Laminated battery cell production process, laminated battery cell production system and laminated battery cell

A production system and production process technology, applied in the direction of electrochemical generators, electrode collector coatings, non-aqueous electrolyte batteries, etc., can solve problems such as battery energy density limitations, safety hazards, thermal runaway, etc., and reduce battery weight , Improve safety, improve energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

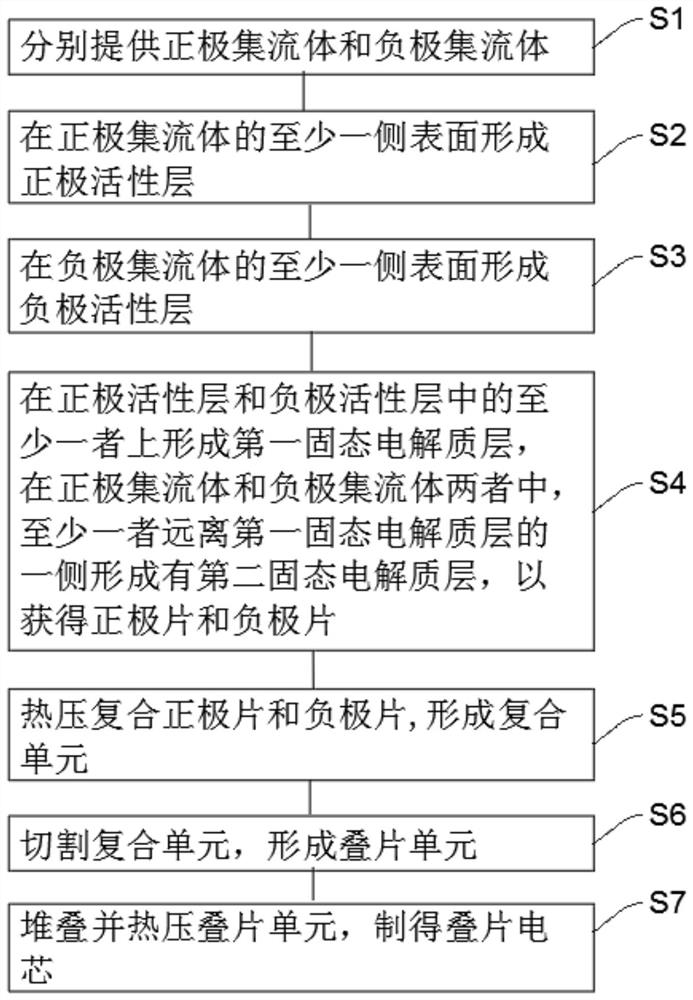

[0054] Please refer to figure 1 , this embodiment provides a production process for laminated batteries, which mainly includes the following steps:

[0055] S1: providing a positive electrode current collector 101 and a negative electrode current collector 201 respectively. It can be understood that the positive electrode current collector 101 is the basic material for making the positive electrode sheet, including but not limited to aluminum foil; the negative electrode current collector 201 is the basic material for making the negative electrode sheet, including but not limited to copper foil.

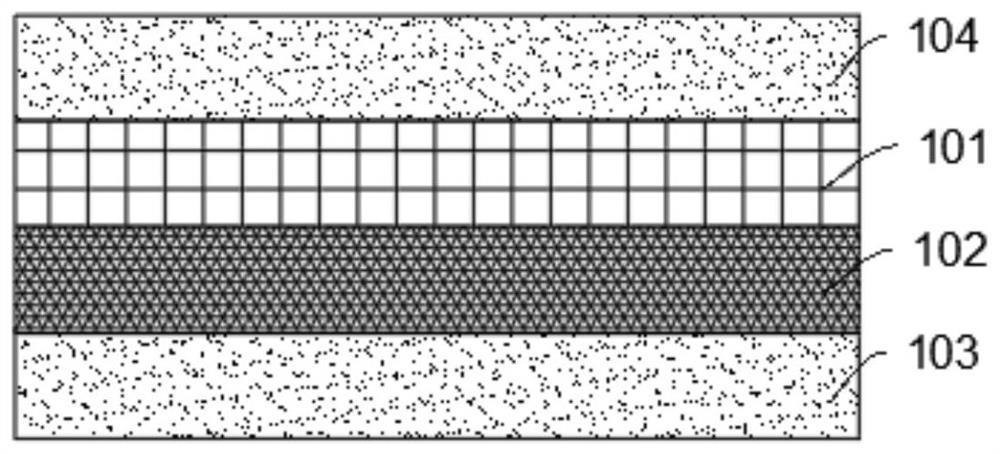

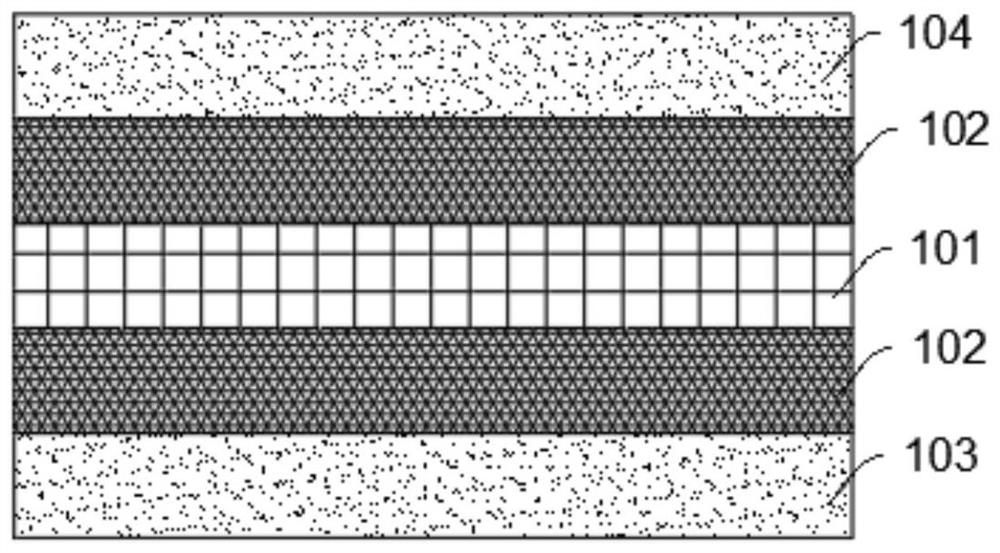

[0056] S2: forming a positive electrode active layer 102 on at least one surface of the positive electrode current collector 101 . Optionally, the positive electrode current collector 101 includes two opposite surfaces, which can be divided into an opposite inner surface and an outer surface according to the division of the later lamination process. Wherein, the positive electrode ...

no. 2 example

[0082] Please refer to Figure 5 , the embodiment of the present invention provides a laminated cell production system 100, including a first discharge device 11, a second discharge device 51, a first positive active coating device 13, a first negative active coating device 53, an electrolyte A coating device 20 , a thermocompression lamination device 16 , a cutting device 17 and a laminating device 18 . The first discharging device 11 and the first positive active coating device 13 are arranged successively, the second discharging device 51 and the first negative active coating device 53 are arranged successively, the first positive active coating device 13 and the first negative active coating At least one of the cloth devices 53 is followed by an electrolyte coating device 20 , and the electrolyte coating device 20 is followed by a thermocompression lamination device 16 , a cutting device 17 and a lamination device 18 in sequence. Wherein, the first discharging device 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com