Aluminum alloy wheel hub gravity casting mould

An aluminum alloy wheel hub and gravity casting technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as unsatisfactory quality, unsightly appearance, and poor mechanical properties, so as to improve product quality and increase tissue density and mechanical properties, smooth effect of slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

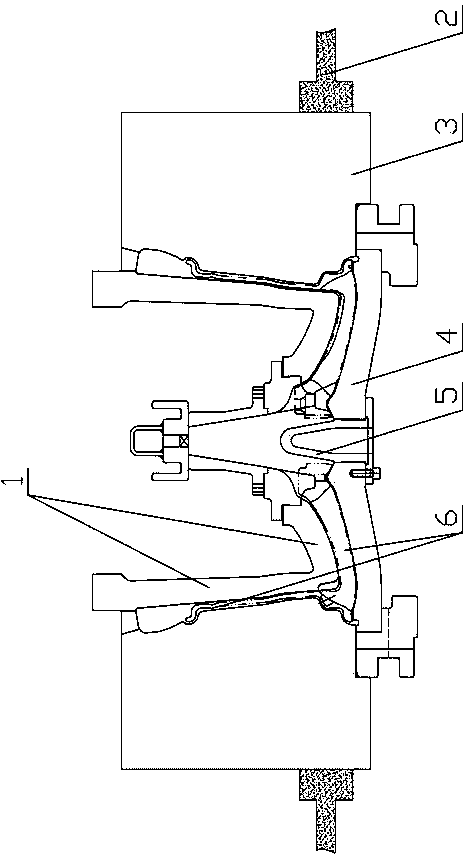

[0008] see figure 1 , the present invention comprises a bottom mold 4 and a side mold 3, a splitter cone 5 is housed in the middle of the bottom mold 4, an upper mold 1 cooperating with the bottom mold 4 is housed in the side mold 3, the upper mold 1, the side mold 3 and the bottom mold 4 A cavity 6 is formed between them; in particular: two high-frequency vibration devices 2 are arranged outside the side mold 3, and the vibrating heads of the high-frequency vibration devices 2 are arranged directly opposite the side mold 3, which constitutes the present invention.

[0009] The size, specification and material selection of upper mold 1, high-frequency vibration device 2, side mold 3, bottom mold 4, splitter cone 5 and cavity 6 of the present invention can be adjusted according to actual needs, and these adjustments are not substantial. Changes in principle all belong to the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com