High-performance double zero aluminum foil and manufacturing method

A manufacturing method and technology of double-zero aluminum foil, applied in the direction of metal rolling, etc., can solve the problems of obvious surface stripe color difference, unstable number of pinholes, and high strip breaking rate, and achieve high yield, high production efficiency, and strip breaking. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

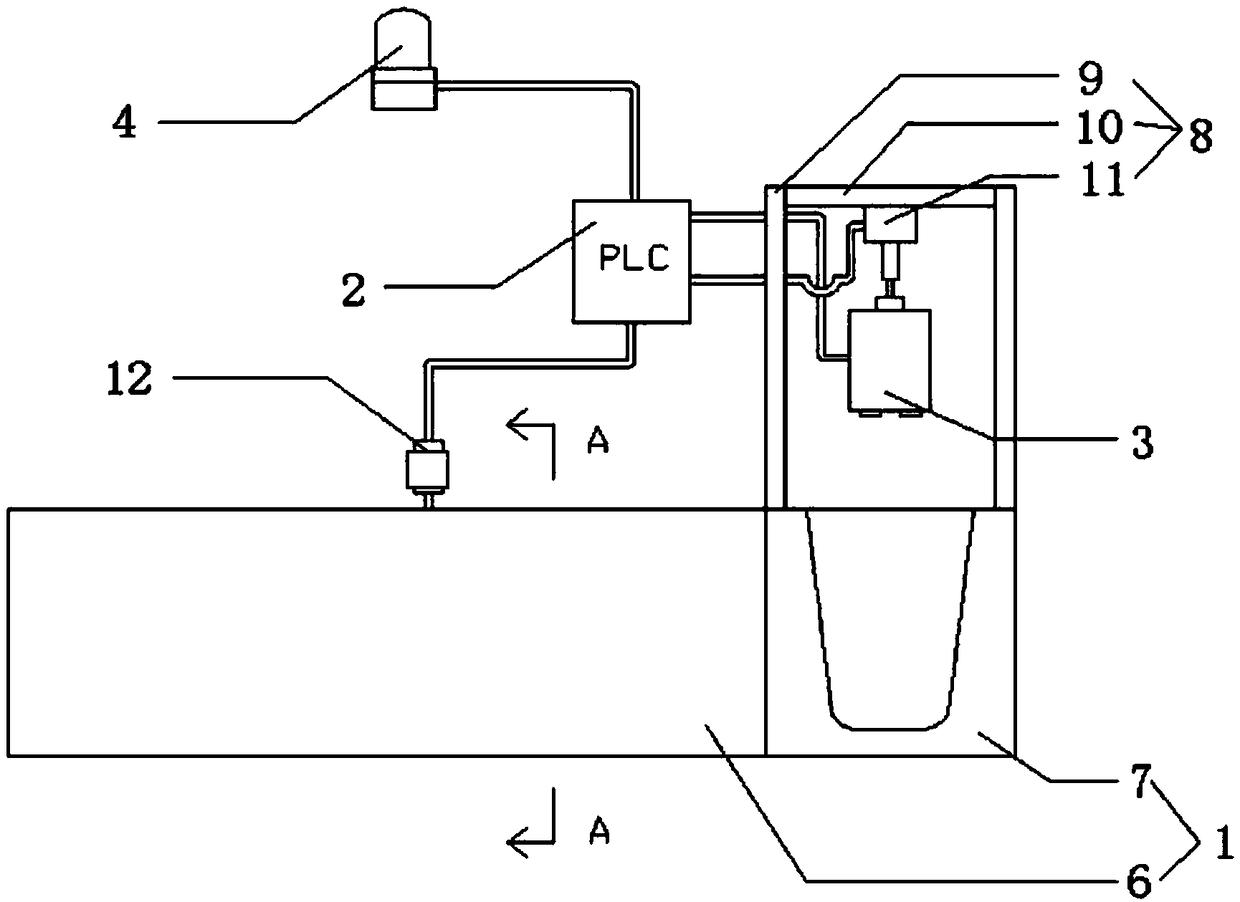

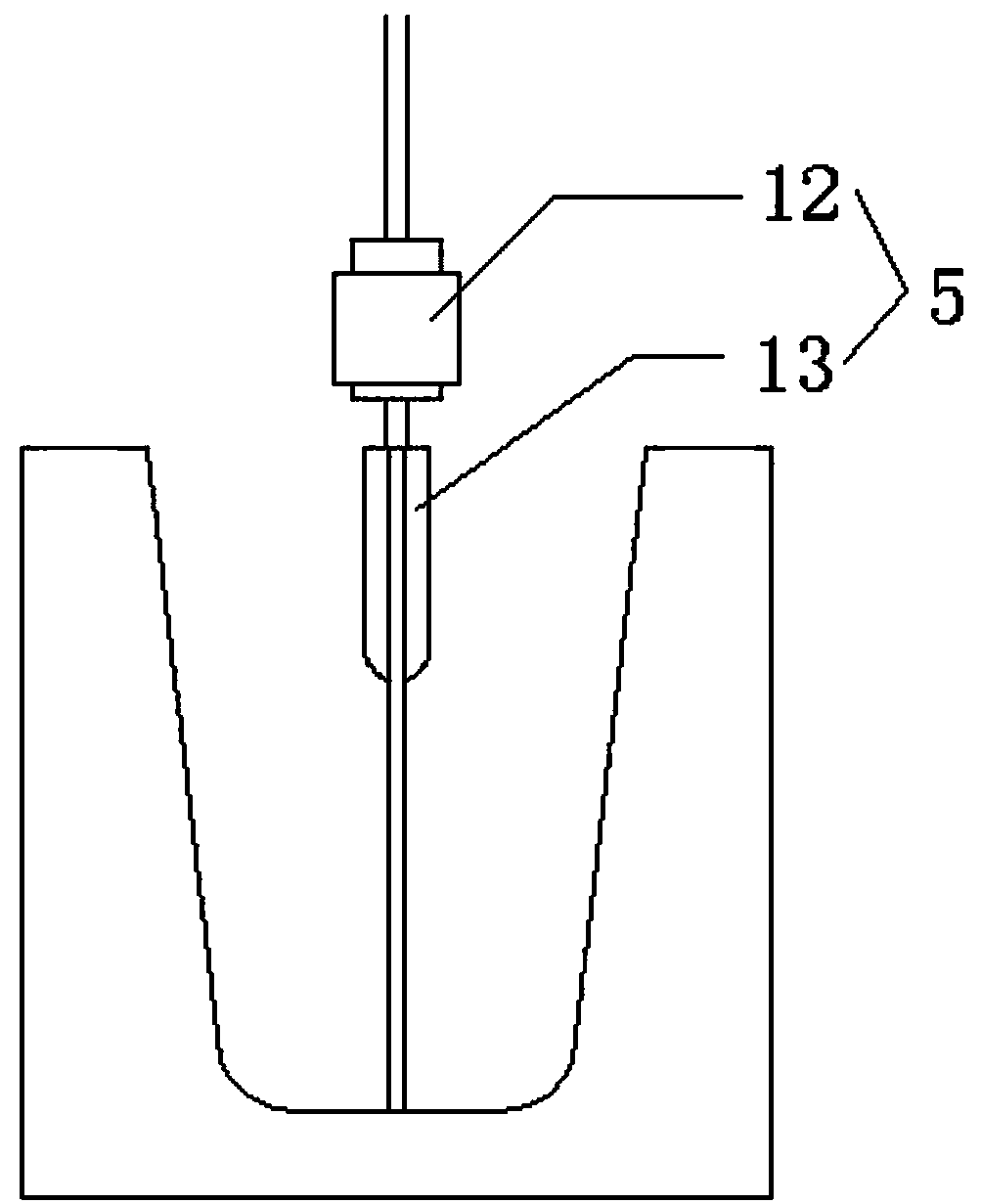

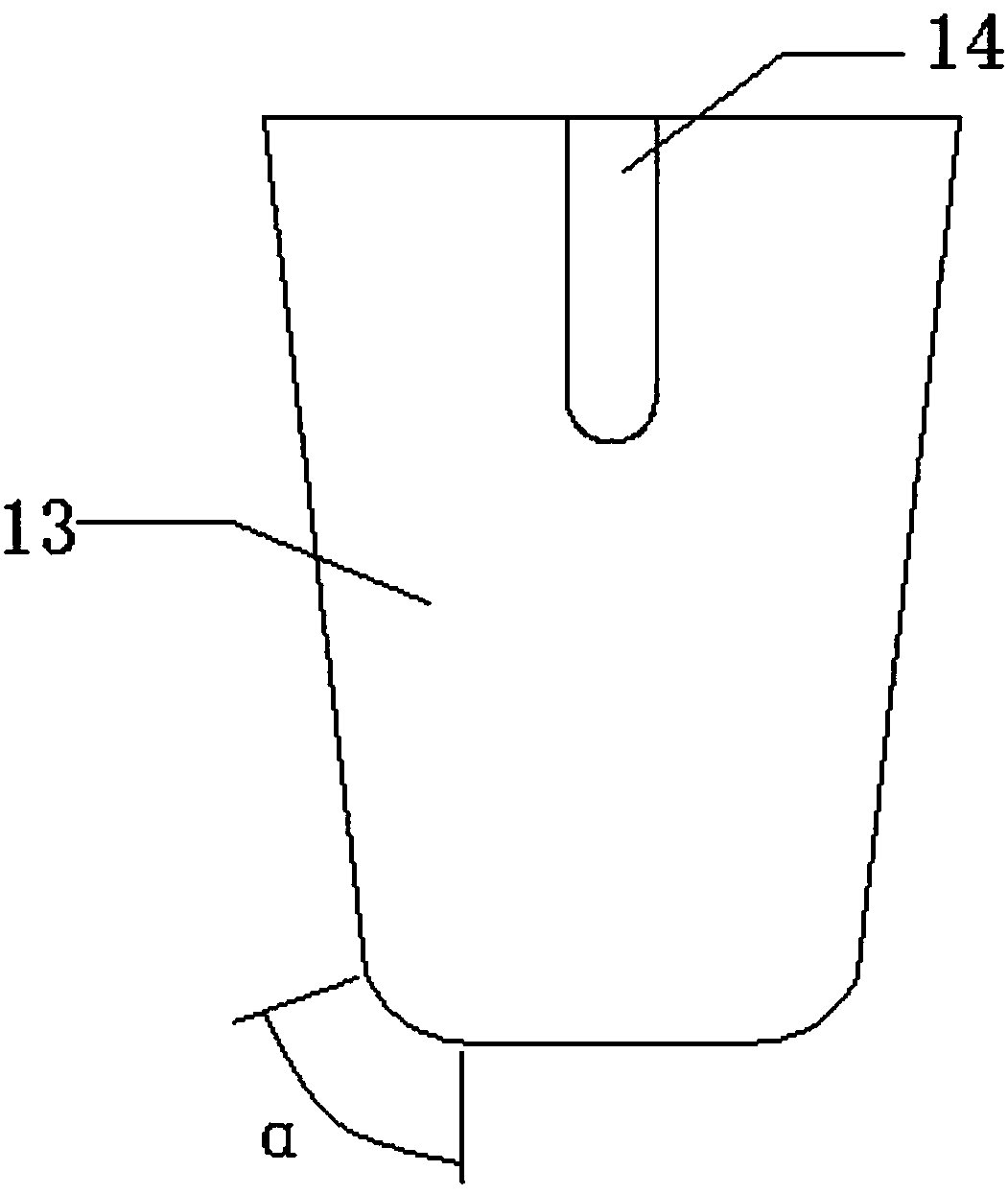

Method used

Image

Examples

Embodiment 1

[0028] A high-performance double-zero aluminum foil and its manufacturing method, characterized in that its material element composition and weight ratio are: Fe: 0.30-0.65%; Si: 0.12-0.30%; Cu: 0.01-0.04%; Ti: 0.008-0.020 %, the rest is Al;

