Trivalent chromium electroplating solution and an electroplating process with the solution

a technology of trivalent chromium and electroplating solution, which is applied in the field of trivalent chromium electroplating solution and an electroplating process with the solution, can solve the problems of difficult to obtain thick chromium deposits and lack of stability, and achieve high current density, low toxic, and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

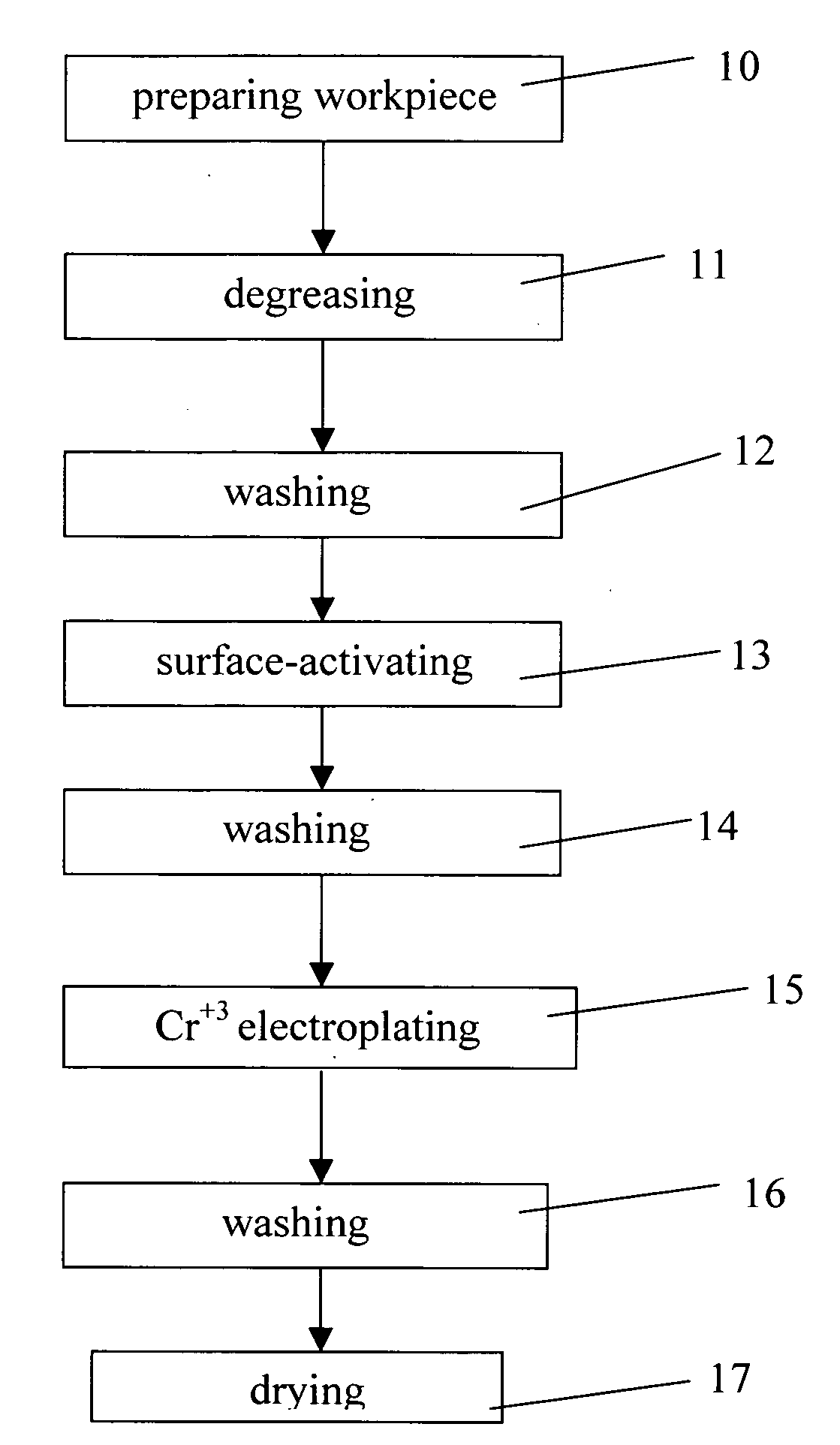

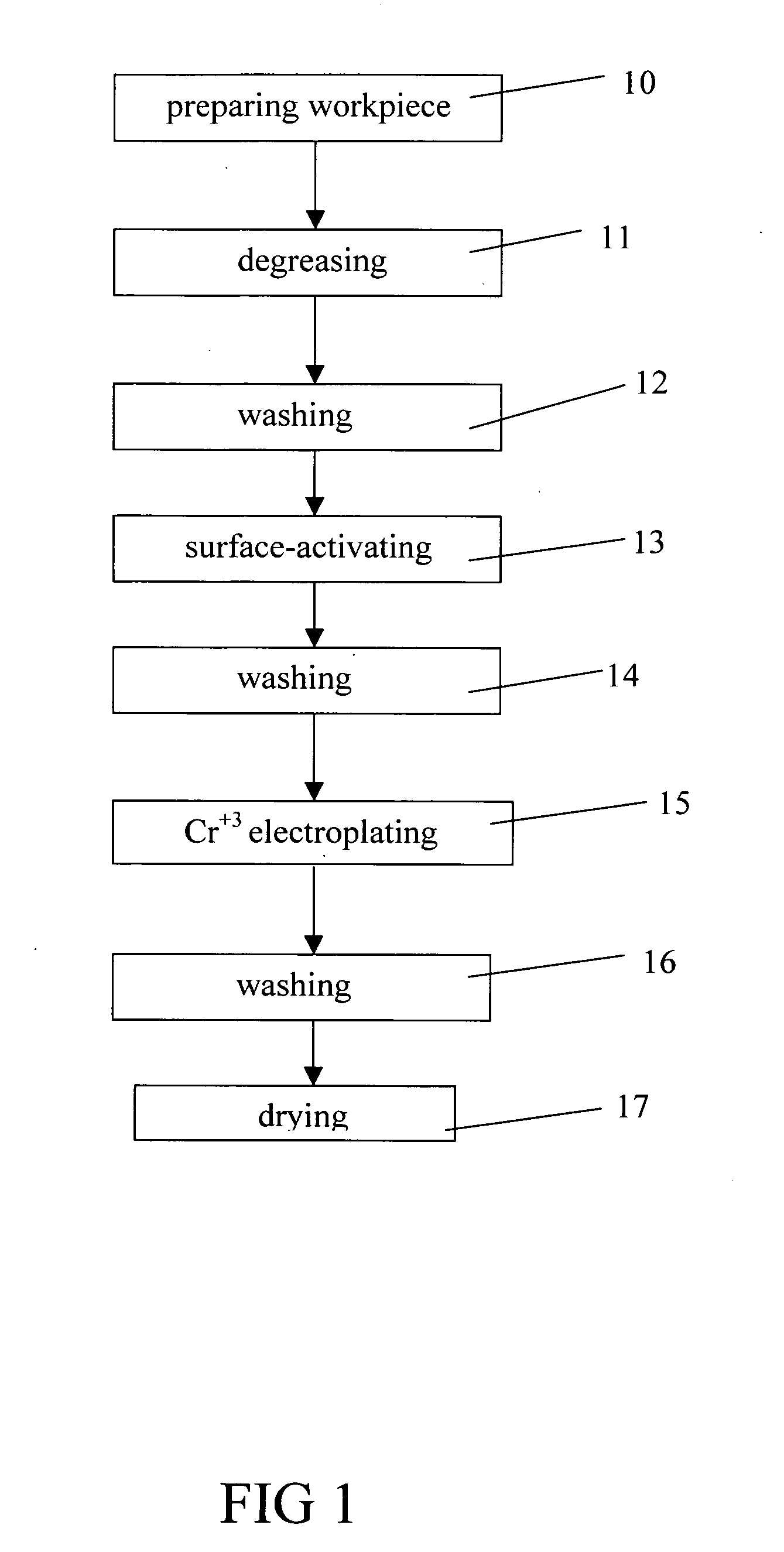

Method used

Image

Examples

Embodiment Construction

[0014]A trivalent chromium electroplating solution in accordance with the present invention contains at least one trivalent chromium salt for electroplating a chromium deposit on a workpiece. To obtain the chromium deposit on a workpiece, electroplating is conducted with the bath containing low toxic trivalent chromium ions to substitute the bath with highly toxic hexavalent chromium ions. Therefore, the electroplating process of the present trivalent chromium electroplating bath is an environmental friendly method.

