System and method for controlling level of molten aluminum in front box of aluminum strip billet cast-rolling machine

A technology of liquid level height and control system, which is applied in the field of casting and rolling of aluminum strip blanks, can solve the problems of surface defects, poor operation safety, and low control precision of cast-rolled aluminum strips, so as to avoid surface defects, low labor cost, The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

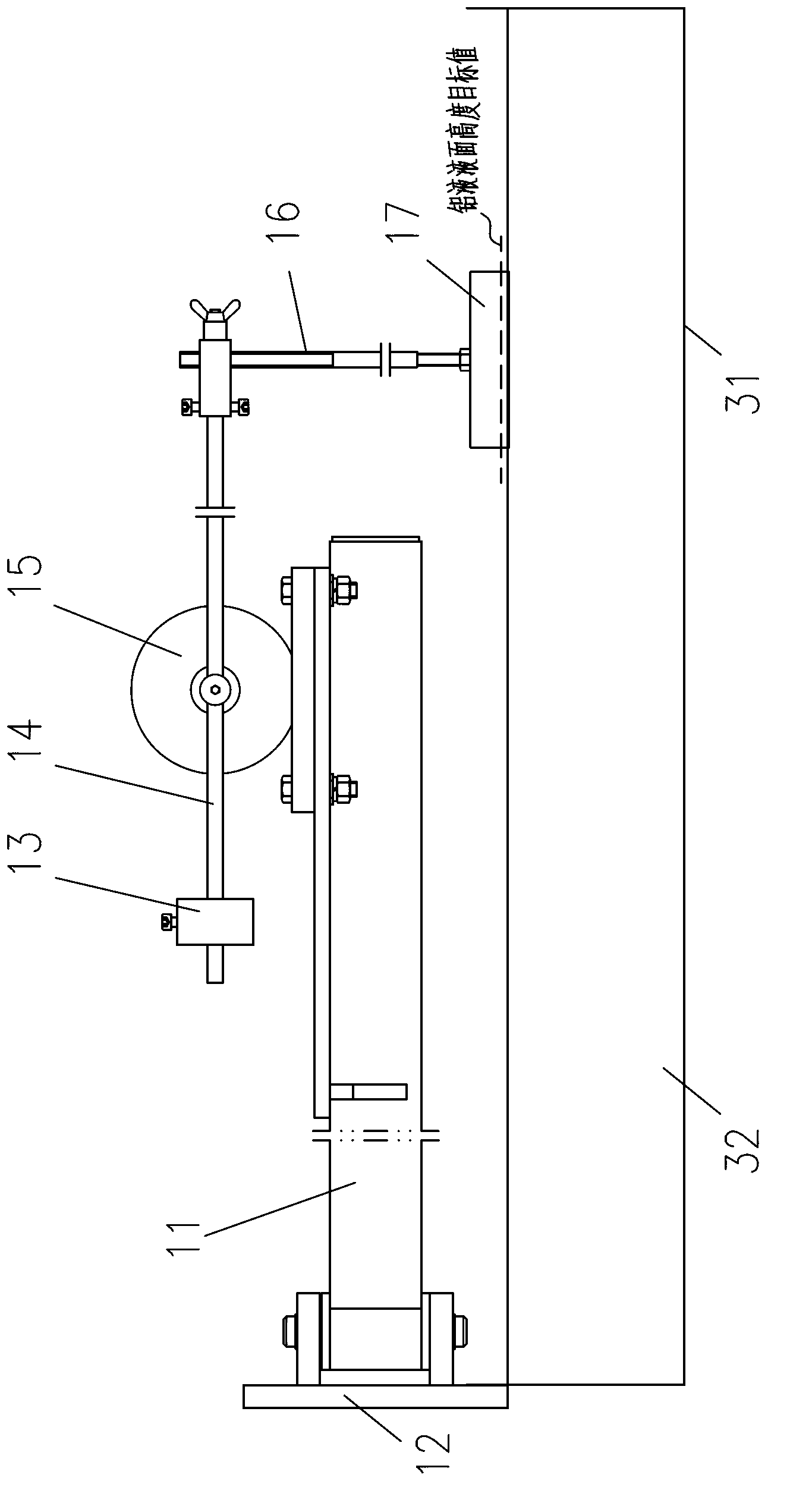

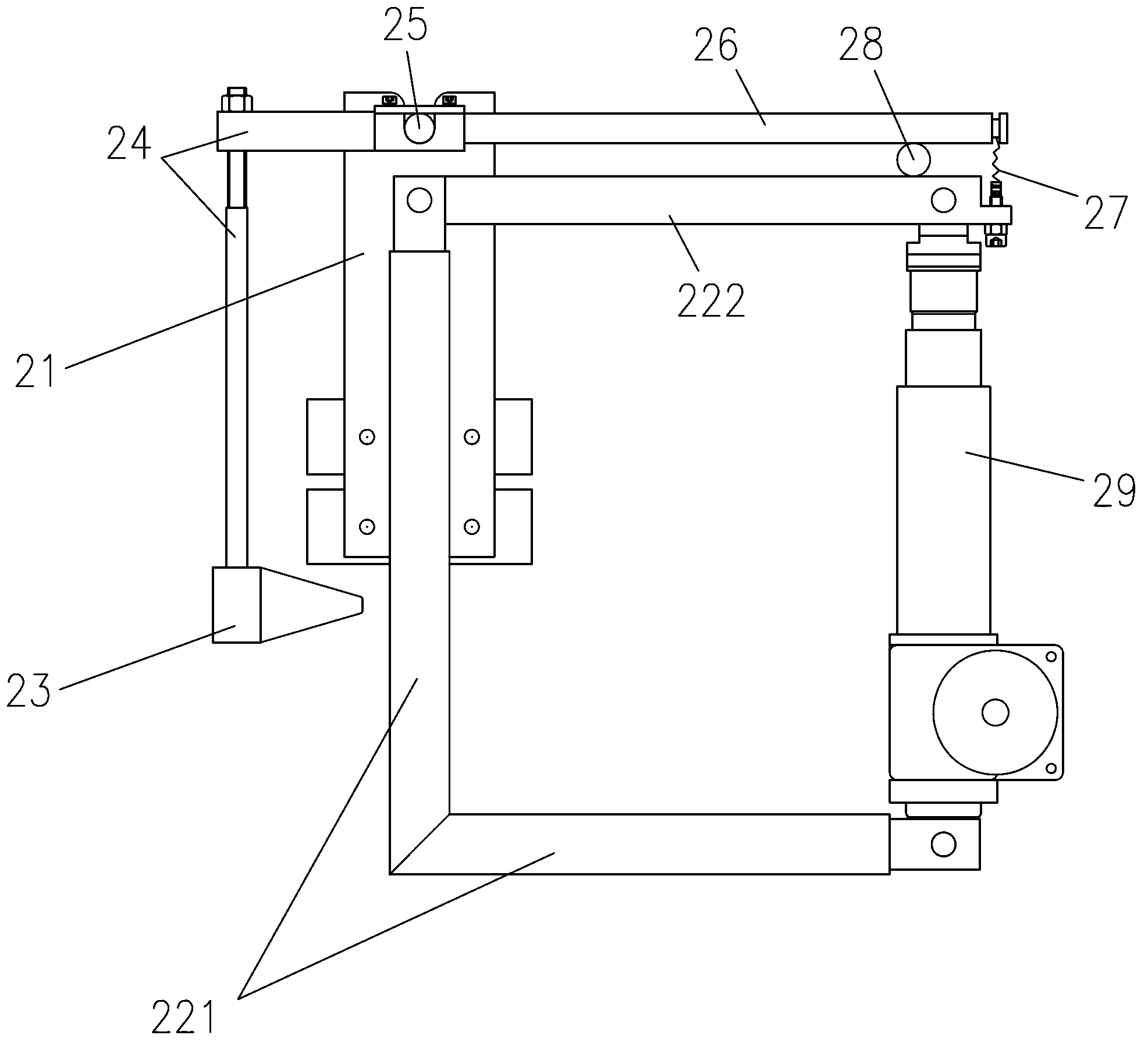

