Anodic aluminum level dyeing retarding aid and operating liquid thereof as well as anodic aluminum level dyeing retarding treatment process

A treatment process, anodized aluminum technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of local color difference surface and fading of anodized aluminum, and achieve easier control of dyeing process and good mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] An anode aluminum leveling and slowing dyeing auxiliary agent, its preparation method is as follows:

[0054] Mix 100g of sodium citrate, 450g of sulfamic acid and 450g of pH stabilizer evenly to prepare 1kg of anode aluminum leveling and retarding auxiliary powder.

Embodiment 2

[0056] An anode aluminum leveling and retarding dyeing auxiliaries operating liquid, its preparation method is as follows:

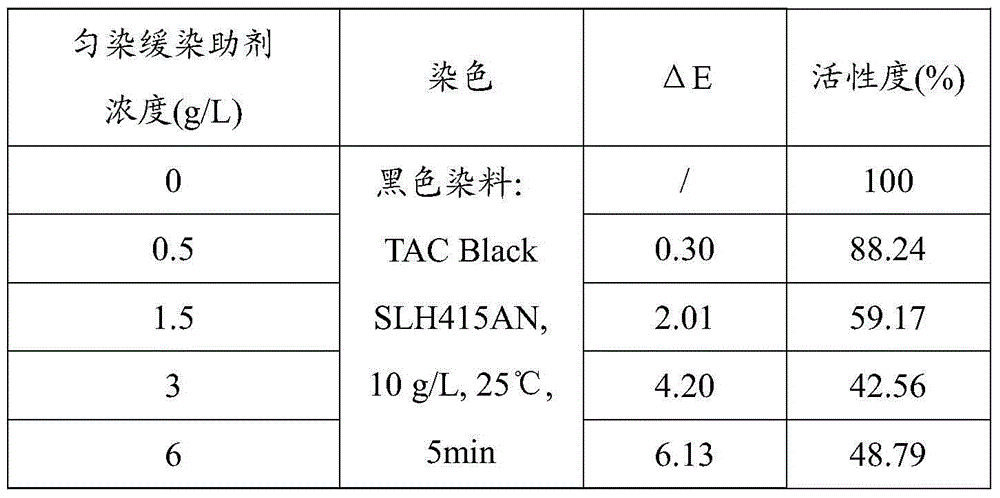

[0057] The anode aluminum leveling and retarding auxiliary agent powder prepared in the above-mentioned embodiment 1 was added into deionized water, and the concentrations were prepared to be 0.5g / L, 1.5g / L, 3g / L and 6g / L (based on the first active Concentration meter of component sodium citrate) anodic aluminum leveling and retarding auxiliary agent operating liquid.

Embodiment 3

[0059] A kind of anodic aluminum level dyeing slow dyeing treatment process, comprises the following steps:

[0060] (1) Take four aluminum material test pieces whose model is 5052, after anodizing and water washing, respectively soak in the anodic aluminum leveling and retarding auxiliary agent operating solution (25°C) of different concentrations prepared in Example 2 of the present invention 5 minutes, take it out and clean it with deionized water; among them, the anodic oxidation time of the aluminum test piece is 20 minutes, and the thickness of the oxide film is ~15μm;

[0061] (2) Then put the aluminum flakes treated with different concentrations of anodic aluminum leveling and retarding dyeing auxiliaries into the dyeing solution for dyeing. The selected dye is the black dye "TAC Black SLH415AN" produced by Okuno Company in Japan. 10g / L, the temperature of the dye vat is controlled at 25°C, dye for 5 minutes, and then take it out for cleaning;

[0062] (3) Finally, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com