Patents

Literature

36results about How to "Reduce casting stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pouring method of hollow turbine guide vane

ActiveCN104308082AUniform temperature fieldEliminate casting stressFoundry mouldsFoundry coresWaxTurbine

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

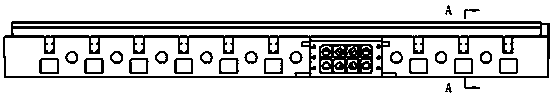

Casting method of hundred-ton ductile cast iron template casting for two-plate injection molding machine

ActiveCN103882286AMeet quality requirementsNo linear defectsFoundry mouldsFoundry coresFiltrationLiquid iron

The invention discloses a casting method of a hundred-ton ductile cast iron template casting for a two-plate injection molding machine. The casting method comprises the steps of mold making, casting system making, sand mold making and molding by casting, thus obtaining the casting, wherein the reverse side of a mold installing surface is designed at the lower part of a casting position; an inner runner hole is formed on the reverse side of the mold installing surface; in the casting process, liquid iron enters lower horizontal runners via sprues, then enters type A filters via the lower horizontal runners and is subjected to inoculation and filtration purification treatment inside the type A filters; then the liquid iron which enters type B filters via upper horizontal runners and is subjected to purification and filtration again enters a casting mold cavity via the inner runner hole; the final strength of a sand mold is 1.3-1.4MPa, and the final strength of a sand core is 0.9-1.0MPa; the casting temperature is 1290-1310 DEG C, and the casting time is 85-100 seconds. The casting method has the advantages that the casting defects such as graphite degeneration, shrinkage cavity, shrinkage porosity, sand inclusion and the like are not easy to occur, thus improving mechanical properties.

Owner:RIYUE HEAVY IND

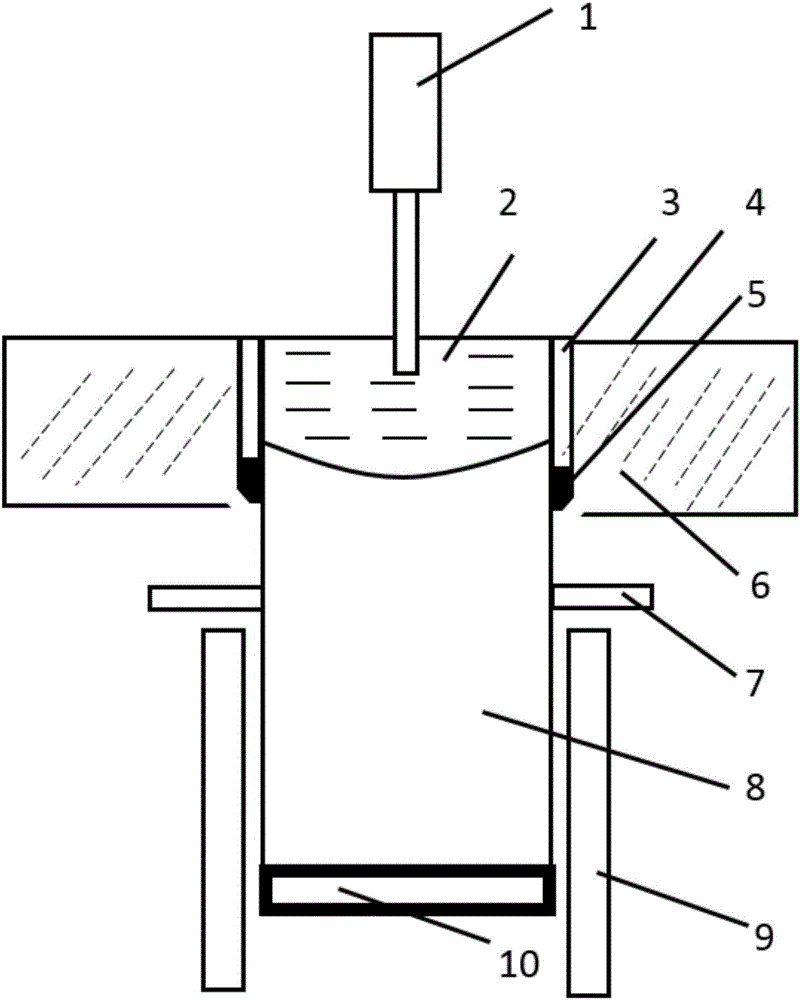

Semi-continuous casting method for in-situ particle reinforced aluminum-based composite

The invention relates to a semi-continuous casting method for an in-situ particle reinforced aluminum-based composite and belongs to the technical field of composite forming. The method includes the following steps that an in-situ ceramic particle reinforced aluminum-based composite is taken, melted and subjected to heat preservation to obtain composite melt; the composite melt is injected into a crystallizer, and meanwhile ultrasonic treatment is carried out; when the melt is solidified at the position of a graphite annulus, a dummy bar head descends, and meanwhile cooling water is started to cool a cast rod; when the dummy bar head descends to the position of a scraper blade, the scraper blade starts to make contact with the surface of the cast rod, and the cooling water is scraped away from the surface of the cast rod; along with descending of the dummy bar head, the cast rod slowly enters a heating furnace to be annealed; and the cast rod is hoisted after casting is completed, and an aluminum-based composite semi-continuous cast rod is obtained. The method is simple in device, easy and convenient to operate and suitable for large-scale industrial production of the aluminum-based composite, and has good practical application value, and large-size in-situ particle reinforced aluminum-based composite cast ingots with fine crystal particles and evenly-distributed particles can be prepared.

Owner:ALUMICS MATERIALS INSTIUTUTE ANHUI CO LTD

Method for manufacturing large-size heat-treatment aluminum alloy slab ingot capable of being strengthened

The invention provides a method for manufacturing a large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, and relates to a method for manufacturing the aluminum alloy slab ingot. The method for manufacturing the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened mainly solves the problems that as for an aluminum alloy slab ingot prepared in the prior art, the casting yield is low, and wide and thick slabs with excellent properties cannot be rolled out. The method comprises the first step of material weighing, the second step of smelting, the third step of casting melt preparation and the forth step of molding, and the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened is obtained. By means of the method, according to the prepared large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, the yield strength ranges from 98 N / mm<2> to 120 N / mm<2>, the tensile strength ranges from 182 N / mm<2> to 201 N / mm<2>, and the elongation percentage in a casting state ranges from 9.56% to 14.7%. By means of the method, the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Large-size and high-strength super hard hollow billet and manufacturing method thereof

The invention relates to a hollow billet and a manufacturing method thereof, and especially relates to a large-size and high-strength super hard hollow billet and a manufacturing method thereof. The purpose of the invention is to solve the problems of low yield, large production workload and difficult process control of casting of aluminum alloy hollow ingots prepared in the prior art. The large-size and high-strength super hard hollow billet comprises Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, B and Al. The manufacturing method comprises the following steps: 1, weighing; 2, smelting; 3, refining and casting of melt; and 4, molding. The method is mainly used for manufacturing the large-size and high-strength super hard hollow billet.

Owner:NORTHEAST LIGHT ALLOY CO LTD +1

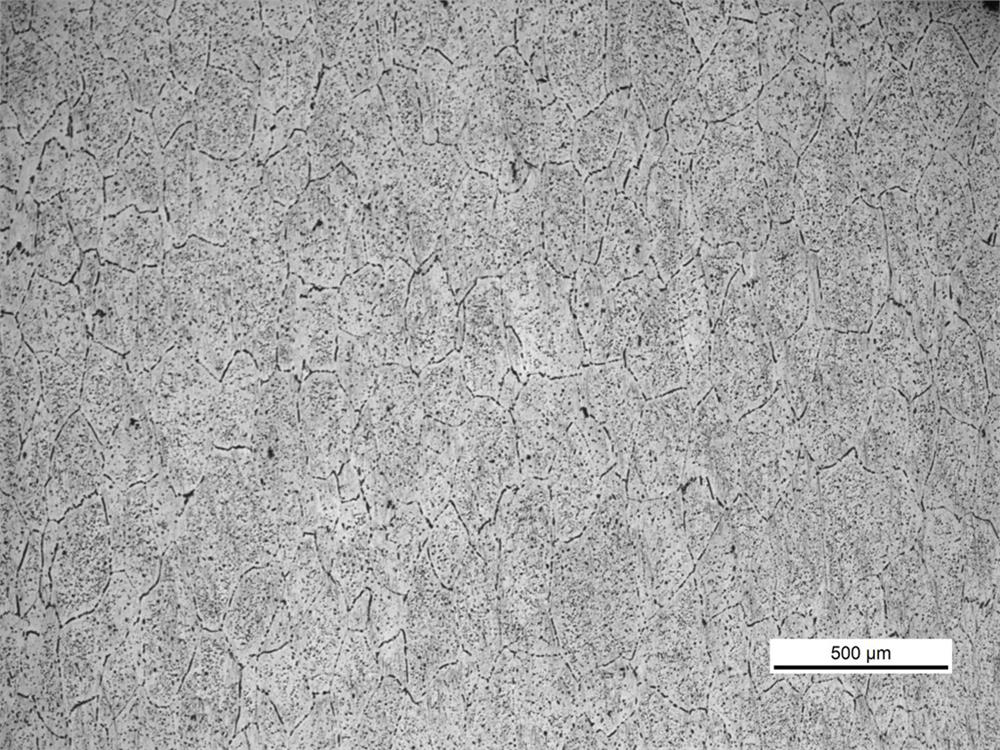

Novel high carbon graphite steel roll ring and preparation method thereof

ActiveCN106636876AReduce exclusivityReduce casting stressFurnace typesHeat treatment furnacesAntioxidant capacityHigh carbon

The invention relates to a preparation method of a novel high carbon graphite steel roll ring. The roll ring is prepared by the following steps: adopting a centrifugal three-layer composite casting process, by adding alloy of special carbide elements V, Nb, Mo and the like, tapping when the temperature of a liquid phase reaches +120-150 DEG C, carrying out spheroidization treatment with 0.30-0.60 percent of BaCa, carrying out inoculation with 0.50-0.60 percent of CaSi as an inoculant after spheroidization, then carrying out killing for 3-8min and pouring, and carrying out special heat treatment by cold opening a box to obtain a finished product with the roll ring surface hardness and the matrix microstructure according with the requirements. Compared with an ordinary roll ring, according to the novel high carbon graphite steel roll ring, by adding the special carbide elements, through spheroidization treatment by the BaCa and inoculation by the CaSi as the inoculant, special fine grained carbides which are distributed uniformly and spheroidal graphite with the antioxidant capacity and the lubrication action are cultivated, so that the comprehensive performance of the roll ring is improved, and the service life of the roll ring is prolonged.