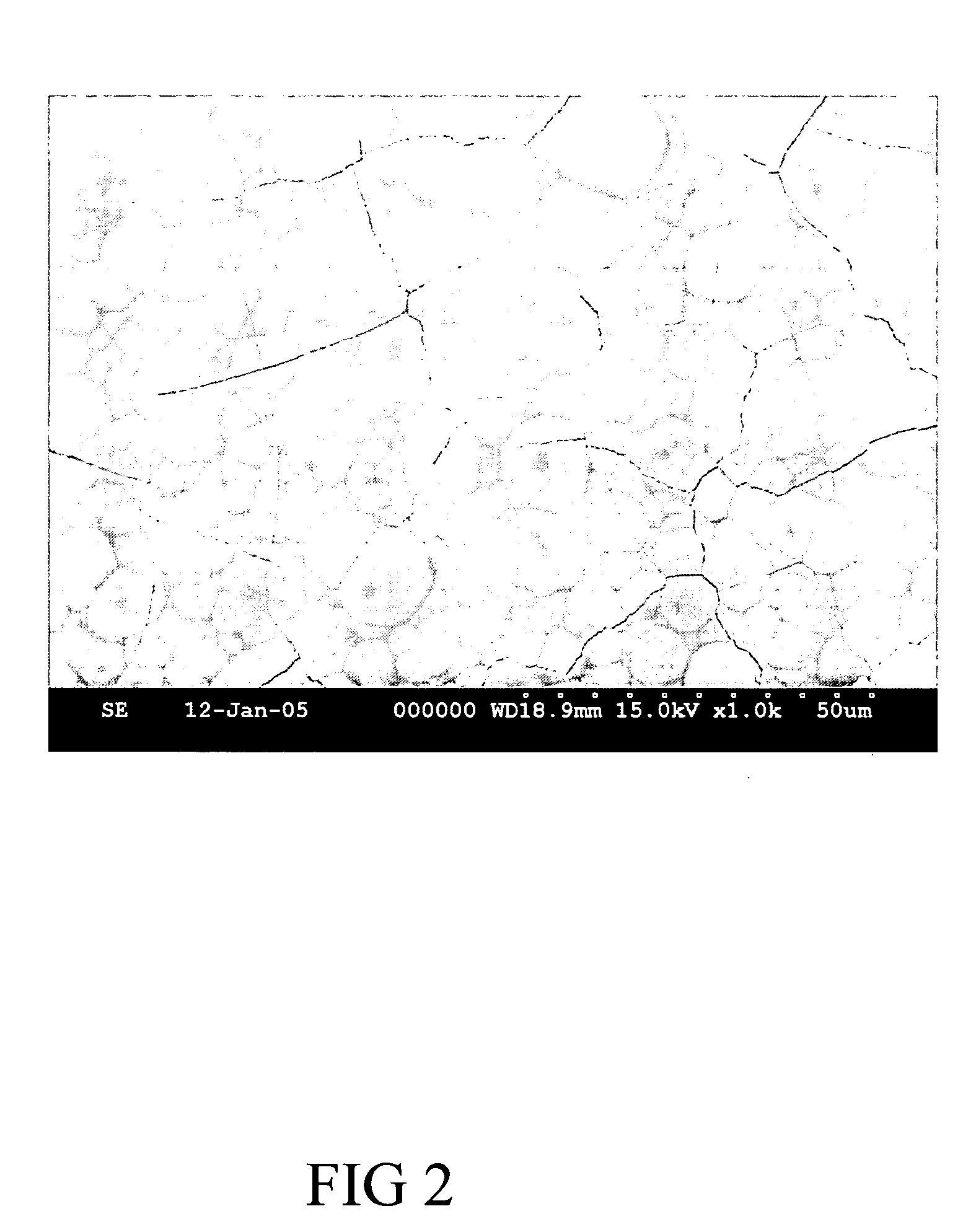

[0015]Owing to its high hardness, superior oxidation and wear resistance, chromium coating is widely used for surface finish of precision mechanical parts, mould, and surgical tool. According to the thickness, two types of chromium deposits xould be classified. The first type is decorative chromium deposit and the other type is hard chromium deposit. The decorative chromium deposit usually has a thickness of about 0.1-0.5 μm. The decorative chromium is mainly used for dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com