Patents

Literature

272results about How to "Guaranteed repair effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mortar for concrete base surface repair, and preparation method thereof

The present invention belongs to a building mortar, and particularly relates to a mortar for concrete base surface repair, and a preparation method thereof. The mortar comprises the following raw materials by mass: 20-80 parts of silicate cement, 20-100 parts of sulphoaluminate cement, 80-190 parts of aggregate, 40-100 parts of a mineral admixture, 30-80 parts of an aqueous epoxy emulsion, 0.2-0.5 part of cellulose ether, 0.1-0.5 part of anti-cracking fibers, and 20-85 parts of water. The mortar of the present invention has characteristics of strong adhesion, excellent cracking resistance, excellent compression resistance, high bonding strength, and low price.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

Cadmium (Cd) passivator for acid soil and application thereof

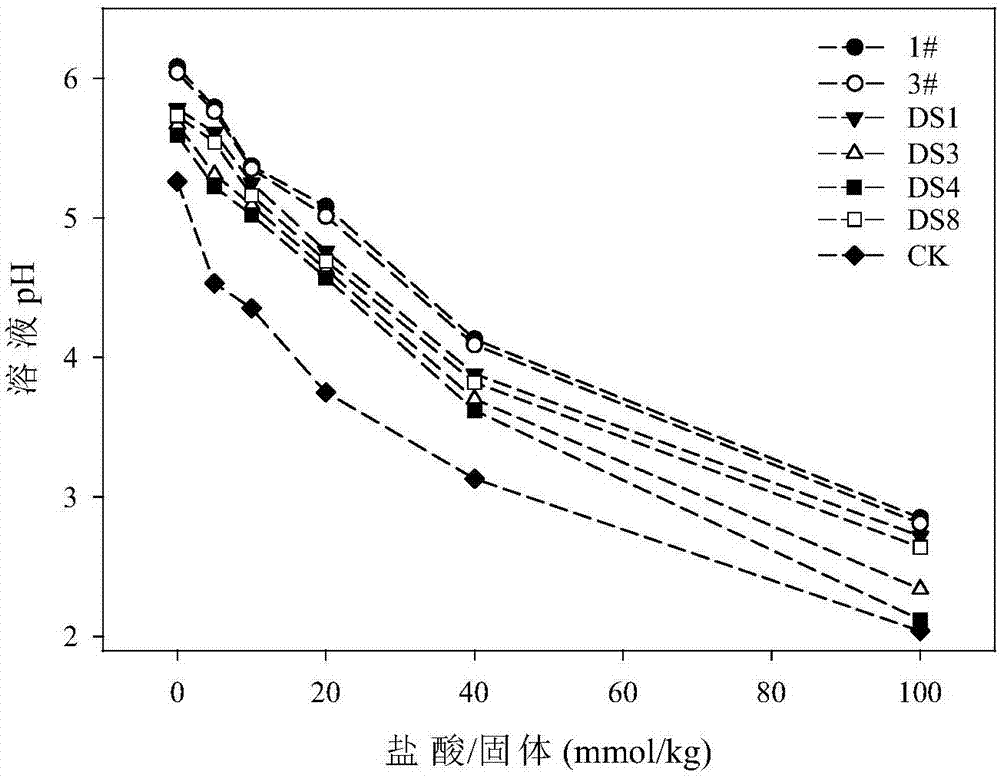

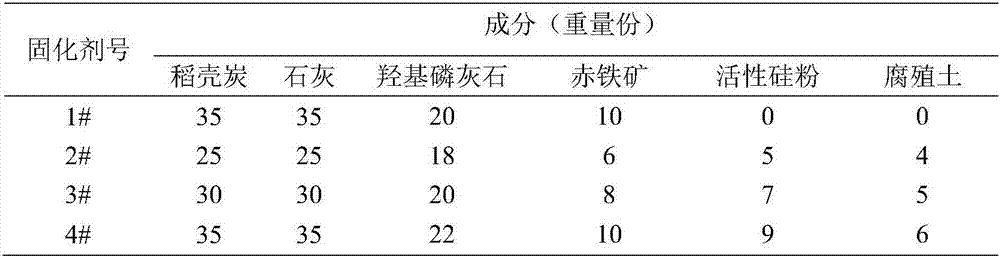

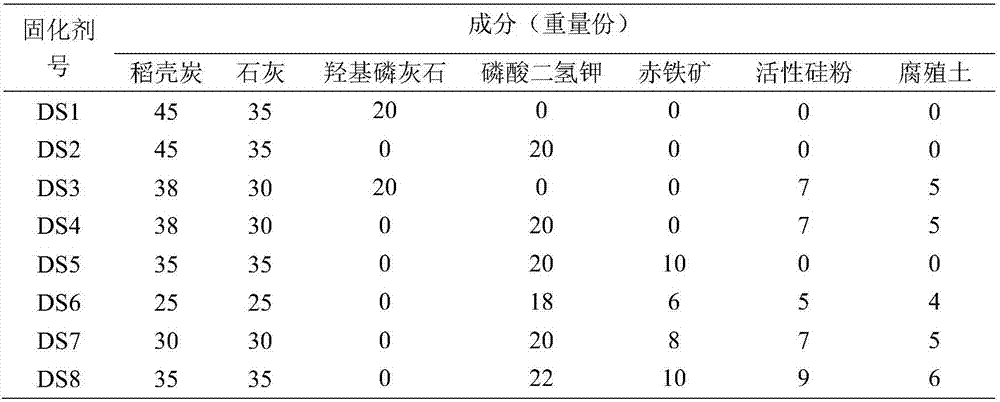

ActiveCN107446589ARaise the pHReduce absorptionAgriculture tools and machinesOther chemical processesEthylic acidBinding state

The invention discloses a cadmium (Cd) passivator for acid soil. The Cd passivator is prepared from the following components of rice hull charcoal, lime, hydroxyapatite and hematite. The Cd passivator for the acid soil, which is provided by the invention, can be used for improving the pH (potential of Hydrogen) of soil and decreasing the content of CaCl2 and ethylic acid