Patents

Literature

48results about How to "Increased flexural section modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

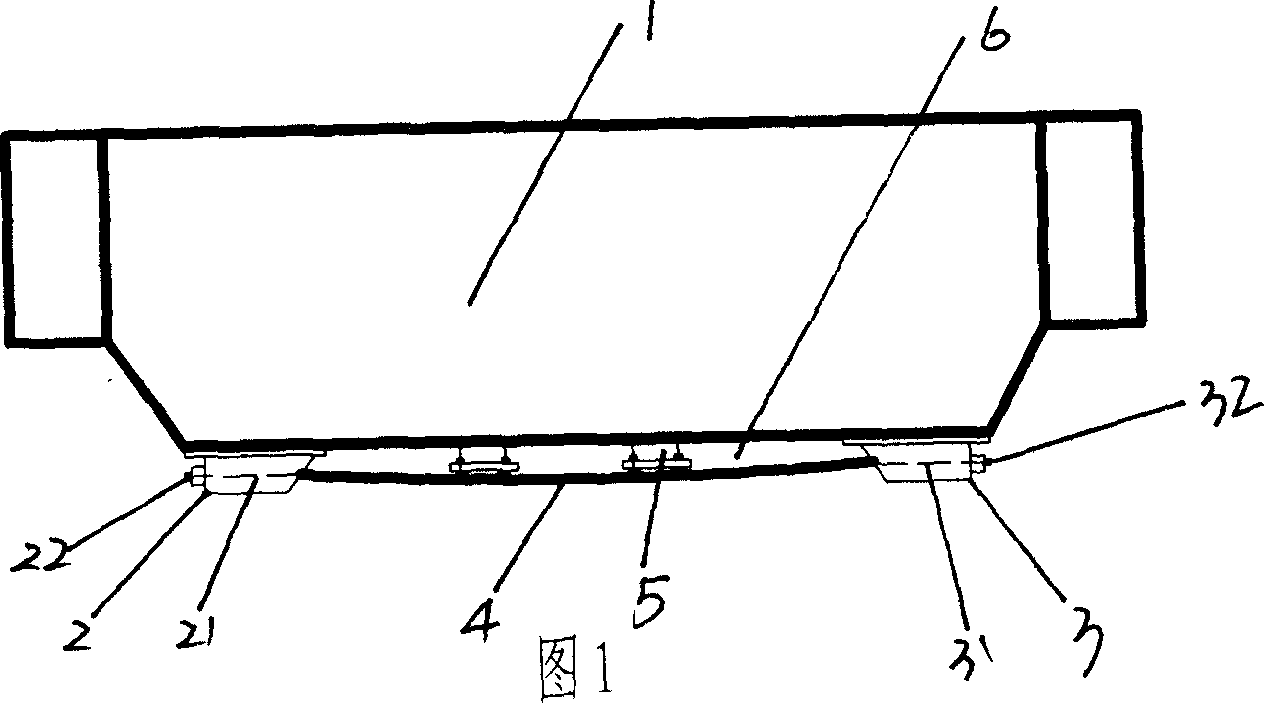

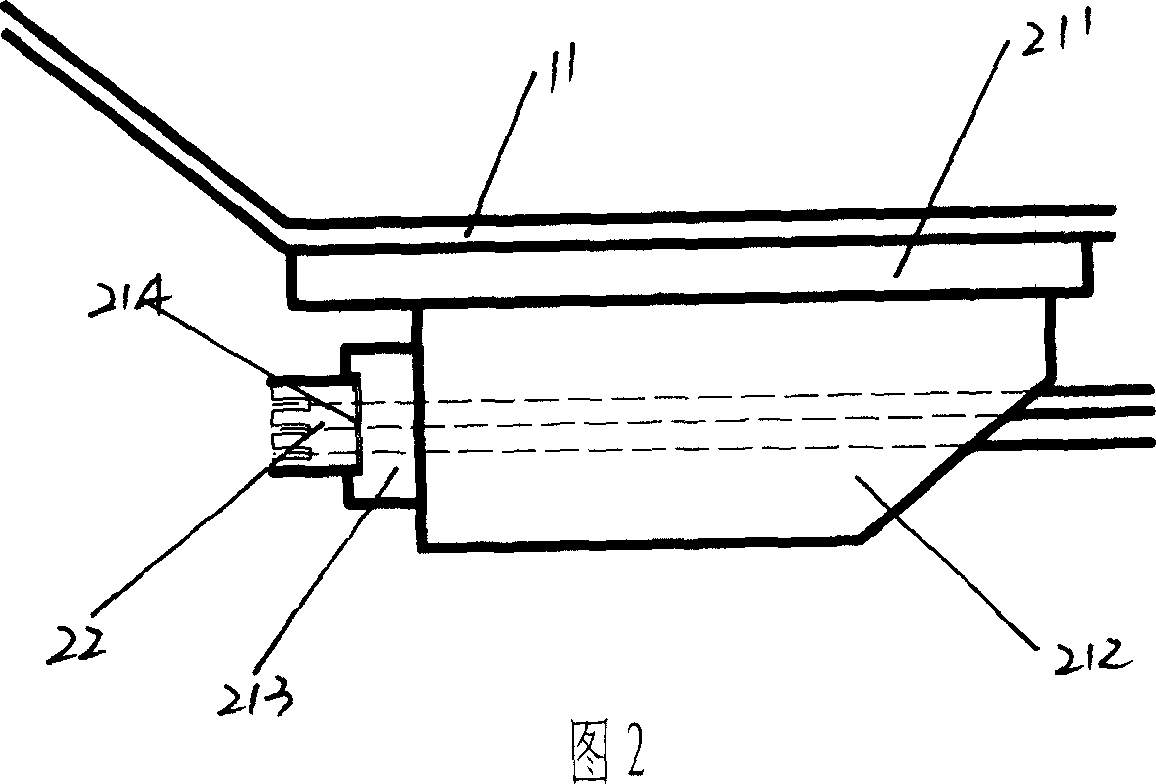

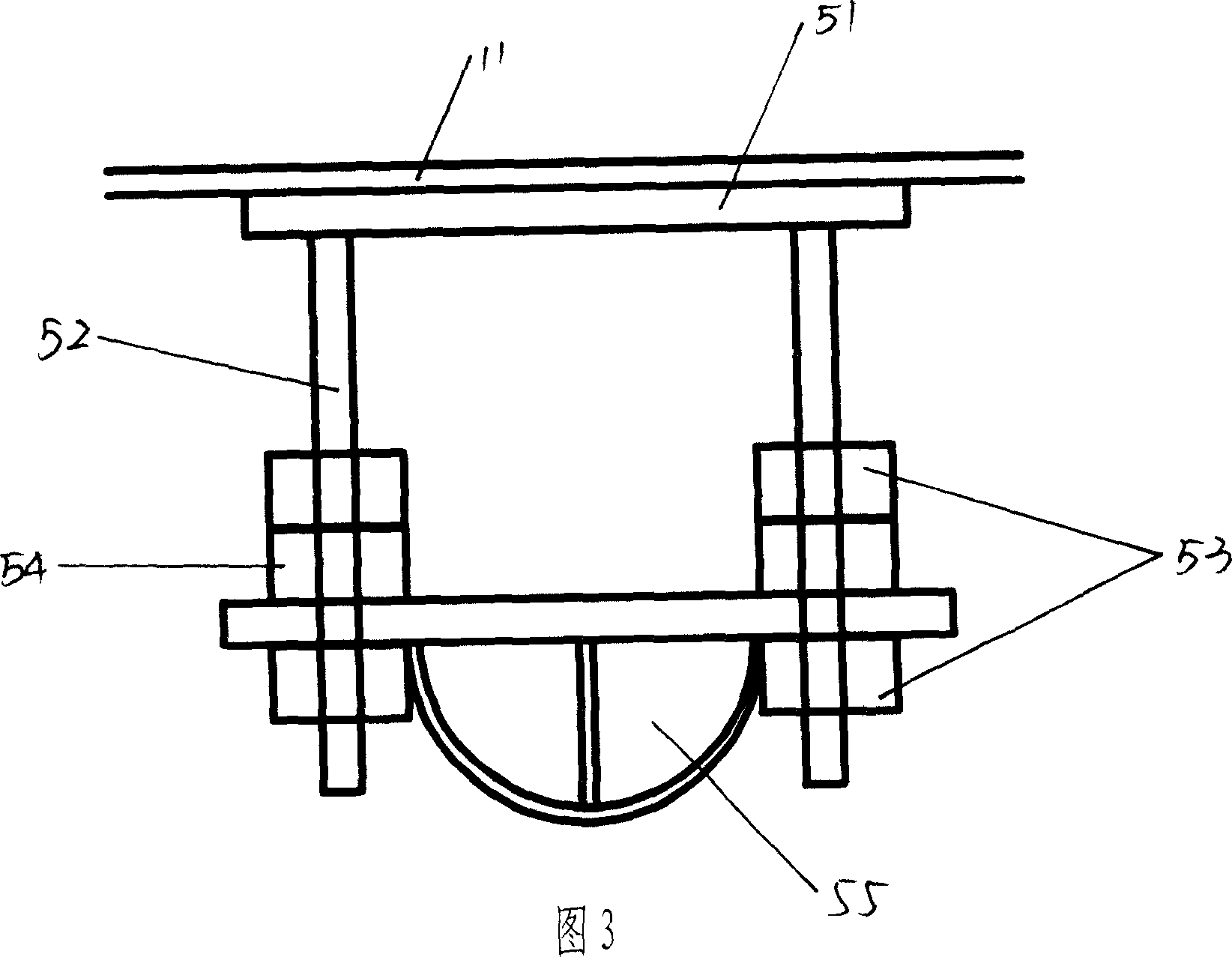

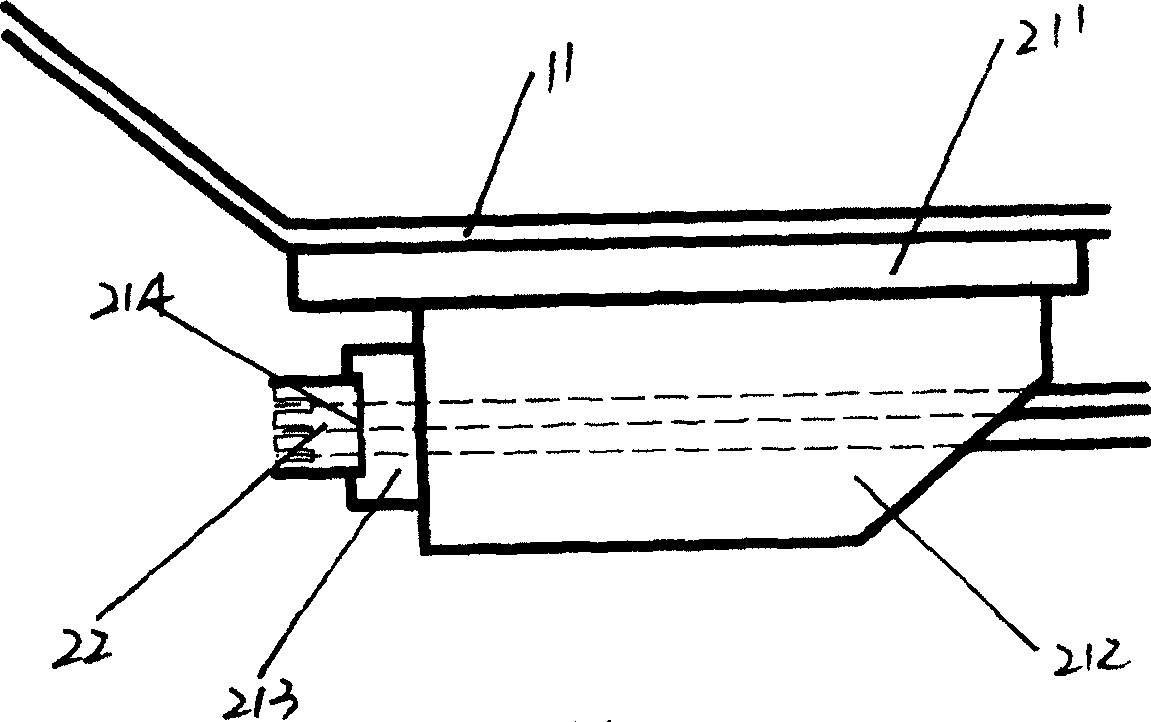

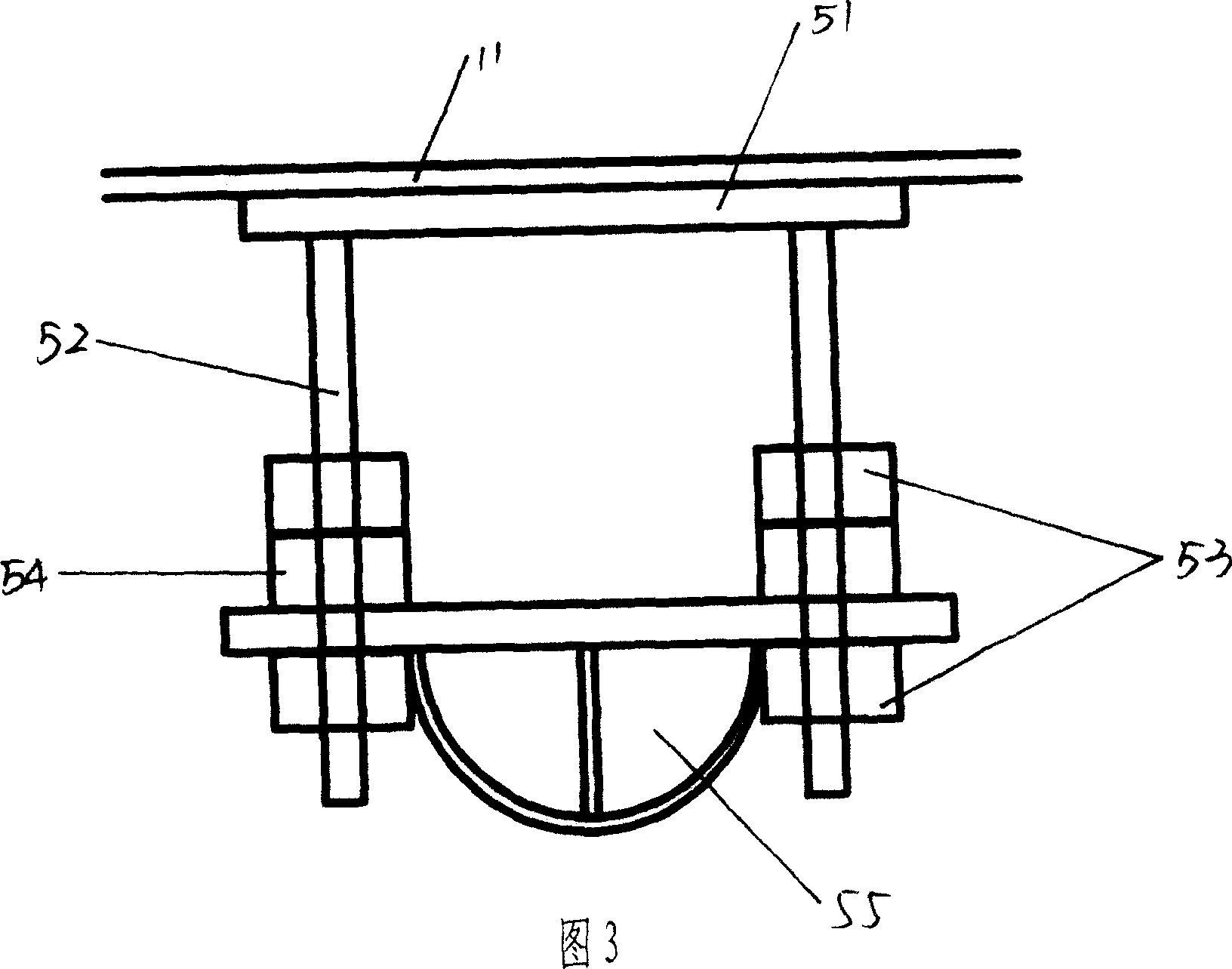

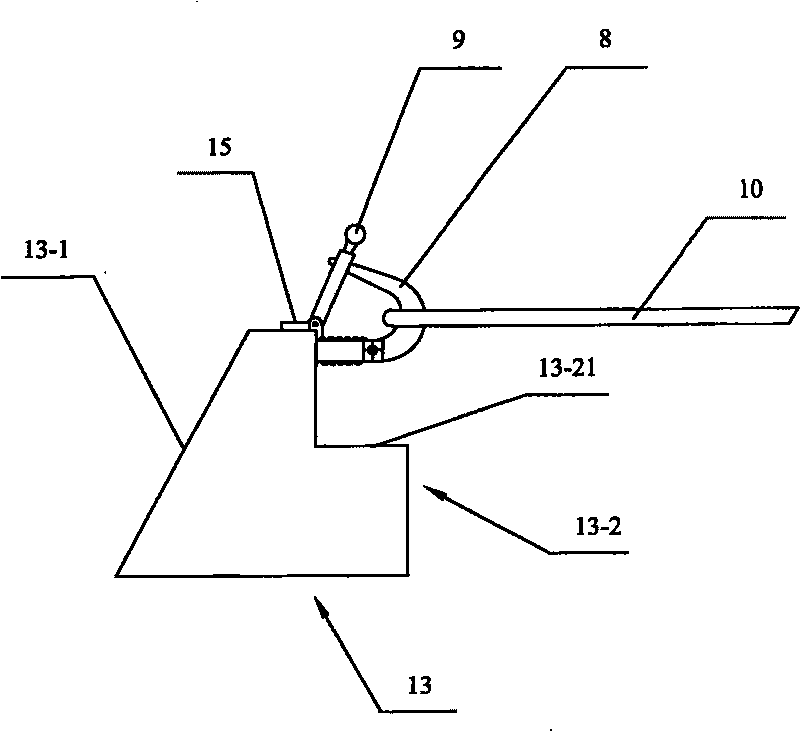

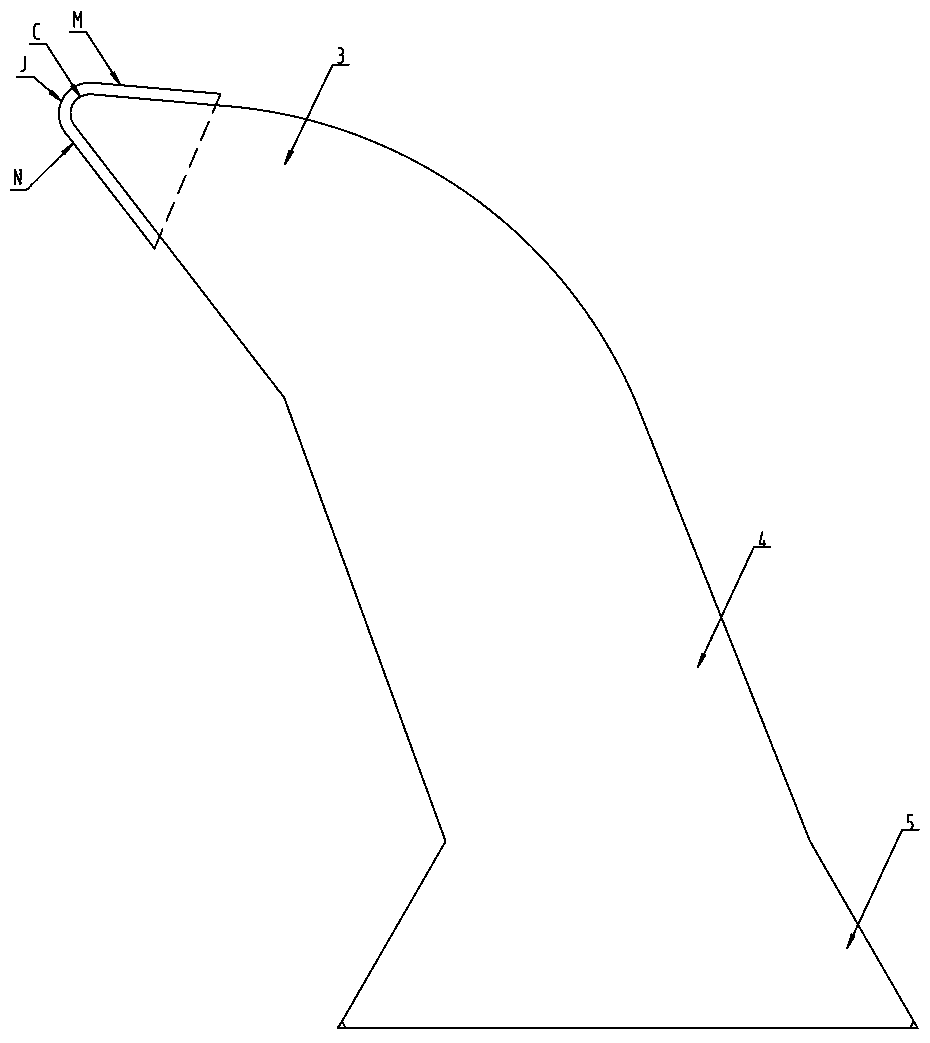

Beam crane and its downward bent beam repairing method

The present invention relates to beam crane, and is especially one kind of self-repaired pre-stressed beam crane and the method of applying external pre-stress to repair the downwards bent beam of beam crane. The method of the present invention includes the following steps: 1. fixing stretching bearing and fixed bearing separately on two ends below the lower cover of the crane beam; 2. stringing steel strands separately in the fixing anchor beside the fixed bearing and the stretching anchor beside the stretching bearing to anchor the fixed end and to pressing the stretching anchor to the outer side of the stretching bearing; 3. regulating the initial stress of each steel strand with jack for equalized stress; 4. fixing 1-4 staying devices on the lower cover of the crane beam and setting the steel strands; and 5. stretching the steel strand of the stretching anchor with jack for the beam to bend upwards, anchoring the stretching end and regulating the staying devices for proper stress.

