Aluminum liquid level simulation control system for casting and rolling mill

A technology of analog control and casting and rolling machine, which is applied in the direction of liquid level control, control/regulation system, non-electric variable control, etc. It can solve the problems affecting the service life of the motor, affecting the stability of the liquid level, and the quality of the casting and rolling plate, etc., to achieve The effect of improving product quality, increasing service life, improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

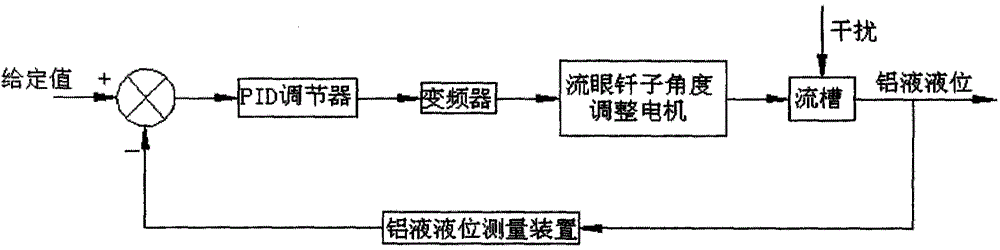

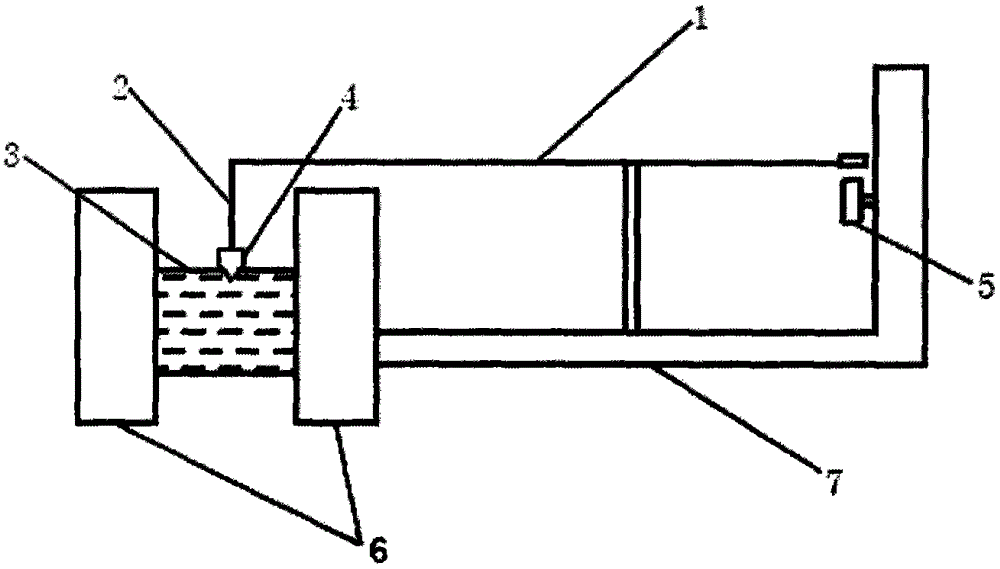

[0013] Depend on Figure 1-2 It can be known from the shown embodiment that the motor for adjusting the angle of the flow hole drill is included, and the motor for adjusting the angle of the flow hole drill is a frequency conversion motor; it also includes a liquid aluminum level measuring device, which includes a liquid aluminum liquid level transmission lever 1 , one end of the aluminum liquid level transmission lever 1 is the liquid level detection end, the liquid level detection end is connected with the floating ball 4 floating on the surface of the aluminum liquid 3 through the connecting rod 2, and the other end of the aluminum liquid level transmission lever 1 is the displacement output Displacement sensor 5 for detecting its displacement is arranged on the motion track line of the displacement output terminal; the output terminal of displacement sensor 5 is connected with the input terminal of the PID regulator, the output terminal of the PID regulator is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com