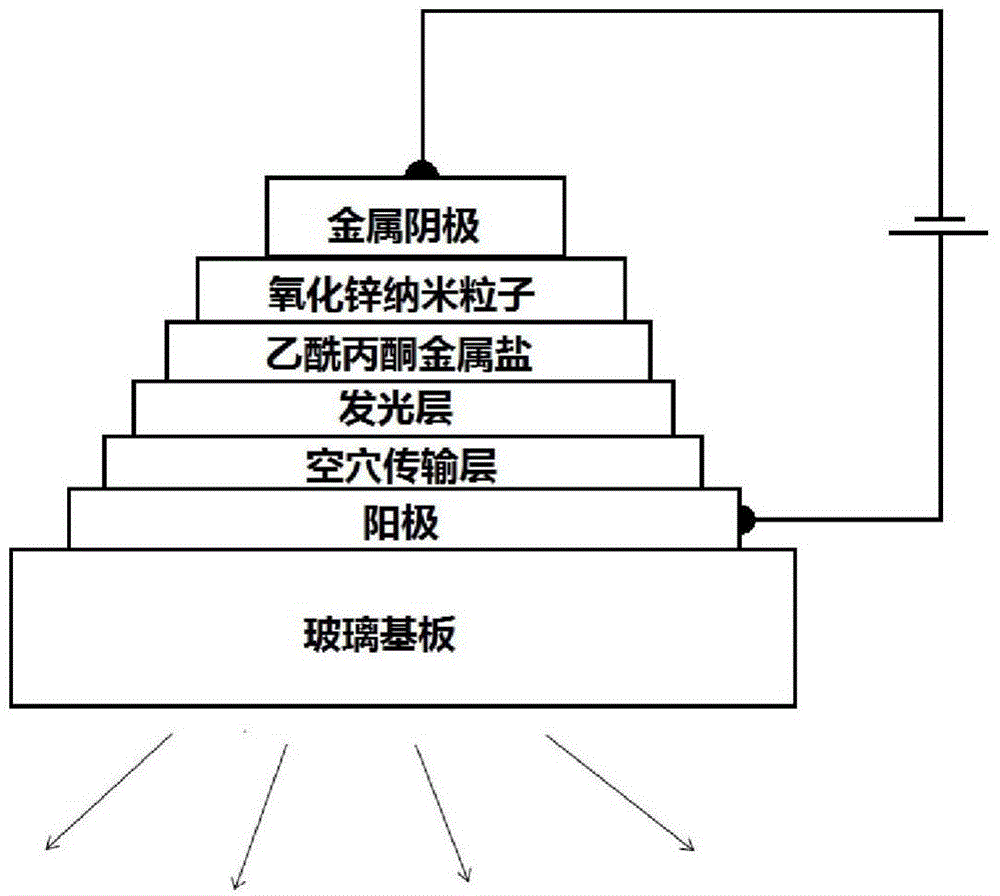

Organic light emitting diode with double-layer electron transport layer and preparation method thereof

A technology of electron transport layer and light-emitting diode, which is applied in the direction of organic semiconductor devices, circuits, electrical components, etc., can solve the problem that electron injection and transport capabilities are inferior to holes, and achieve large-area production, reduce costs, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 2) Alcohol solution of acetylacetonate metal salt: Dissolve lithium acetylacetonate (Li(acac)) in anhydrous methanol to prepare a solution with a concentration of 1 mg / ml.

[0073] An organic light-emitting diode with a double-layer structure electron transport layer was prepared according to the following steps:

[0074] (1) Spin-coated hole transport layer PEDOT:PSS:

[0075] Firstly, the PEDOT:PSS solution was filtered with a 0.45 μm filter head, and then spin-coated at a speed of 3000 rpm for 40 s with a homogenizer to form a film. Subsequently, the film was annealed at 120 °C for 30 min.

[0076] (2) Spin-coated luminescent layer:

[0077] The light-emitting layer is made of blue phosphorescent materials (bis(4,6-difluorophenylpyridine-N,C2) pyridine iridium) (Firpic) and 2,2'-(1,3-phenyl)bis[5 -(4-tert-butylphenyl)-1,3,4-oxadiazole] (OXD-7) into the blue light-emitting material layer made of polymer host polyvinylcarbazole (PVK), according to PVK: FIrpic: OXD-7=...

Embodiment 2

[0090] Example 3

[0091] The device was prepared according to the method of Example 1, except that the luminescent material was a white light luminescent material mixed with blue light and orange red phosphorescent materials. As a lighting application, the complementary color scheme device has a simple structure and high efficiency. Usually, phosphorescent materials can be used to obtain high efficiency, and the chromaticity of white light can be controlled to a certain extent. Among them, FIrpic is selected as the blue-light phosphorescent material, and FIrpic is selected as the orange-red phosphorescent material (acetylacetonate bis(2-phenylbenzothiazole-C2,N) iridium(III)) (Ir(BT) 2 (acac)), the main material is PVK, the carrier transport material is OXD-7, and the ratio (weight ratio) of each compound in the light-emitting layer is PVK:FIrpic:OXD-7:Ir(BT) 2 (acac) = 10:1:4:0.04. In white light devices, when octane is used as the dispersant of ZnO nanoparticles, the de...

Embodiment 3

[0093] Implementation steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com