Owner:王冠华

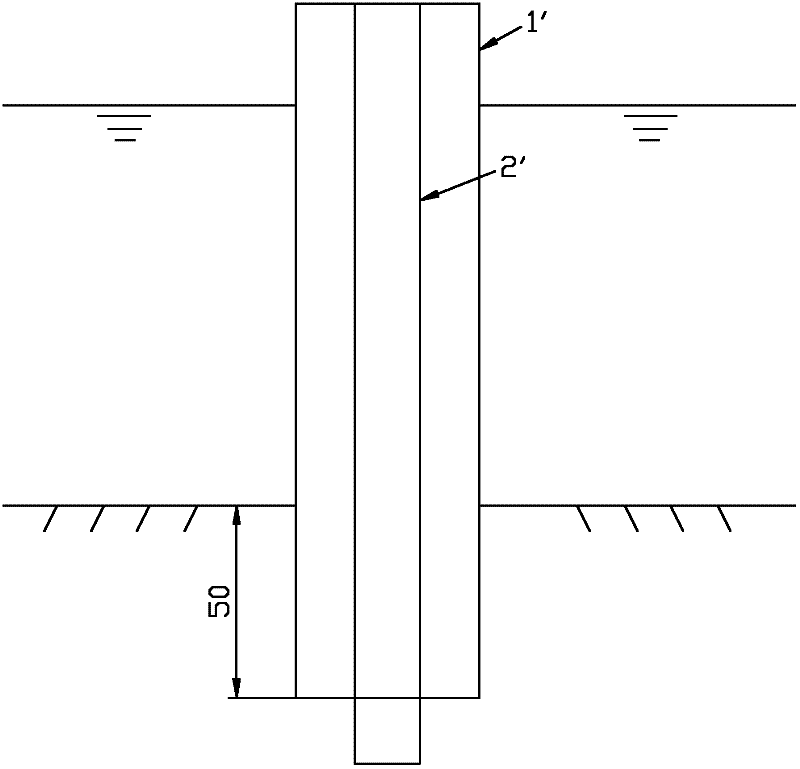

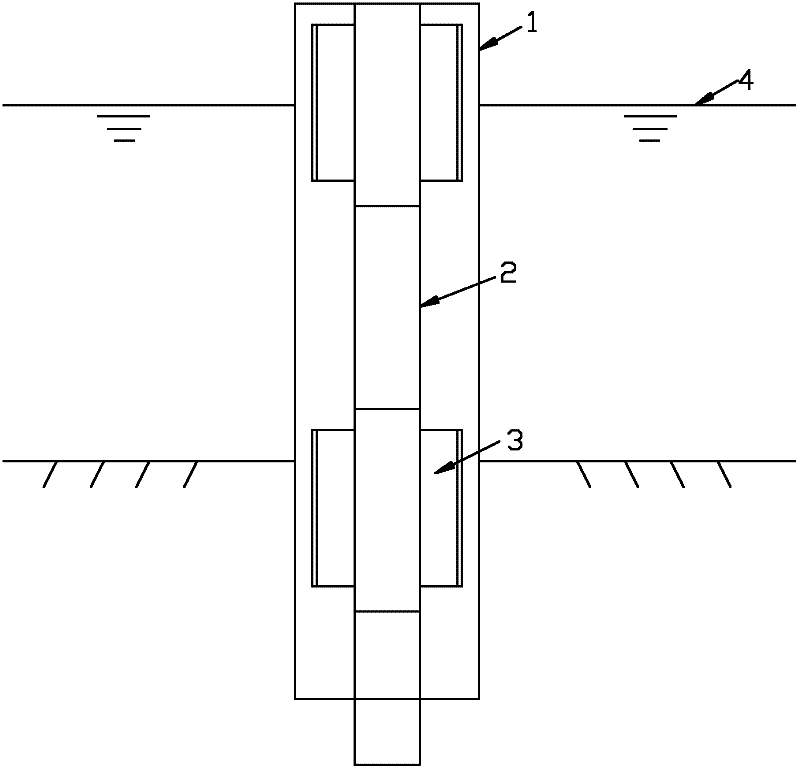

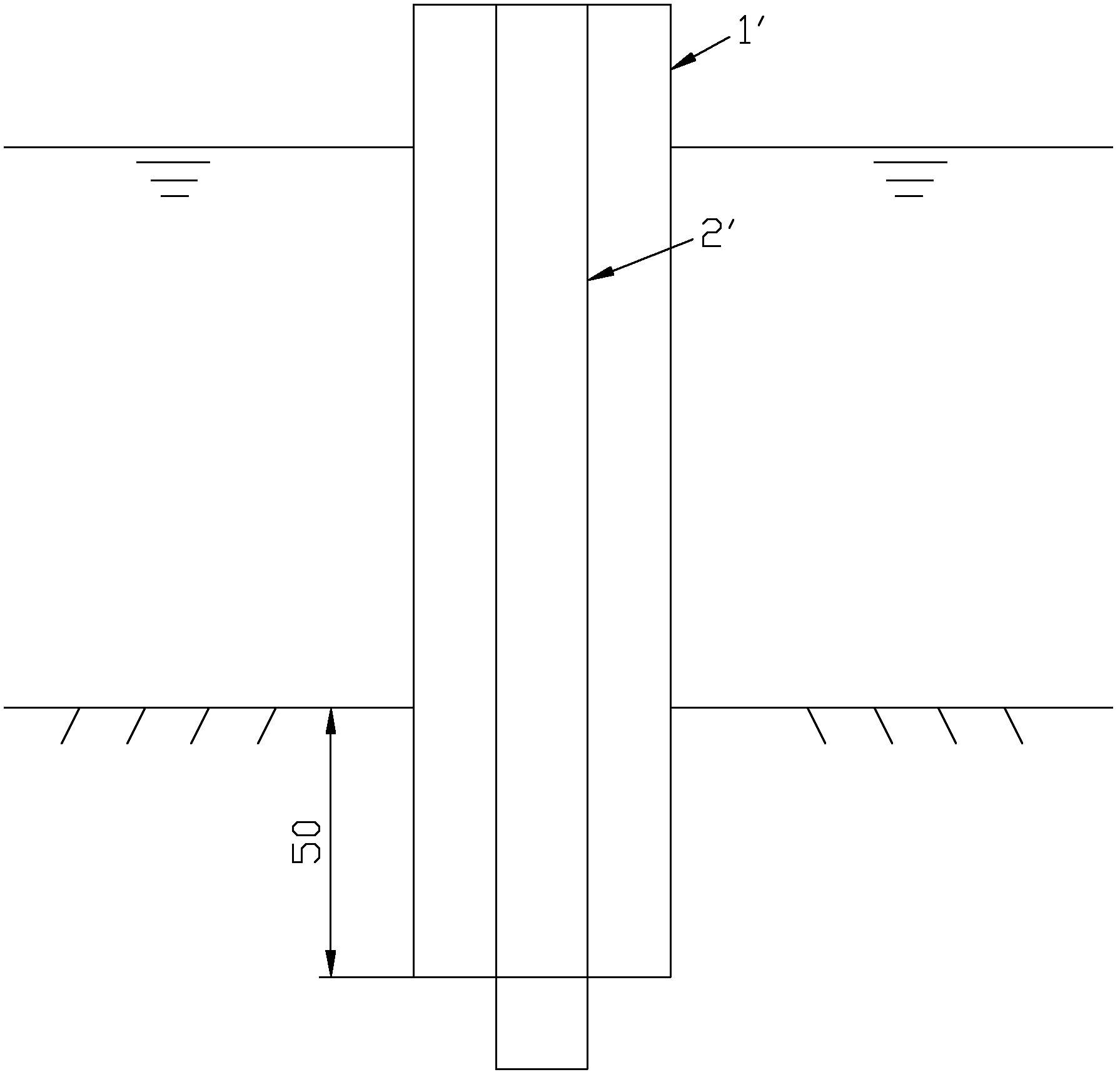

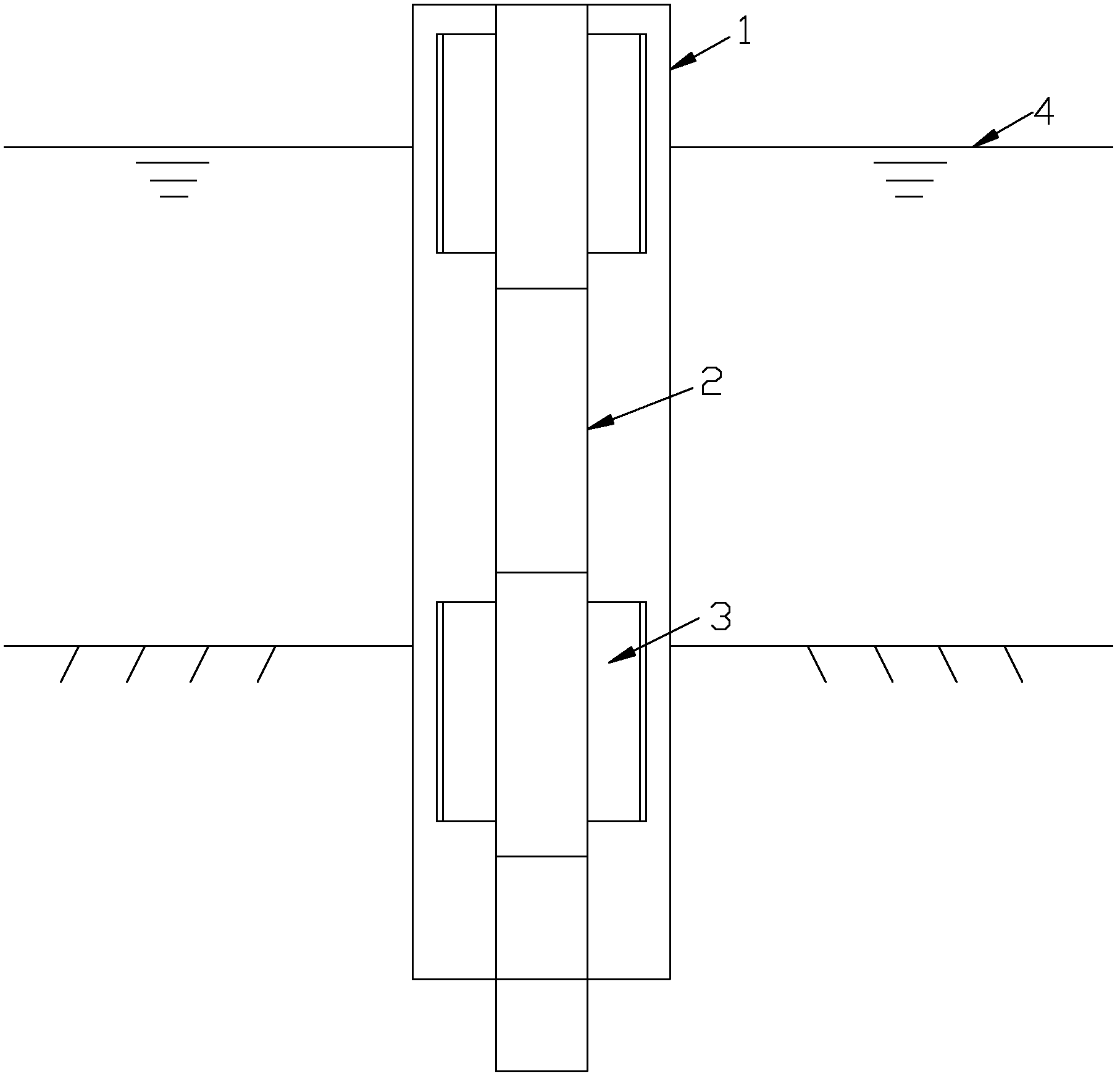

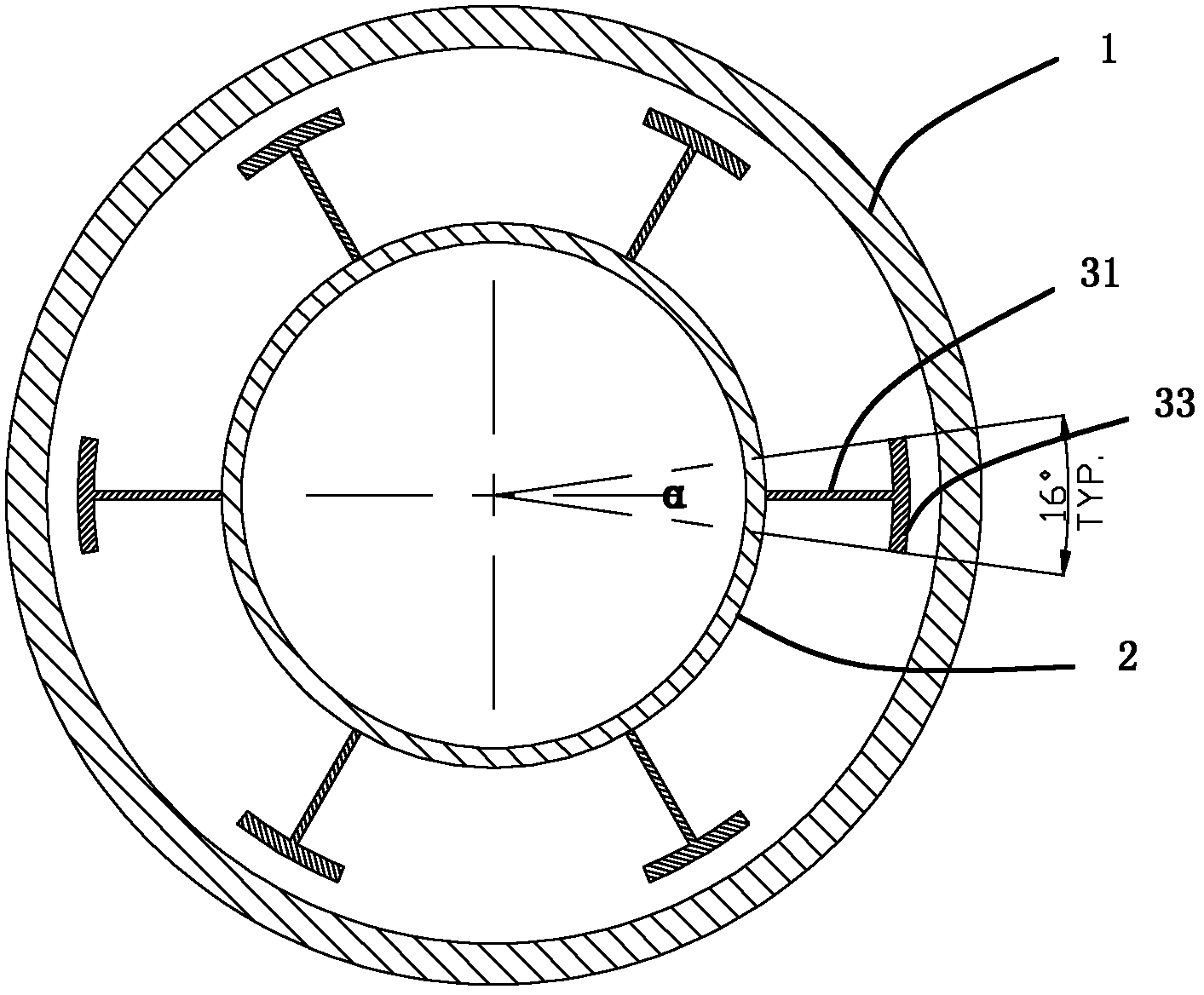

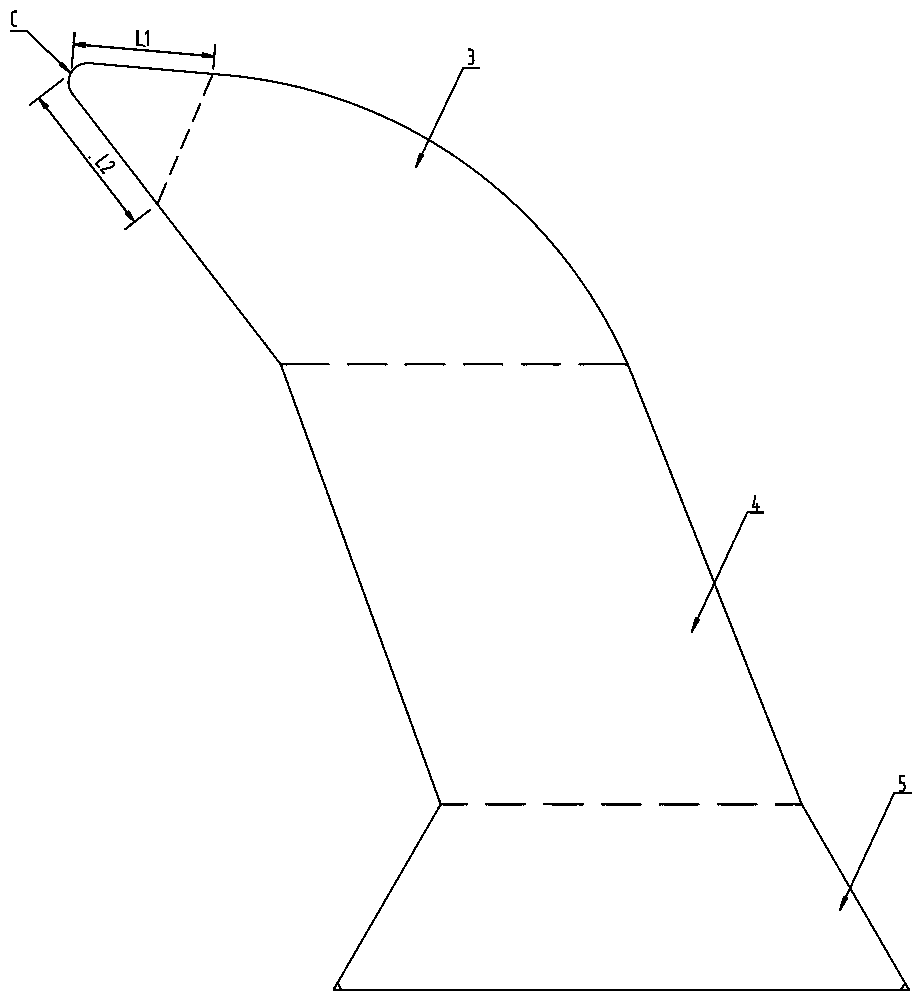

Reinforced riser pipe combined structure and construction method thereof

ActiveCN102226378AIncreasing the thicknessIncreased stiffness against lateral stressDrilling rodsUnderwater drillingWell drillingT-beam

The invention discloses a reinforced riser pipe combined structure and a construction method thereof, and the reinforced riser pipe combined structure comprises an inner-layer sleeve and a riser pipe, wherein a T-like beam structure is welded on the outer surface of the inner-layer sleeve; and the inner-layer sleeve which is of the T-like beam structure is arranged at a position which is 5-10m below a mud line and 3-10m above the sea level, and an annular space part between the riser pipe and the inner-layer sleeve is poured and consolidated through cement. The T-like beam structure is welded on the outer surface of the inner-layer sleeve and simultaneously set along with the inner-layer sleeve, thereby facilitating the construction. By adopting the reinforced riser pipe combined structure and the construction method thereof, the size of the riser pipe can be reduced while the safe construction of well drilling is ensured, the use amount of steel can be greatly reduced while the same mechanical properties of the large-size riser pipe are ensured, and the engineering cost can be greatly saved on the premise of not affecting the construction period of well drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