Owner:江苏凯达重工股份有限公司

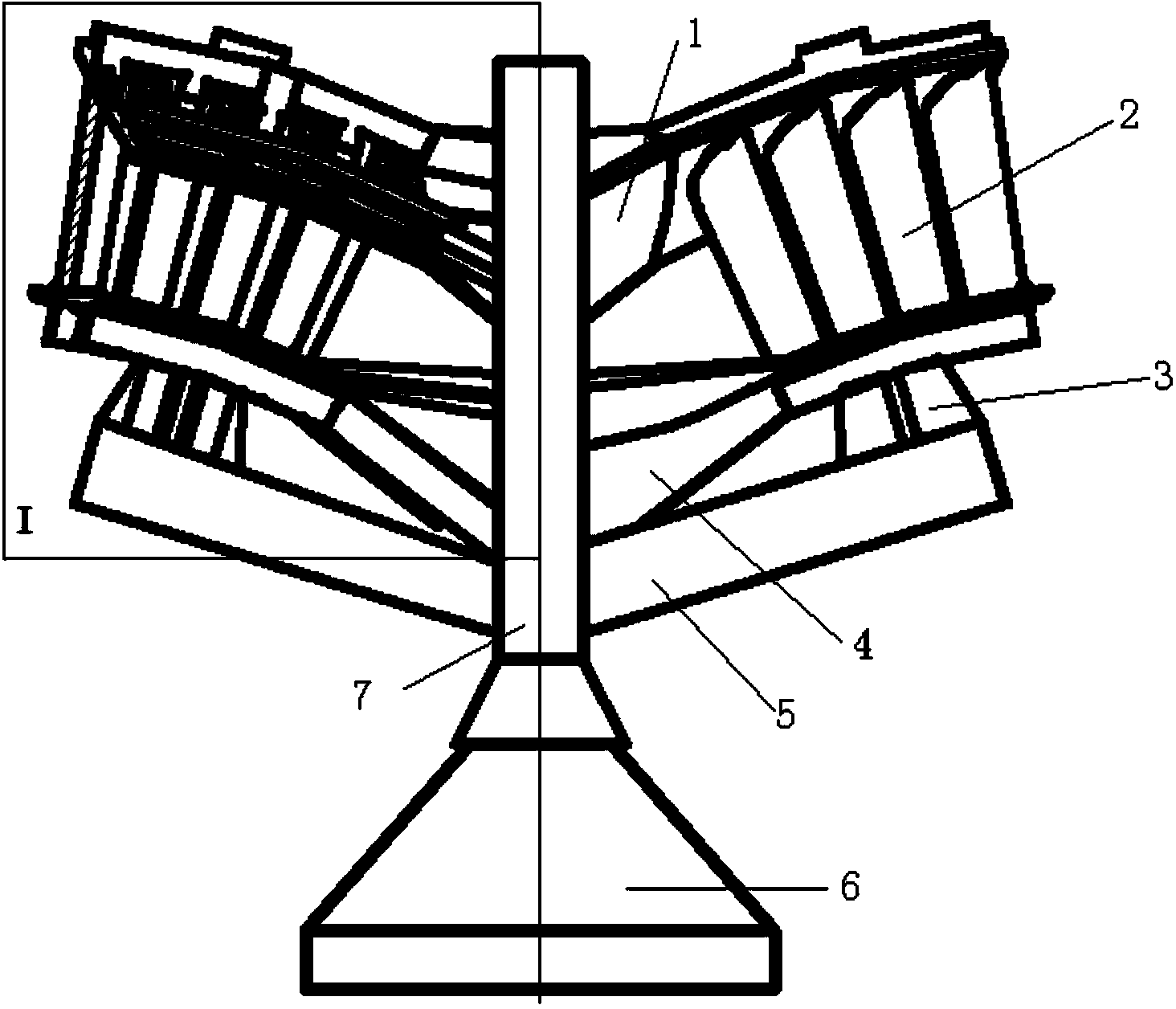

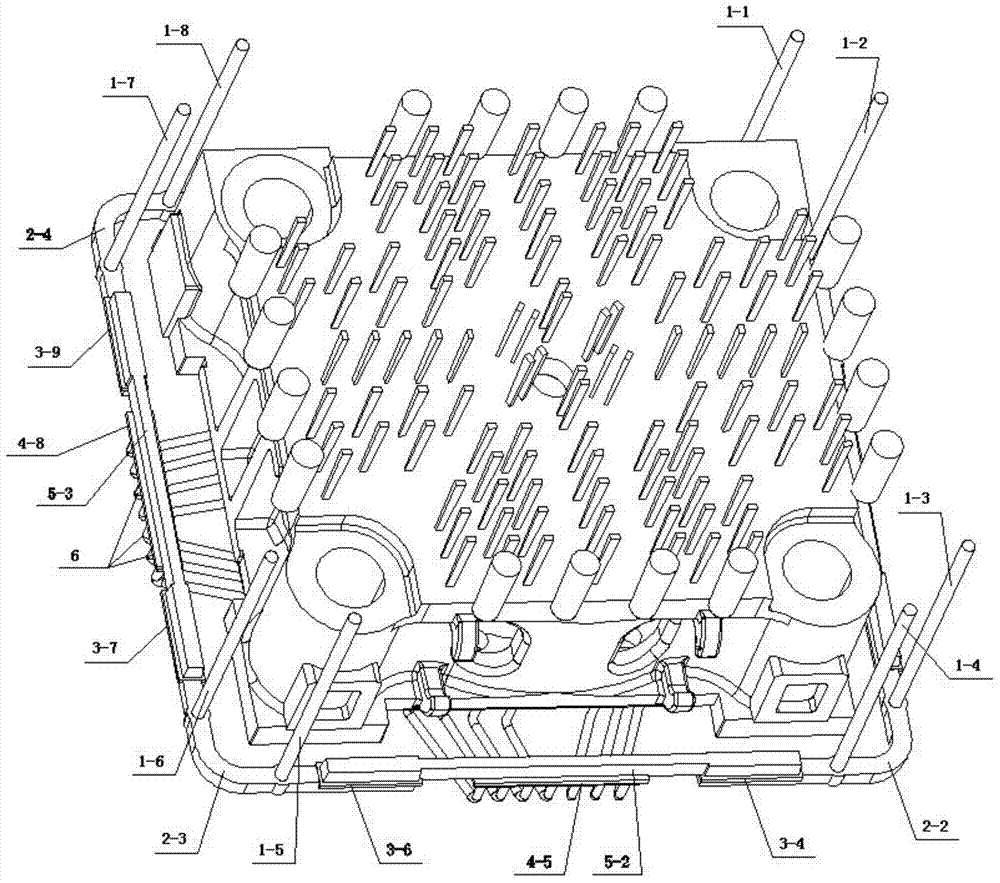

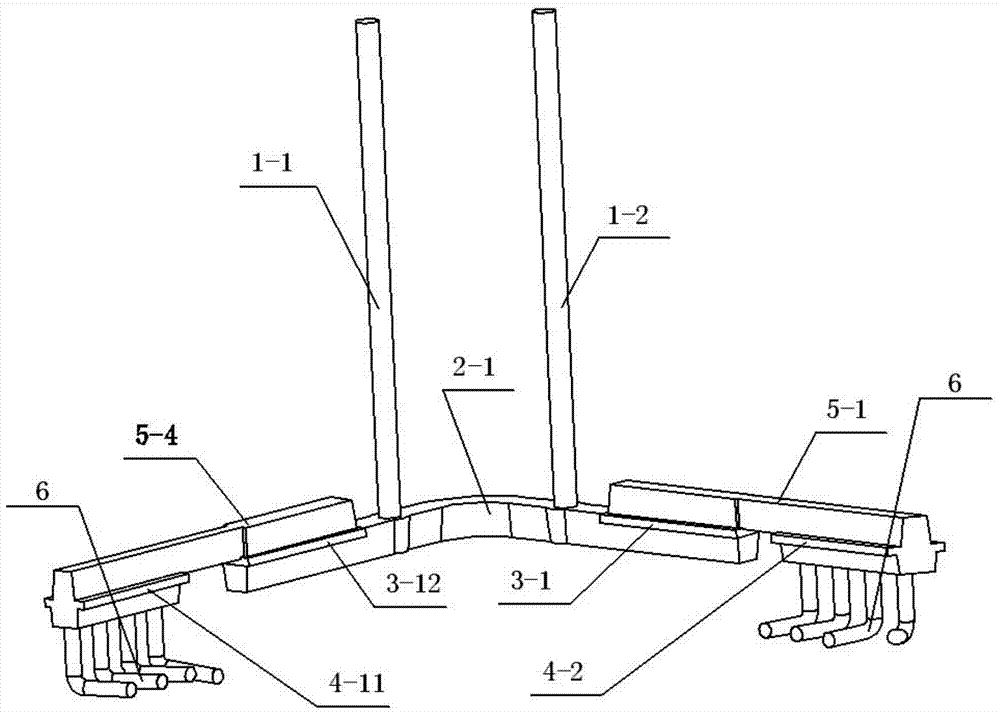

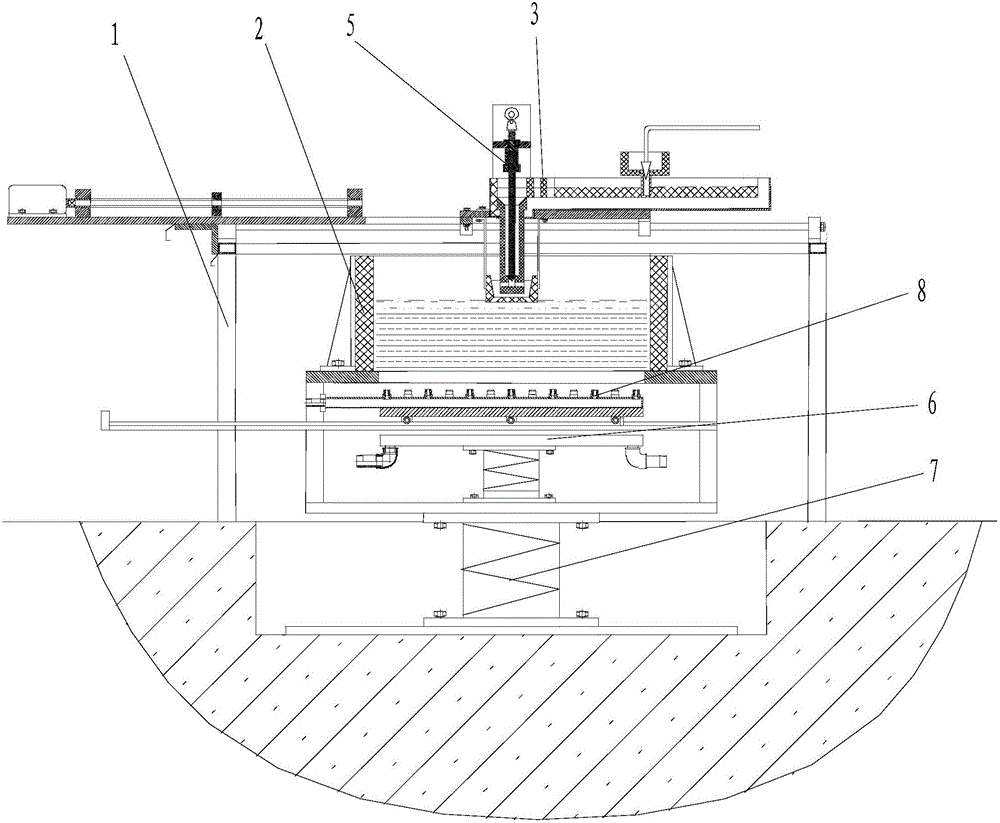

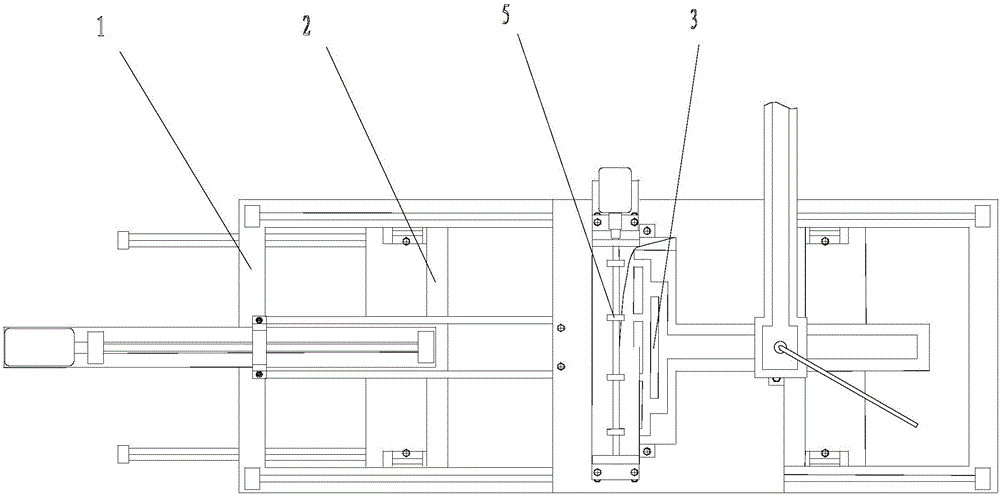

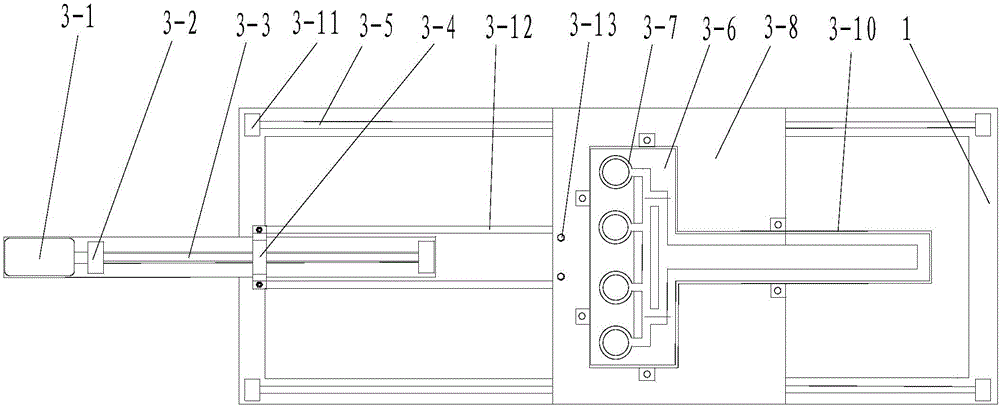

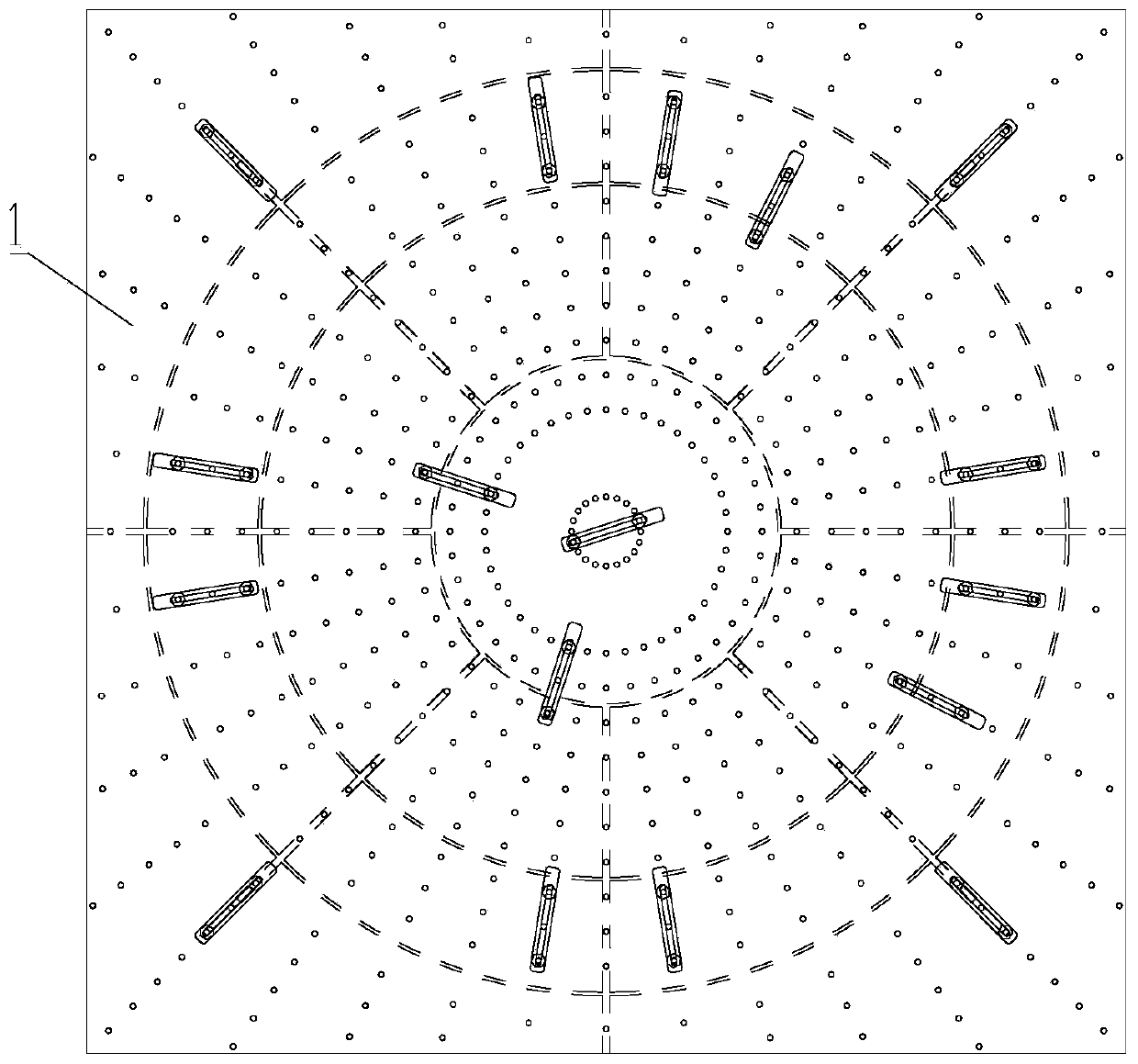

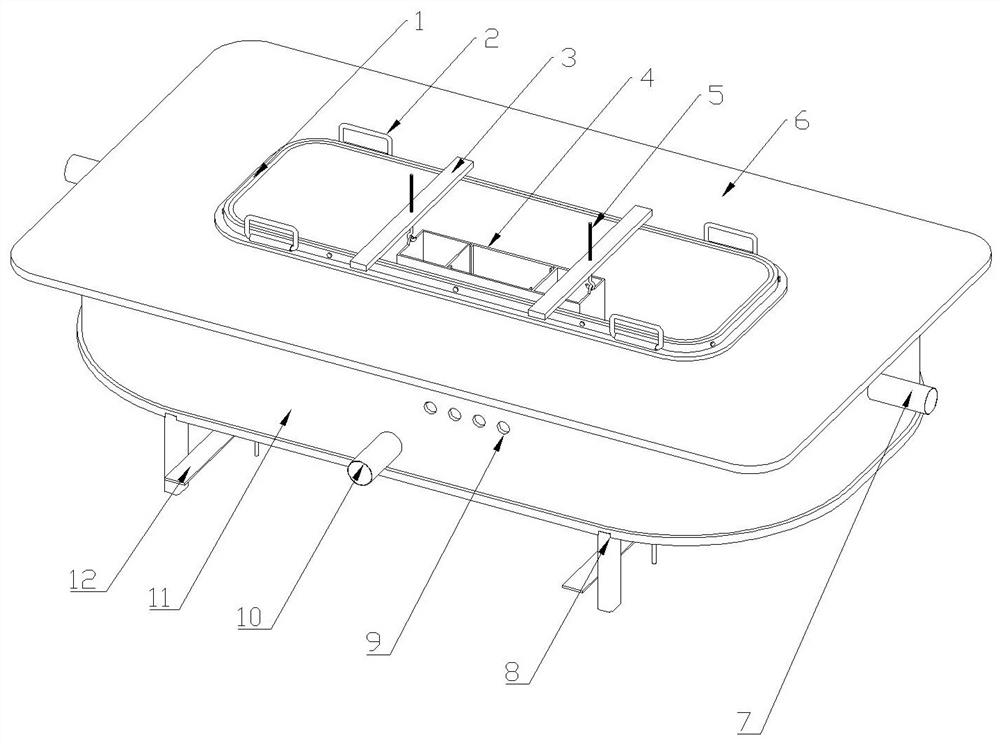

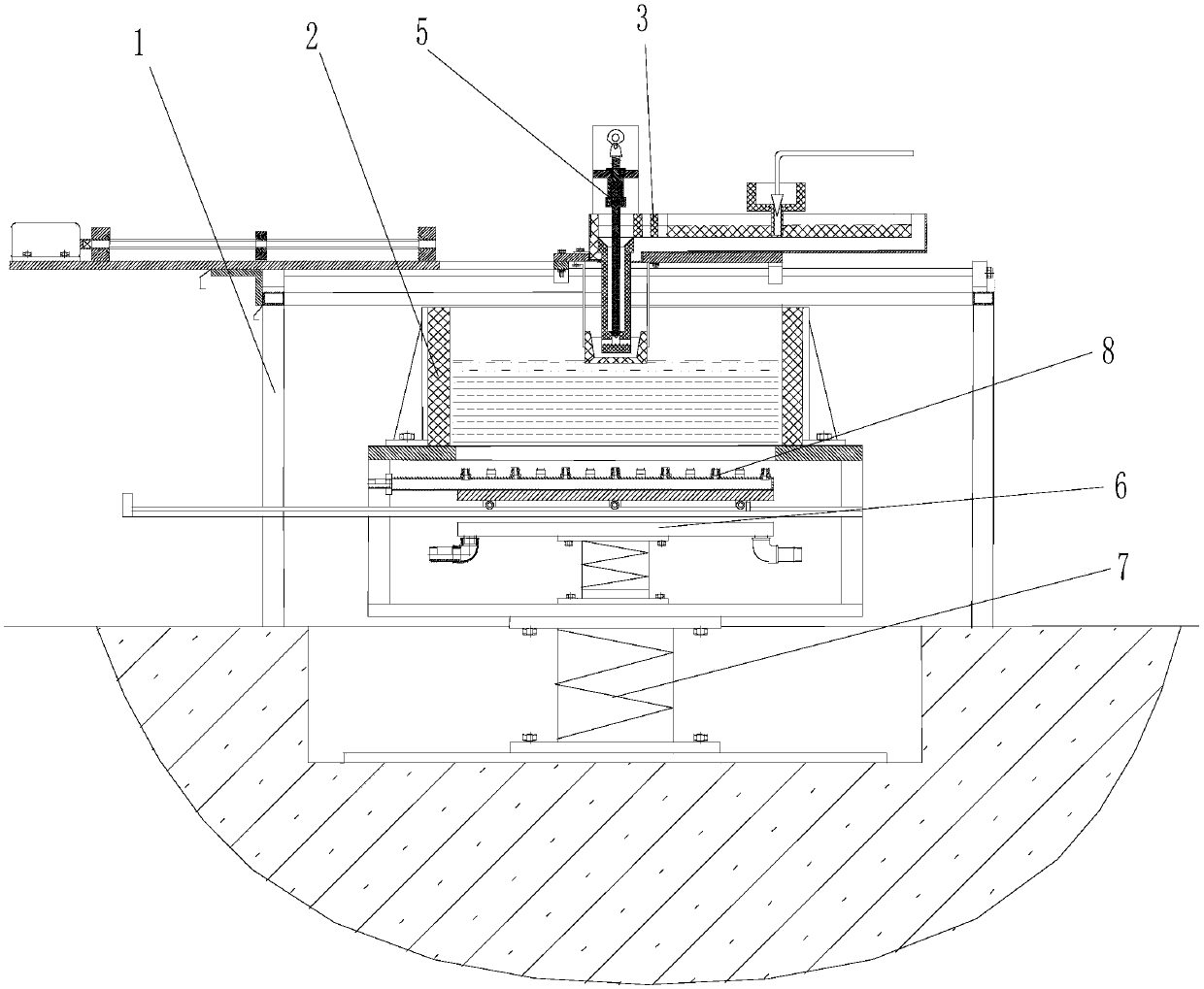

Aluminum alloy laminar flow distribution plane solidification casting device and casting method thereof

ActiveCN106238716AAchieve laminar distributionAvoid local overheatingMolten metal pouring equipmentsIngot castingWater spray

The invention discloses an aluminum alloy laminar flow distribution plane solidification casting device and a casting method thereof, and belongs to the technical field of aluminum alloy ingot blank casting. The device comprises a support. A translation flow distribution mechanism capable of moving horizontally is arranged on the upper portion of the support. A flow control mechanism is arranged at an outlet of the translation flow distribution mechanism. A casting tank is arranged below the translation flow distribution mechanism. A water spraying system and a cooling plate system are arranged below the casting tank. The method includes the steps that the cooling plate system rises into the casting tank, and molten aluminum alloy enters a flow distribution groove and then enters a guide rod sleeve; a second motor is started to control flow of the molten aluminum alloy; a first motor is started, a movable plate drives the flow distribution groove to move horizontally, and the molten aluminum alloy flows to a cooling plate upper plate body in a laminar mode; when an aluminum alloy solidification layer can be supported, a cooling plate oil cylinder is started, and thus the cooling plate system descends; then the water spraying system is pushed in, and sprayed water is cooled; the descending speed of a main oil cylinder is controlled until casting reaches a preset thickness; and after all the cooling is completed, water spraying is stopped, the water spraying system is extracted, ingot castings are taken out, and accordingly casting is completed.

