxygen content less than 0.5ppm. image 3 For the test res...

Embodiment 3

[0048] Dissolve 0.1163 g of lithium dioxalate borate (LiBOB) in 2.0 mL of N‐methyl‐N‐butylpyrrole bis(trifluoromethylsulfonyl)imide (PYR 14 TFSI), get 0.3mol / L PYR 14 TFSI / LiBOB solution, then add 5wt% fluoroethylene carbonate (FEC), mix well, in which the ionic liquid cationic PYR 14 + The structural formula is:

[0049] (wherein R1=CH2CH2CH2CH3, R2=CH3)

[0050] Polyvinyl butyral (PVB)-based polymer film has a thickness of 85.7 μm and a density of 0.234 g / cm 3 And the porosity is 61.2%, cut into Φ16 discs, and soaked in 0.3MPYR which is 8 times its weight 14 In TFSI / LiBOB+5% FEC solution, soak at 50°C for 10 hours, take it out, and absorb the surface solution with filter paper, and the liquid absorption rate of the polymer film reaches 758%. The structural units of the polymer matrix are:

[0051]

[0052] (where R3=R4=CH2CH2CH3)

[0053] The preparation of electrolyte solution and composite electrolyte is carried out in an argon glove box with water content and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com