Neural network-based method and system for predicting shapes of three-dimensional hearths of aluminum cells in real time

An aluminum electrolytic cell and neural network technology, which is applied in the field of real-time prediction of the three-dimensional furnace shape of the aluminum electrolytic cell based on the neural network, can solve the problem of the undisclosed specific method of calculation and analysis of the shape of the aluminum electrolytic cell furnace side, the verification of the calculation results, and the inability to determine the furnace Whether the shape of the inner furnace is regular or not, to achieve the effect of ensuring convergence, improving prediction accuracy, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

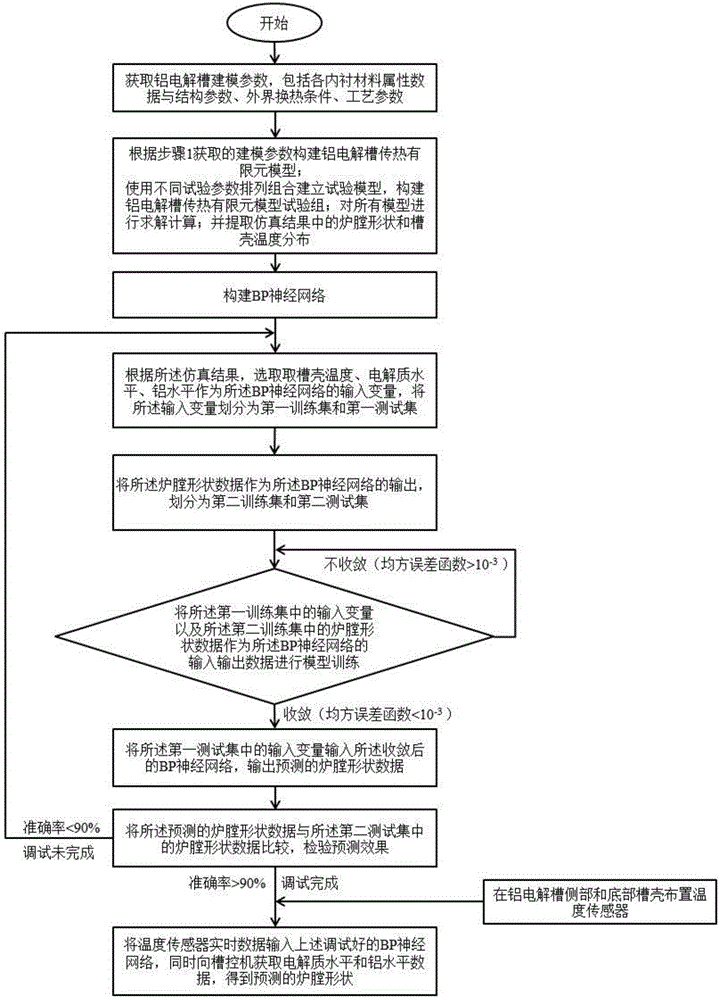

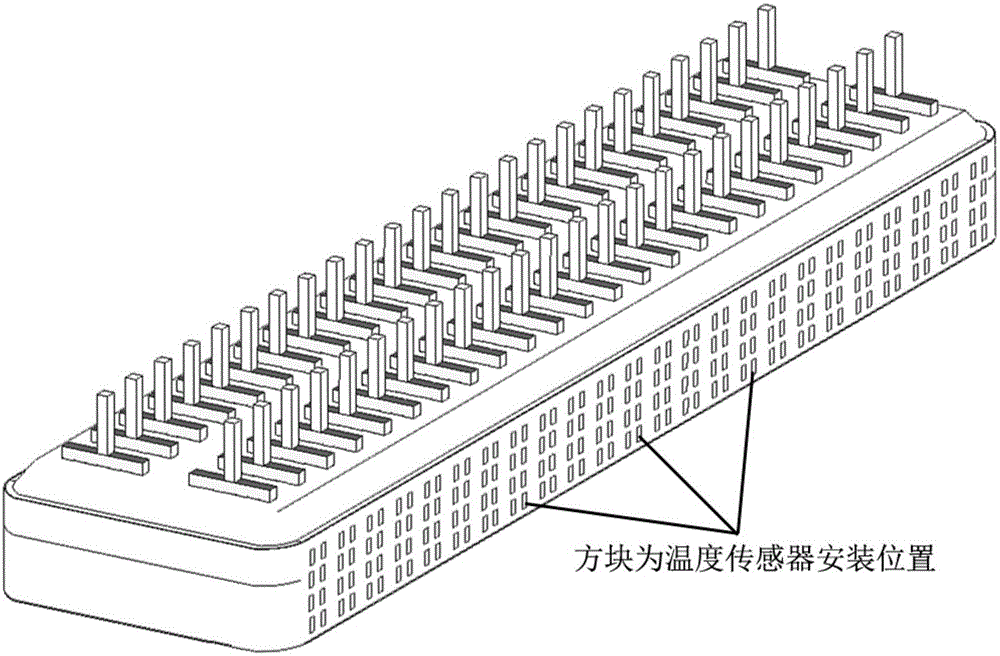

[0064] A neural network-based real-time prediction method for the three-dimensional furnace shape of an aluminum electrolytic cell, characterized in that it includes the following steps:

[0065] 1) Obtain the modeling parameters of a 420kA aluminum electrolytic cell, including the property data and structural parameters of each lining material, external heat exchange conditions, and process parameters, as shown in Table 1;

[0066] Table 1 Key parameters of a 420kA electrolyzer

[0067]

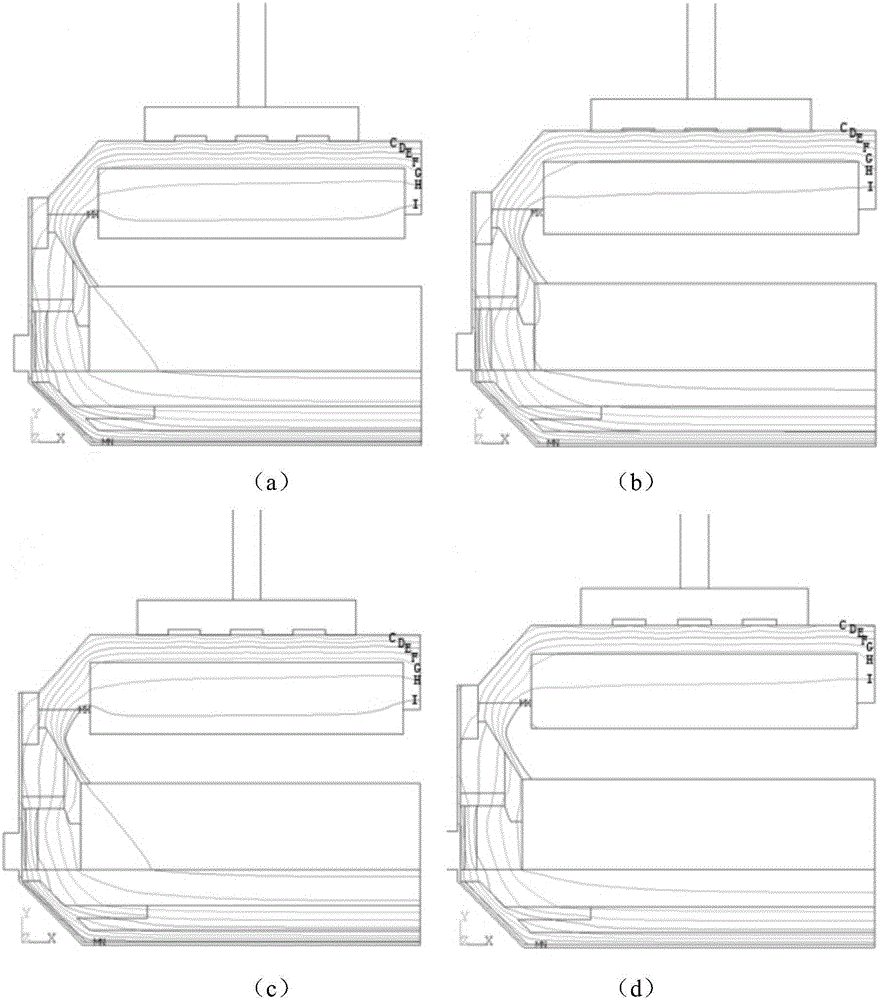

[0068] 2) Construct the heat transfer finite element model of the aluminum electrolytic cell according to the modeling parameters obtained in step 1. At the same time, in order to cover most of the situations in production and facilitate subsequent training, it is necessary to calculate the furnace shape under different test conditions. Therefore, different test parameters are arranged and combined to form a test group; each group of test parameters in the test group is input into the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com