Owner:NORTHEASTERN UNIV

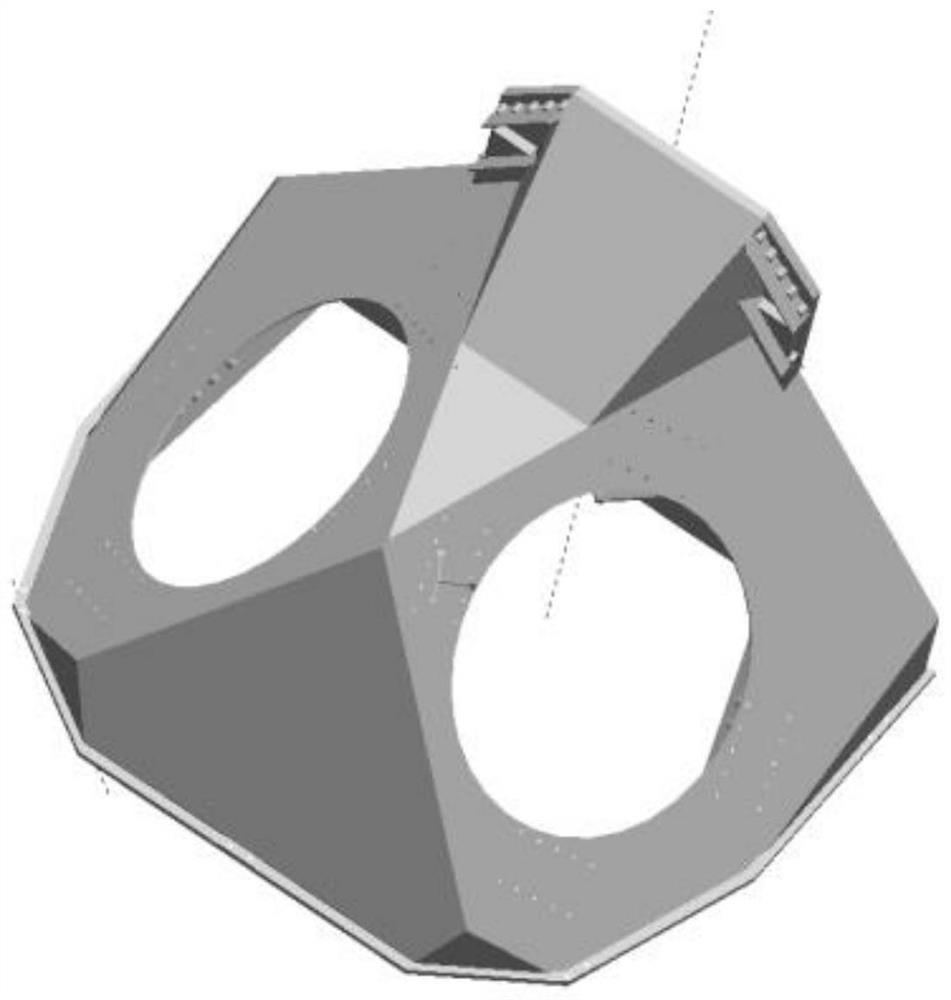

Aluminum alloy wheel hub gravity casting mould

InactiveCN103962513ASmooth exhaust and slag dischargeHigh densityFoundry mouldsFoundry coresMechanical propertyHigh frequency vibration

The invention discloses an aluminum alloy wheel hub gravity casting mould, which comprises a bottom die and a side die. A shunting cone is mounted in the middle of the bottom die, an upper die cooperating with the bottom die is mounted in the side die, and the upper die, the side die and the bottom die together form a cavity. The device is characterized in that: the side die is externally provided with several high-frequency vibration devices, the vibration heads of which are over against the side die. The mould provided by the invention can reduce or eliminate ventilation micropores in aluminum alloy wheel hubs, simultaneously strengthens the deslagging ability of liquid aluminum and improves the texture density and mechanical properties of casts, so that the produced aluminum alloy wheel hubs have improved quality. The aluminum alloy wheel hub gravity casting mould is mainly used as the casting mould for production of aluminum alloy wheel hubs.

Owner:湖北省阳新昂运铝轮有限公司

High-ductility soluble magnesium-lithium alloy and preparation method and application thereof

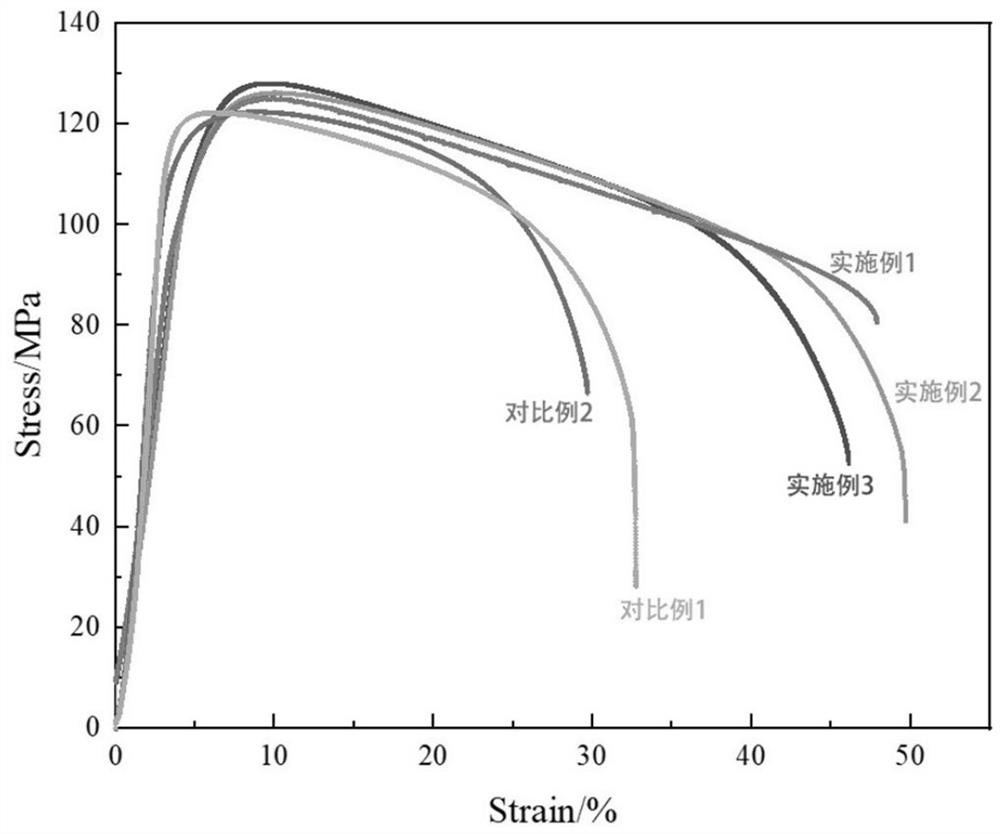

PendingCN113667871AImprove plasticityImprove solubilitySealing/packingVacuum castingUltimate tensile strength

The invention belongs to the technical field of magnesium-lithium alloys, and particularly relates to a high-ductility soluble magnesium-lithium alloy and a preparation method and application thereof. Aiming at the problems of low ductility, incomplete dissolution and the like of a packing tool in fracturing transformation construction of an oil and gas field, the high-ductility soluble magnesium-lithium alloy is obtained through alloy component design and by adopting the processes of vacuum casting, low-temperature severe plastic deformation, heat treatment and the like, and the alloy is prepared from the following components in percentage by mass: 9.0-12.0% of Li, 0-2.5% of Al, 0.1-1.0% of Zn, 0.1-1.0% of Ni, 0.2-1.0% of Cu, less than or equal to 1.0% of RE, and the balance of Mg. The tensile strength of the prepared magnesium-lithium alloy is not lower than 120 MPa, the yield strength is not lower than 90 MPa, the ductility is not lower than 45%, and the magnesium-lithium alloy can be used for machining and preparing high-plasticity soluble downhole tools used in the oil and gas field fracturing process, such as all-metal full-bore soluble bridge plugs, sealing rings or sealing rings.