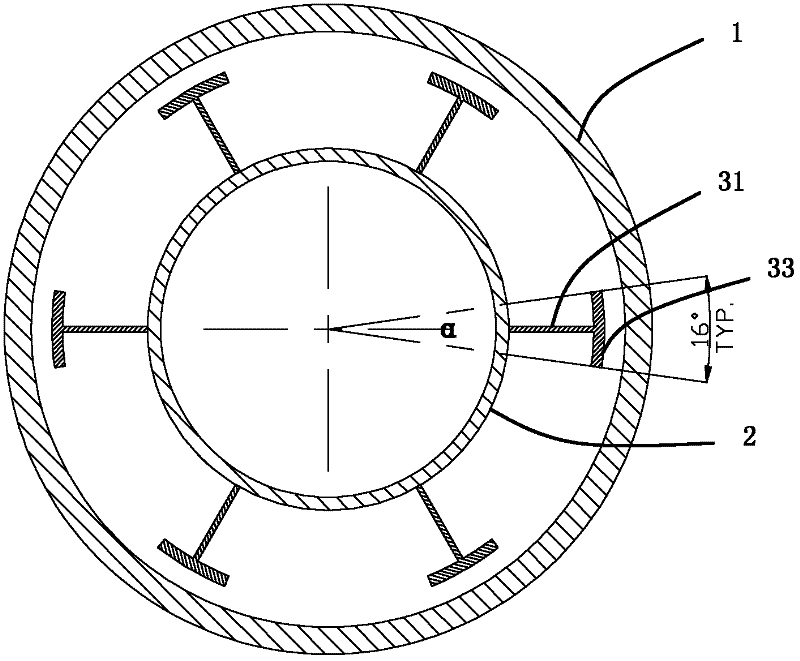

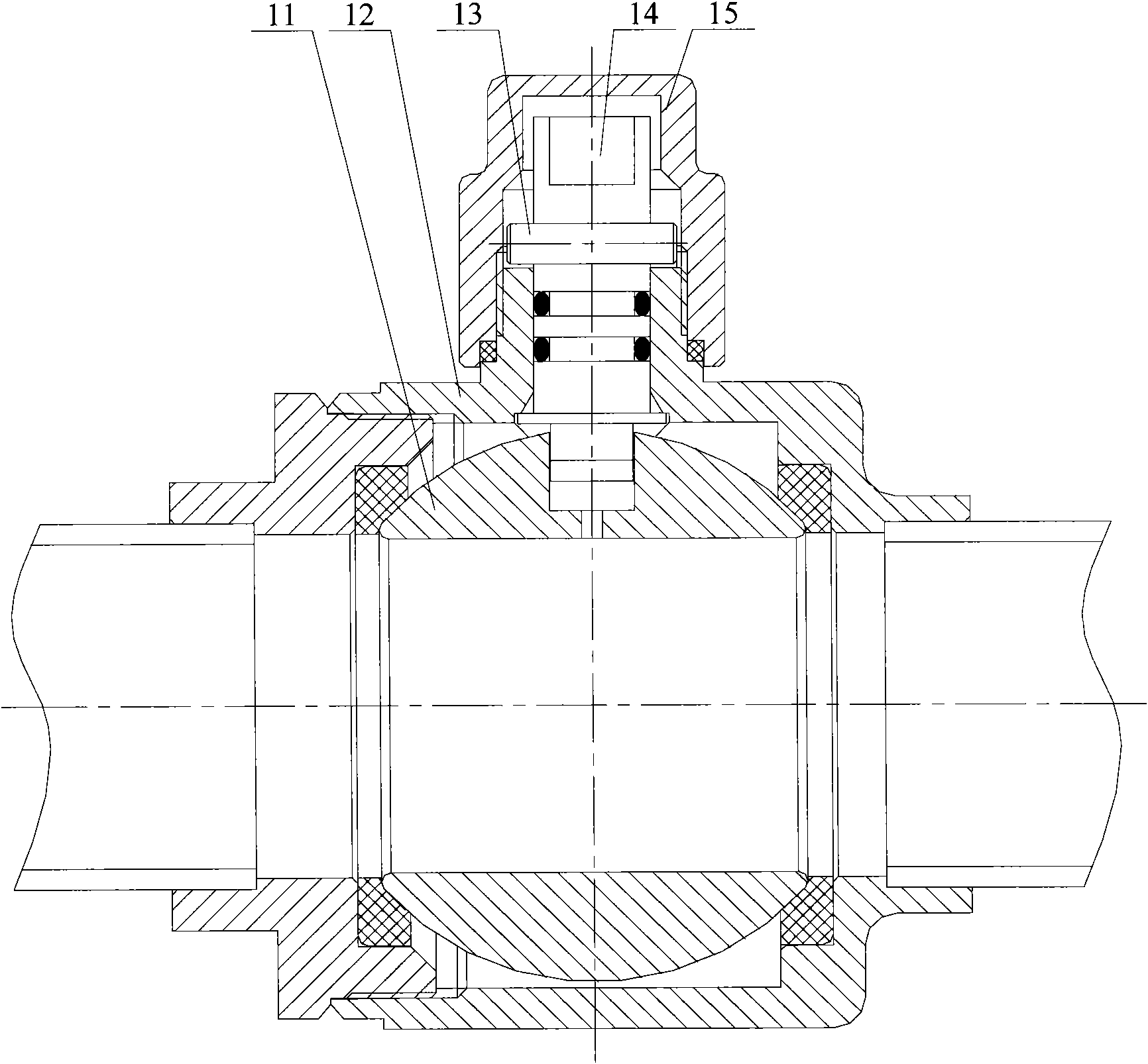

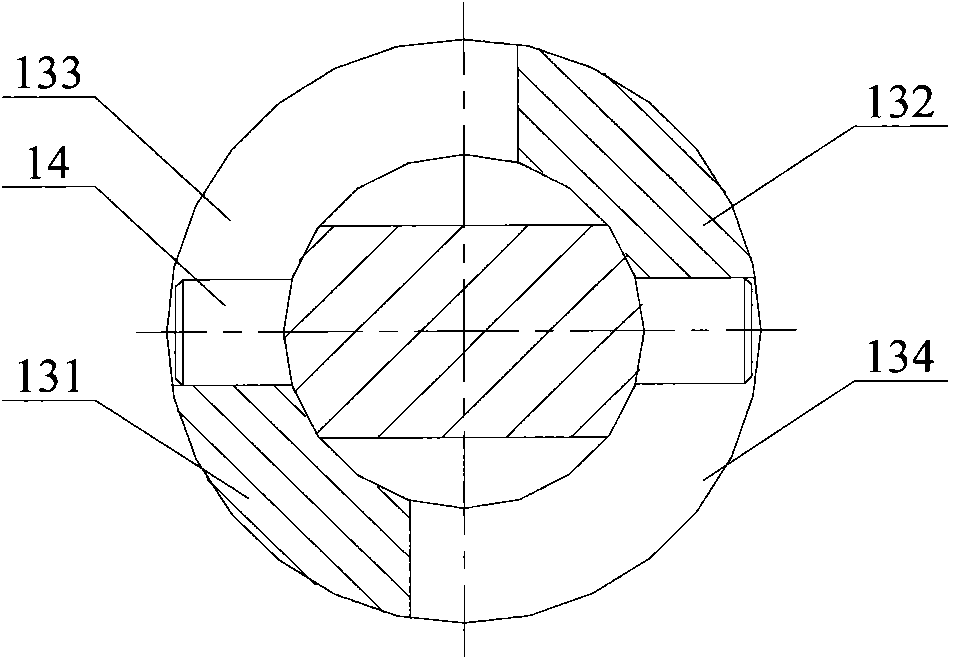

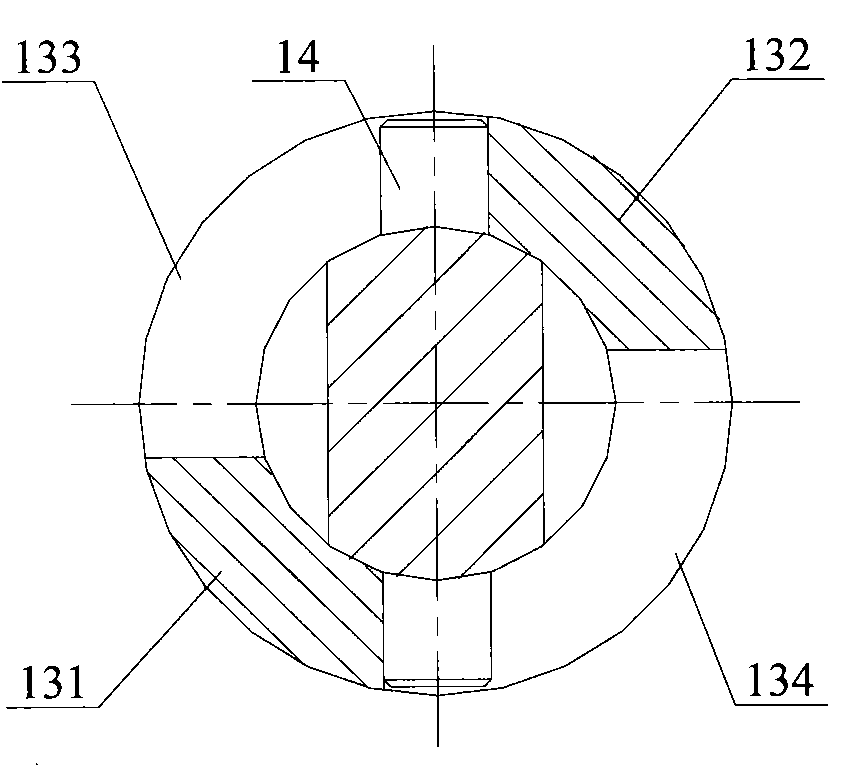

Ball valve

The invention discloses a ball valve comprising a locking part and a positioning boss, wherein the locking part is arranged on a valve rod, and the positioning boss is arranged on the valve body; the extending part of the locking part is matched with the positioning boss so as to limit the full-open position and the full-closed position of the ball valve; the anti-bending section of the locking part is rectangular, and the height-breadth ratio h / b of the rectangle anti-bending section satisfies the condition that h / b is less than 6 and is more than 1; the ball valve has better anti-bending property. Preferably, the positioning boss is provided with a first positioning surface and a second positioning surface, the deflection angle for the locking part to extend between the first positioning surface and the second positioning surface is 180 degrees; when the extending part rotates to the middle position between two positioning surfaces, the ball valve is in the full-open position and the full-closed position; when the extending part rotates to the position on which the side end surface is abutted with the first positioning surface or the position on which the other end surface is abutted with the second positioning surface, the ball valve is in the full-open position and the full-closed position. Thus, the valve rod can rotate within the range of 180 degrees so as to greatly improve the adaptability and the maneuverability of the ball valve.

Owner:ZHEJIANG SANHUA CO LTD

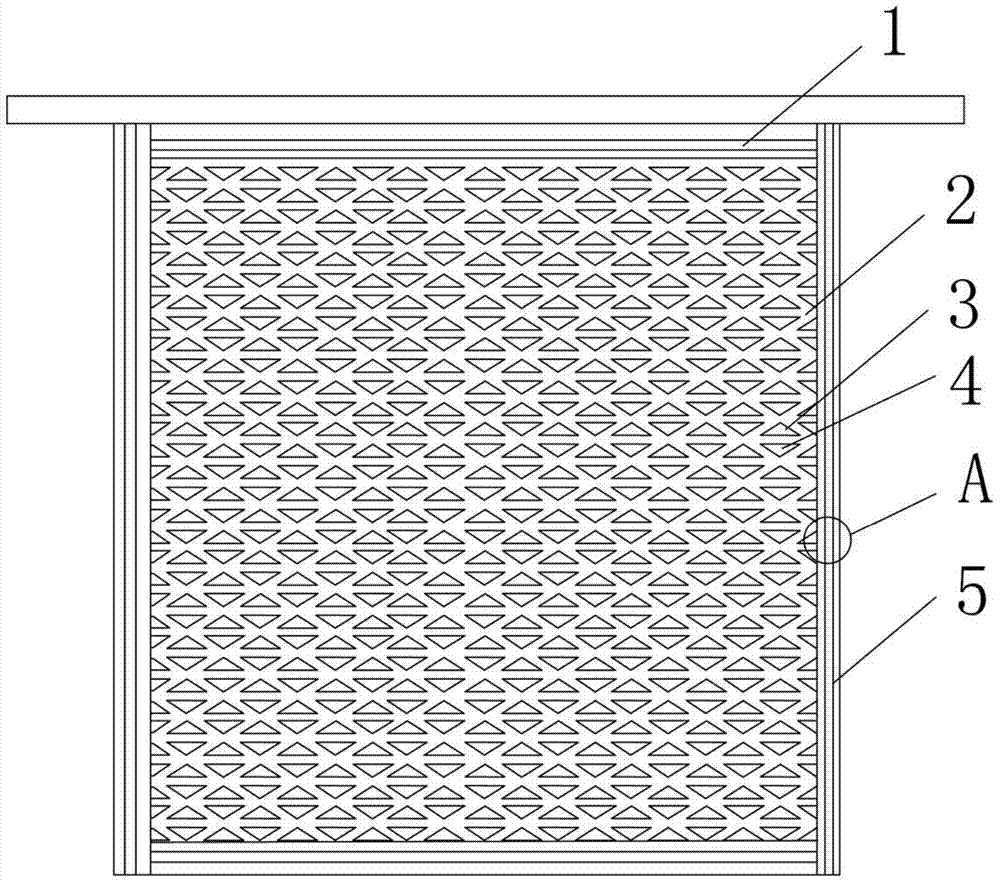

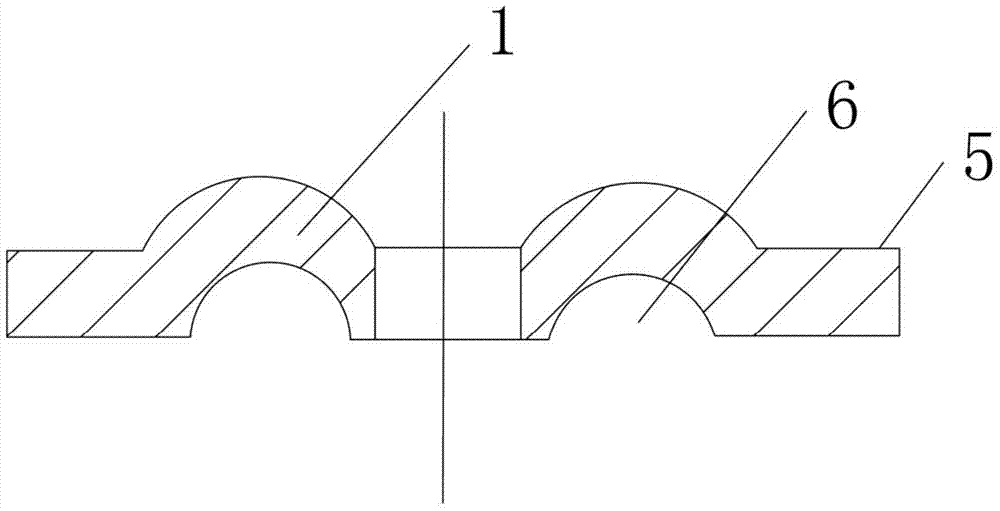

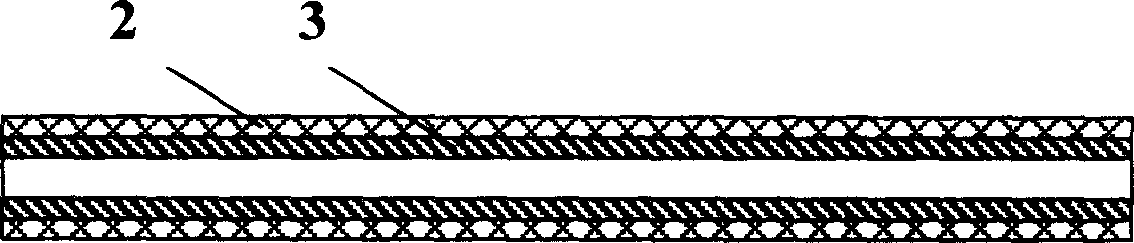

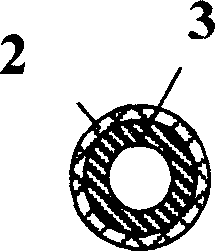

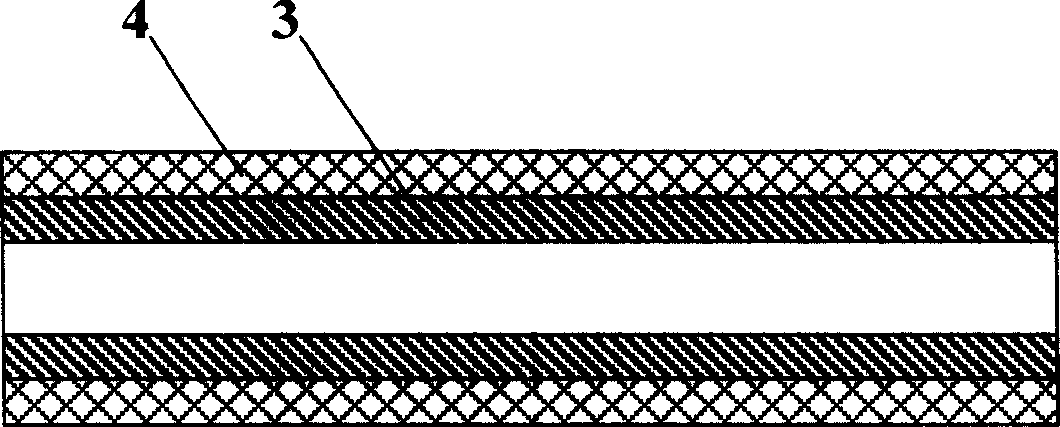

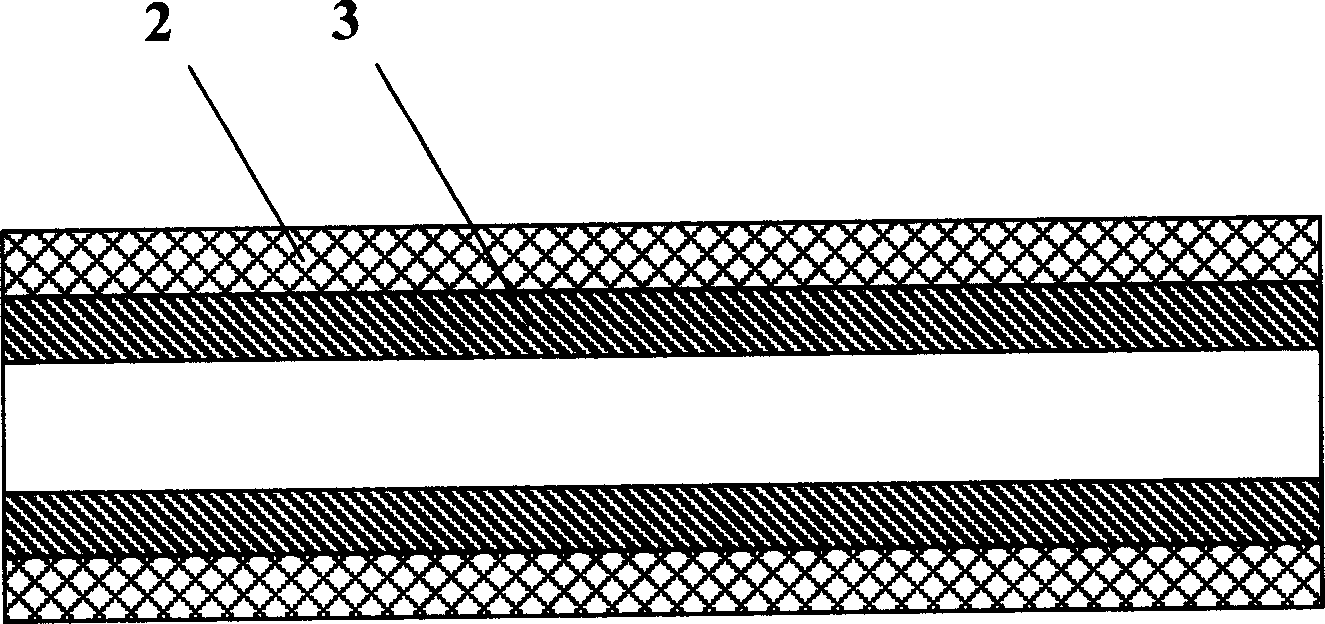

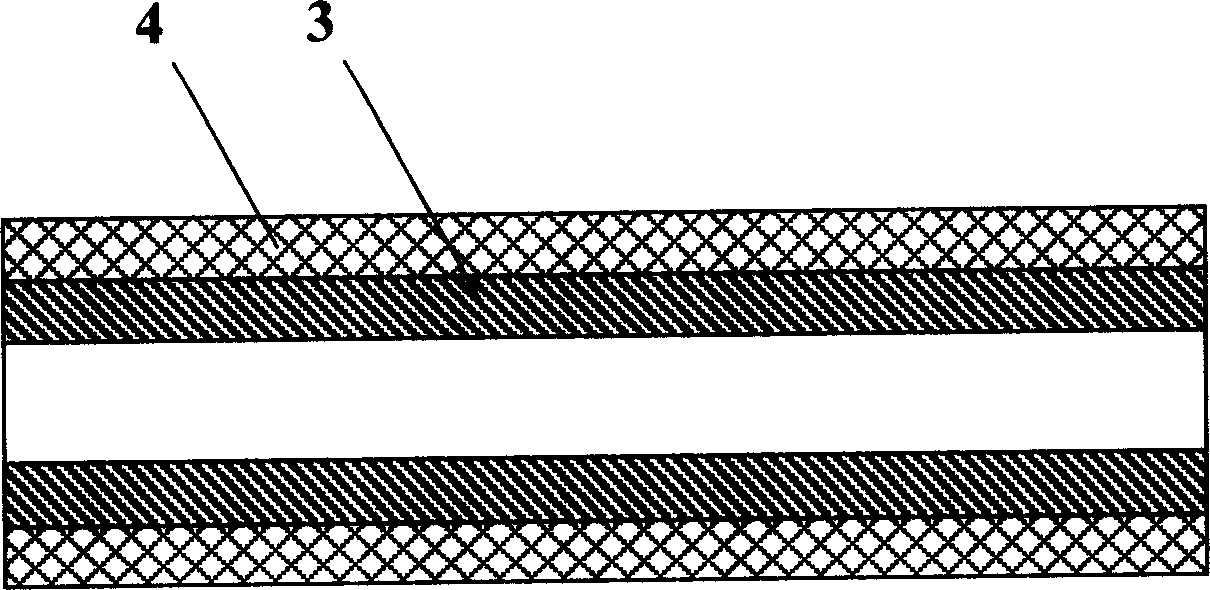

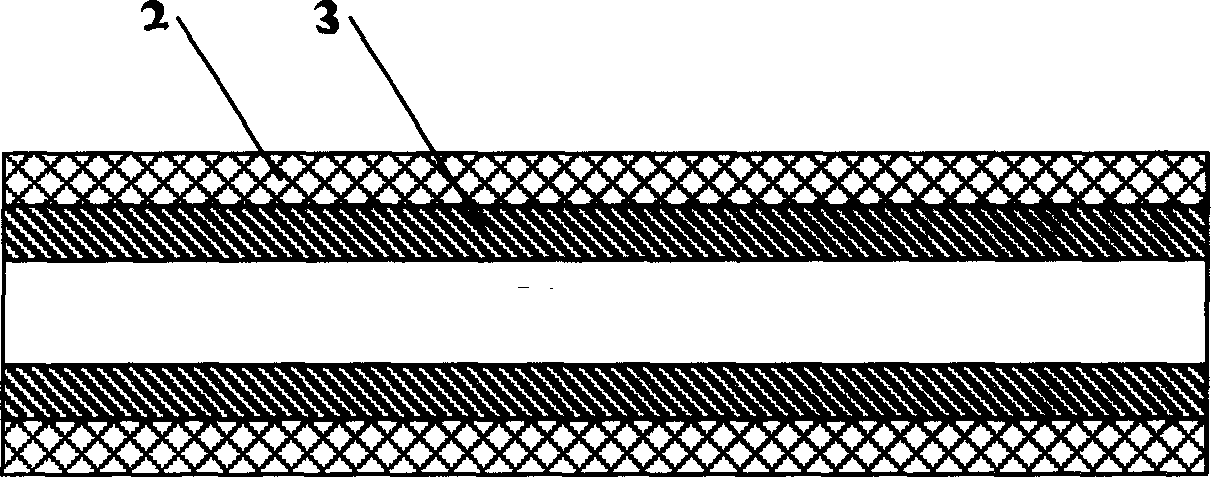

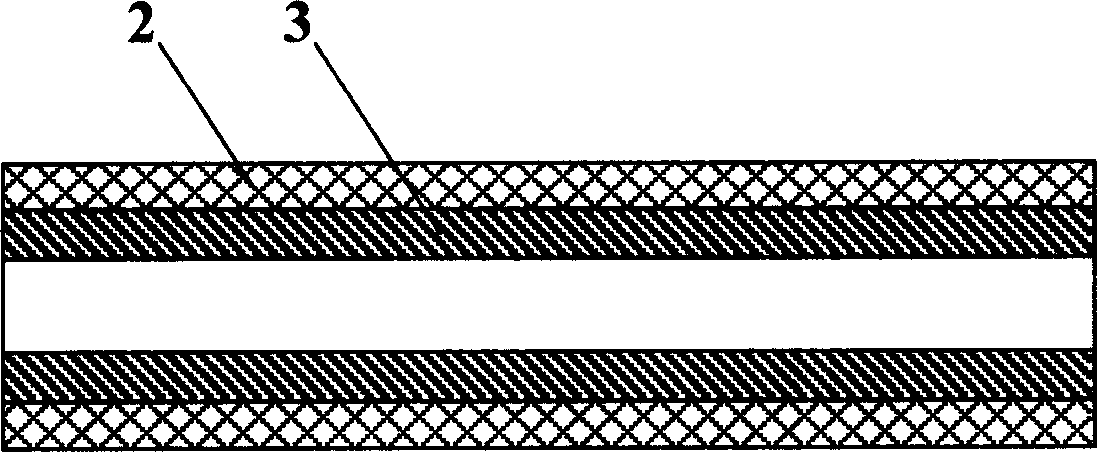

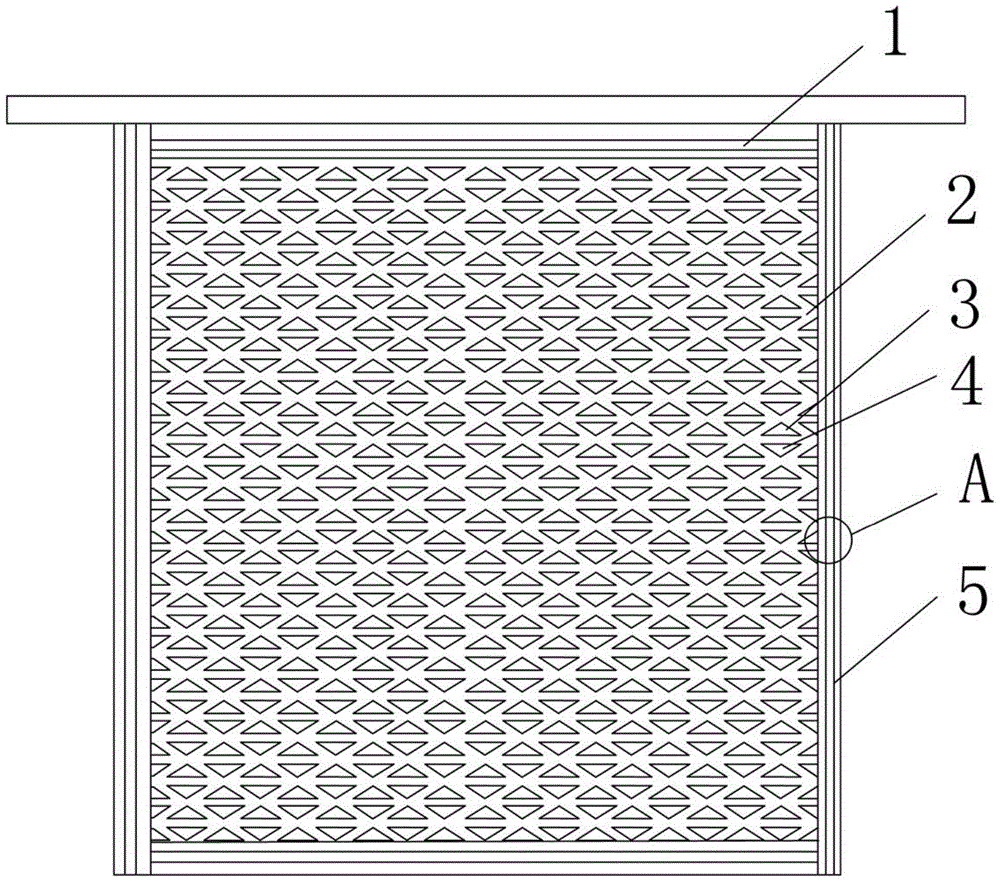

Embossed flattened rigidity-reinforced electrolytic electrode plate and preparation method thereof