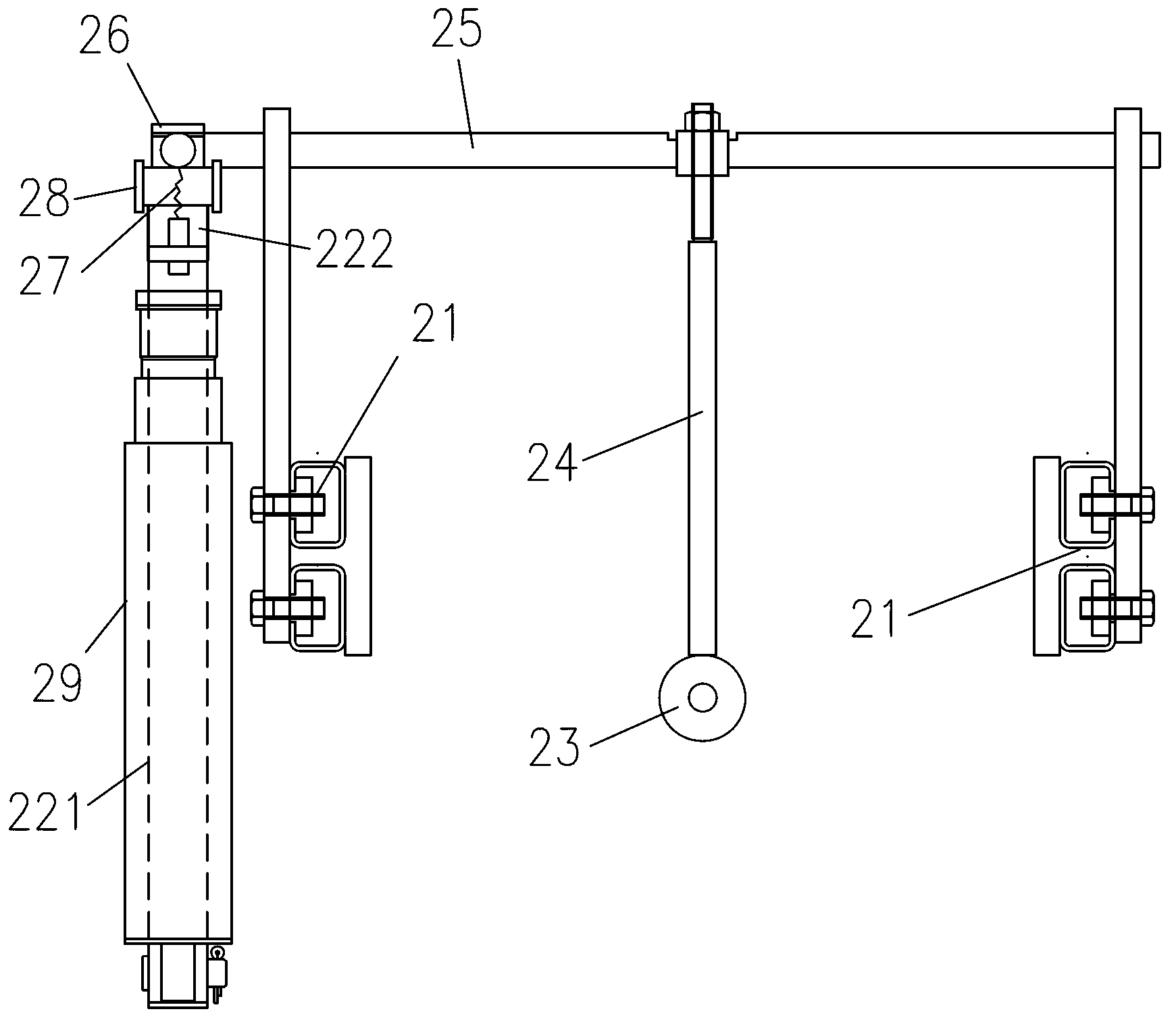

[0021] The aluminum liquid level control system of the front box of the aluminum strip blank casting and rolling machine of the present invention is used for the front box of the aluminum strip blank casting and rolling mill. Generally speaking, the aluminum strip billet casting and rolling mill includes a holding furnace, a front box, a casting and rolling device, and a coiler. Flow smoothly into the front box. The casting and rolling device includes a frame, a nozzle, and a roll. The output port of the front box is connected with the nozzle so that the molten aluminum in the front box flows into the nozzle. The molten aluminum is injected onto the roll cooled by cooling water, the aluminum liquid is distributed along the width of the roll surface, cooled and solidified, and then rolled and formed by the roll to form cast-rolled aluminum strips, and then when the cast-rolled aluminum strips leave the After the roll gap, after the corresponding treatment of the lead-out roll, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com