Owner:郑州轻研合金科技有限公司

A casting method for hollow turbine guide vanes

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

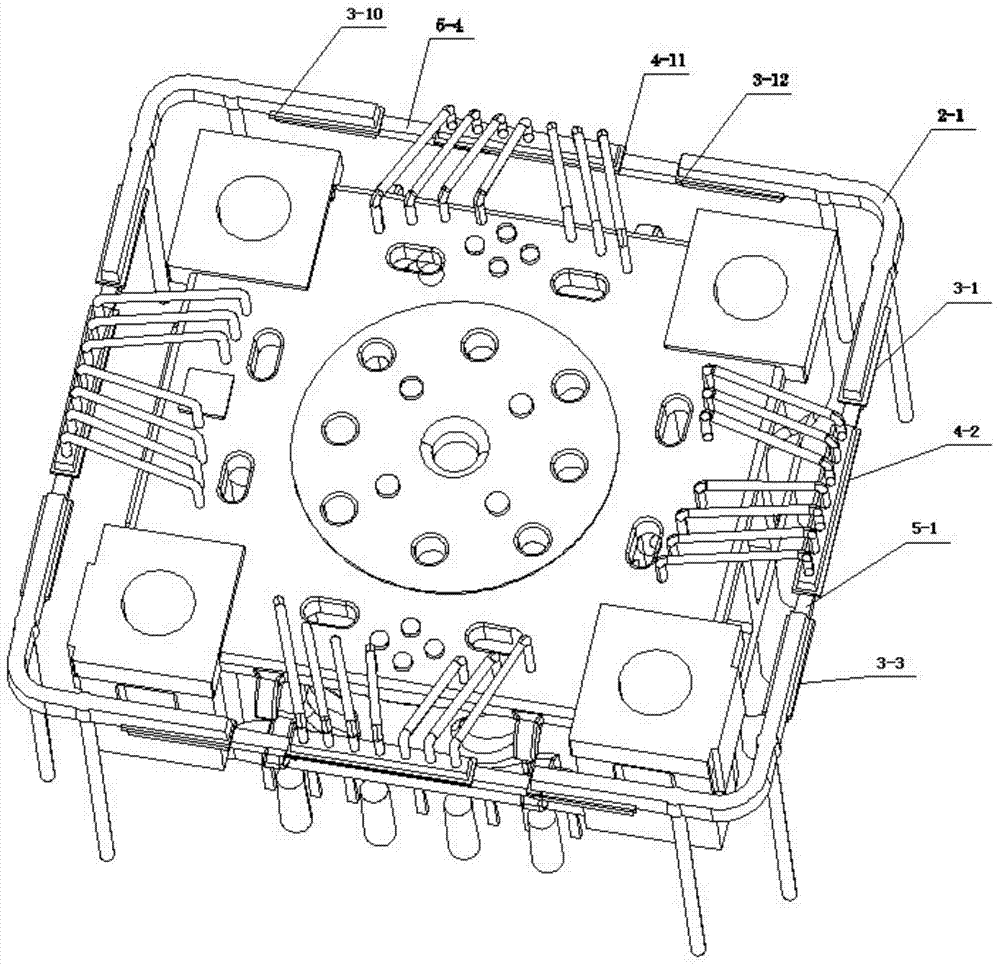

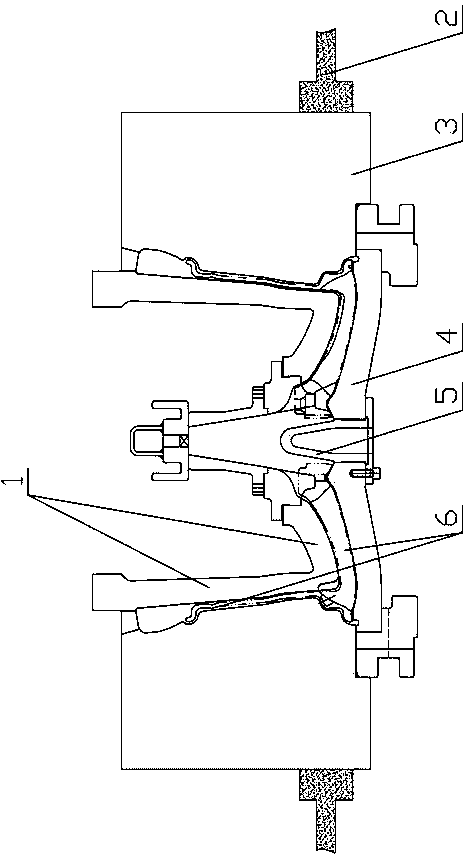

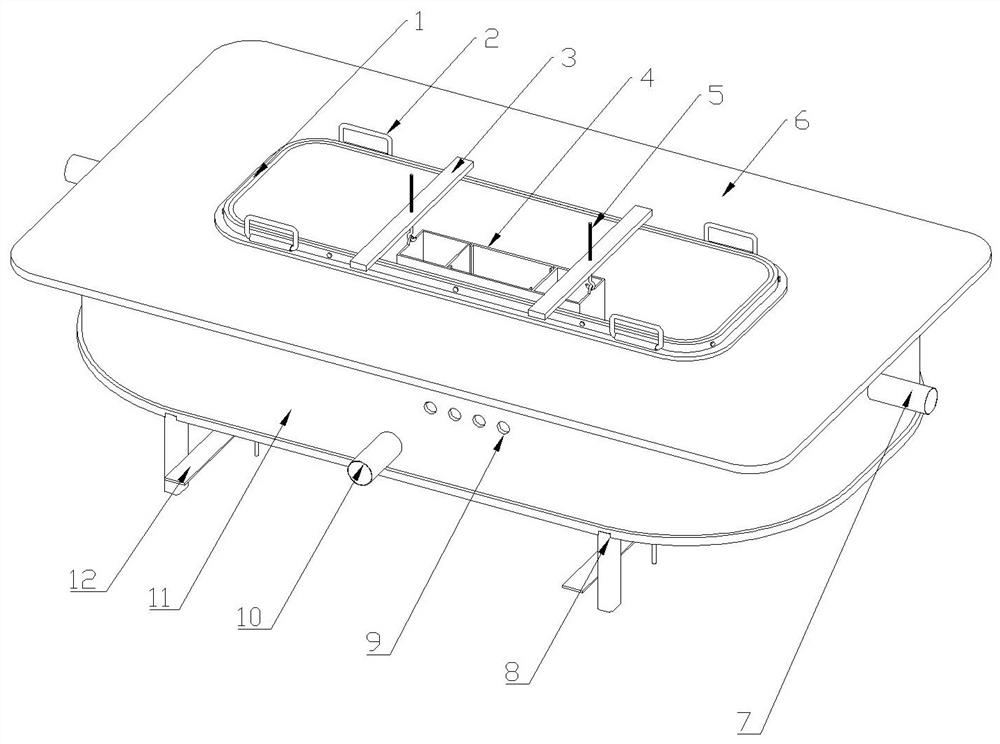

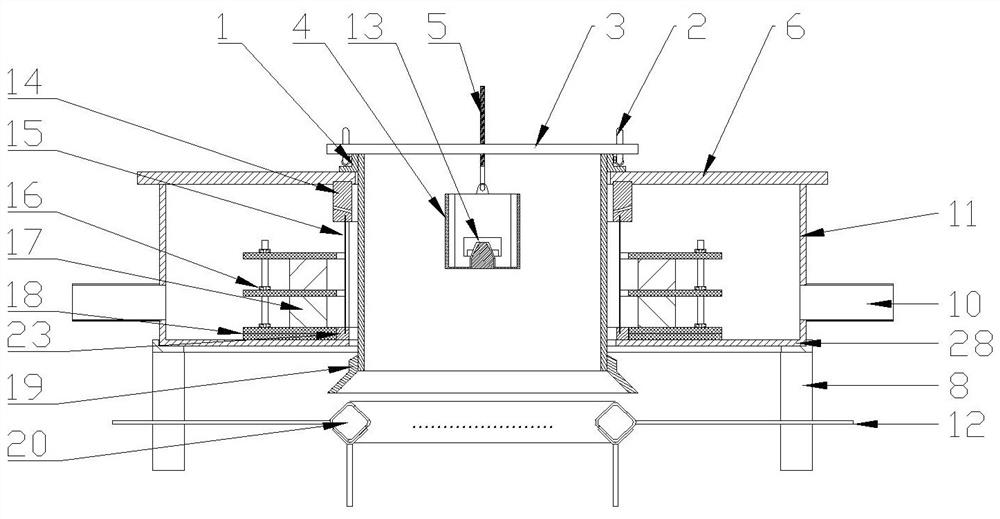

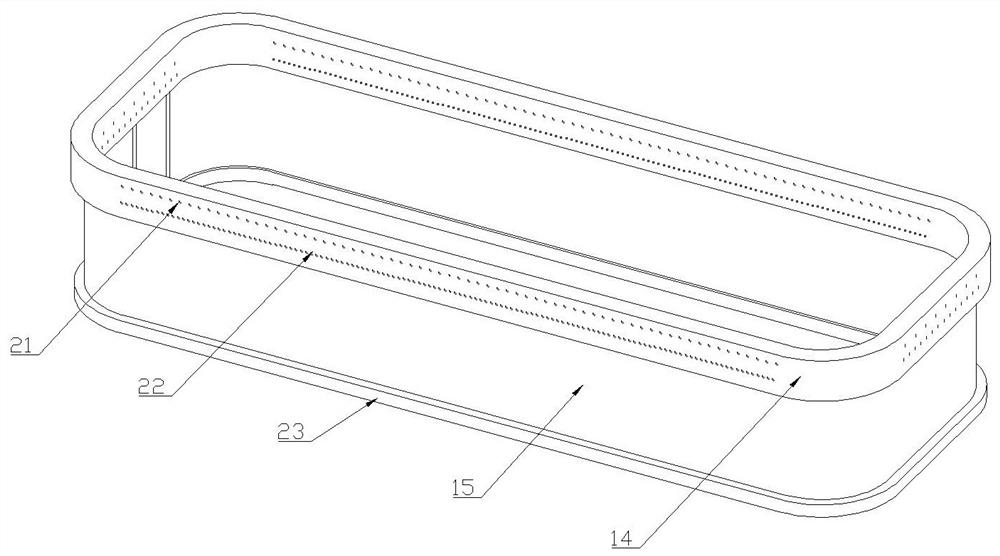

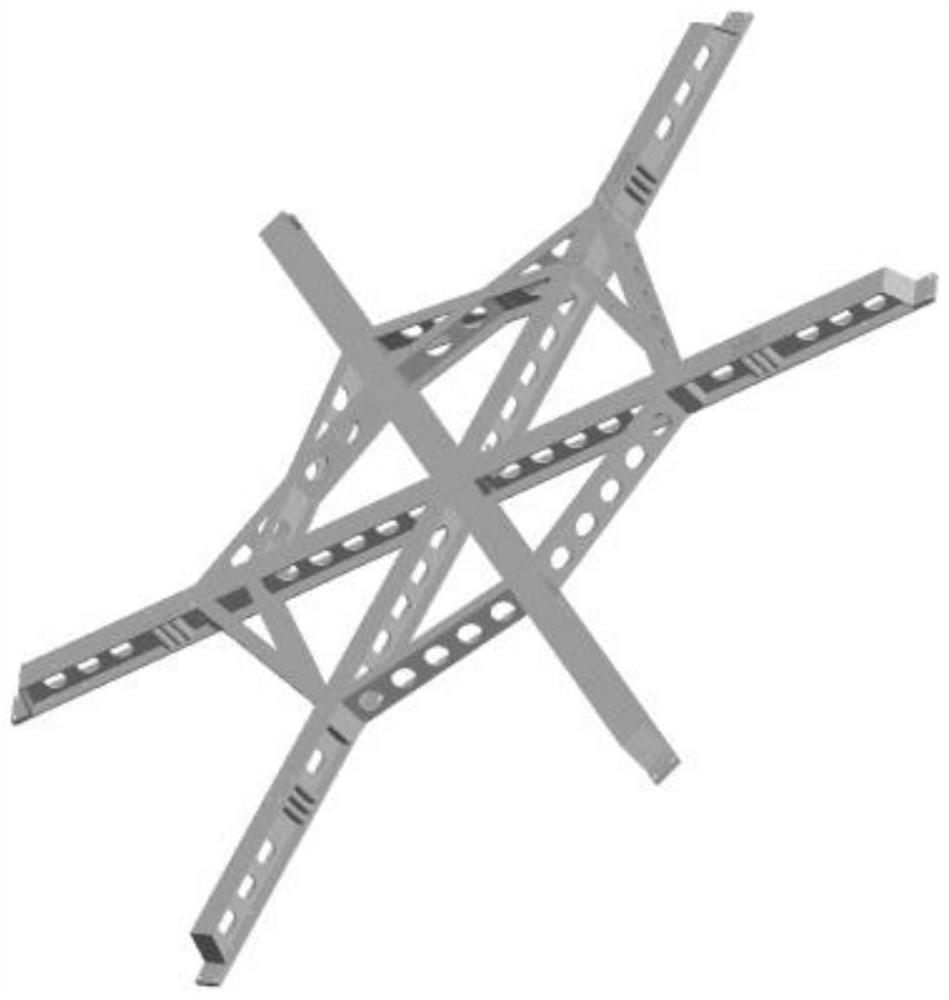

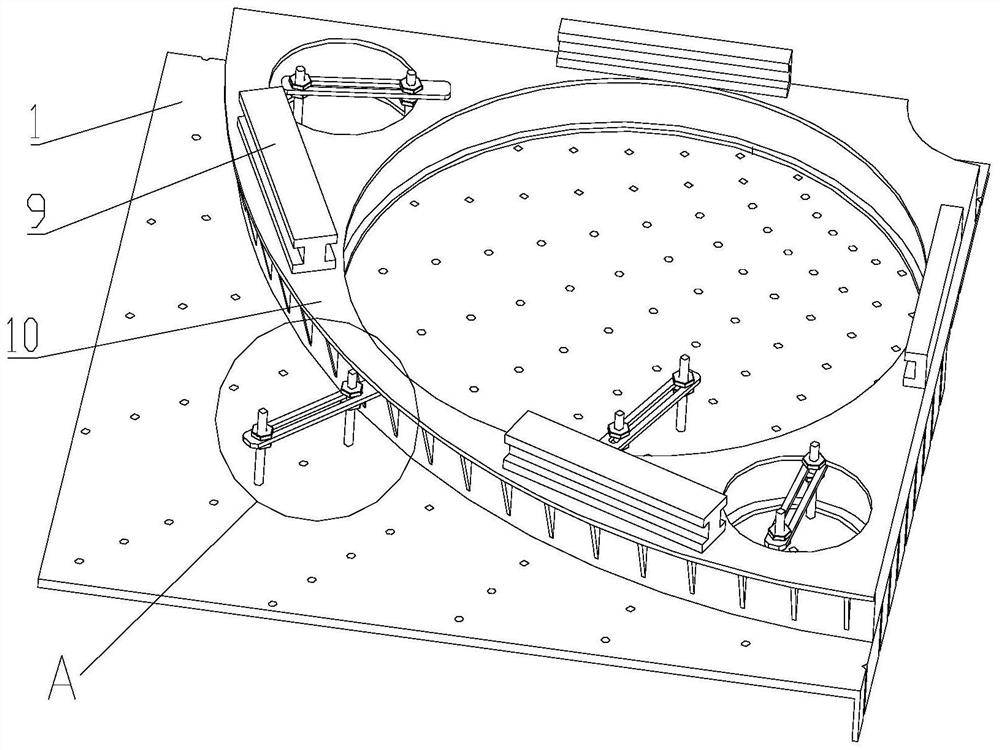

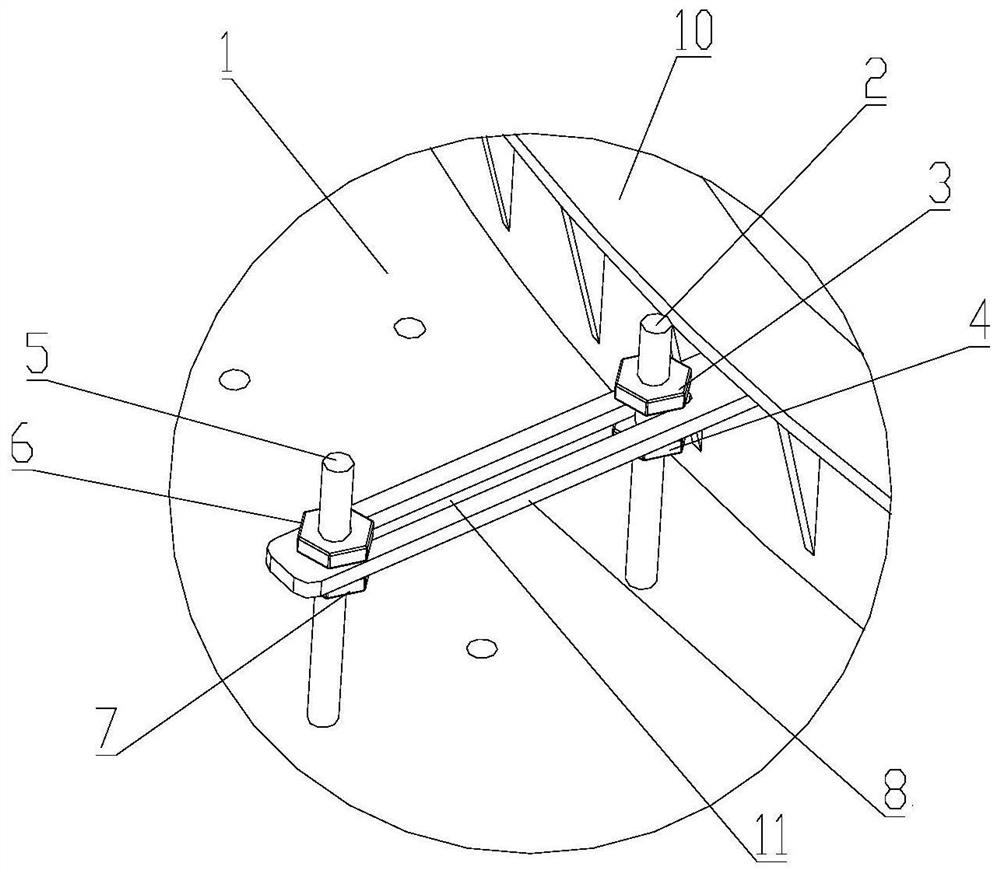

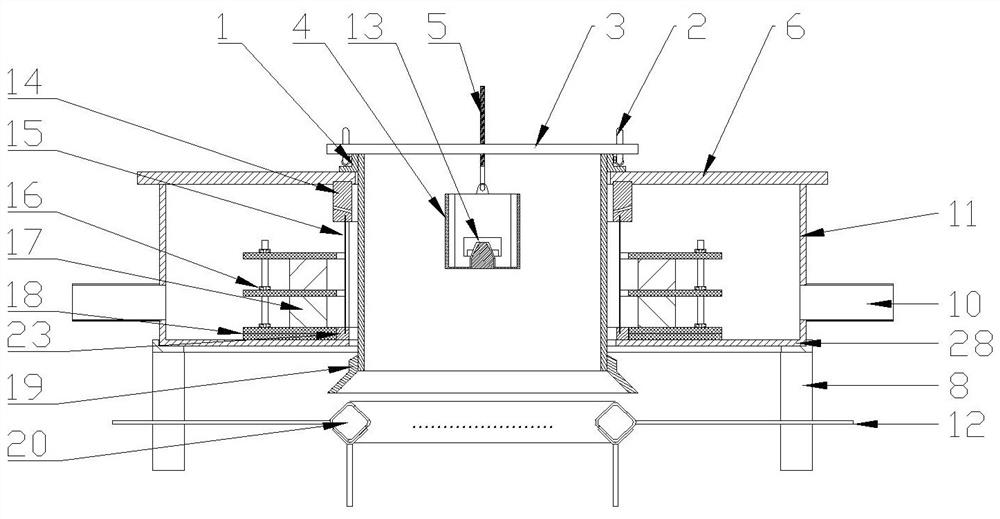

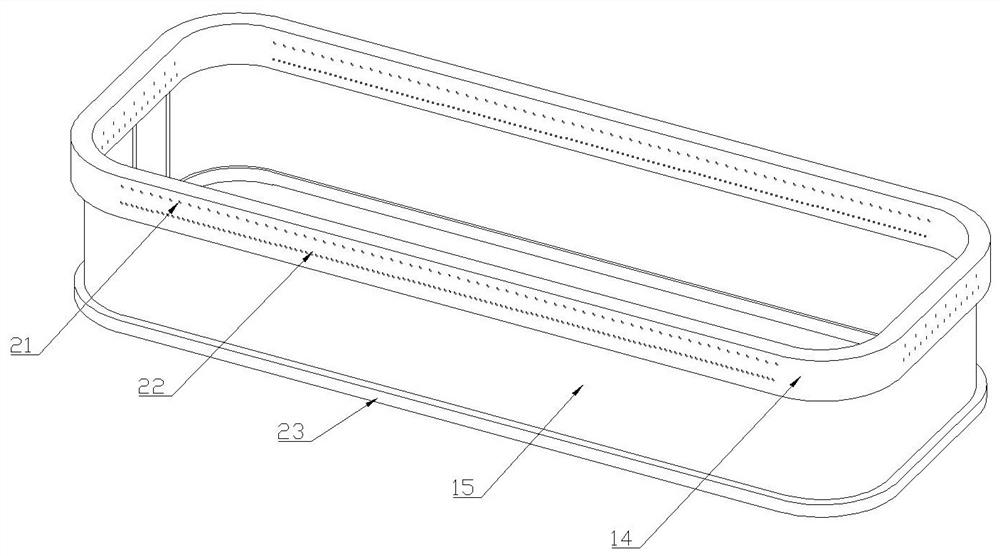

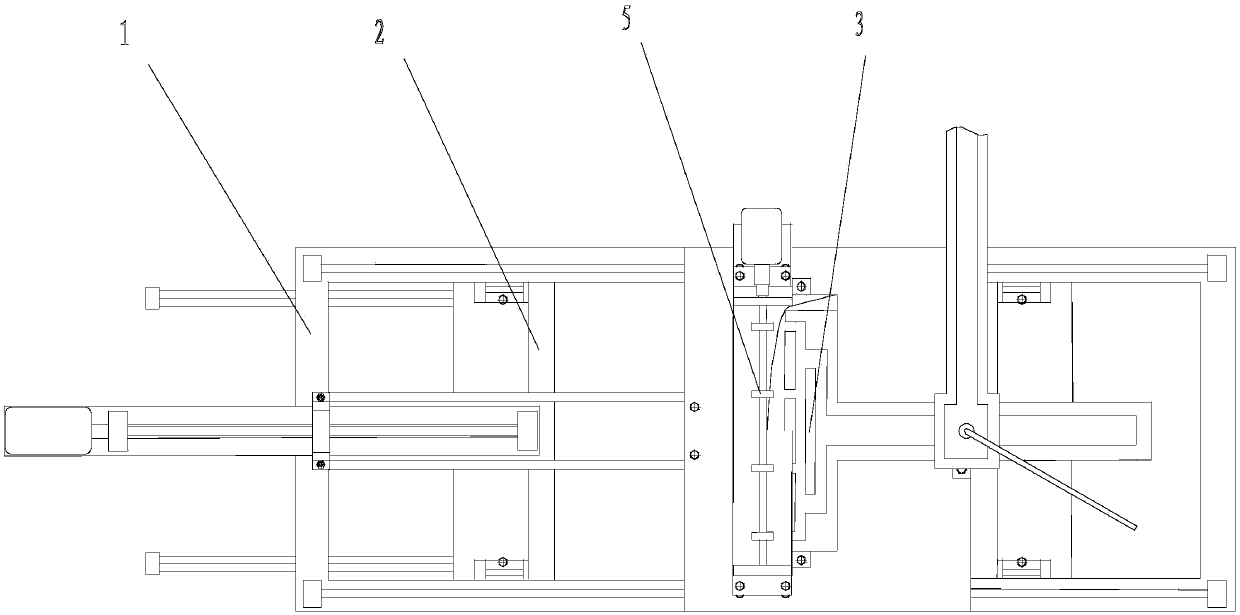

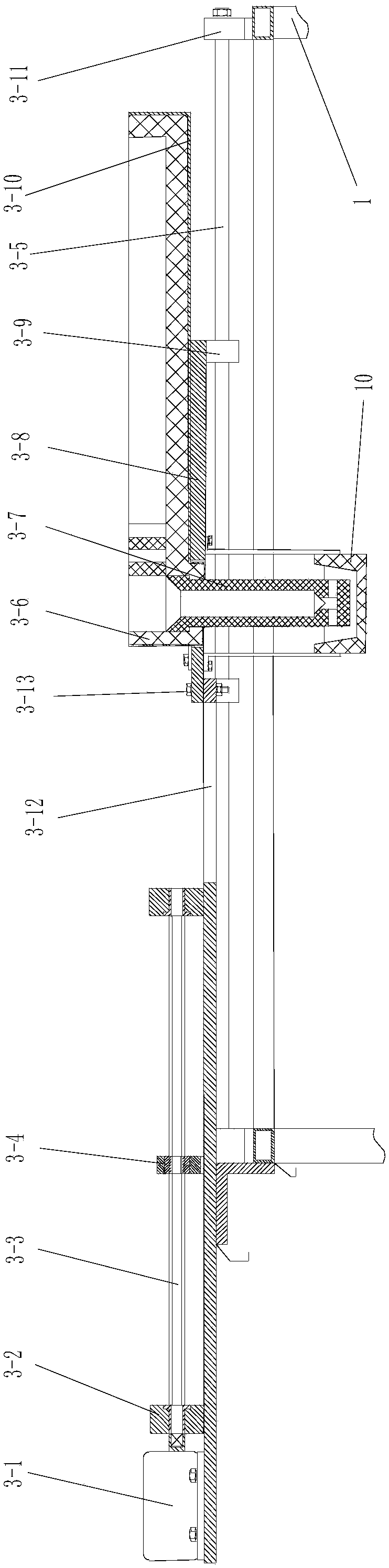

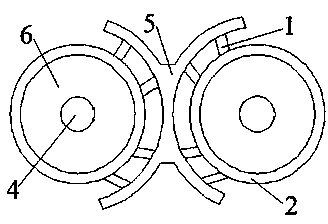

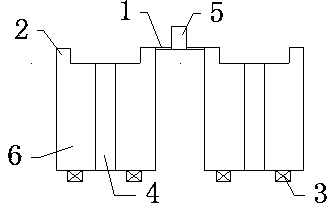

Electromagnetic semi-continuous casting device for high-casting-stress alloy cast ingot and method

The invention belongs to the technical field of casting, and particularly relates to an electromagnetic semi-continuous casting device for a high-casting-stress alloy cast ingot and a method for casting the cast ingot by applying the electromagnetic semi-continuous casting device. The electromagnetic semi-continuous casting device mainly comprises a diversion trench, a crystallizer and a dummy barhead, wherein the crystallizer comprises a crystallizer inner sleeve, a cold water tank, a coil and a bottom bracket. Under the condition that the amount of cold water is not changed, the cold watertank with double rows of different-diameter crossed water holes is adopted, so that double water flow beams appear in cold water, the cooling rate of alloy melt at the contact position of the cold water and the crystallizer inner sleeve is reduced, and the crack generation probability is reduced; through the arrangement of the distance between the two rows water holes, control over the cooling strength during casting can be achieved, and the surface quality of the cast ingot can be improved; the temperature gradient and the casting stress of the center and the edge of a slab ingot can be effectively reduced by using the diversion trench in the electromagnetic semi-continuous casting device, so that the cracking possibility of the cast ingot is reduced; and according to the electromagneticsemi-continuous casting device, production of products within a certain specification range can be achieved by replacing the specification of the crystallizer inner sleeve.

Owner:NORTHEASTERN UNIV

Heat treatment process for large thin-wall casting of high-strength magnesium alloy

ActiveCN111500954AGuaranteed not to deformGuaranteed deformationFurnace typesHeat treatment furnacesSolution treatmentUltimate tensile strength

The invention provides a heat treatment process for a large thin-wall casting of high-strength magnesium alloy. The heat treatment process is characterized by comprising the following steps of a, preliminarily scribing the large thin-wall casting and machining at least one reference plane; b, assembling the casting and a high-rigidity and easy-heat-conductive tool and then performing solution treatment; and c, performing high-external-force assembling on the casting subjected to solution treatment and the high-rigidity easy-heat-conductive tool, and then performing aging treatment, performingscribing detection on the casting and the tool after the casting and the tool are taken out of a furnace to be air-cooled, and if the local part does not meet the dimensional precision requirement, performing local high-external-force loading for secondary aging. According to the heat treatment process provided by the invention, a special tool is used during solution treatment and aging treatment,parameters such as heating speed, heat preservation time, a quenching air rate and stripping temperature drop of the solution treatment and the aging treatment are adjusted, deformation and cracks, caused by casting stress, of the large thin-wall component can be eliminated, and the strength is improved.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

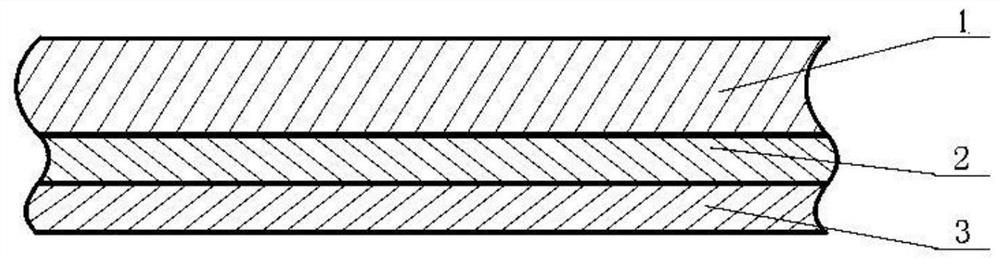

Three-body type composite casting wear-resistant lining plate and manufacturing method thereof

ActiveCN114480954AGood casting performanceImprove mechanical propertiesFurnace typesProcess efficiency improvementTemperingDuctile iron

The invention provides a three-body type composite casting wear-resistant lining plate which comprises a back layer, a transition layer and a surface layer which are arranged in sequence, the back layer is made of medium and low carbon steel, a filter layer is made of ferritic nodular cast iron, and the surface layer is made of high-chromium molybdenum wear-resistant white cast iron. According to the wear-resistant lining plate, the transition layer is additionally arranged between the surface layer high-chromium-molybdenum wear-resistant white cast iron and the back layer medium-low carbon steel, so that the wear-resistant lining plate not only has wear resistance, but also can endure a violent impact working condition, the adhesion between the layers is better, and the casting technological process is simplified; the invention further provides a manufacturing method of the three-body type composite casting wear-resistant lining plate, the ideal three-body type composite casting wear-resistant lining plate can be obtained, the shrinking percentage is in smooth transition, combination is tight and natural, casting stress is greatly reduced, and casting defects are remarkably reduced; and then the three-body type composite casting wear-resistant lining plate blank is subjected to quenching and tempering treatment, so that the three-body type composite casting wear-resistant lining plate has better mechanical properties.

Owner:武汉市科发铁合金有限公司

A method for manufacturing a large-scale high-strength superhard hollow round ingot

The invention relates to a hollow billet and a manufacturing method thereof, and especially relates to a large-size and high-strength super hard hollow billet and a manufacturing method thereof. The purpose of the invention is to solve the problems of low yield, large production workload and difficult process control of casting of aluminum alloy hollow ingots prepared in the prior art. The large-size and high-strength super hard hollow billet comprises Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, B and Al. The manufacturing method comprises the following steps: 1, weighing; 2, smelting; 3, refining and casting of melt; and 4, molding. The method is mainly used for manufacturing the large-size and high-strength super hard hollow billet.