ActiveCN104328459AIncreased flexural section modulusImprove rigidityElectrodesElectrolysisEngineering

The invention relates to an embossed flattened rigidity-reinforced electrolytic electrode plate and a preparation method thereof, the electrolytic electrode plate comprises an electrode plate, an embossed groove is arranged on the surface of the electrode plate, and forms a concave convex pattern to improve the electrode plate surface strength and bending resistant ability. The embossed groove is composed of a plurality of transverse embossed grooves and oblique embossed grooves to form a structure shaped like a Chinese character mi, and raised structure composed of an upper triangular convex block and a lower triangular convex block is formed on the electrode plate. The beneficial effects of the embossed flattened rigidity-reinforced electrolytic electrode plate are that: aiming at the electrode plates of different types, reinforced stripes with different specifications and different shapes are designed, through embossing and shaping of the reinforced stripes, the electrode plate rigidity is greatly enhanced, the internal stress is eliminated, the objective of improving the electrode plate surface flatness, reducing the bending deformation, and enhancing the electrode plate bending resistant ability can be achieved, anode and cathode short circuit phenomenon in the process of electrolysis due to deformation can be avoided, the power consumption in the electrolysis or plating process can be effectively reduced, at the same time, cathode product quality is improved, the labor intensity is reduced, and production efficiency is improved.

Owner:HANGZHOU EMPEROR LOSSEN TECH

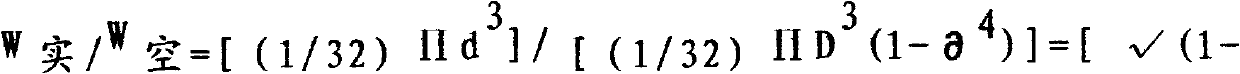

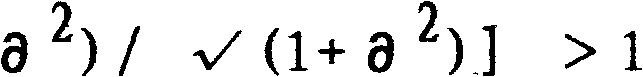

Method for manufacturing novel, energy-saving and environmental-friendly bicycle pipe support components through bamboo skin coiled materials

ActiveCN103659991AFree from mothsControl crackingWood treatment detailsFlat articlesPipe supportEnvironmental resistance

The invention discloses a method for manufacturing novel, energy-saving and environmental-friendly bicycle pipe support components through bamboo skin coiled materials. The method comprises the following steps that firstly, moso bamboo is selected and steamed; secondly, the bamboo is flattened, pressure maintaining and rolling-in are carried out on the bamboo, and the bamboo is processed in a planing mode; thirdly, drying is carried out, and gluing and machining are carried out; fourthly, assembling and hot-pressing are carried out, and bamboo skin coils are pressed into the bamboo skin coiled materials; fifthly, the components (some components can be made of bamboo pressing sheets according to the practical application) needed by all pipe supports are made of the bamboo skin coiled materials, and component assembling is carried out. By the adoption of the technical scheme, a bicycle is better in stability, the weight of the bicycle can be reduced, and meanwhile the overall strength of the bicycle is further improved; the bicycle is firmer, so that guarantee is provided for safe use; the bicycle and the manufacturing method are economical and practical, economic benefits and social benefits are obvious, and therefore the method can be popularized and applied conveniently.

Owner:苏州天健竹业科技有限公司

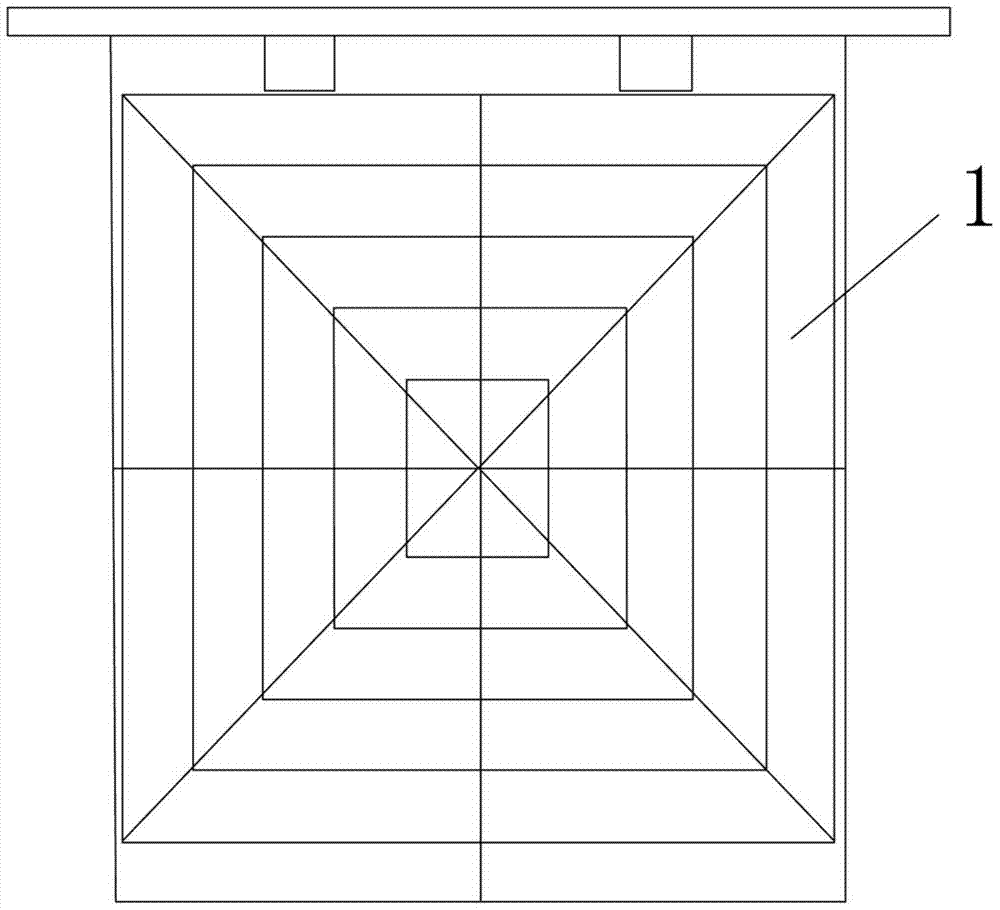

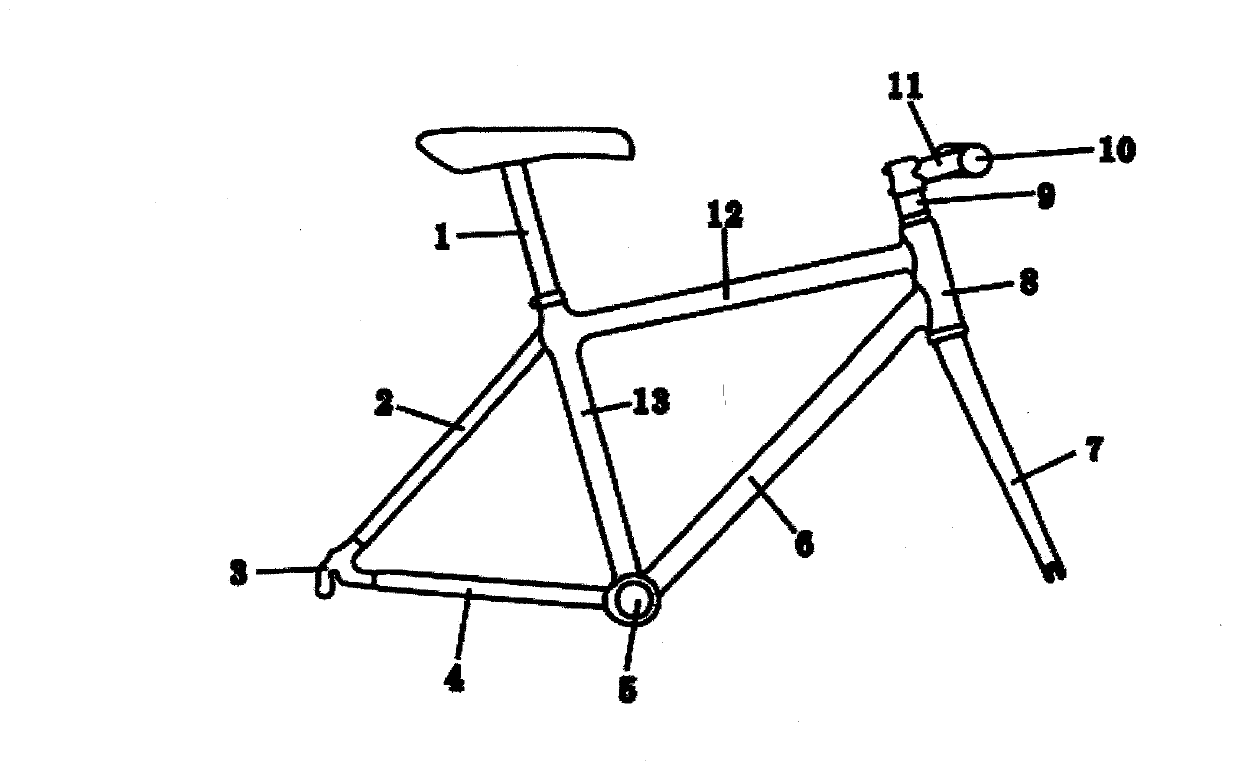

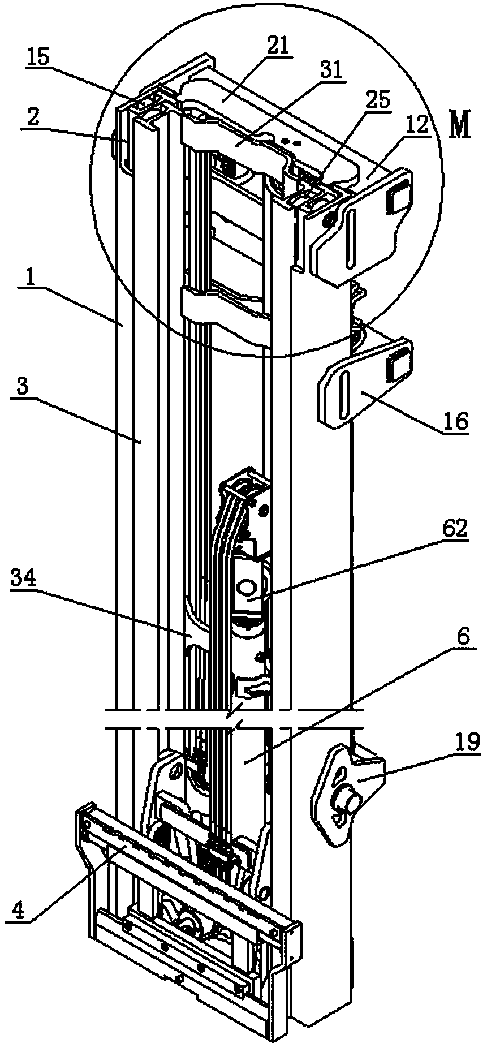

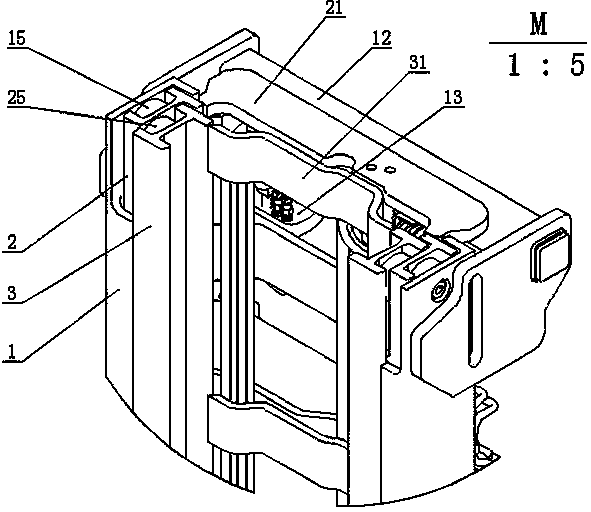

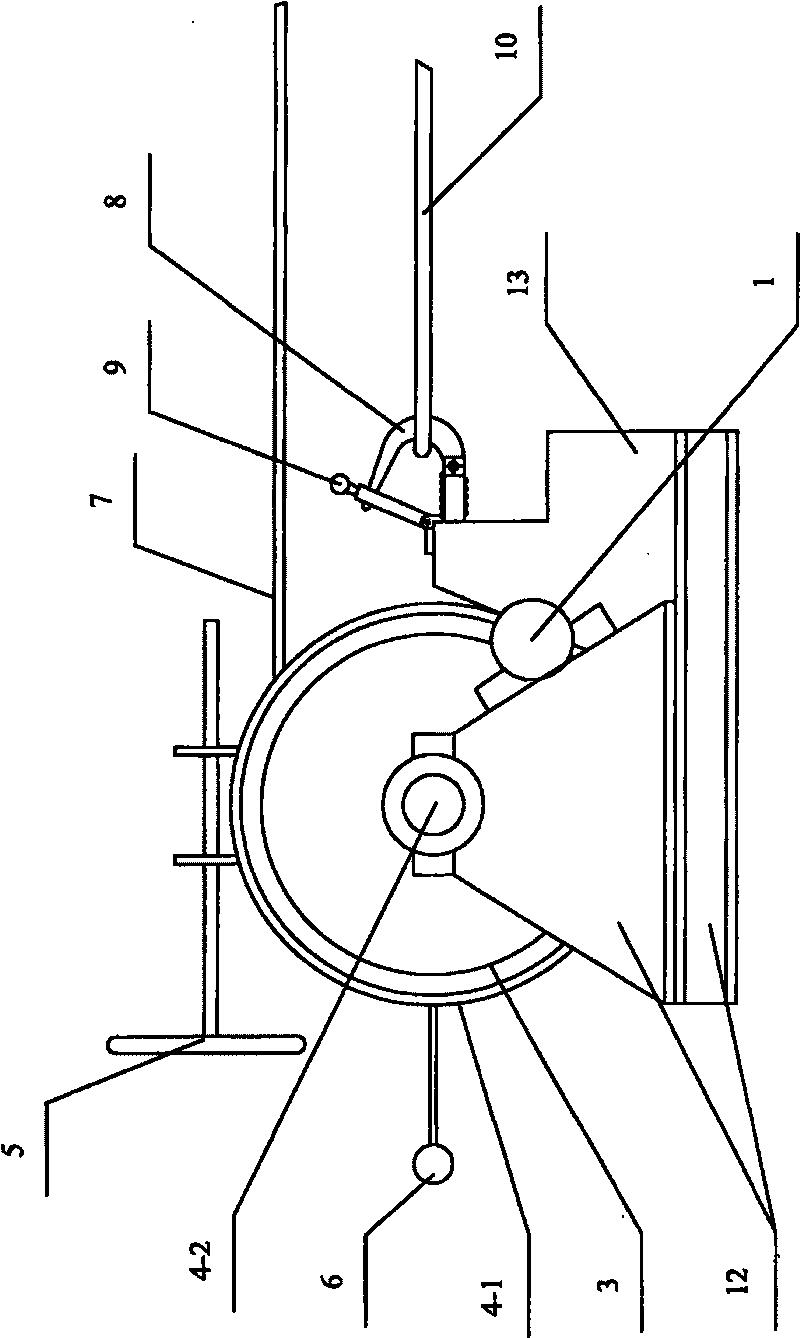

Method for opening doors on four sides of observation elevator without machine room and observation elevator with opening doors on four sides

ActiveCN104016212AIncrease profitSpace maximizationElevatorsBuilding liftsEngineeringBuilding construction

The invention discloses a method for opening doors on the four sides of an observation elevator without a machine room and an observation elevator with the opening doors on the four sides. According to the method, two stand columns are installed on one pair of opposite corners of a well, a machine placing beam is installed on the upper portion of the well and used for bearing the total weight of the elevator, the pair of opposite corners of a lift car are installed on the inner sides of the stand columns through guide rails, the top of the lift car is connected with a counter-weight assembly through car roof wheels, wherein the counter-weight assembly is fixed to the outer sides of the stand columns, and the counter-weight assembly is connected with a traction machine installed on the machine placing beam. In this way, the lift car is opened on the four sides. The space of the well is sufficiently utilized, the large space of the lift car is guaranteed, people feel comfortable when taking the elevator, and construction cost can also be lowered.

