Device and method for comprehensively measuring temperature and aluminum level in aluminum electrolytic process

The technology of a measuring device and measuring method, which is applied in the field of aluminum electrolysis, can solve the problems of large relationship between measurement accuracy, operation and experience, and high labor intensity, and achieve the effect of shortening the measurement time and increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

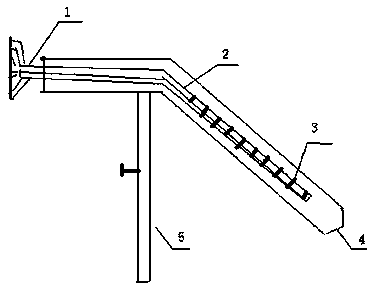

[0012] see figure 1 , the aluminum electrolysis process temperature and aluminum level measuring device of the present invention comprises 8-12 temperature-sensing nodes 3, the temperature-sensing nodes are arranged along a straight line, and the distance between adjacent temperature-sensing nodes 3 is 0.8cm-1.2cm, when in use, These temperature-sensing nodes 3 can be respectively located in the electrolyte and the aluminum liquid. In order to facilitate height adjustment, the sensor is also provided with an adjustable support rod 5, and the height of the support rod 5 is 30cm-50cm.

[0013] The temperature sensing node is preferably a thermocouple, and the temperature sensing node 3 is the joint point of the thermocouple wire 2. The thermocouple wire is drawn out from the lead wire 1 and connected to the data collector (not shown in the figure), and the outer side of the thermocouple wire is covered with a stainless steel sleeve The pipe 4 and the support rod 5 are arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com