Owner:NORTHEAST LIGHT ALLOY CO LTD +1

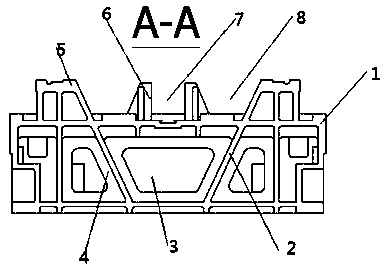

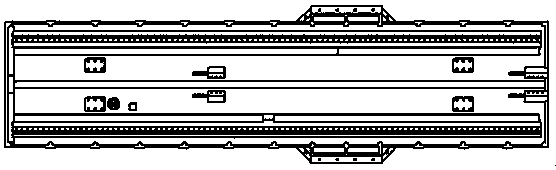

Lightweight high-rigidity gantry machining center machine base

PendingCN107914149AIncreased flexural section modulusHigh tensile strengthLarge fixed membersEngineeringMachine tool

The invention discloses a lightweight high-rigidity gantry machining center machine base. The lightweight high-rigidity gantry machining center machine base comprises a machine base body. A base is composed of two downwards parallel base plates. The two base plates are connected and fixed through a strengthening rib. The strengthening rib is in an inverted-W shape. The sharp ends of the triangularshapes of the two sides of the upper end of the strengthening rib penetrate the top base plate, top sliding rails are arranged on the tops of the sharp ends of the triangular shapes of the strengthening rib, and the three end portions of the lower end of the strengthening rib are connected and fixed to the base plate on the lower side. The lower parts of double guide rails of the base are supported by the inverted-W-shaped strengthening rib, and the weight of a movable component workbench on the guide rails and machined workpieces is scattered through the strengthening rib, the supporting area and range are set from small to large, the interior of the base is supported by the multiple triangles likely, the casting stress of castings is reduced to be minimum, the residual stress of the castings is eliminated through annealing and the rest of precipitation heat treatment, and the stability during machine tool movement is greatly improved; and meanwhile, the material cost is saved, and meanwhile rigidity is improved.

Owner:湖南巨人机床集团有限公司

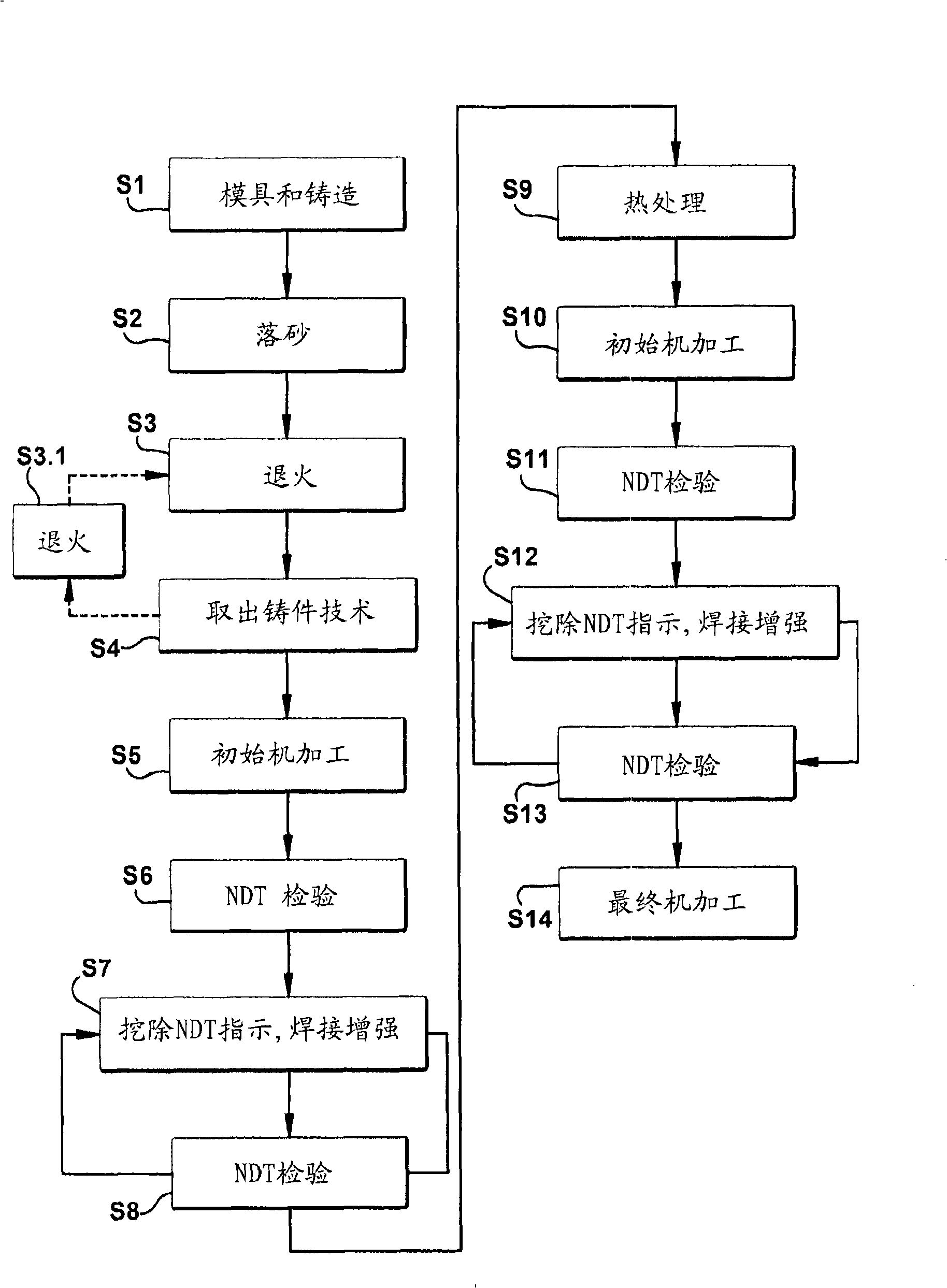

Method and system for restoring parent metal properties across welds

A method, with an associated system, for providing a cast component comprises annealing heat treatment to reduce casting stresses; initial machining the cast component; initial nondestructive testing (NDT) the machined cast component to identify NDT indications in the cast component; treating and removing NDT indications from the machined cast component; weld upgrading the treated and removed NDT indications from the machined cast component, the weld upgrading providing stress relief; intermediate nondestructive testing the cast component to identify NDT indications in the weld upgraded cast component; normalizing and temper heat treatment of the cast component; second intermediate nondestructive testing the cast component to identify NDT indications in the cast component; further treating and removing NDT indications from the cast component; post-normalization and temper weld upgrading the treated and removed NDT indications providing stress relief; and final nondestructive testing the cast component to identify NDT indications in the cast component.

Owner:GENERAL ELECTRIC CO

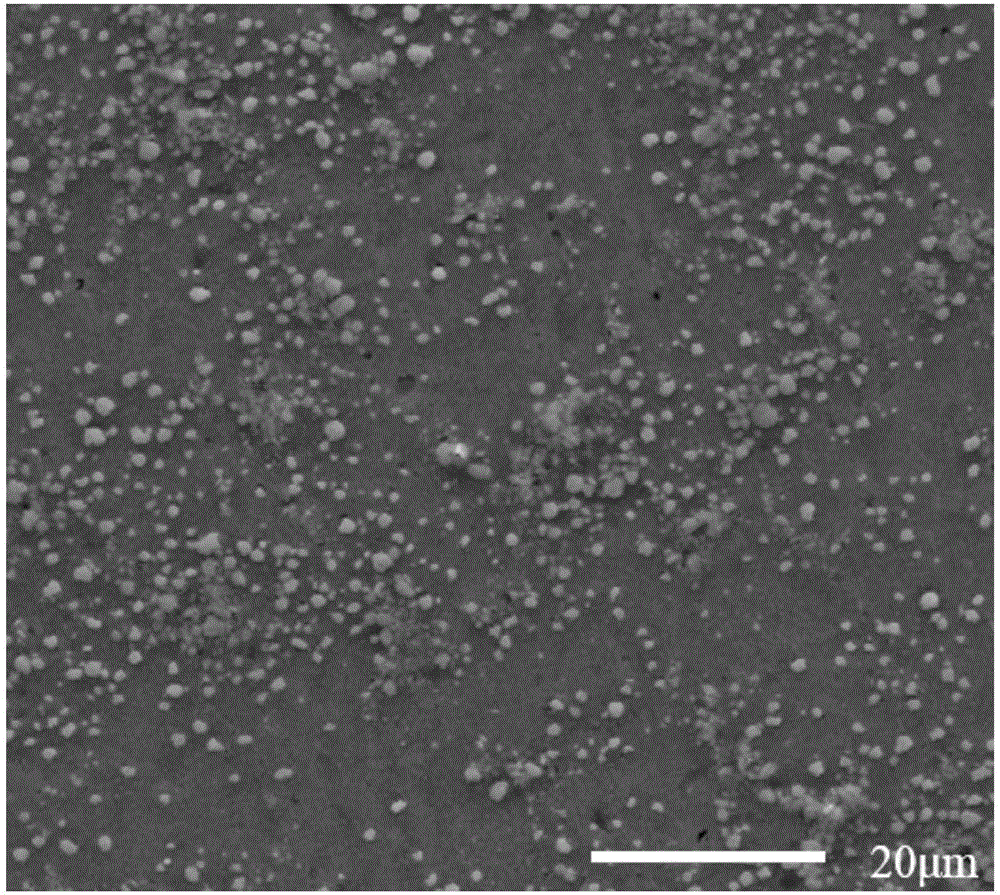

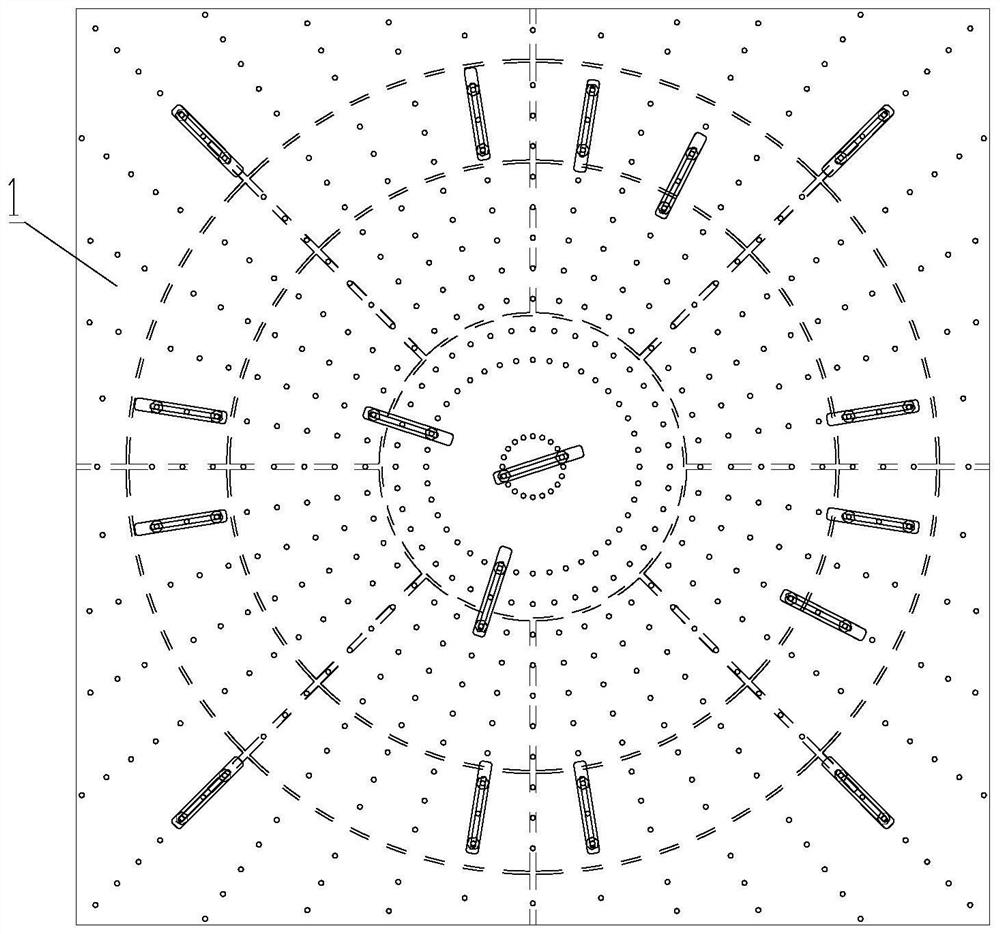

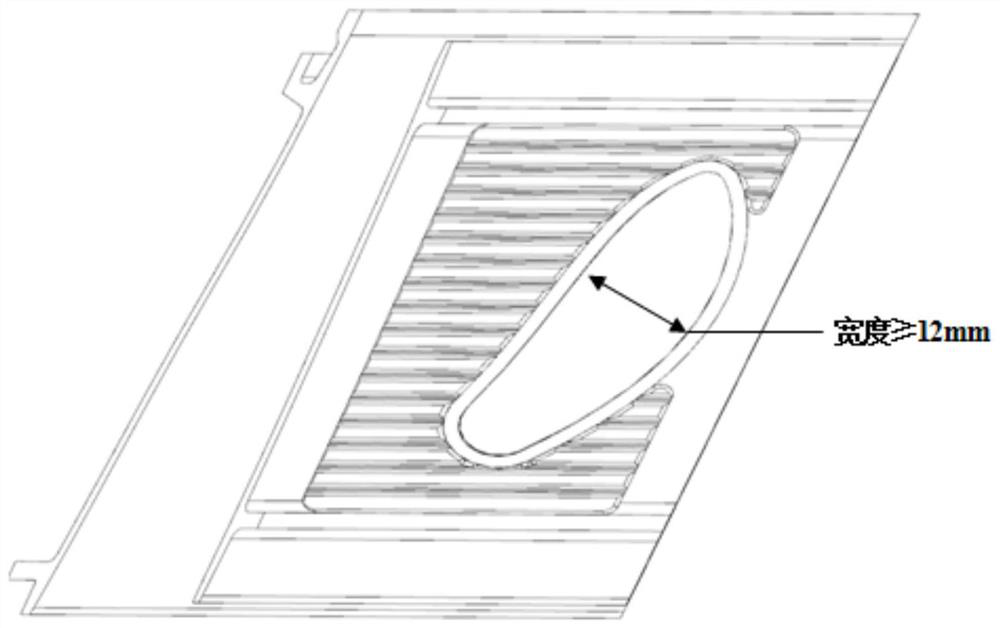

Method for improving metallurgical quality of large-specification 2000 series aluminum alloy cast ingot

ActiveCN112974747AReduce the degree of component segregationReduce crackingCasting cleaning apparatusWater flowIngot

The invention provides a method for improving the metallurgical quality of a large-specification 2000 series aluminum alloy ingot, and is suitable for a large-specification flat ingot with the size of 520mm (thickness) x 1620mm (width) and a large-specification round ingot with a diameter of 1000mm. The method comprises the following steps of: jointly applying ultrasonic waves and electromagnetic waves to molten aluminum (such as molten aluminum in a front groove) during casting; and selecting ultrasonic frequency, coupling parameters of electromagnetic waves, casting temperature, casting speed and water flow according to alloy components. According to the method, the casting stress of the large-specification cast ingot can be effectively reduced, cracks are reduced, the composition segregation degree of the cast ingot is reduced, microporosity is reduced, the cast ingot is prevented from cracking, and the casting forming rate is increased.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

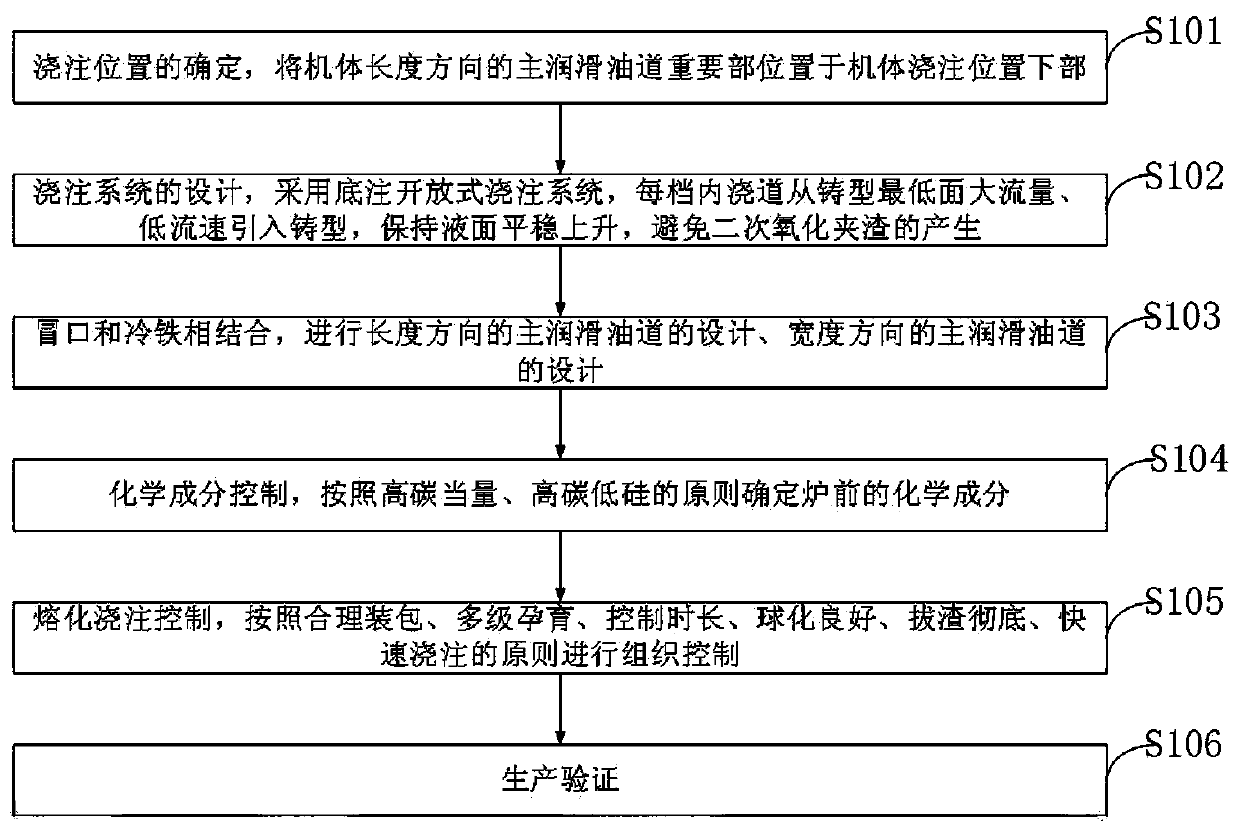

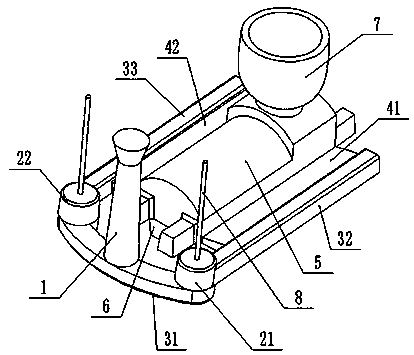

Method for forming main lubricating oil passage of nodular cast iron diesel engine body and application

The invention belongs to the technical field of cast iron casting, and discloses a method for forming a main lubricating oil passage of a nodular cast iron diesel engine body and application. A bottom-pouring open-type gating system with a filter device is adopted to purify molten iron, a feeding head is arranged at the thermal center part of the main lubricating oil passage, and cold iron is usedin cooperation to balance the temperature field of nodular cast iron; and the stokehold chemical composition, reasonable charging, multi-stage inoculation, duration control, good nodularization, thorough slagging-off and fast pouring parameters are determined according to the principles of high carbon equivalent and high carbon and low silicon, and internal compaction of the thick and large thermal center part is performed to eliminate shrinkage and slag inclusion inside the main lubricating oil passage of the engine body. The method is beneficial to realizing the basic balance of the temperature field of the nodular cast iron. The method guarantees the high quality of the molten iron, realizes the internal compaction of the thick and large thermal center part, eliminates the quality risks of shrinkage and slag inclusion defects inside the main lubricating oil passage of the engine body, and overcomes the shrinkage casting defect of the main lubricating oil passage of the complicatednodular cast iron diesel engine body.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

A Method for Improving the Metallurgical Quality of Large Size 2000 Series Aluminum Alloy Ingots

ActiveCN112974747BReduce the degree of component segregationReduce crackingCasting cleaning apparatusWater flowIngot

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A heat treatment method for magnesium alloys used in large-scale satellites

The invention provides a heat treatment method for a magnesium alloy used in large-scale satellites, and belongs to the technical field of heat treatment of magnesium alloys. The invention uses high-rigidity and heat-conducting tooling, which can ensure that the tooling itself does not deform during heat treatment and shape correction, and is easy to strictly control the deformation of the casting during the stress release process, and then strictly control the size of the casting. Heat conduction can ensure the uniformity of tooling and casting temperature and avoid new deformation; if the temperature drops too much during the unmounting process, the temperature inconsistency between the first unmounting and the last unmounting part and the difference in stress state will cause new deformation of the casting . The invention controls the temperature drop at 50°C and 20°C, which can prevent new deformation.