Owner:SL ELEVATOR

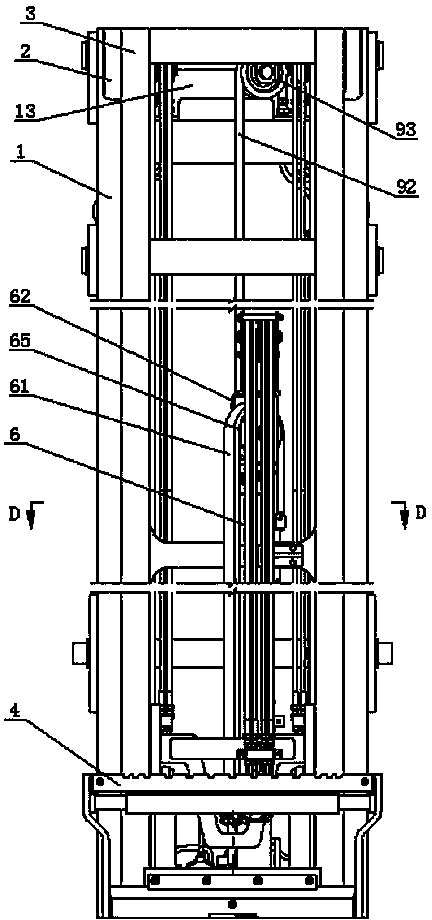

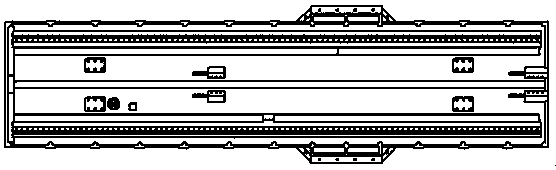

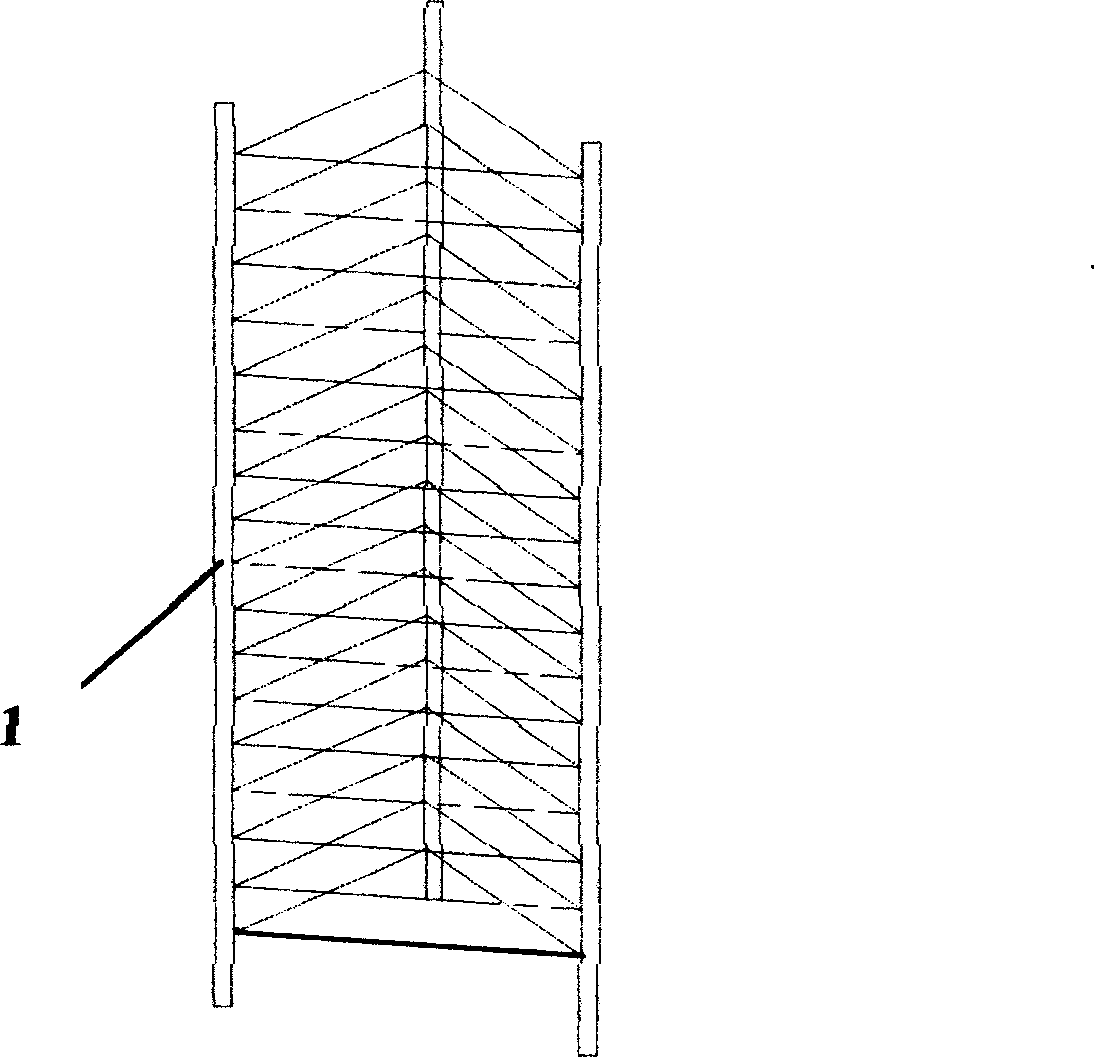

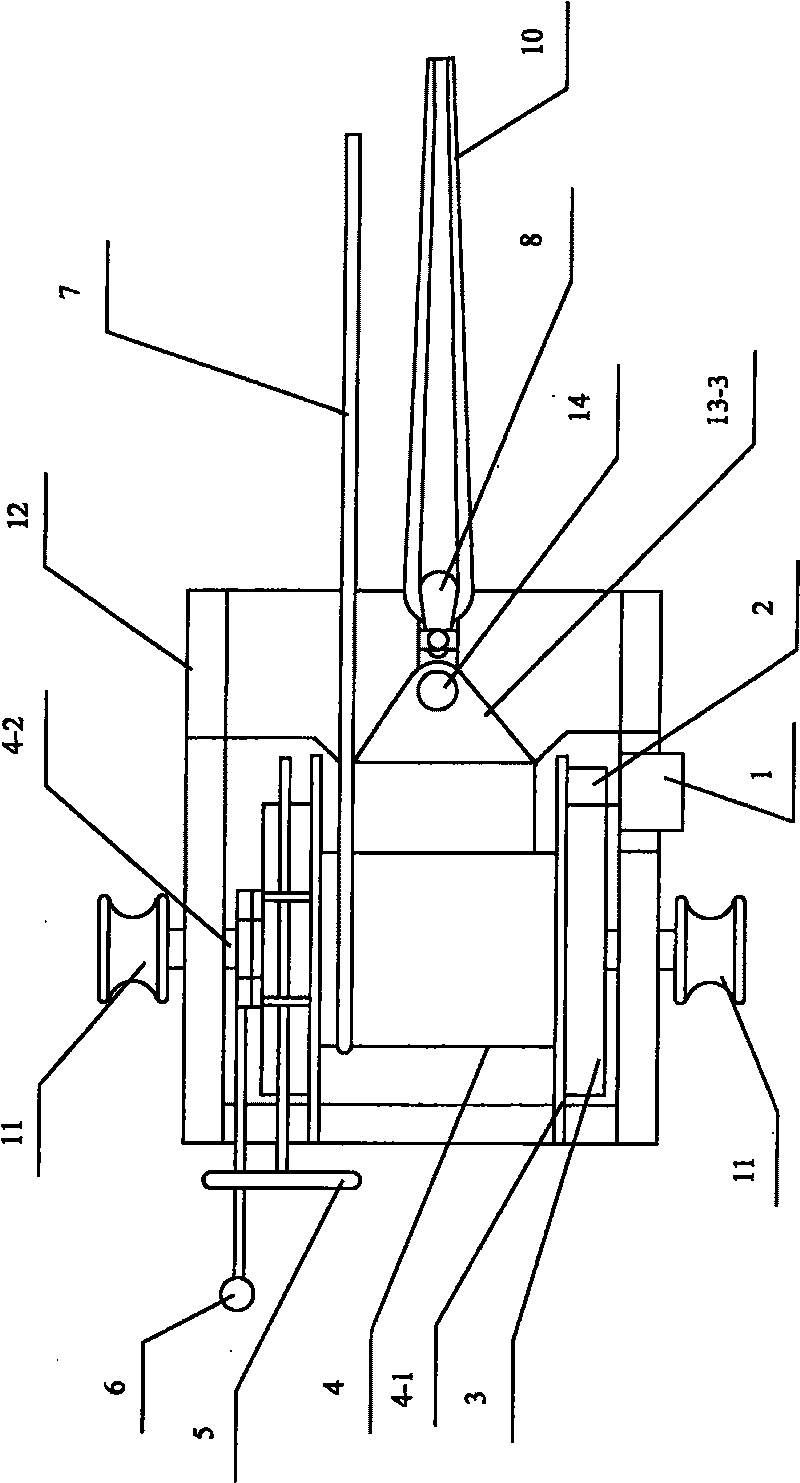

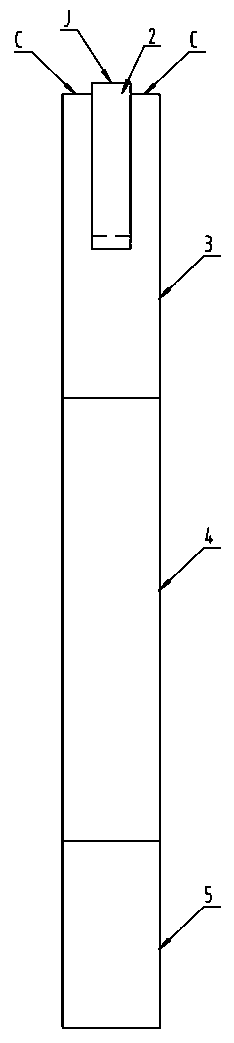

Hoisting system capable of implementing high hoisting of reach truck

The invention relates to a hoisting system capable of implementing high hoisting of a reach truck. The hoisting system comprises a three-stage hoisting gantry, a side shifter, a front hoisting oil cylinder, two rear hoisting oil cylinders and a hydraulic pipeline system, wherein the three-stage hoisting gantry comprises an outer gantry, an intermediate gantry and an inner gantry; the width A of the outer gantry is 730 mm; the total width B of three gate posts on one side of the width direction after assembling of the three-stage hoisting gantry is 149 mm, and the total thickness C is not greater than 175 mm; the gantry structure is high in strength, can implement high hoisting of 12.5 m, is provided with the side shifter with the inclining and side shifting dual functions to implement separate inclination of the cargo while the gantry is vertical; the radial direction of a front cylinder chain wheel at the top of the front hoisting oil cylinder is inclined with the plane of the three-stage hoisting gantry; four rubber tubes at the cylinder head are crossly arranged with the front cylinder chain; the four rubber tubes are forward lapped with the front hoisting oil cylinder to form a wider space in the inner gantry above the front hoisting oil cylinder, so as to maximally enlarge the view field of a driver.

Owner:ANHUI HELI CO LTD

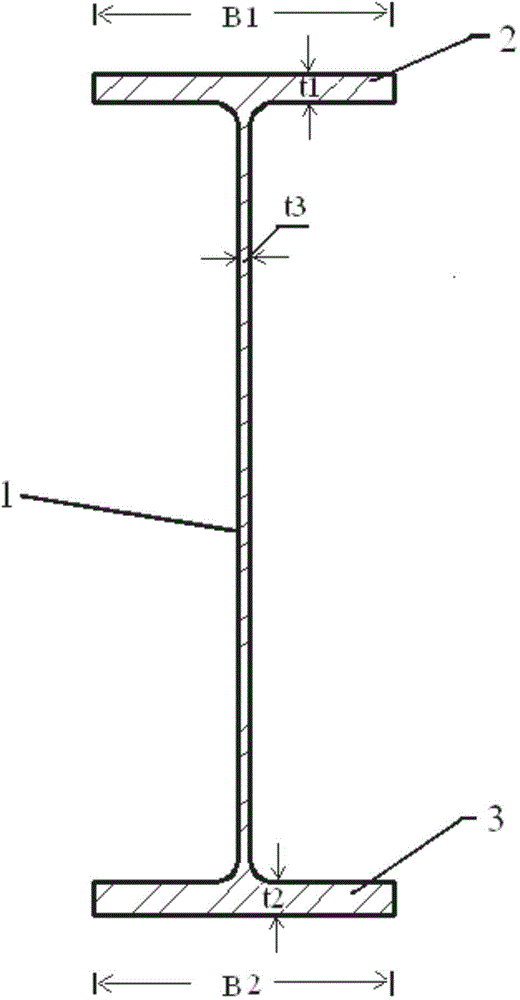

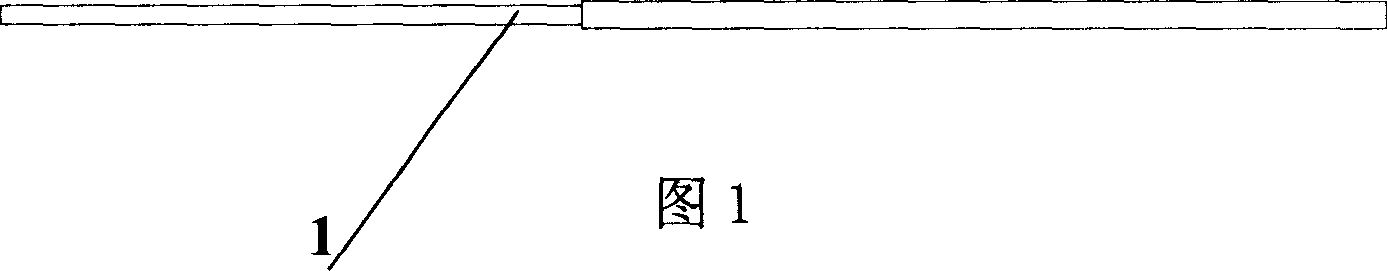

Flange variable thickness hot-rolled H-shaped steel and production method thereof

InactiveCN103557426AIncrease stiffnessIncrease loading capacityElongated constructional elementsMetal rolling arrangementsVariable thicknessEngineering

The invention discloses flange variable thickness hot-rolled H-shaped steel and a production method thereof. The H-shaped steel comprises an upper flange, a lower flange and a web plate, wherein the web plate is vertically positioned between the upper flange and the lower flange, and the upper flange and the lower flange are different in thickness. The production method includes a BD area rolling process and a universal area rolling process, and the difference between rolling reduction in the thickness direction of the upper flange and the lower flange in a BD area in groove design is smaller than 8mm. The manufacturing process is simple, welding workload is decreased, the steel is saved, and traditional welded H-shaped steel can be replaced. The sectional mechanical property of the H-shaped steel is optimized by changing the thicknesses of the flanges on two sides, anti-bending section modulus can be increased by 4-15% as compared with that of H-shaped steel with the same thickness of an upper flange and a lower flange, and the rigidity and the loading capacity of an automobile girder are improved.

Owner:LAIWU IRON & STEEL GRP

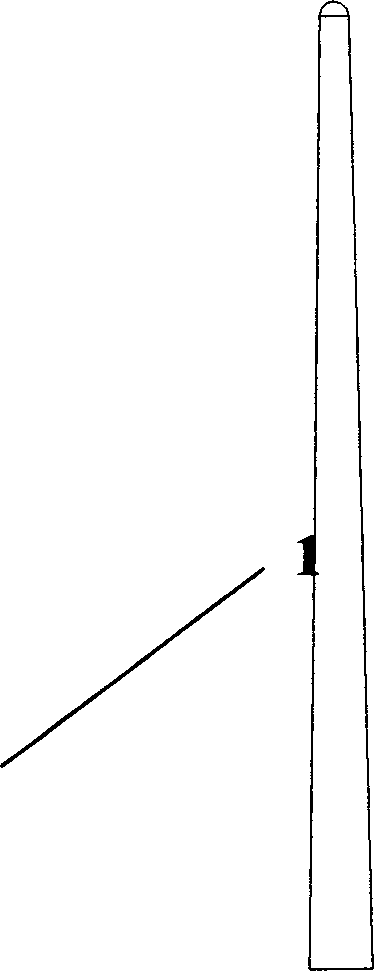

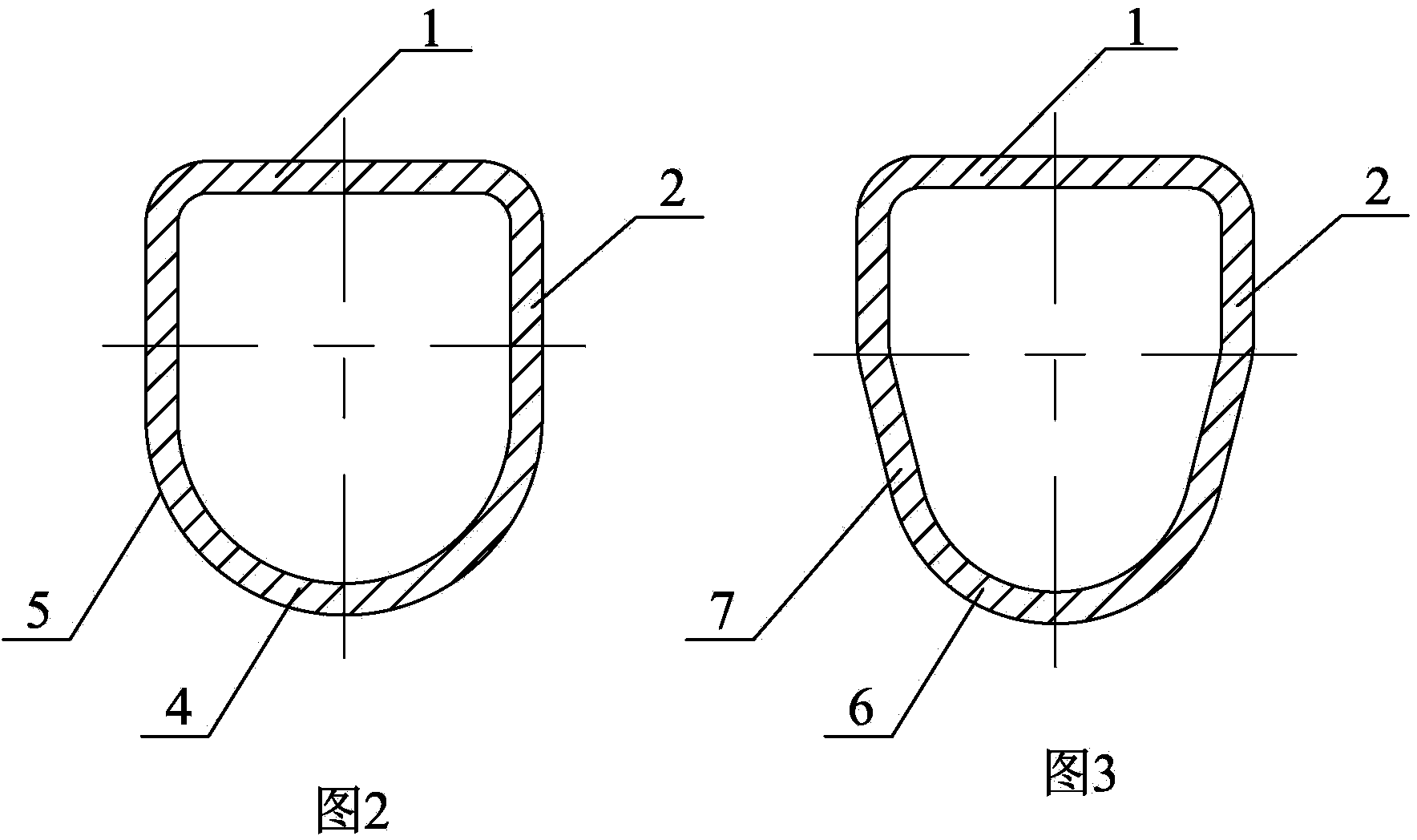

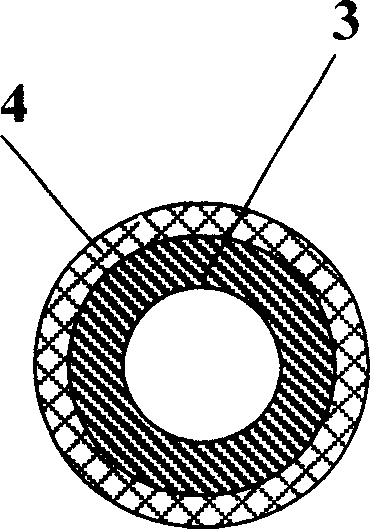

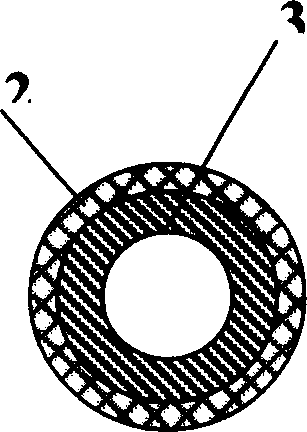

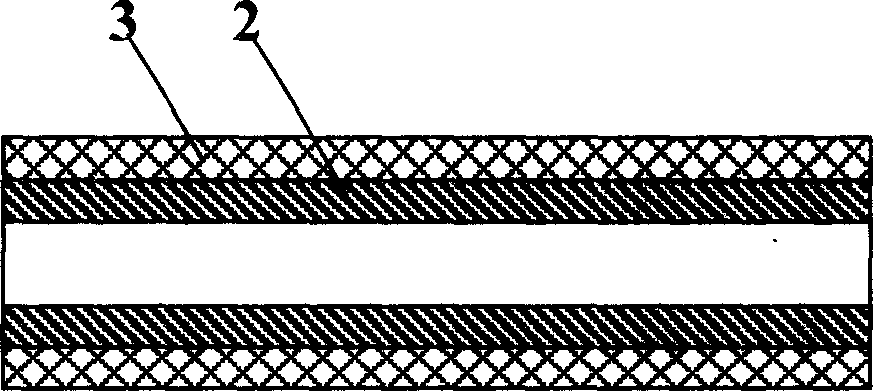

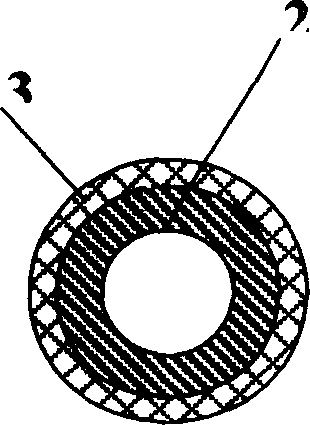

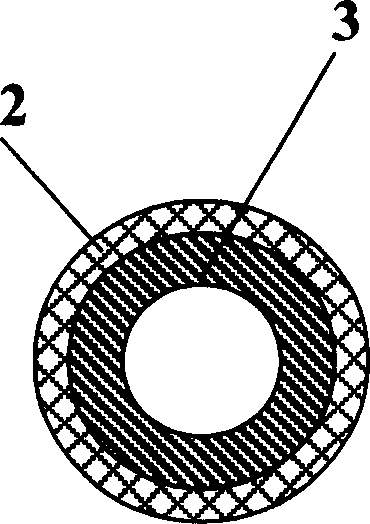

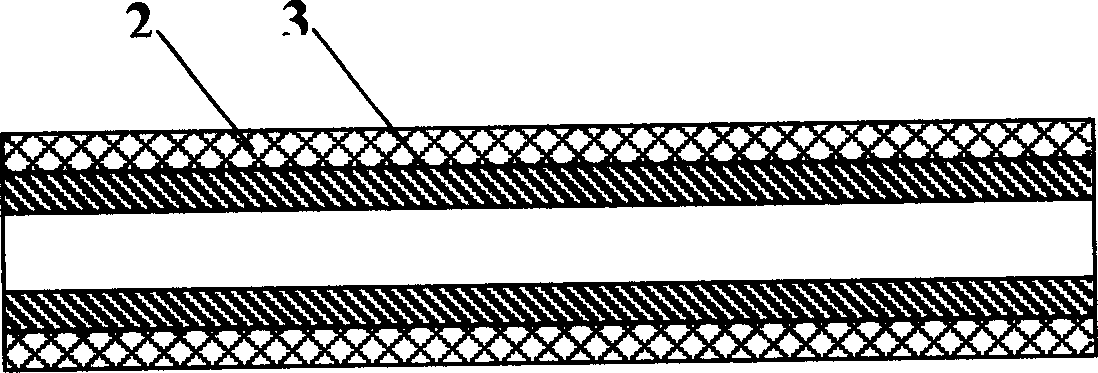

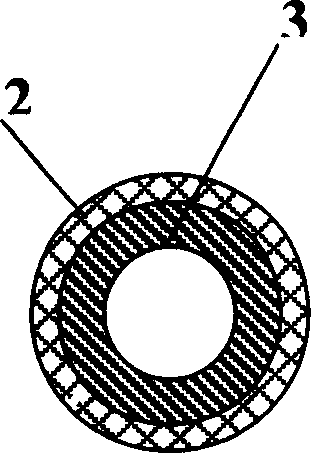

Improved fishing rod part

An improved fish rod is composed of at least one tubular member, consisting of a stainless steel tube and a fiber-reinforced plastic tube fixed in said stainless steel tube. Its advantages are light weight, high strength, high resistance to corrosion and beautiful appearance.

