Rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using liquid cathode

A liquid cathode and rare earth metal technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems that metal products are easily polluted, the service life needs to be improved, and the scale of the electrolytic cell is limited, so as to reduce the radiation heat loss and the unit product Energy consumption, low production cost, and the effect of solving large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

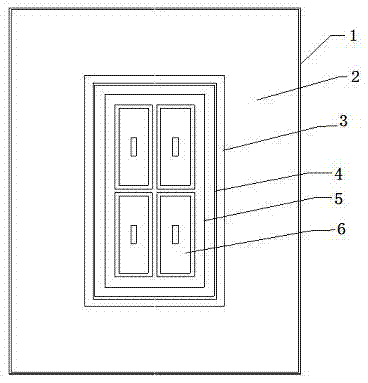

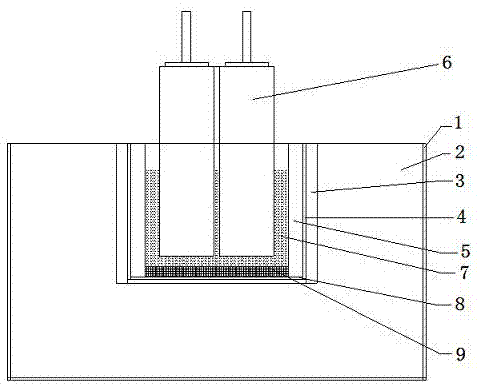

[0026] The molten salt electrolytic cell for producing rare earth metals and alloys with a liquid cathode according to the present invention includes an electrolytic cell body, a cathode bottom plate 8, a liquid cathode 9, an anode 6, a cover plate, and the like. The electrolytic cell body is assembled from the inside to the outside by the crust protective layer 5, the high temperature resistant steel liner 4, the water cooling system 3, the refractory insulation layer 2, and the metal outer steel sleeve 1. The bottom and sides of the electrolytic cell are closed on five sides, and the electrolytic cell The upper surface is an opening; the crust protection layer 5 is formed by the molten rare earth molten salt electrolyte 7 being cooled by the water cooling system 3 and formed by crusting on the surface of the inner tank 4, and the liquid cathode 9 and the cathode bottom plate 8 are externally connected to the negative electrode of the rectifier device, which is the cathode and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com