Owner:CENT SOUTH UNIV +2

A kind of heat treatment process for large-scale thin-wall casting of high-strength magnesium alloy

ActiveCN111500954BGuaranteed not to deformGuaranteed deformationFurnace typesHeat treatment furnacesSolution treatmentUltimate tensile strength

The invention provides a high-strength magnesium alloy large-scale thin-walled casting heat treatment process, which is characterized in that it includes the following steps: a. Preliminarily scribing the large-scale thin-walled casting and processing at least one reference plane; b. Solid solution treatment is carried out after the rigid and easy-to-heat-conducting tooling is assembled; c. Aging treatment is carried out after the solution-treated castings and high-rigid and easy-to-heat-conducting tooling are assembled with high external force. If the dimensional accuracy requirements are not met, local high external force loading is carried out for secondary aging. The present invention can eliminate the large thin wall caused by casting stress by using special tooling during solution treatment and aging treatment, and adjusting parameters such as heating rate, holding time, quenching air rate, and dismounting temperature drop of solution treatment and aging treatment. Component deformation, cracks, and increase the strength.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

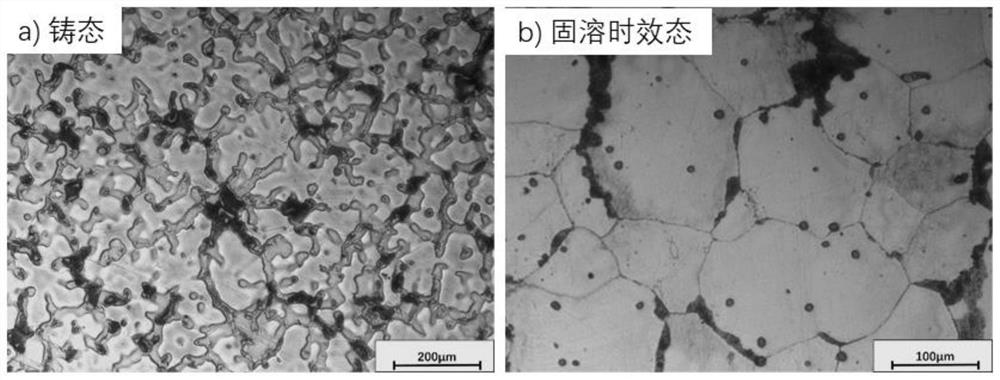

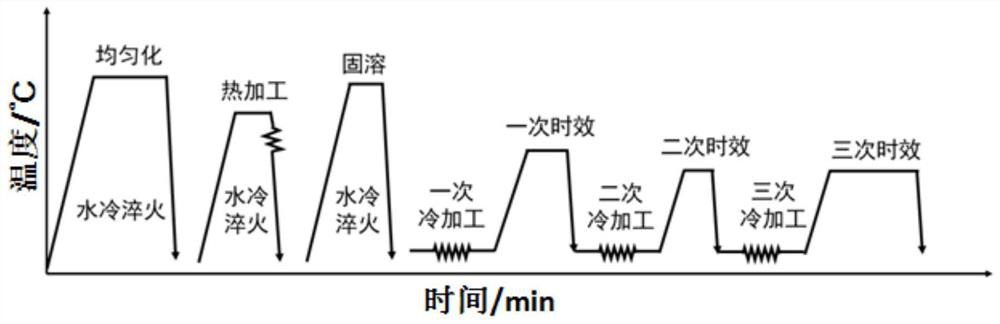

Cu-Ni-Si-Fe alloy and preparation method and application thereof

ActiveCN114540663AReduce casting stressIncrease contentConductive materialMetal/alloy conductorsCo elementFe element

The invention provides a Cu-Ni-Si-Fe alloy as well as a preparation method and application of the Cu-Ni-Si-Fe alloy. According to the alloy, through component optimization, a base metal Fe element is adopted to replace part or even all Co elements in a Cu-Ni-Co-Si alloy, high-hardness and high-heat-resistance nanoscale FeSi phase particles are formed by means of the strong atom binding force between Fe and Si, and the low-cost, high-strength and high-conductivity alloy is obtained. The invention further provides a preparation method and application of the alloy.

Owner:CENT SOUTH UNIV

Electromagnetic semi-continuous casting device and method for alloy ingot with high casting stress

Owner:NORTHEASTERN UNIV LIAONING

Aluminum Alloy Layered Distribution Plane Solidification Casting Device and Casting Method

ActiveCN106238716BAchieve laminar distributionAvoid local overheatingMolten metal pouring equipmentsIngot castingElectric machinery

An aluminum alloy layered flow planar solidification casting device and a casting method thereof belong to the technical field of aluminum alloy ingot casting. The device includes a bracket, a horizontally movable translational diverting mechanism is provided on the upper part of the bracket, a flow control mechanism is provided at the outlet of the translational diverting mechanism; a casting box is provided below the translational diverting mechanism, and a water spray is provided below the casting box systems and cooling plate systems. Method, the cooling plate system is raised into the casting box, and the aluminum alloy liquid enters the shunt trough and enters the guide rod sleeve; the second motor is started to control the flow of the aluminum alloy liquid; the first motor is started, and the moving plate drives the shunt trough to move horizontally, and the aluminum alloy The liquid flows to the top of the cooling plate in a laminar manner; when the aluminum alloy solidified layer can support it, start the cooling plate cylinder to lower the cooling plate system; then push the water spray system in to spray water for cooling; control the descending speed of the main oil cylinder , until the casting reaches the predetermined thickness; after all cooling, stop spraying water, pull out the water spray system, take out the ingot, and the casting is completed.

Owner:NORTHEASTERN UNIV LIAONING

A method for manufacturing a large-scale heat-treated aluminum alloy flat ingot

The invention provides a method for manufacturing a large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, and relates to a method for manufacturing the aluminum alloy slab ingot. The method for manufacturing the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened mainly solves the problems that as for an aluminum alloy slab ingot prepared in the prior art, the casting yield is low, and wide and thick slabs with excellent properties cannot be rolled out. The method comprises the first step of material weighing, the second step of smelting, the third step of casting melt preparation and the forth step of molding, and the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened is obtained. By means of the method, according to the prepared large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, the yield strength ranges from 98 N / mm<2> to 120 N / mm<2>, the tensile strength ranges from 182 N / mm<2> to 201 N / mm<2>, and the elongation percentage in a casting state ranges from 9.56% to 14.7%. By means of the method, the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

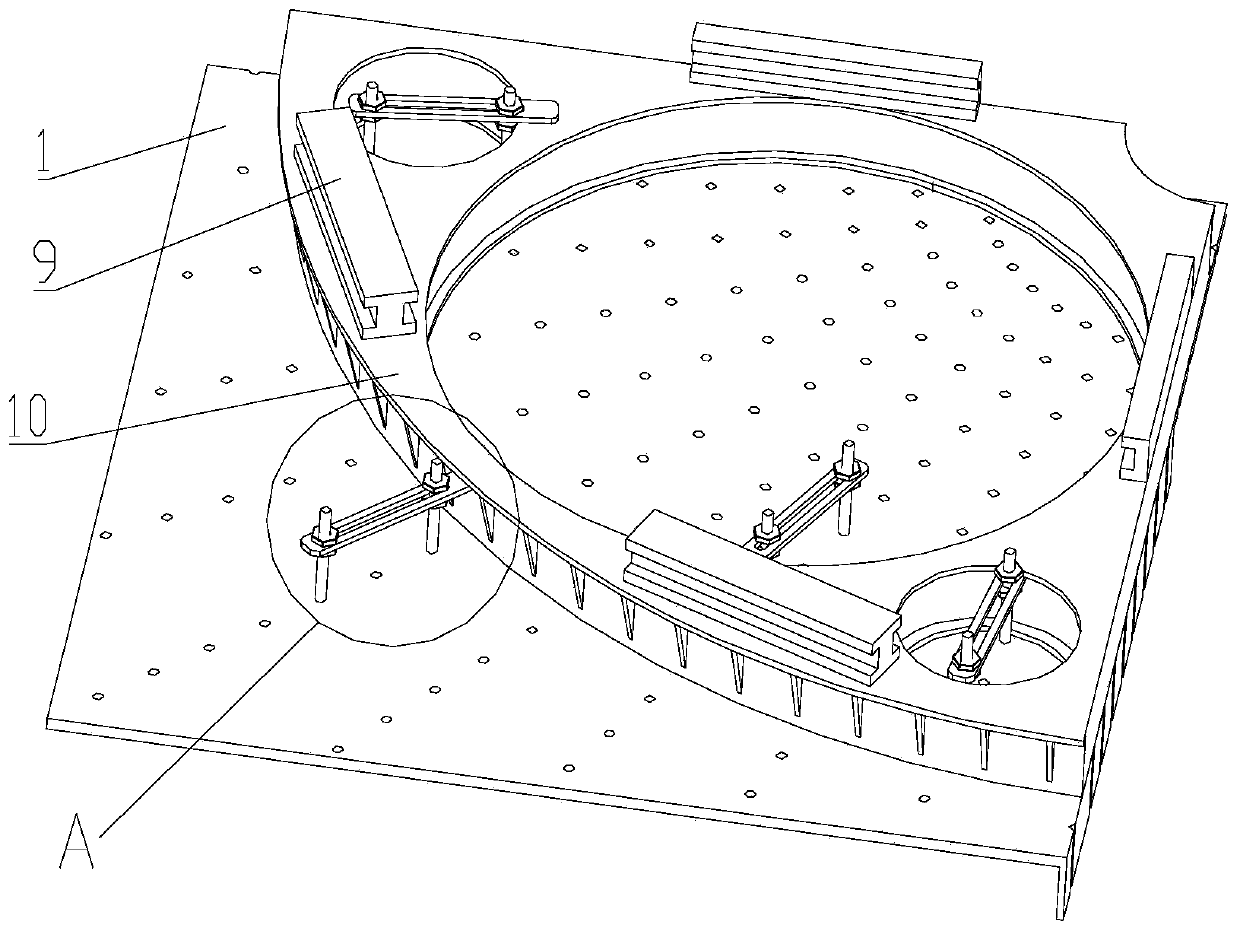

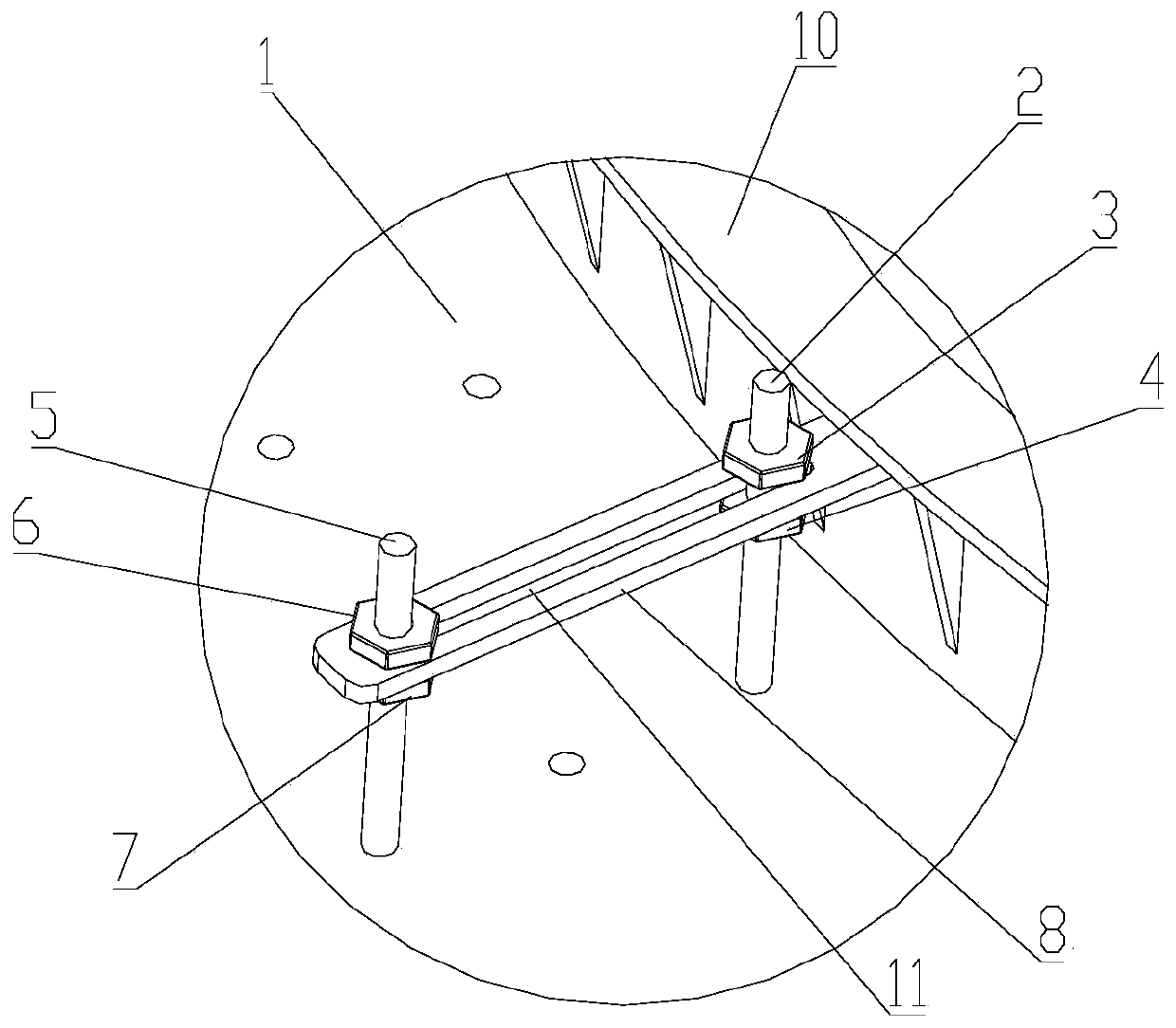

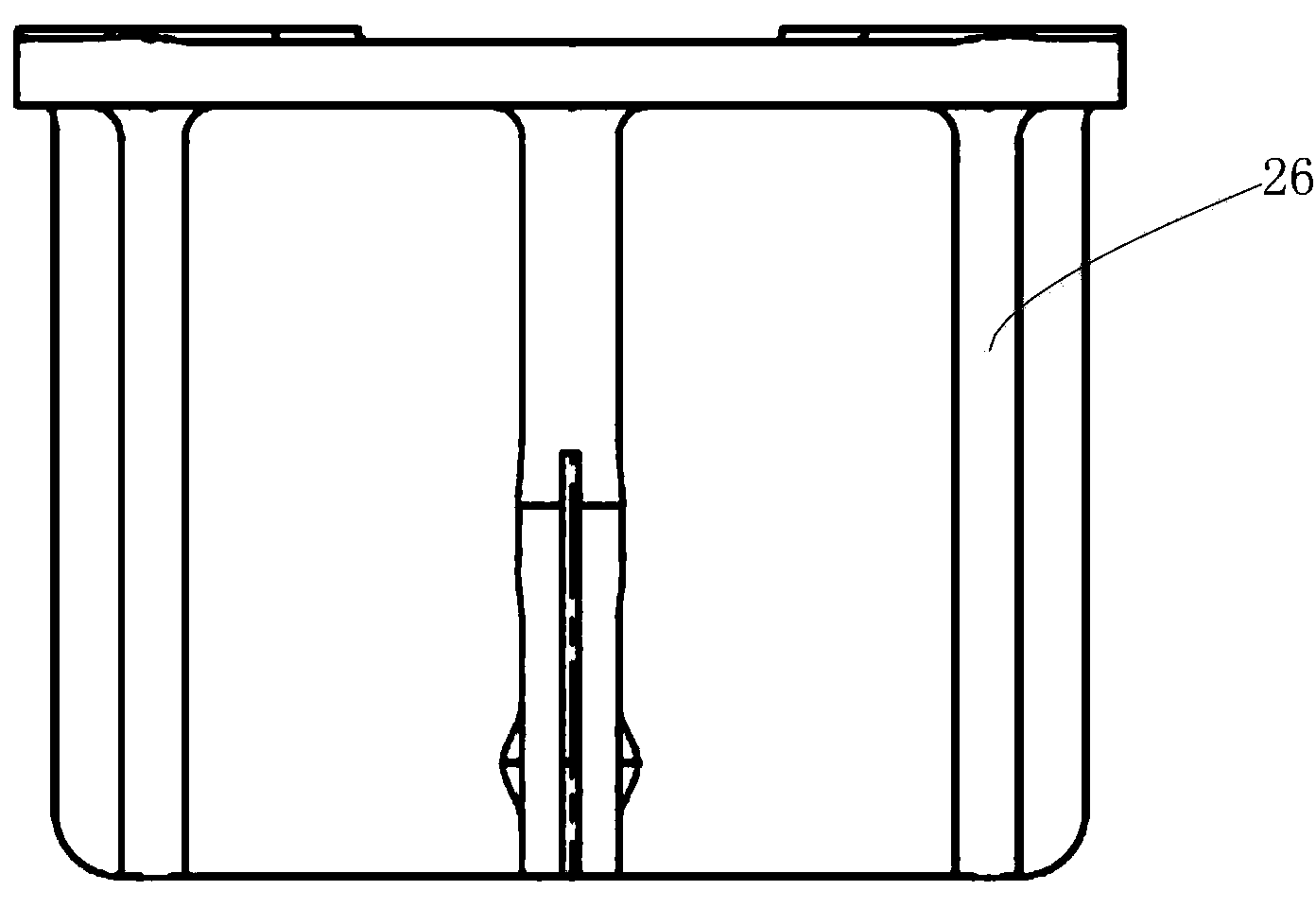

Casting apparatus for eliminating cracks of thick and large belt pulley shaft hole

InactiveCN103736940AReduce casting stressSpeed up coolingFoundry mouldsFoundry coresCasting moldMaterials science

The present invention provides a casting apparatus for eliminating cracks of a thick and large belt pulley shaft hole. According to the present invention, according to a casting mold, an inner gate and an annular transverse runner are connected; a rectangular pouring riser is arranged above the outer wall of a belt pulley casting mold along the belt pulley circumference outer ring by adopting the shaft hole of the belt pulley casting mold as the circle center; a proper amount of chill is arranged on the sand mold inner bottom surface of the thick and large position of the belt pulley cast; and the rectangular pouring riser is uniformly distributed along the circumference direction above the cast outer wall, the mold casting chill is uniformly arranged on the bottom surface of the middle thick position of the thick and large belt pulley casting mold, and the annular transverse runner is connected with the belt pulley casting mold through the inner gate. With the casting apparatus, the cooling rate of the thick and large position between the cast outer wall and the shaft hole is accelerated, the cracks can be eliminated, the operation process can be simplified, and the casting cost can be reduced.