Owner:上海温兴生物工程有限公司

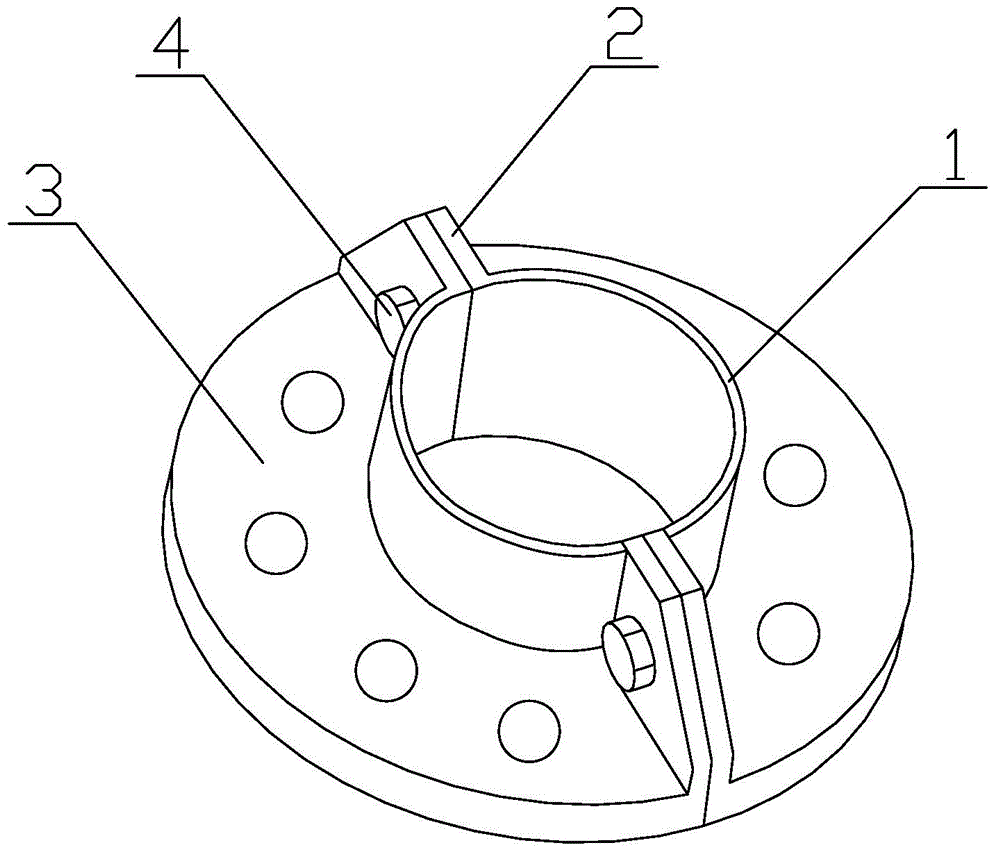

Method for manufacturing nano-composite tower capable of resisting strong breeze whose speed is greater than 60 m/s

InactiveCN104963541AImprove mechanical propertiesFirmly connectedTowersTransmission towerGlass fiber

The invention provides a method for manufacturing a nano-composite tower capable of resisting strong breeze whose speed is greater than 60 m / s. The method comprises 1. preparing composite material, 2. preparing composite rods of a transmission tower, 3. preparing flange hoops, 4. assembling the composite rods and the flange hoops, and 5. sequentially connecting a plurality of composite rods provided with flange hoops to obtain a composite tower capable of resisting strong breeze, wherein flange hoops between ends of two adjacent composite rods are connected through bolts. In the method for manufacturing a nano-composite tower capable of resisting strong breeze whose speed is greater than 60 m / s, nano material and reinforcing material are added in a resin, and the content of glass fiber in composite material is controlled, the mechanical properties of the composite material can be improved, the tensile strength of the manufactured composite rod is 0.6 GPa to 1.0 GPa, and the bending strength is 1.0 GPa to 1.5 GPa. The composite tower manufactured by the method is hydrophobic, anti ultraviolet, acid and alkali resistant, and heat and cold resistant, the service life can be as long as 40 years, so the nano-composite tower can be used as a 110 KV to 220 kV power transmission tower.

Owner:孙仲齐

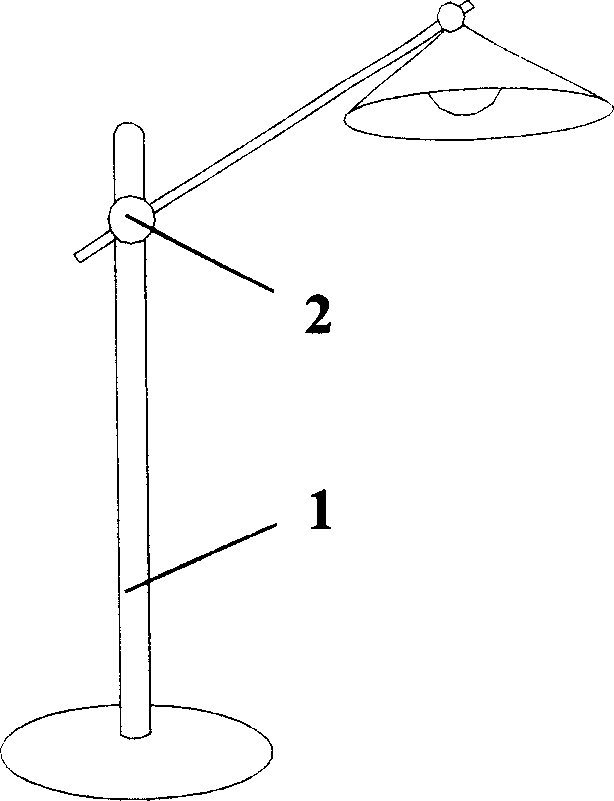

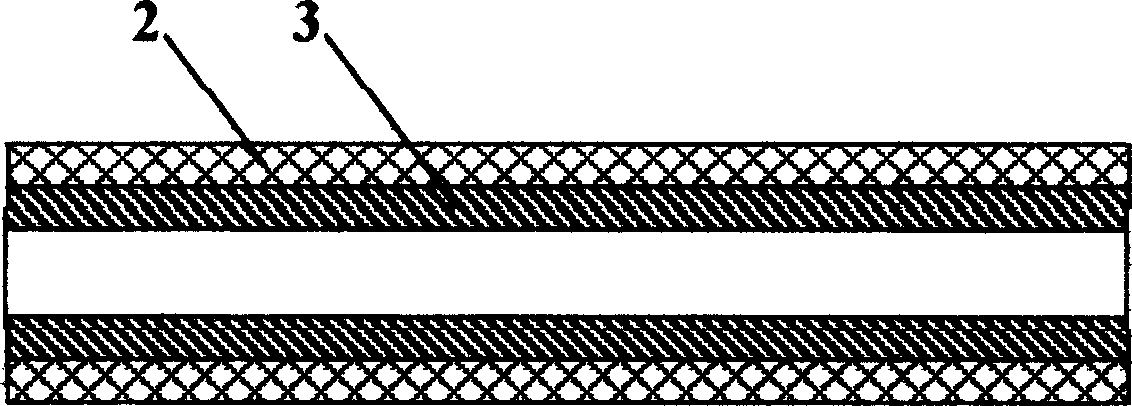

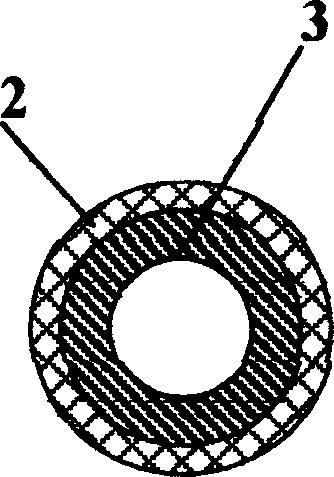

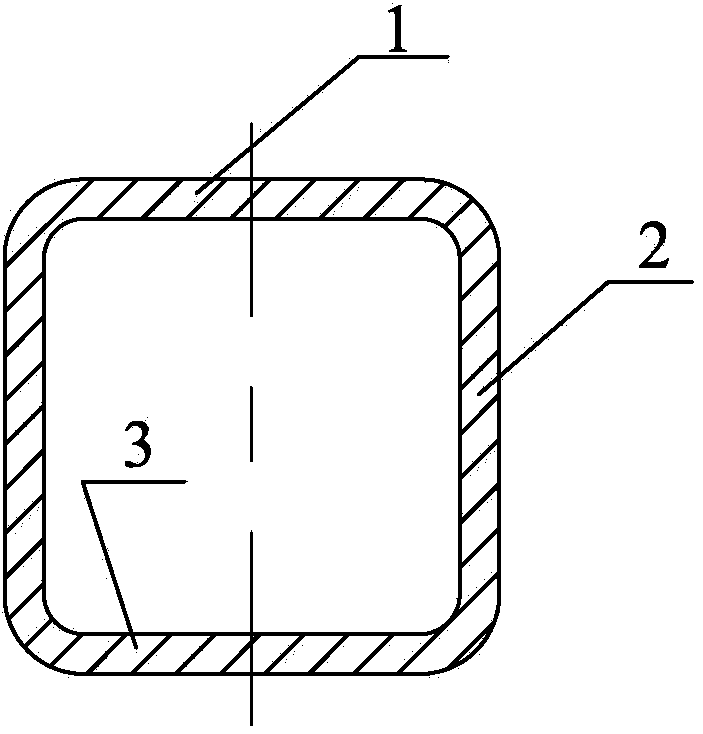

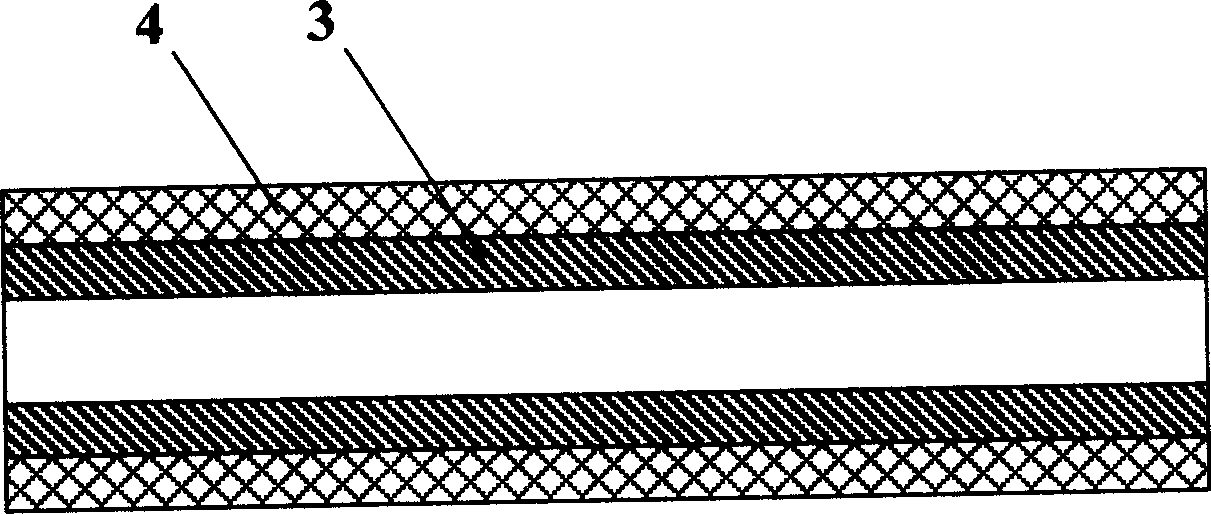

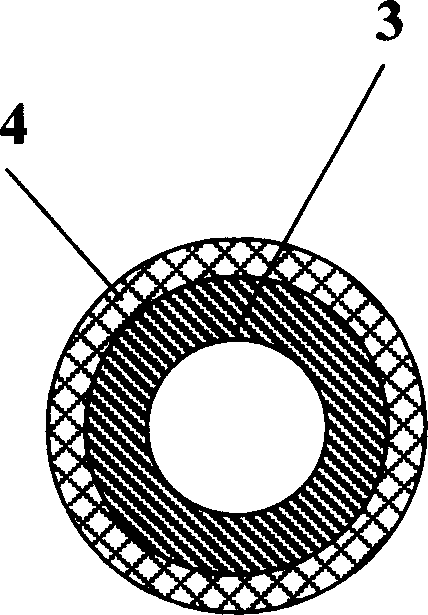

Stand structure of floor lamp

InactiveCN1854600AImprove bending resistanceSimple structureLighting support devicesFree standingMechanical engineeringEngineering

A floor lamp stand structure consists of at least one tubular connecting piece made up of a stainless steel pipe body, in which is set a reinforced campo pipe body. The diameters of the said reinforced campo pipe body and the said stainless steel pipe body are fit each other and the two tube bodies are jointed firmly. The tubular connecting pieces are connected via joints.

Owner:上海温兴生物工程有限公司

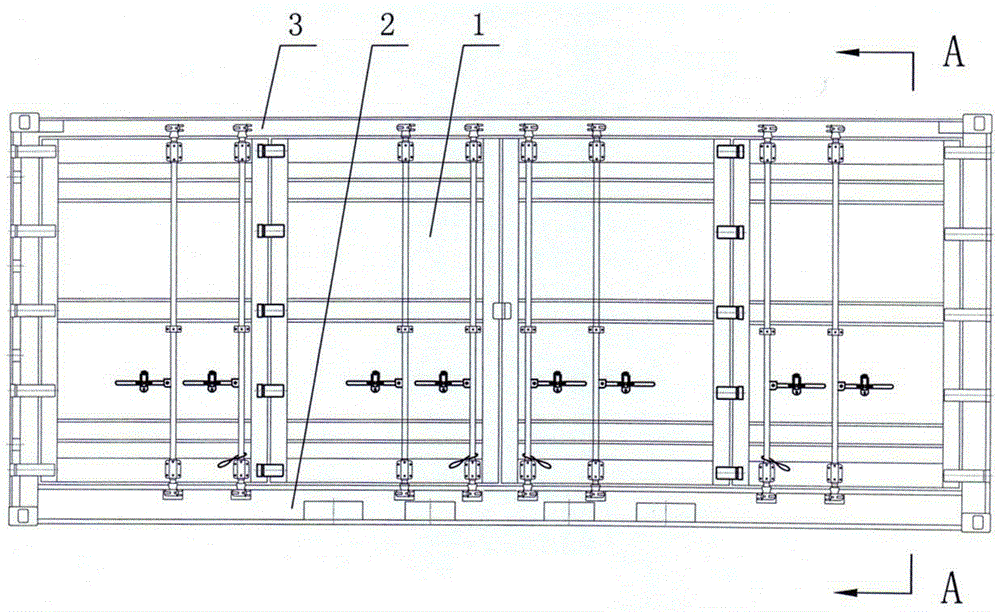

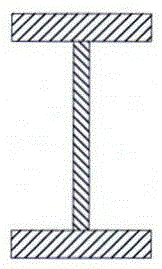

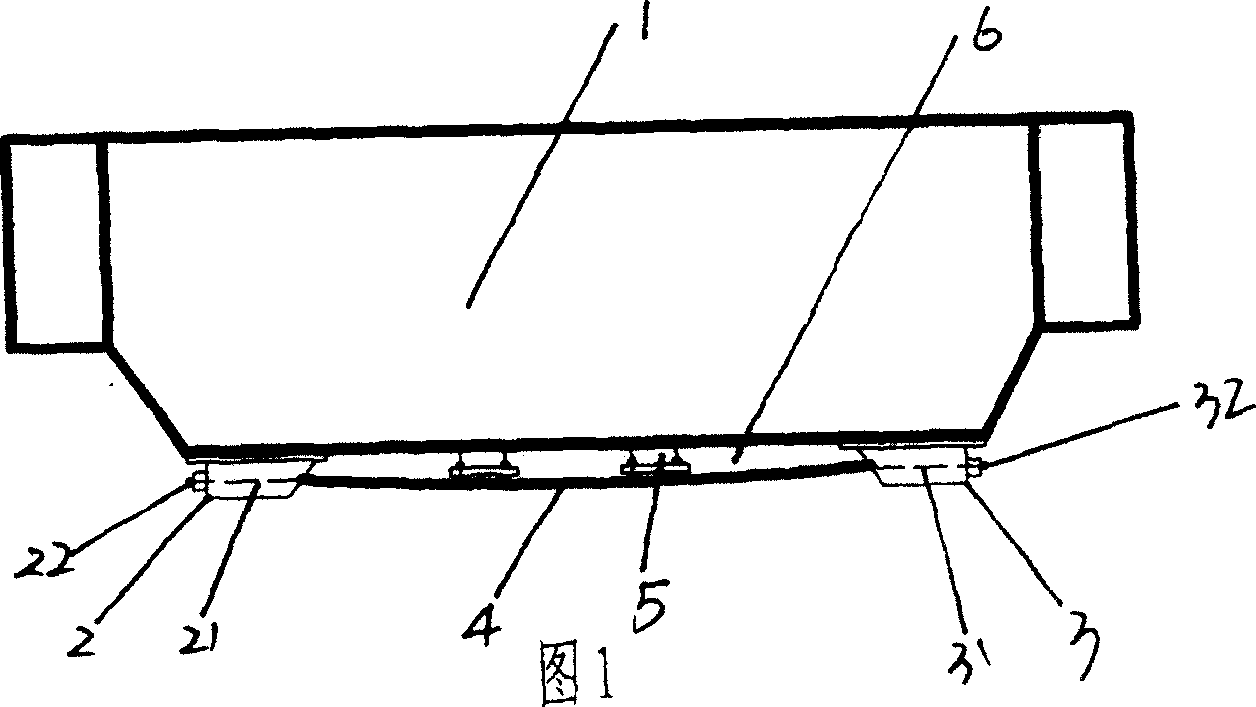

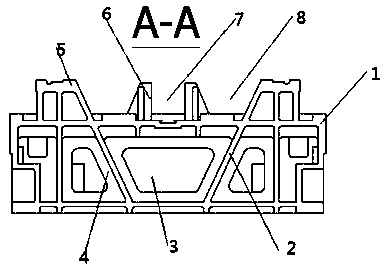

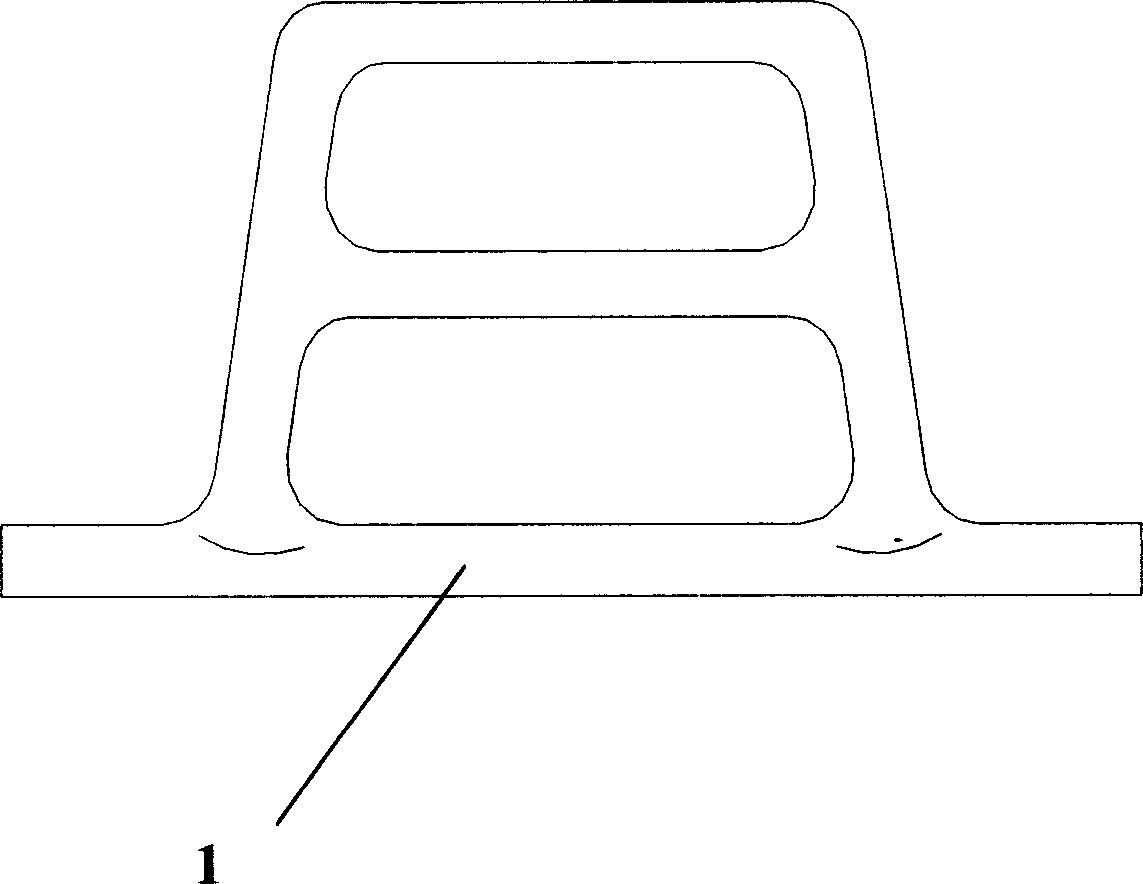

Lower side beam structure of side-opening container

InactiveCN105292824AIncreased flexural section modulusHigh strengthLarge containersLower wingUpper wing

The invention discloses a lower side beam structure of a side-opening container. The lower side beam structure of the side-opening container aims at being simple in structure, convenient to manufacture and high in strength and rigidity. The lower side beam structure of the side-opening container comprises I-shaped steel which is formed by welding an upper wing plate, a lower wing plate and a web plate between the upper wing plate and the lower wing plate, wherein the cross section of the I-shaped steel is in an I shape. The lower side beam structure is characterized in that a strengthening plate parallel to the web plate is welded to the outer side end between the upper wing plate and the lower wing plate; the length and the height of the strengthening plate are the same with those of the web plate; and the upper wing plate, the lower wing plate, the web and the strengthening plate are flat steel. According to the lower side beam structure of the side-opening container, due to the fact that the strengthening plate parallel to the web is added on the bases of the original I-shaped steel, the modulus of a bending resistance section of the lower side beam is effectively increased, a whole lower side beam becomes a closed frame type structure, strength and rigidity of the lower side beam are improved, and the requirement for mechanical performance for the side-opening container lower side beam bearing heavy cargoes can be met.

Owner:嘉善新华昌集装箱有限公司

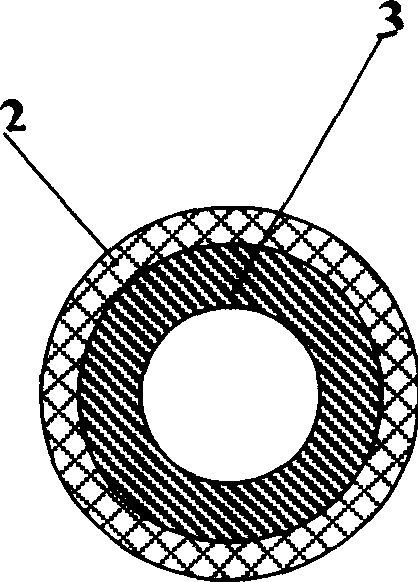

Structure stainless steel plastic composite tubular flagpole

InactiveCN1854436AImprove bending resistanceImprove shock absorptionLayered productsTowersFiberMaterials science

A plastic and stainless steel combined flag pole includes an enhanced fiber plastic inner pole and a stainless steel outer pole. The inner and outer poles are fixed together.