[0029] Its manufacturing method includes the following steps: smelting, casting and rolling, cold rolling, high temperature annealing, secondary cold rolling, intermediate annealing, foil rolling to finished products, specifically:

[0030] 1. Melting: Put the aluminum alloy ingot that meets the element composition and weight ratio into the melting machine, and control the temperature of the melting machine within the range of 740°C; the hydrogen content is controlled below 0.10ml / 100g Al; when the aluminum alloy ingot is completely melted, After fully stirring, send it into the degassing box, use high-purity argon, and use the rotary blowing method to perform online degassing. After the aluminum melt is stable, remove the surface scum; ...

Embodiment 2

[0046] A high-performance double-zero aluminum foil and its manufacturing method, characterized in that its material element composition and weight ratio are: Fe: 0.30-0.65%; Si: 0.12-0.30%; Cu: 0.01-0.04%; Ti: 0.008-0.020 %, the rest is Al;

[0047] Its manufacturing method includes the following steps: smelting, casting and rolling, cold rolling, high temperature annealing, secondary cold rolling, intermediate annealing, foil rolling to finished products, specifically:

[0048] 1. Melting: Put the aluminum alloy ingot that meets the element composition and weight ratio into the melting machine, and control the temperature of the melting machine within the range of 745°C; the hydrogen content is controlled below 0.10ml / 100g Al; when the aluminum alloy ingot is completely melted, After fully stirring, send it into the degassing box, use high-purity argon, and use the rotary blowing method to perform online degassing. After the aluminum melt is stable, remove the surface scum; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com