Owner:TIANSHUI SPARK MACHINE TOOL

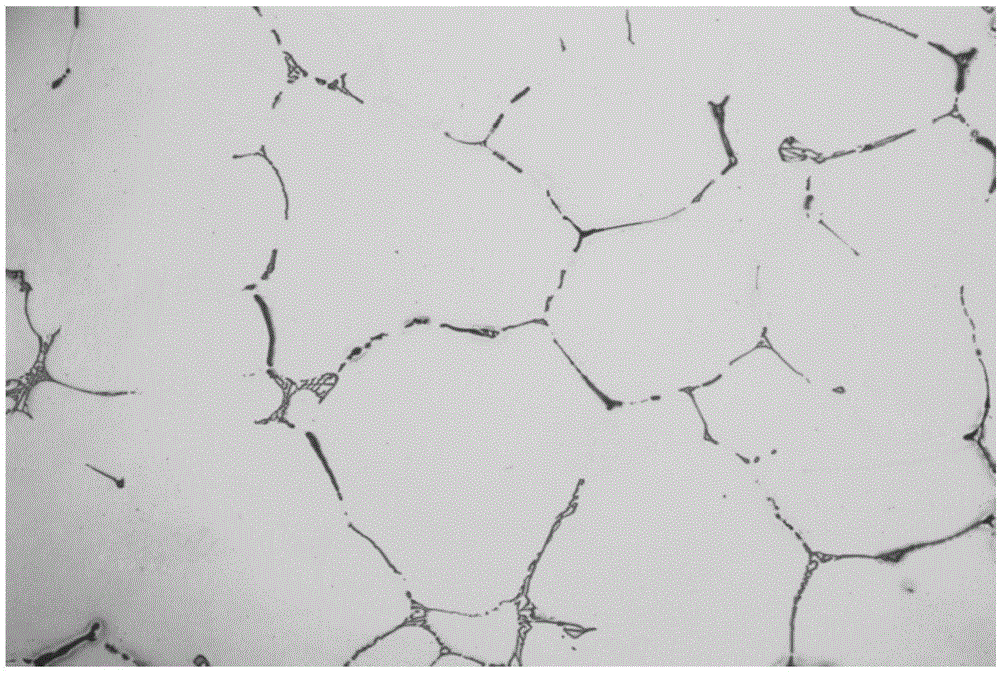

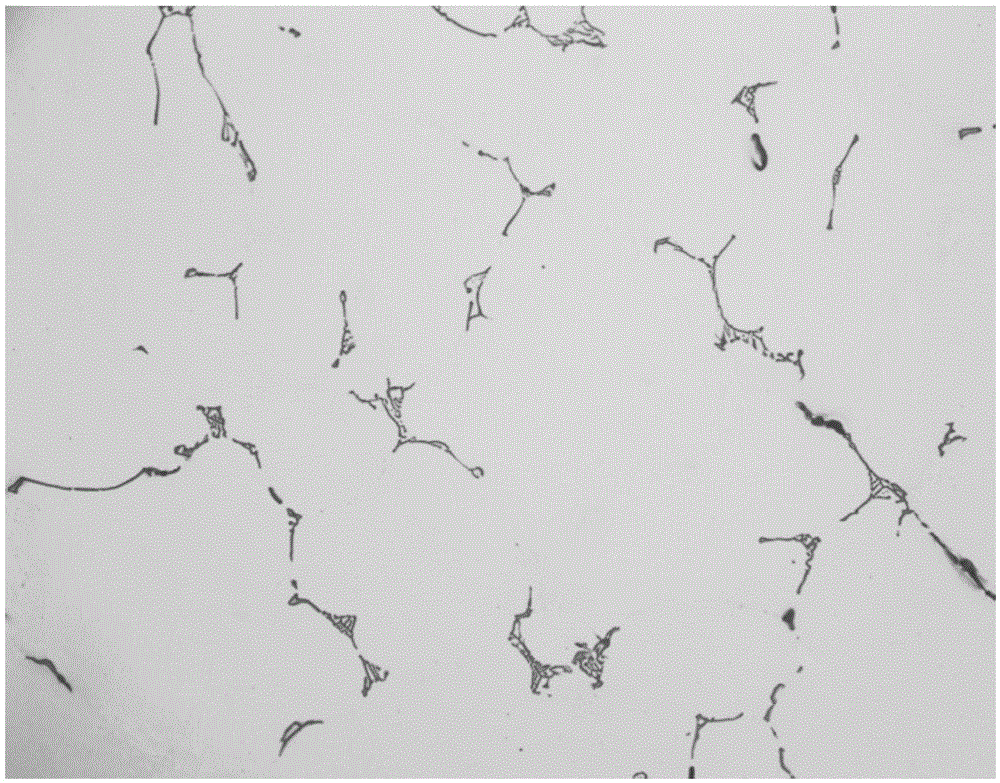

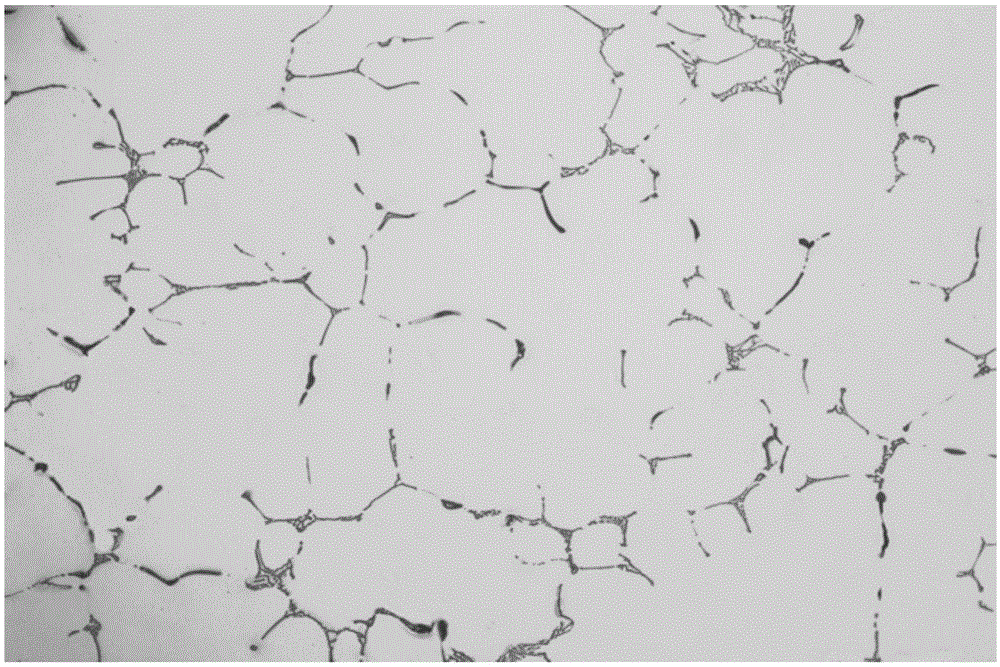

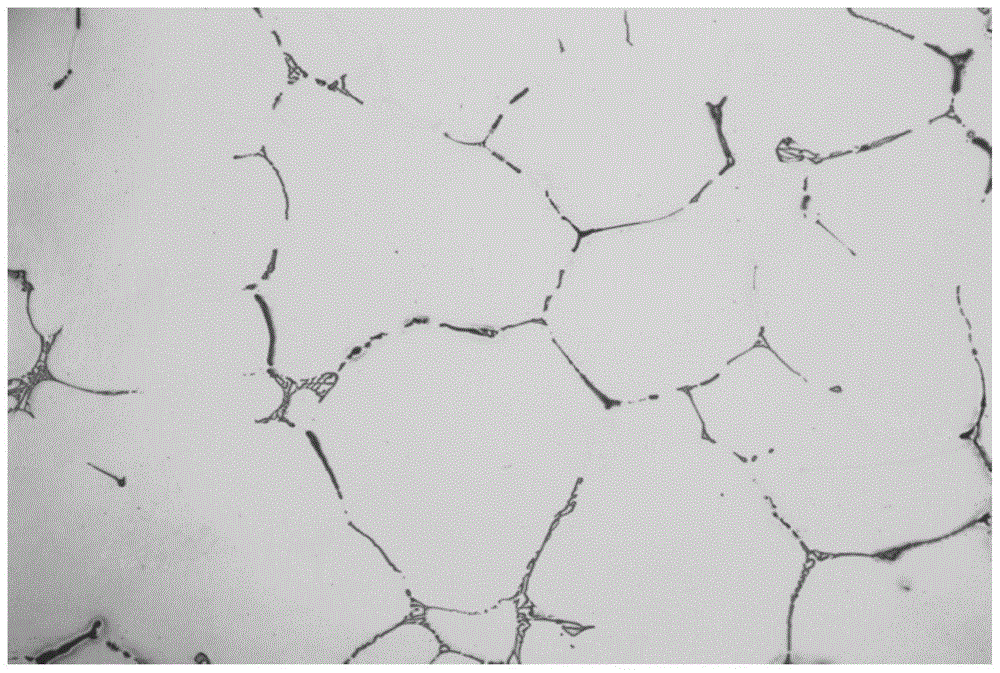

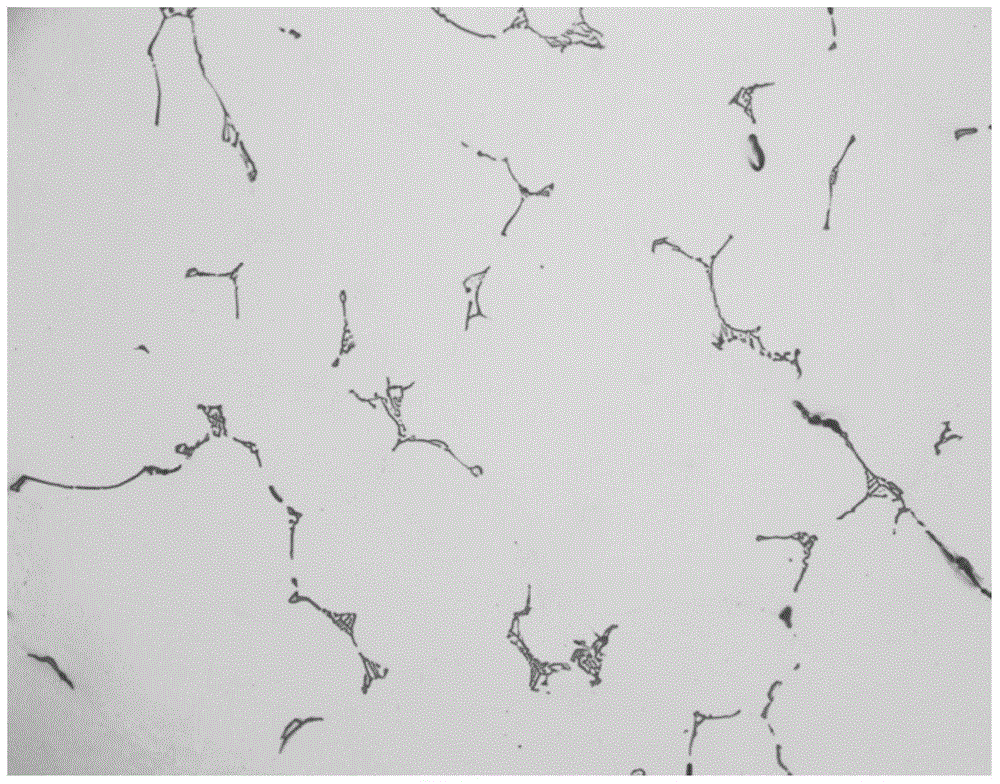

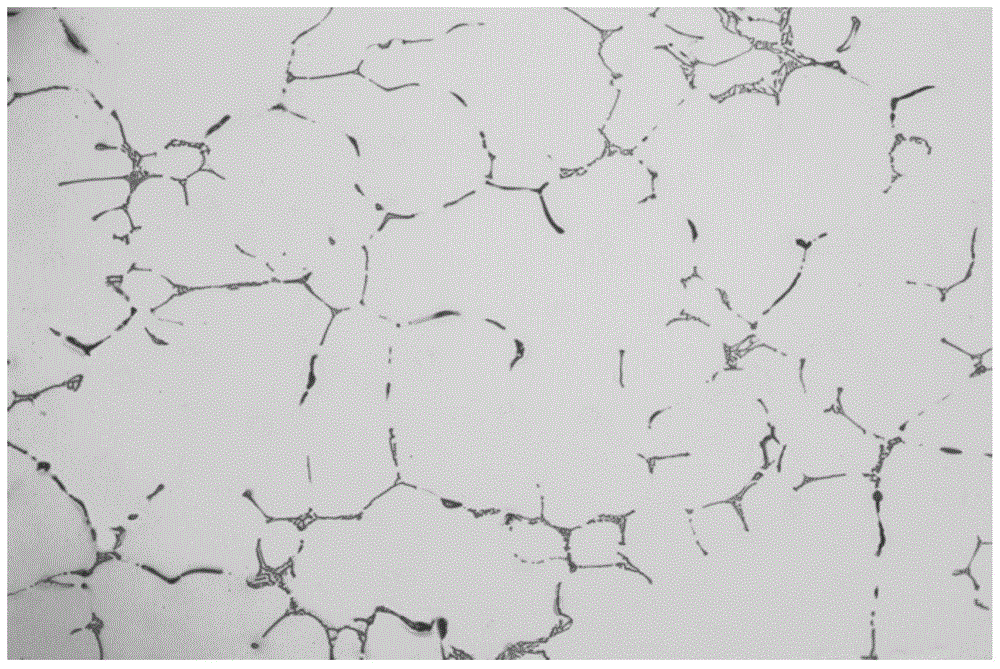

Vermicular graphite cast iron glass mold material and mold preparation method

The invention discloses a vermicular graphite cast iron glass mold material and a mold preparation method. The vermicular graphite cast iron glass mold material is prepared from the following chemicalelements including3.8%-4.0% of carbon, 1.2%-1.8 % of silicon, 0.1%-0.2% of manganese, less than 0.1% of phosphorus, less than 0.03% of sulfur, less than 0.05% of magnesium, and the balance iron and other unavoidable impurity elements. According to the vermicular graphite cast iron glass mold material and the mold preparation method, the formula of vermicular graphite cast iron is optimized, the degree of graphitization of a vermicular graphite cast iron glass mold blank in the as-cast state is increased, the amount of a pearlite matrix is reduced, and the casting stress is reduced. Besides conventional alloys like ferrosilicon, there is no other alloying element added. The manganese element is self-contained in Q10 pig iron instead of being artificially added, so that the cost of the casting material is greatly reduced. More importantly, due to the small quantity of alloying elements, unpacking is carried out after the casting is naturally cooled to 250 DEG C in a casting system, theamount of pearlite in the as-cast state does not exceed 15%, and it is not necessary to perform high-temperature graphitization annealing at 930 DEG C or above.

Owner:SUZHOU DONGHAI GLASS MOLD

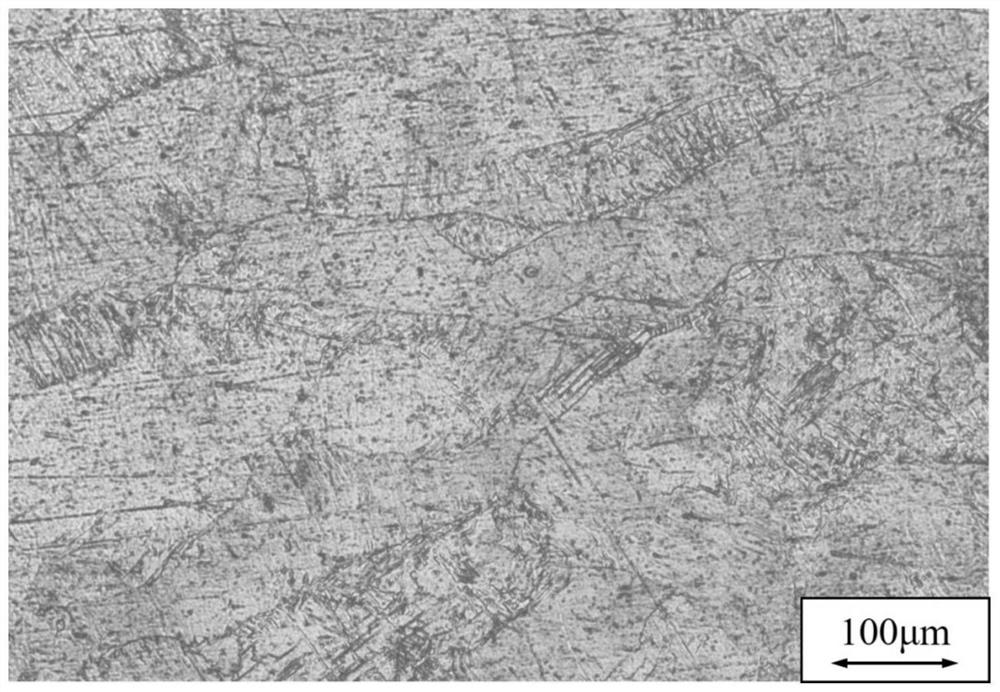

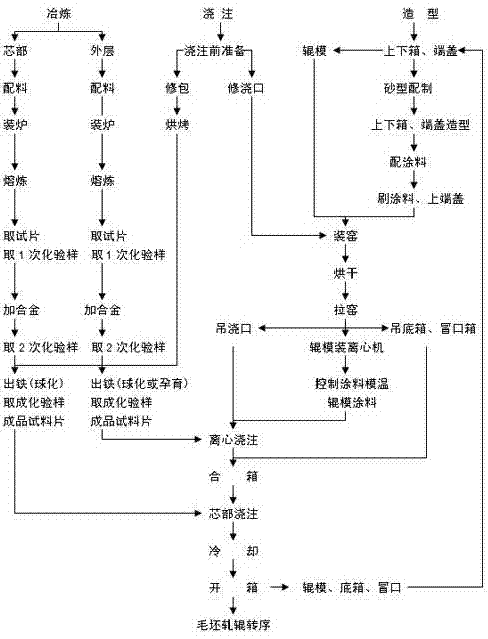

Manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls

The invention relates to a manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls, and belongs to the technical field of metallurgical rolls. The technical scheme includes that eutectic compositions are selected as materials of a roll working layer, and besides five elements of C, Mn, Si, P and S commonly existing in steel, not less then five alloying elements of Cr, W, Mo, V, Nb, Ti, Al, Cu, B and Mg need to be added into the roll materials to form a multi-element alloying state; carbon content of the roll materials is controlled to be 1.3%-2.8% in mass percent. The manufacturing process is small in solidification temperature range of the eutectic compositions, and particularly suitable for obtaining high-quality castings under the circumstance that feeding conditions are insufficient; the castings are crystallized simultaneously, and optimal in composition uniformity, concentrated cavity shrinkage is formed, metallic yield by casting moulding is high; the metal is solidified at the same time, and casting stress in the process of solidification is minimum; the eutectic compositions in alloy are lowest in melting point, and smelting cost is also low; liquid of the eutectic compositions is best in fluidity; castability is improved, and abrasion resistance and heat resistance are taken into consideration.