Owner:上海温兴生物工程有限公司

Girder downwarping repairing method for beam crane and beam type crane

The present invention relates to beam crane, and is especially one kind of self-repaired pre-stressed beam crane and the method of applying external pre-stress to repair the downwards bent beam of beam crane. The method of the present invention includes the following steps: 1. fixing stretching bearing and fixed bearing separately on two ends below the lower cover of the crane beam; 2. stringing steel strands separately in the fixing anchor beside the fixed bearing and the stretching anchor beside the stretching bearing to anchor the fixed end and to pressing the stretching anchor to the outer side of the stretching bearing; 3. regulating the initial stress of each steel strand with jack for equalized stress; 4. fixing 1-4 staying devices on the lower cover of the crane beam and setting the steel strands; and 5. stretching the steel strand of the stretching anchor with jack for the beam to bend upwards, anchoring the stretching end and regulating the staying devices for proper stress.

Owner:王冠华

Reinforced riser pipe combined structure and construction method thereof

ActiveCN102226378BIncreasing the thicknessIncreased stiffness against lateral stressDrilling rodsUnderwater drillingWell drillingT-beam

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

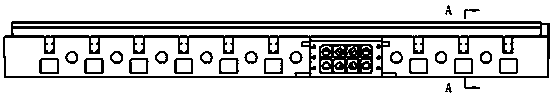

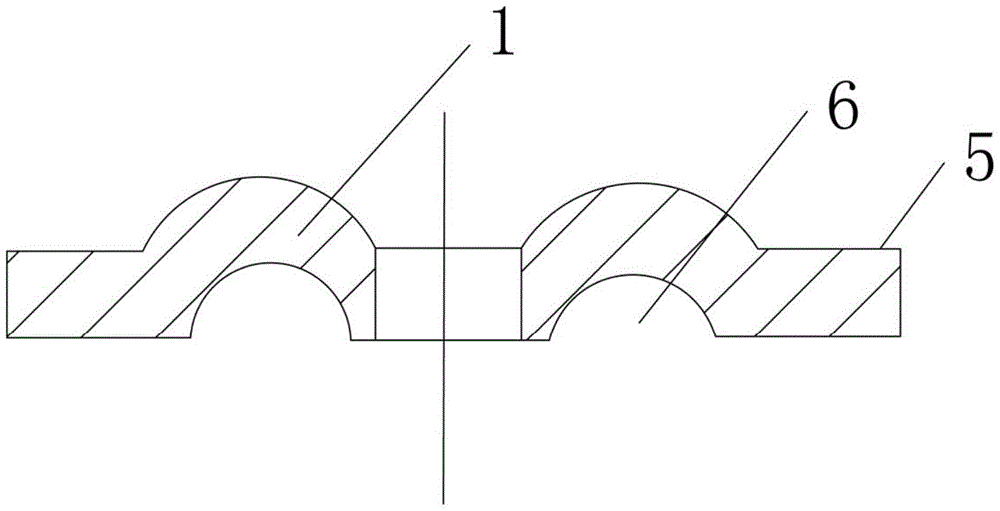

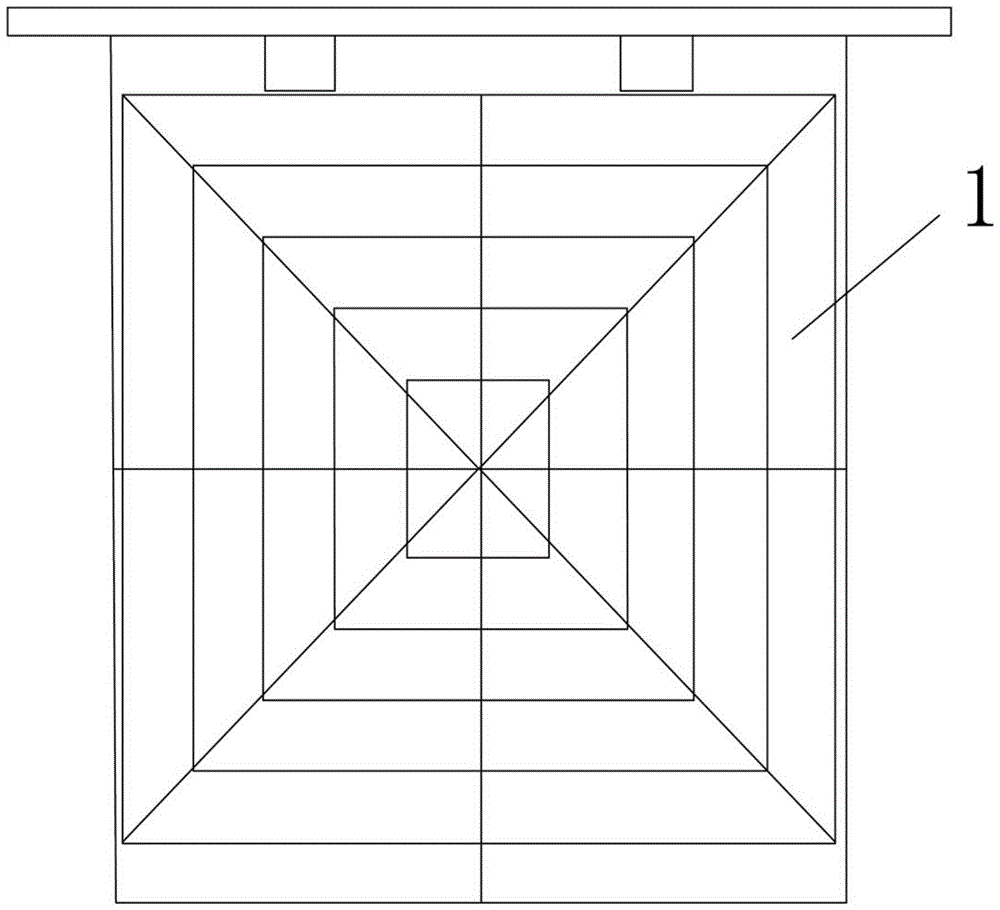

Lightweight high-rigidity gantry machining center machine base

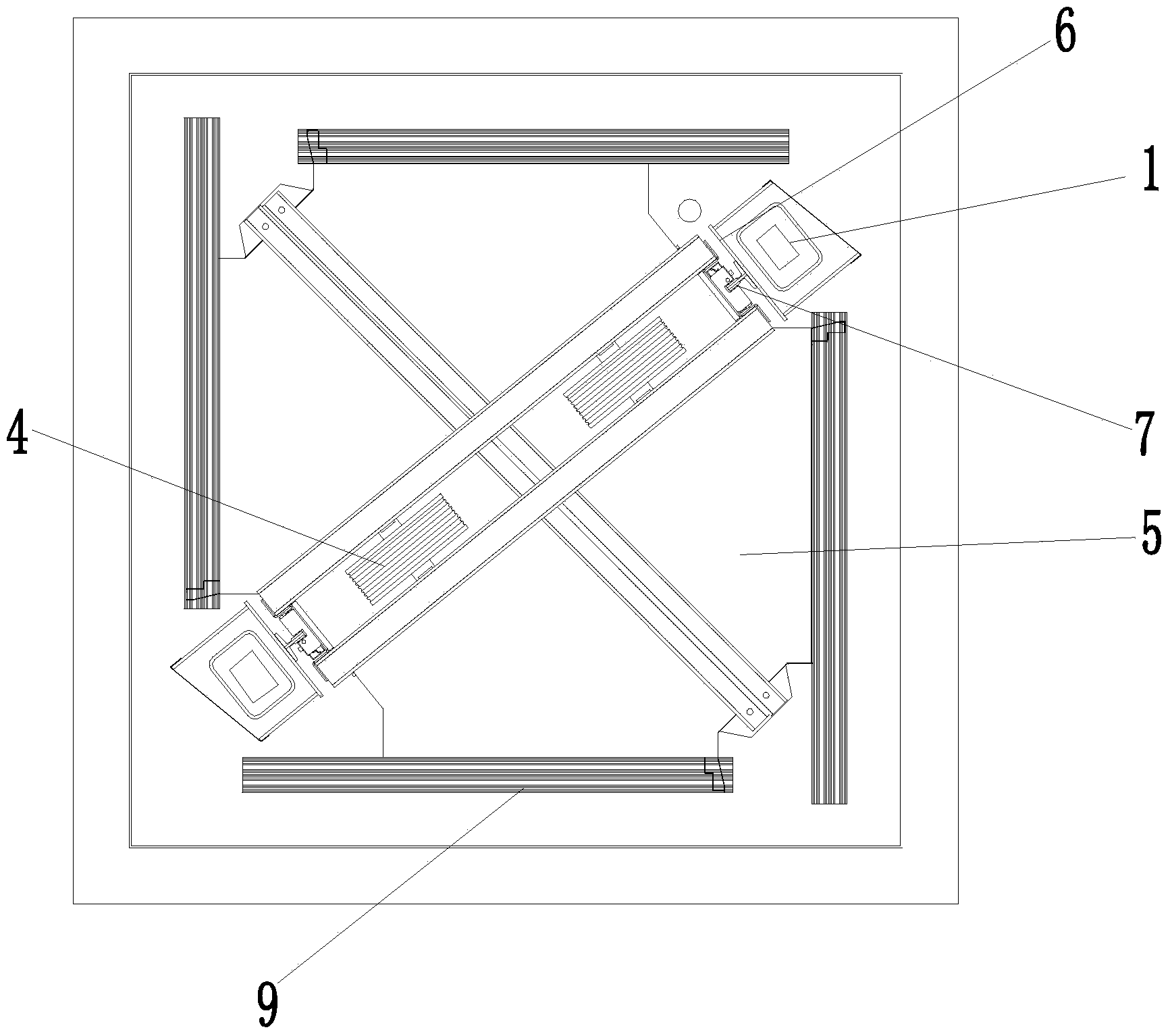

PendingCN107914149AIncreased flexural section modulusHigh tensile strengthLarge fixed membersEngineeringMachine tool

The invention discloses a lightweight high-rigidity gantry machining center machine base. The lightweight high-rigidity gantry machining center machine base comprises a machine base body. A base is composed of two downwards parallel base plates. The two base plates are connected and fixed through a strengthening rib. The strengthening rib is in an inverted-W shape. The sharp ends of the triangularshapes of the two sides of the upper end of the strengthening rib penetrate the top base plate, top sliding rails are arranged on the tops of the sharp ends of the triangular shapes of the strengthening rib, and the three end portions of the lower end of the strengthening rib are connected and fixed to the base plate on the lower side. The lower parts of double guide rails of the base are supported by the inverted-W-shaped strengthening rib, and the weight of a movable component workbench on the guide rails and machined workpieces is scattered through the strengthening rib, the supporting area and range are set from small to large, the interior of the base is supported by the multiple triangles likely, the casting stress of castings is reduced to be minimum, the residual stress of the castings is eliminated through annealing and the rest of precipitation heat treatment, and the stability during machine tool movement is greatly improved; and meanwhile, the material cost is saved, and meanwhile rigidity is improved.

Owner:湖南巨人机床集团有限公司

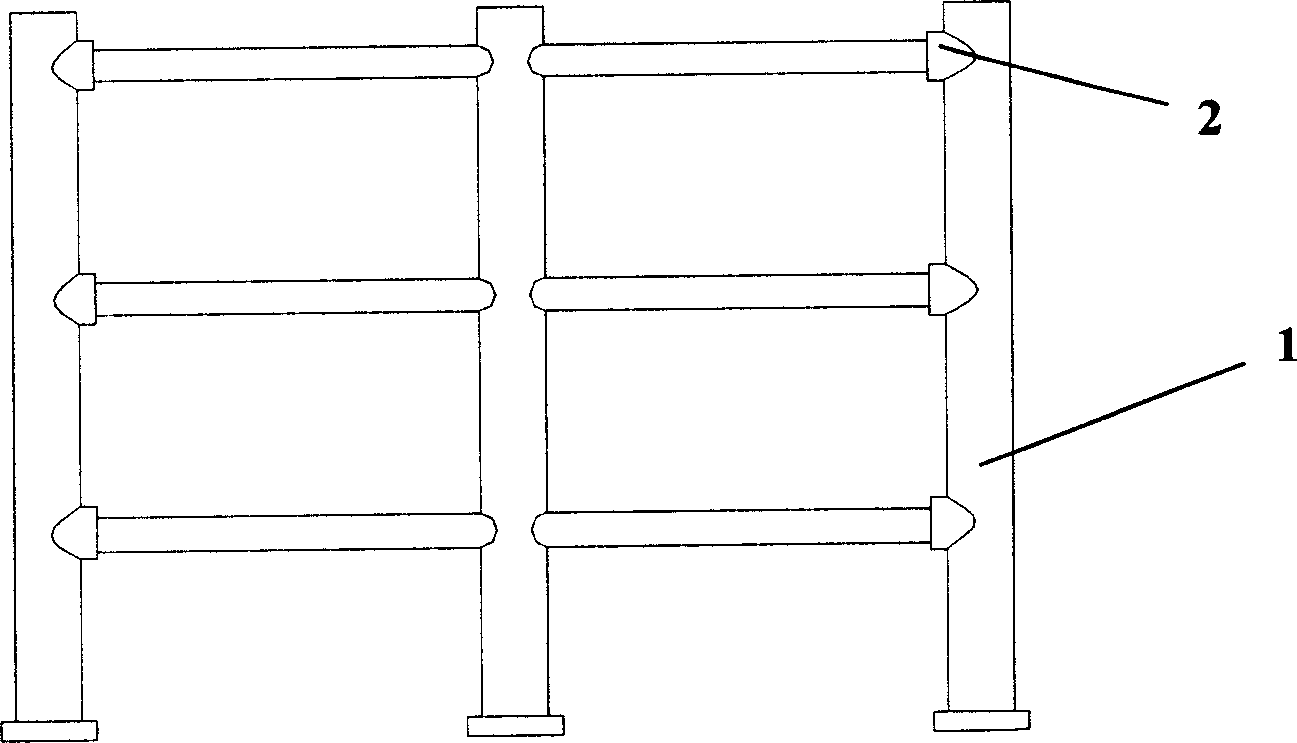

Improved CD rack

InactiveCN1866383AIncreased flexural section modulusImprove bending resistanceApparatus modification to store record carriersFlat record carrier containersSteel tubeCorrosion prevention

The improved CD frame comprises at three vertical stainless-steel tubular elements with horizontal connection members connected. Wherein, it arranges reinforced fiber plastic tube in every stainless steel tube connected together. This invention has simple structure, light weight, and pretty view fit to corrosion prevention.

Owner:上海温兴生物工程有限公司

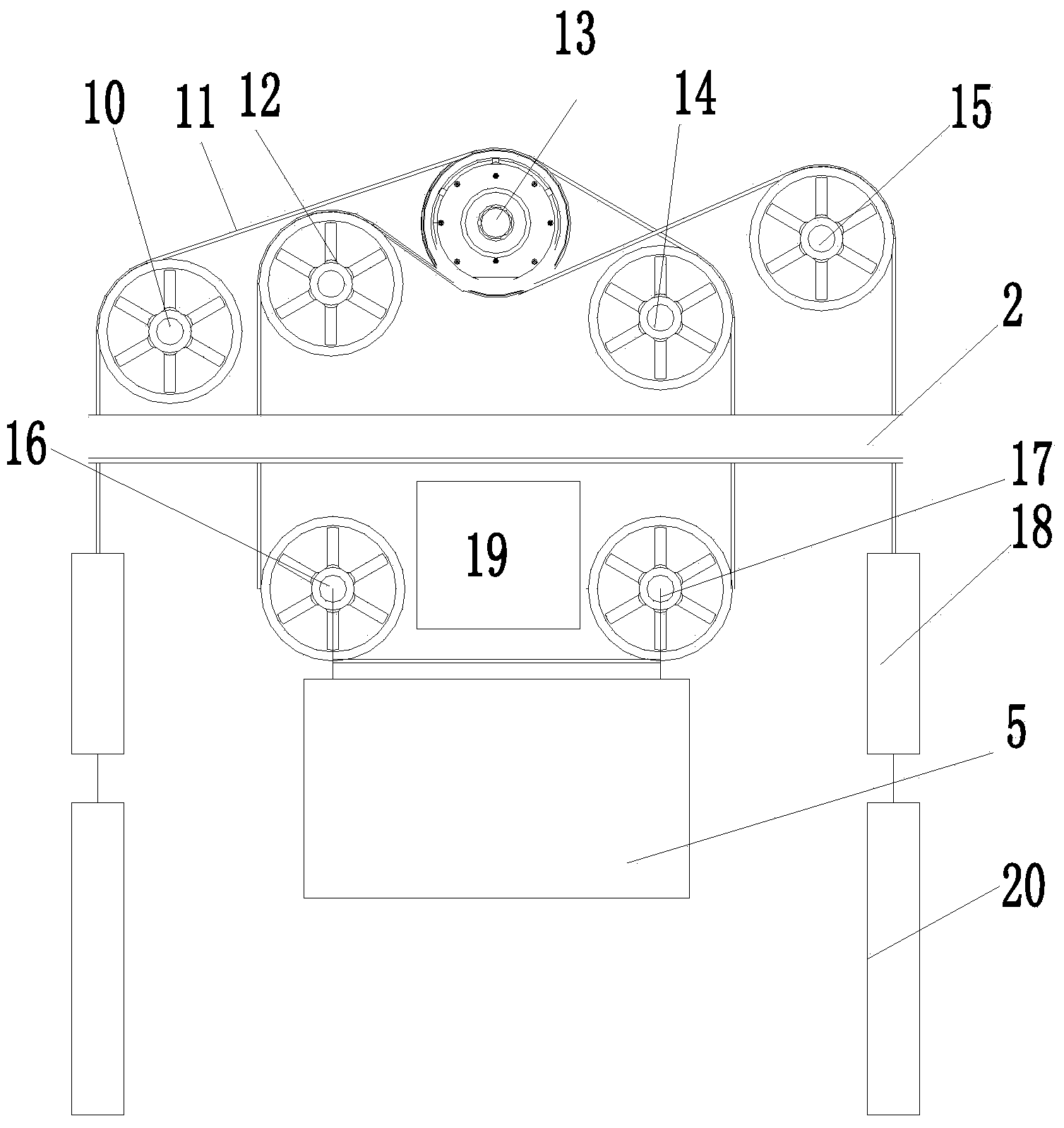

Multifunctional cable towing machine and towboat having the same

InactiveCN101249877BAlleviate technical problems of space tensionReduce manufacturing costTowing/pushing equipmentBasementIndependent function

The invention discloses a multifunctional towing winch and a towing ship with the multifunctional towing winch, which comprises a frame, a cylinder, ropes and a brake apparatus arranged on the cylinder, a motor, a speed reducing apparatus and a clutch, wherein a basement for installing tow hooks is arranged on one side of the towing winch frame near the stern, the tow hooks are arranged at the upper end of the clutch. As integrating various independent functions of equipments of the prior arts to a towing winch, the multifunctional towing winch not only saves production cost, but also resolvesthe technical problem of narrow space of the towing ship and increases the economic beneficial.

Owner:中诚国际海洋工程勘察设计有限公司

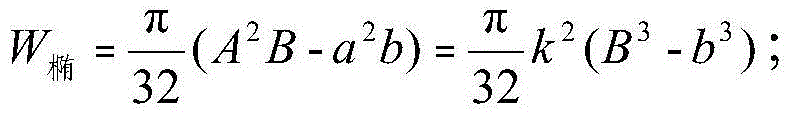

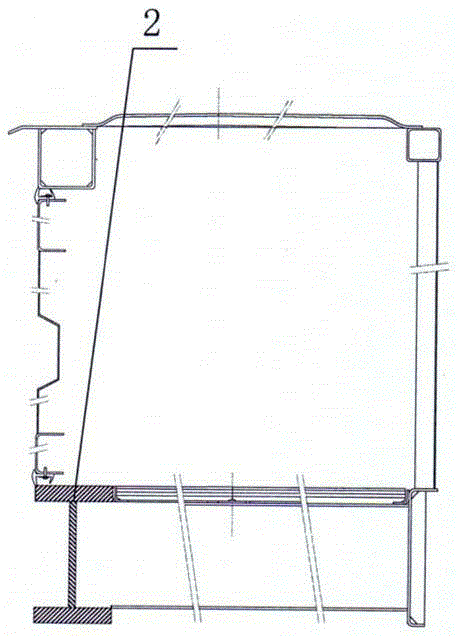

High-rigidity semitrailer axle body

InactiveCN103625212AGuaranteed versatilityShorten the lengthAxle unitsSection modulusAutomotive engineering

The invention relates to a high-rigidity semitrailer axle body and belongs to the field of automobile axles. The high-rigidity semitrailer axle body comprises a plate spring seat assembling plane, a perpendicular plane and a lower plane, wherein the perpendicular plane is adjacent to the plate spring seat assembling plane and the lower plane is opposite to the plate spring seat assembling plane. The high-rigidity semitrailer axle body is characterized in that a specially-shaped structure is formed by combining the perpendicular plane with the lower plane. Through changes of the shape of the cross section of the axle body, the section modulus in bending of the axle body is improved, and therefore the rigidity of the axle body is improved, but the height of a whole semitrailer will not be changed along with the changes of the shape. Existing parts can serve as most connection parts needed by assembling of a suspension system and an axle. The high-rigidity semitrailer axle body is easy to machine and produce.

