Casting system and casting method for aluminum alloy sleeper beam of standard motor train unit steering frame

A technology for EMUs and bogies, which is applied to casting molding equipment, casting molds, and casting mold components. Guarantee and other issues can be achieved to achieve the effect of improving internal quality and body performance, reliable casting technology, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

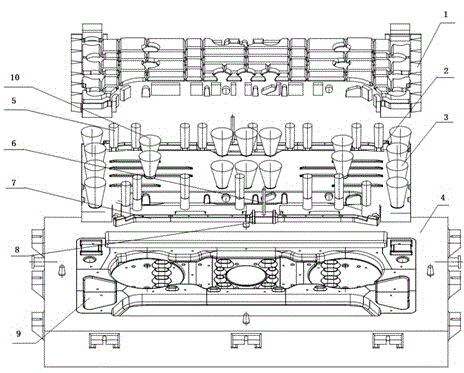

[0017] Such as figure 1 As shown, the aluminum alloy bolster casting system of the standard EMU bogie includes molded chill iron 1, gap runner 2, thermal insulation risers 3 at both ends, metal base mold 4, thermal insulation side risers 5, sprue 6, Runner 7, ceramic filter sheet 8, replaceable module 9 and middle insulation riser 10.

[0018] The casting method is as follows: pour aluminum liquid into the pouring trough, when the aluminum liquid reaches a certain height and the liquid level is stable, pull out the plug, the aluminum liquid enters the sprue 6, passes through the ceramic filter 8 to remove slag, and then enters the "double pass". Bridge" runner 7, and then through the gap runner 2, into the cavity, stop pouring when the aluminum liquid fills the heat preservation riser 10, the heat preservation riser 3 at both ends and the heat preservation side riser 5 by half , when the casting starts to solidify and shrink, the liquid level in the riser drops, and then pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com