Owner:朝阳联强轧辊有限公司

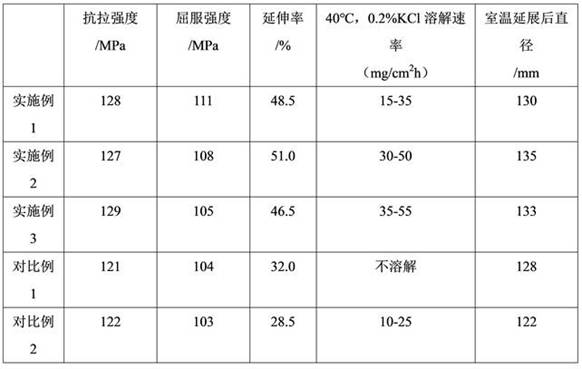

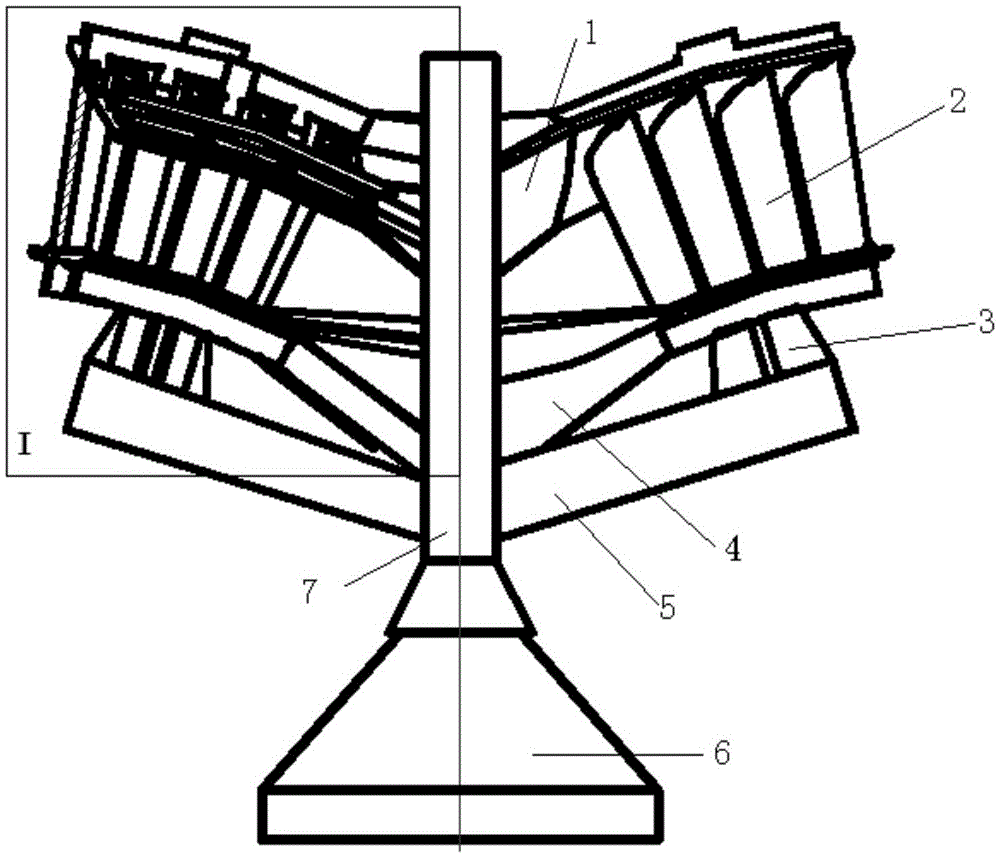

Method for forming inner cavity of high-temperature alloy hollow guide vane

PendingCN114589290AReduce manufacturing costSolve the deformationFoundry mouldsFoundry coresSuperalloyMolten metal

The invention relates to the technical field of high-temperature alloy investment precision casting, in particular to a method for forming an inner cavity of a high-temperature alloy hollow guide vane. When the mold core mold is designed, the whole inner cavity mold core is divided into an exhaust edge and an air inlet edge, an inner cavity mold block on one side of the exhaust edge is made into a ceramic mold core mold, and a mold block on one side of the air inlet edge is made into a water-soluble mold core mold. When the inner cavity mold core is prepared, the ceramic mold core and the water-soluble mold core are pressed respectively, and after the two pressed mold cores are combined into a complete mold core, a blade wax mold is pressed; according to the principle that a water-soluble mold core is dissolved in water, the water-soluble mold core is removed, the remaining ceramic mold core is pressed into a wax mold, the side close to an air inlet edge serves as a fixed end, an exhaust edge serves as a free end, shell preparation is conducted, and the high-temperature alloy guide blade is prepared through the method that the ceramic mold core is fixed through an inner cavity shell. The casting stress generated by the shrinkage difference of the ceramic core and the molten metal can be reduced, and the crack and recrystallization tendency of the blade can be reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

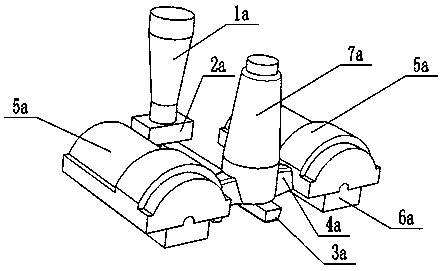

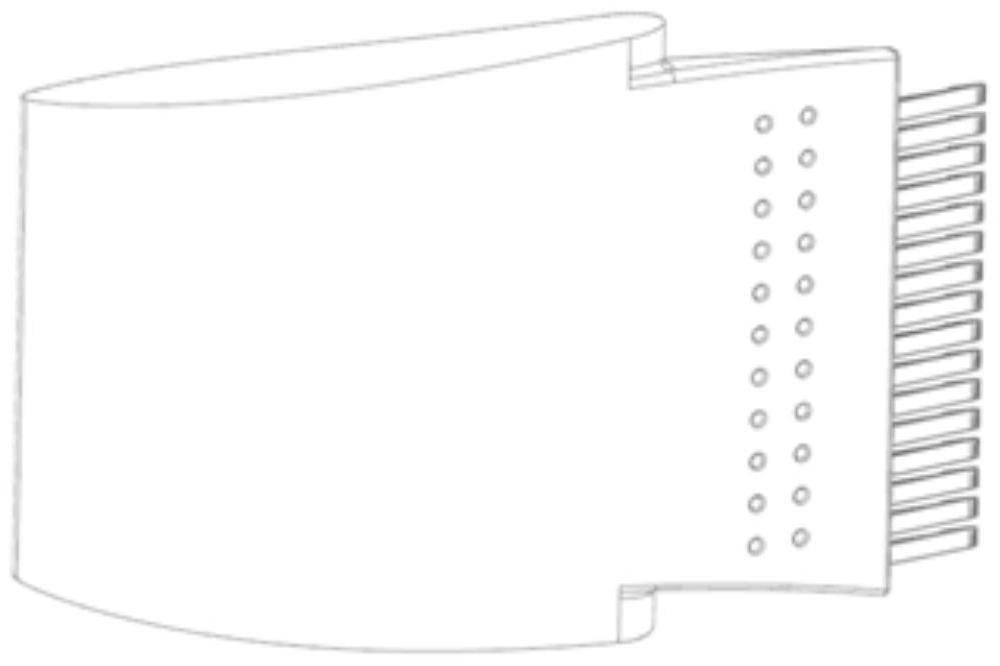

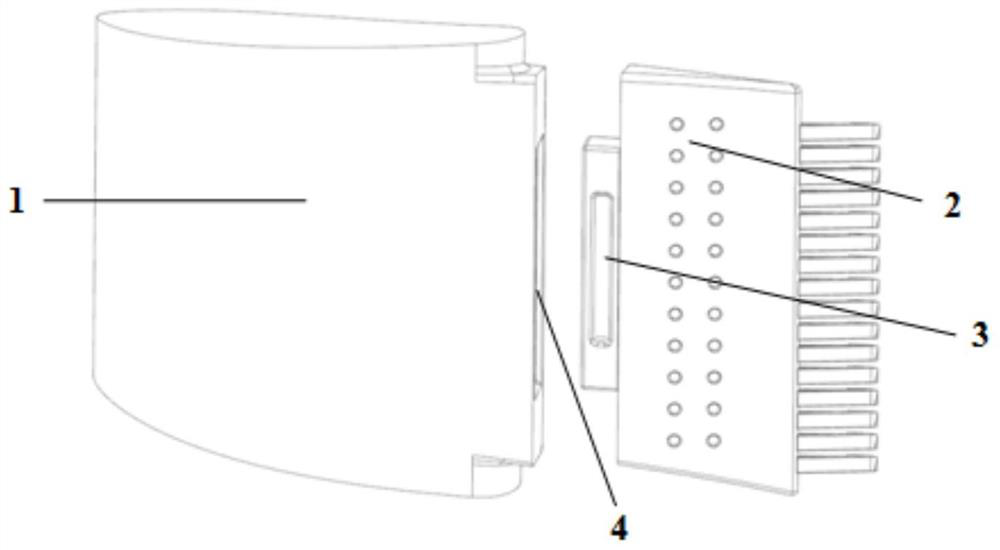

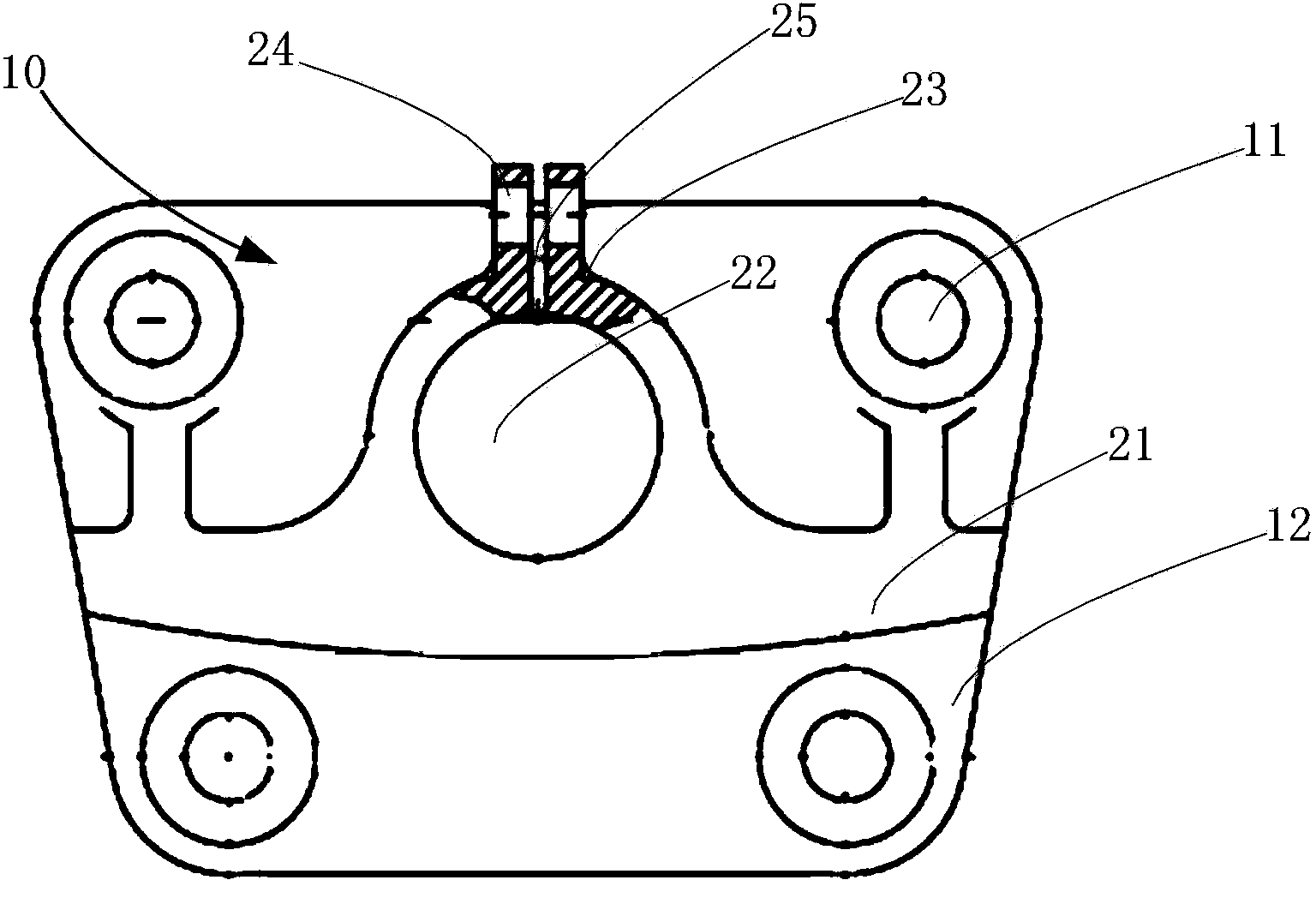

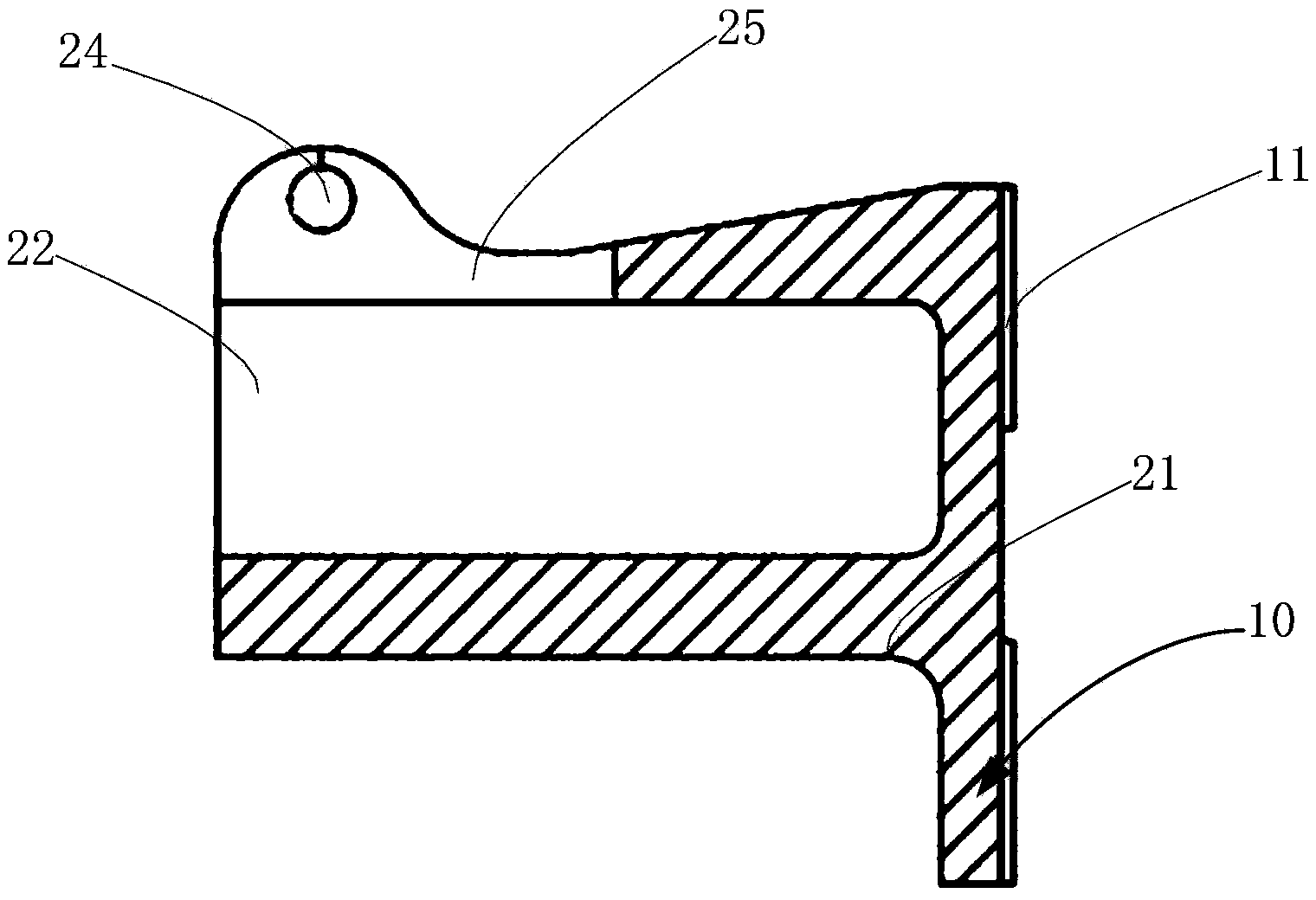

Auxiliary spring bracket

The invention belongs to the technical field of the suspension system of the commercial vehicle, and particularly relates to an auxiliary spring bracket comprising a bracket installation part and a plate spring contact part. The plate spring contact part extends by being perpendicular to the side end face of the bracket installation part; the side end face of the bracket installation part is in the shape of a trapezoid; the bracket installation part and a frame are detachably connected; the plate spring contact part comprises an auxiliary plate spring connection part and a fender steel bar connection part, the cross section of the auxiliary plate spring connection part in the shape of an arc; the fender steel bar connection part is connected with the sunken side of the auxiliary plate spring connection part; the side wall, away from the auxiliary plate spring connection part, of the fender steel bar connection part is provided with a groove; the side walls of the groove are respectively provided with a first fin and a second fin; the first fin and the second fin are provided with through holes correspondingly; and the fender steel bar connection part is connected with a steel bar, so that the auxiliary plate spring connection part is connected with an auxiliary plate spring when the fender steel bar connection part is connected with the steel bar. According to the invention, the functions of the auxiliary spring bracket and a fender support are integrated as a whole, the structure is simple, and the weight is low.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com