Owner:SHANDONG SPECIAL INDUSTRY GROUP CO LTD

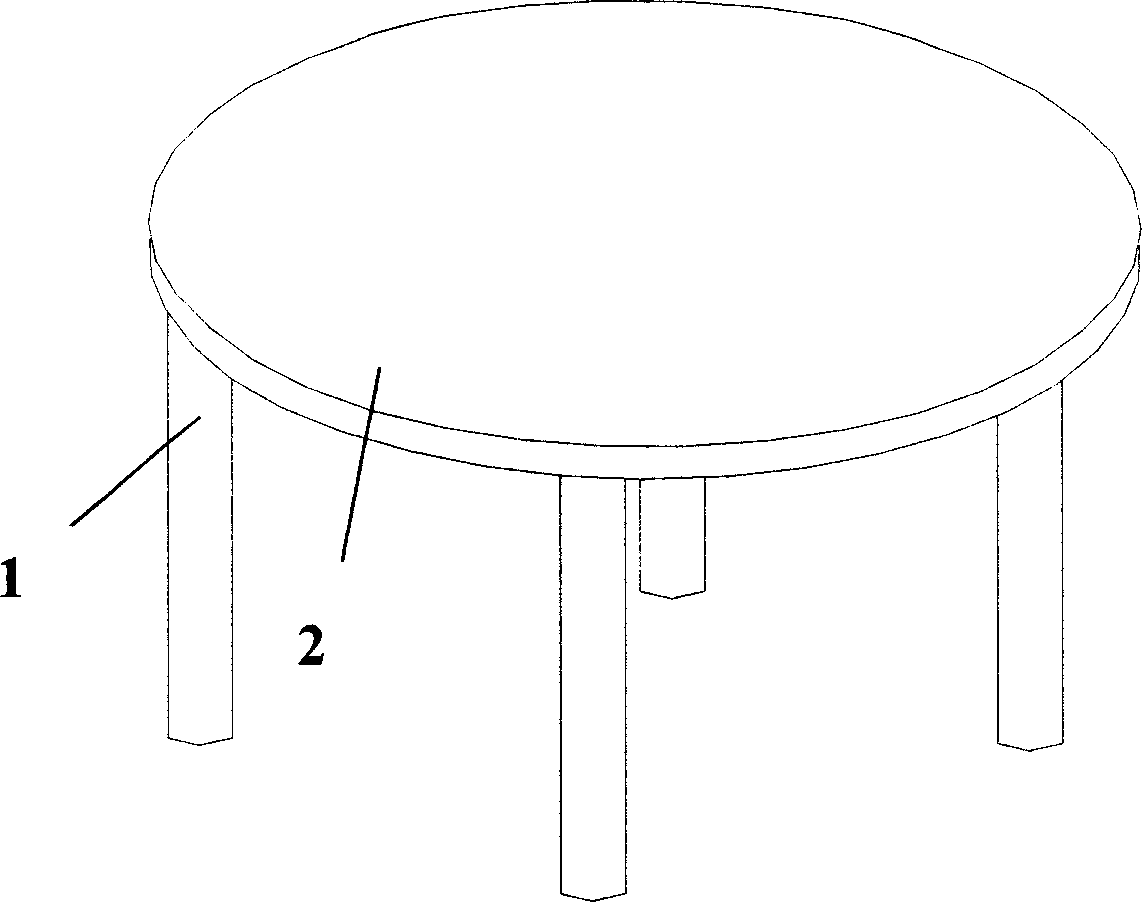

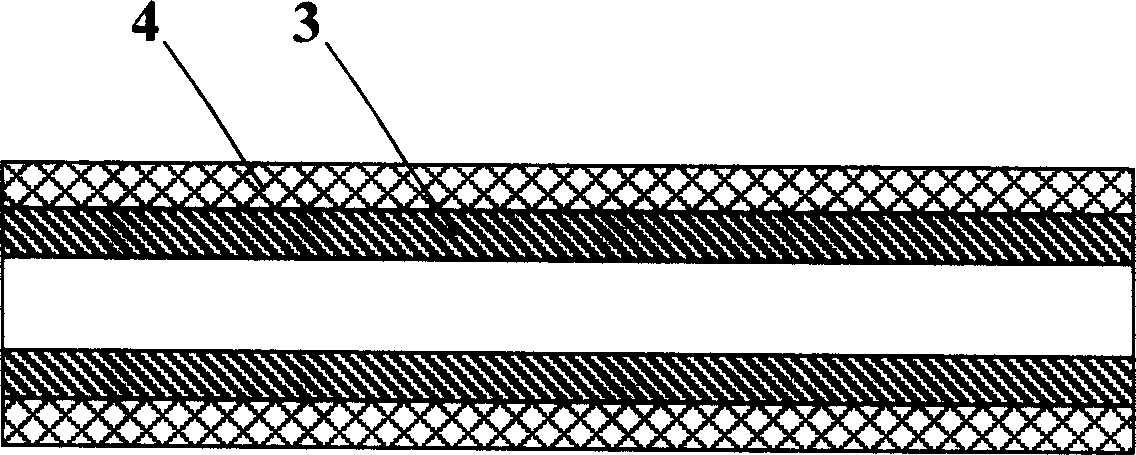

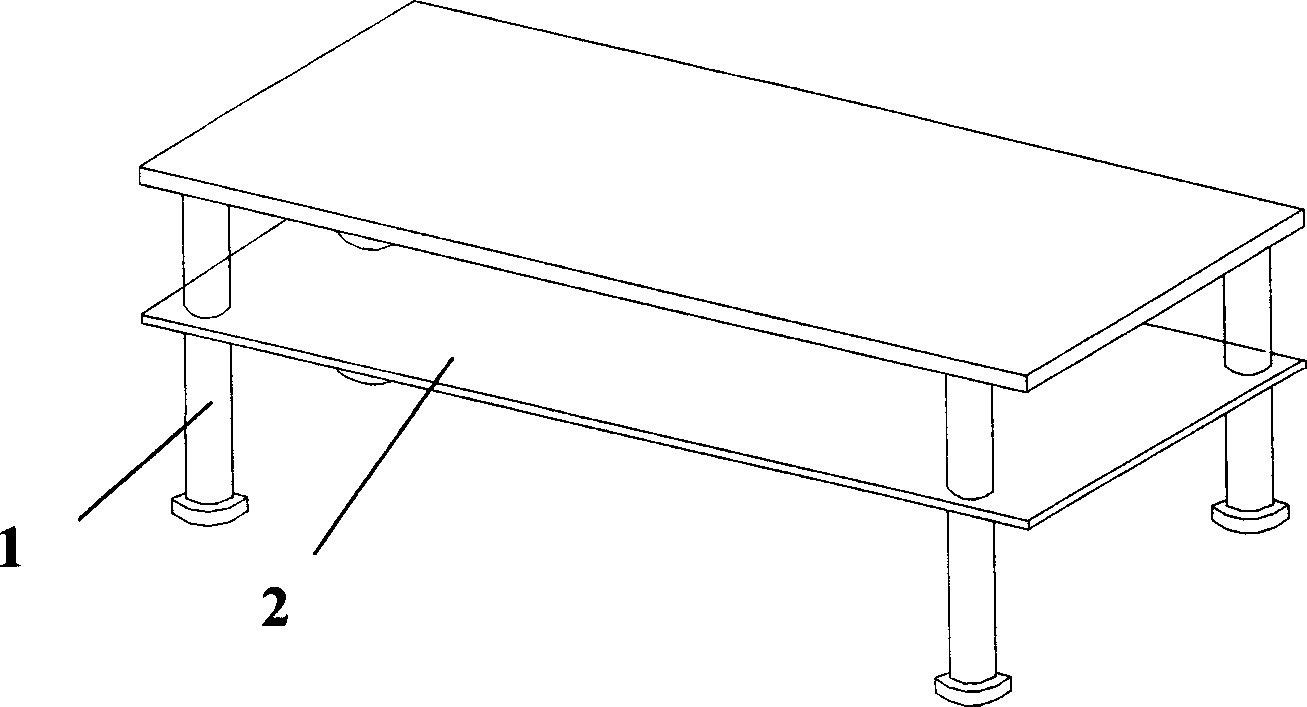

Improved structure of table

An improved structure of table is composed of at least three tubular members and a table top arranged on the tops of said tubular members. Each tubular member consists of a stainless steel tube and a fiber reinforced plastic tube fixed tightly in said stainless steel tube.

Owner:上海温兴生物工程有限公司

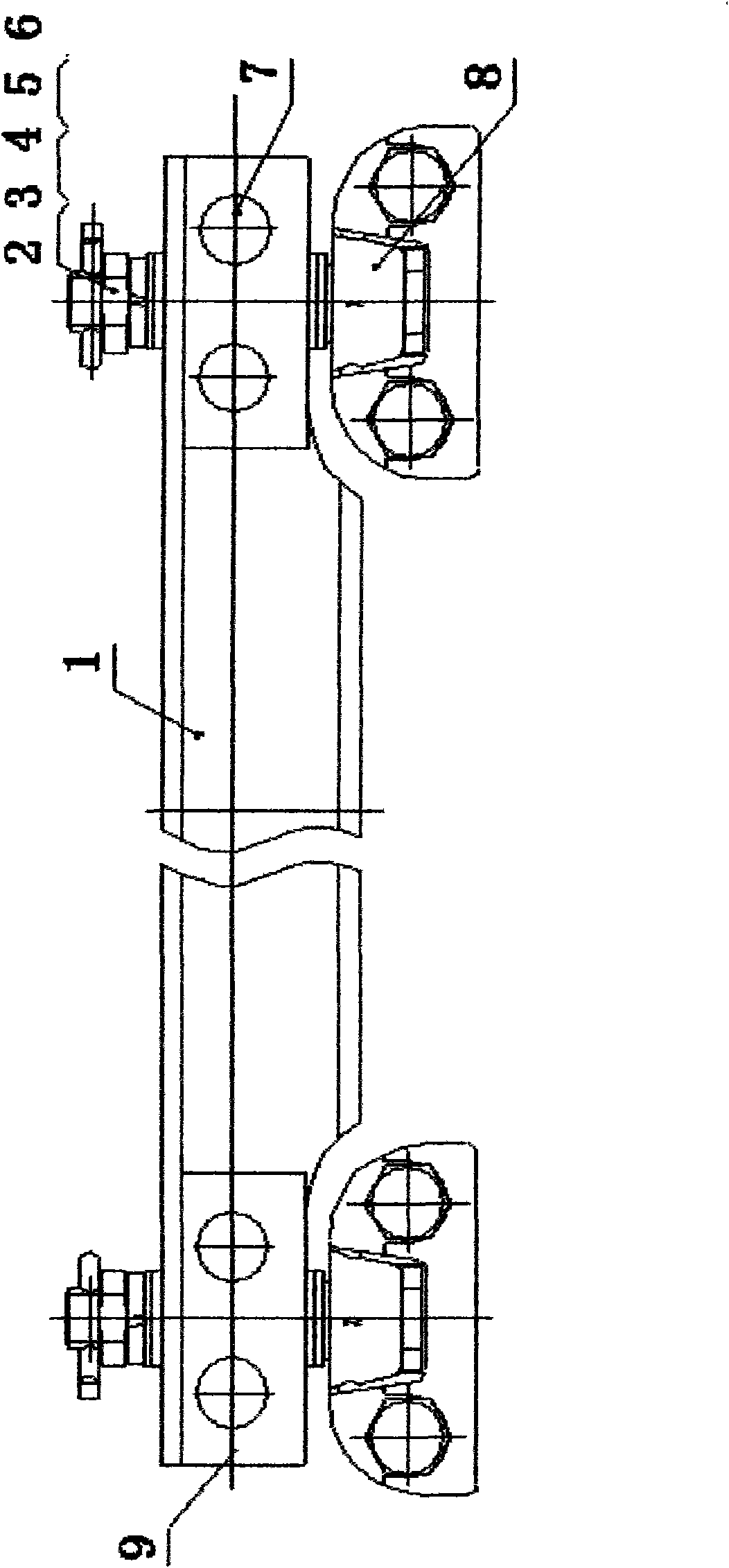

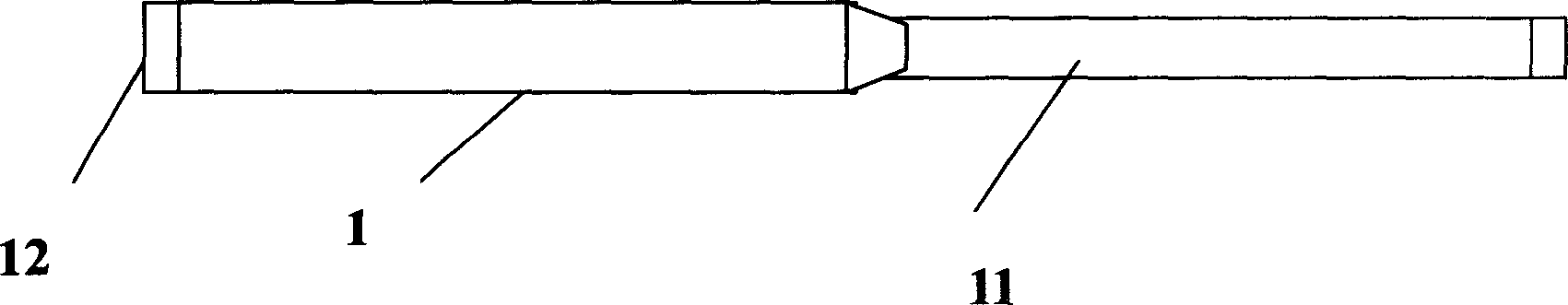

Crossover

The invention belongs to a crossover applied to two intersecting contact wires in an electrified railway contact system, which is characterized in that aluminum alloy plates (9) are embedded at two ends of a groove-shaped crossover body (1) and riveted together by rivets (7). The crossover has light weight and large anti-bending section modulus, low possibility of bending and deformation under force and no resistance against contact wire movement, and the phenomena like pantograph scratch and pantograph drilling which influence transportation safety are avoided.

Owner:周建科

Improved hanger for curtain of bath-room

An improved hanger for hanging a bath curtain between two opposite wall in bathroom is composed of a first tubular member with a rubber pad at its one end and consisting of an external stainless steel tube and an external reinforcing plastic tube with internal spiral threads, and a second tubular member with internal spiral threads for coupling with said reinforcing plastic tube and a rubber pad at its another end.

Owner:上海温兴生物工程有限公司

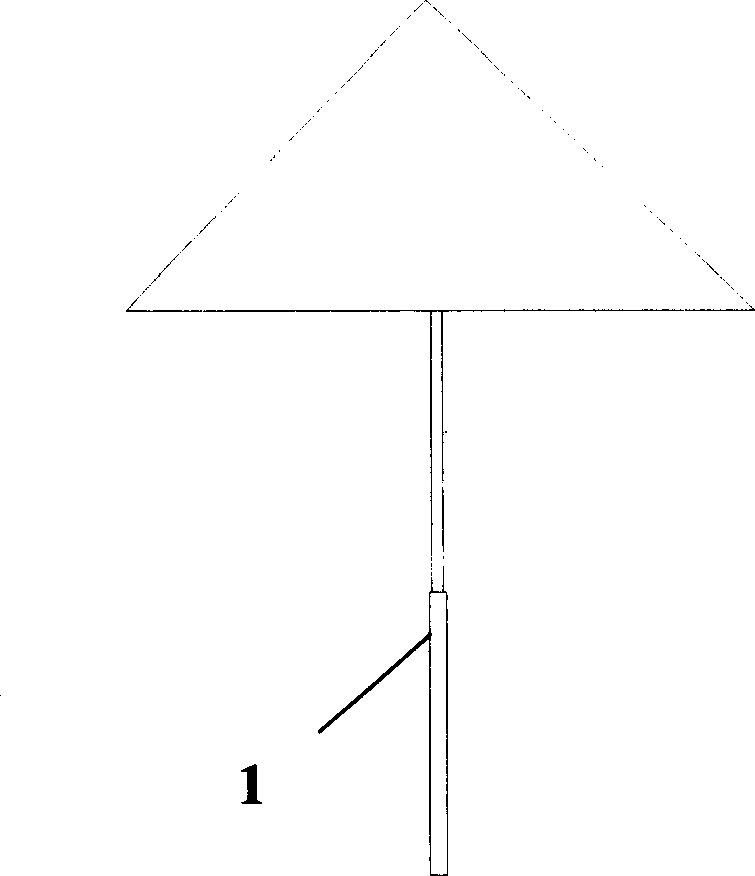

A sun-shade umbrella structure

The sunshade structure has at least one tubular member, and the tubular member comprises composite tubes, each of which consists of a stainless steel tube and a fiber reinforced plastic tube fixed inside the stainless steel tube. The present invention has simple structure, light weight, great strength, good appearance and high corrosion resistance.

Owner:上海温兴生物工程有限公司

Safety window

InactiveCN1854451AImprove bending resistanceImprove shock absorptionFixed grillesFiberUltimate tensile strength

A guard window is composed by at least three connecting tubes which are all made by an enhanced fiber plastic inner tube and a stainless steel outer tube fixed together. The three connecting tubes are fixed together.

Owner:上海温兴生物工程有限公司

Sugarcane tearing machine cutter

InactiveCN110283946AImprove stress stabilityHigh bonding strengthSugar raw material preprocessing knivesSugarcane shreddingWear resistantButt joint

The invention relates to the technical field of sugar industry, and provides a sugarcane tearing machine cutter. The cutter comprises a cutter head, a matrix and a forked tail portion which are siamesed, whose thicknesses are the same, and whose end portions are in flush butt joint, wherein the side face of the matrix is an oblique quadrangle with substantially-equal opposite sides; the cutter head is gradually narrowed, and the arc of the tail portion, far away from the matrix, of the cutter head forms an arc end face through transition; particularly, the middle of the tail portion of the cutter head is longitudinally provided with a slotting; the slotting is internally embedded with a wear-resistant alloy block; the width of the slotting is 1 / 3 to 5 / 6 of the thickness of the cutter head; the distance from the midpoint of the arc end face to the slotting end is greater than the thickness of the cutter head; the thickness of the alloy block is adapted to the slotting; the bottom face of the alloy block directly faces the bottom slot face of the slotting, and the side connecting faces of the alloy block are respectively abut to the side slot faces of the slotting; the other faces of the alloy block are crushing working surfaces which are 0 to 10 mm higher than the surface of the corresponding position of the cutter head; optimally, an auxiliary working surface, on the outer side of the slotting, of the cutter head is firmly adhered to a wear-resistant alloy layer with the thickness of less than 2 mm. The cutter provided by the invention has the characteristics of good wear resistance and impact resistance, and the service life of the tearing machine cutter can be prolonged.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Automotive bumper

InactiveCN1853987AImprove bending resistanceBeautiful appearanceLayered productsBumpersFiberSteel tube

A bumper of car is composed of at least curved tubular member made of the stainless steel tube reinforced by the fiber-plastic tube fixed in said stainless steel tube. Its advantages are high strength, light weight and beautiful appearance.

Owner:上海温兴生物工程有限公司

An electrolytic plate with embossed leveling and enhanced rigidity and its preparation method

ActiveCN104328459BIncreased flexural section modulusImprove rigidityElectrodesElectrolysisChinese characters

The invention relates to an embossed flattened rigidity-reinforced electrolytic electrode plate and a preparation method thereof, the electrolytic electrode plate comprises an electrode plate, an embossed groove is arranged on the surface of the electrode plate, and forms a concave convex pattern to improve the electrode plate surface strength and bending resistant ability. The embossed groove is composed of a plurality of transverse embossed grooves and oblique embossed grooves to form a structure shaped like a Chinese character mi, and raised structure composed of an upper triangular convex block and a lower triangular convex block is formed on the electrode plate. The beneficial effects of the embossed flattened rigidity-reinforced electrolytic electrode plate are that: aiming at the electrode plates of different types, reinforced stripes with different specifications and different shapes are designed, through embossing and shaping of the reinforced stripes, the electrode plate rigidity is greatly enhanced, the internal stress is eliminated, the objective of improving the electrode plate surface flatness, reducing the bending deformation, and enhancing the electrode plate bending resistant ability can be achieved, anode and cathode short circuit phenomenon in the process of electrolysis due to deformation can be avoided, the power consumption in the electrolysis or plating process can be effectively reduced, at the same time, cathode product quality is improved, the labor intensity is reduced, and production efficiency is improved.

Owner:HANGZHOU EMPEROR LOSSEN TECH

Tea table made of plastic stainless-steel composite-tubes

A tea table with composite stainless steel-plastic tubes is composed of at least three tubular members and a table top arranged on the tops of said tubular members. Each tubular member consists of a stainless steel tube and a fiber reinforced plastic tube fixed tightly in said stainless steel tube.

Owner:上海温兴生物工程有限公司

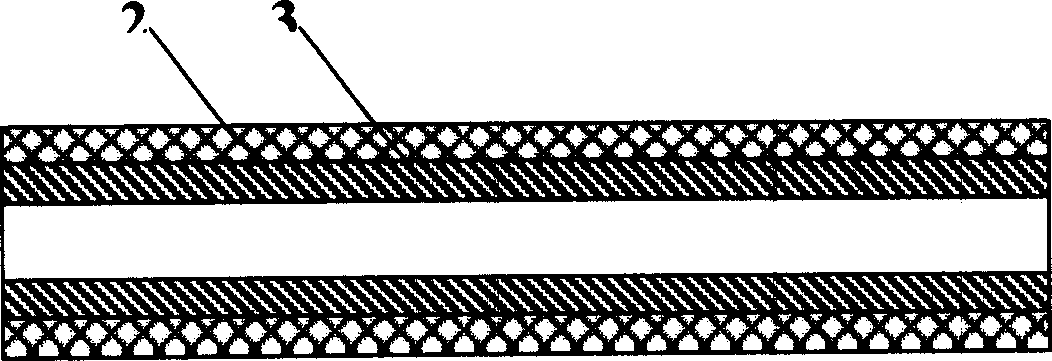

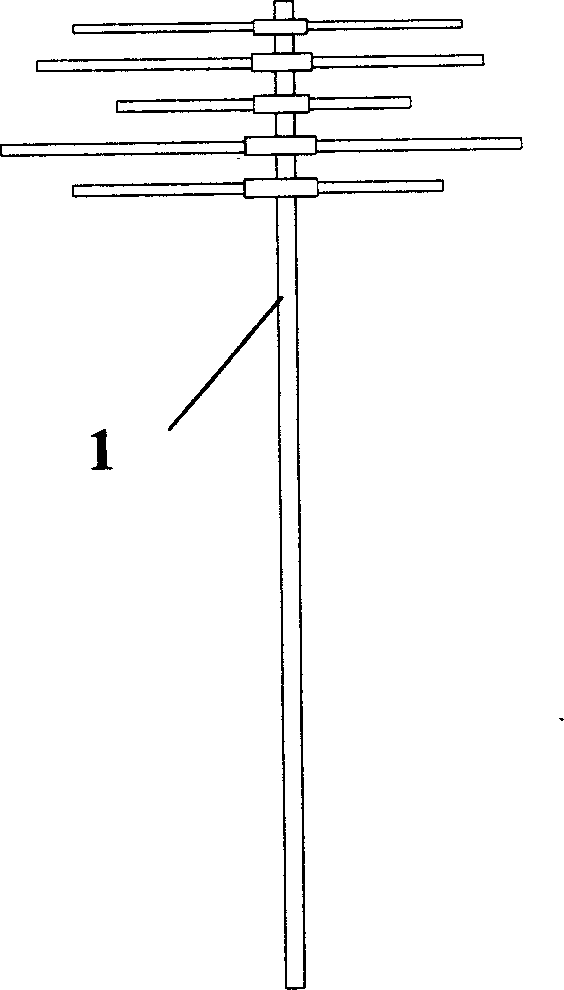

TV antenna structure

InactiveCN1855627AIncreased flexural section modulusImprove bending resistanceAntennasSteel tubeEngineering

A TV antenna structure comprises more than one tube like components, which are connected together in a securing state. Wherein each said tube is made of stainless steel, and inside each said tube there is a fiber-reinforced plastic pipe having a diameter matching the diameter of said stainless steel tube. Said stainless steel tube and the said fiber-reinforced plastic pip are jointed together in a securing state.

Owner:上海温兴生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com