extraction state Cd, and is used for promoting the conversion of Cd in the soil from a bioavailable state (an ion exchange state) to a potential available state (a carbonate binding state and a ferromanganese oxide binding state) and an unavailable state (a residue state), reaching the purpose of passivating the activity of the Cd, effectively restoring Cd polluted acid soil, promoting the growth of a plant and decreasing the absorption to the Cd of a crop.

Owner:JIANGXI JIEDI ENVIRONMENTAL TREATMENT & ECOLOGICAL TECH CO LTD

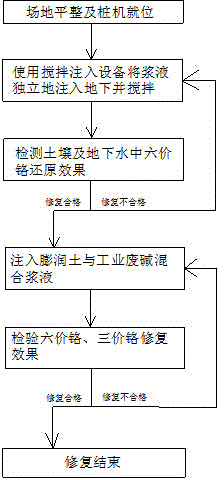

Remediation method for hexavalent chromium polluted soil and underground water

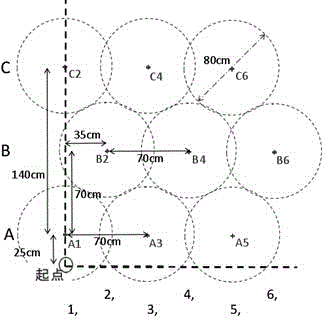

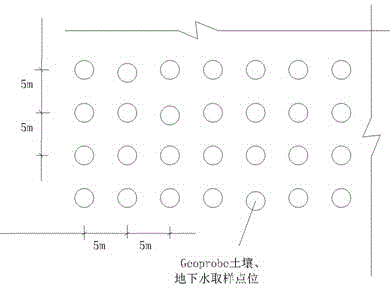

ActiveCN104624632AComplete restorationEfficient removalWater contaminantsContaminated soil reclamationSodium BentoniteInjection equipment

The invention discloses a remediation method for hexavalent chromium polluted soil and underground water. The remediation method comprises the following steps: step (10): putting a pile machine in place; step (20): independently injecting acidified bentonite slurry loaded with active carbon powder and bentonite slurry loaded with zero-valent iron powder into the ground by using stirring and injection equipment and stirring; step (30): detecting the reduction effect of hexavalent chromium in the soil and the underground water; step (40): injecting bentonite and industrial waste alkali mixed slurry; and step (50): detecting the remediation effect of hexavalent chromium and trivalent chromium. By virtue of the remediation method, remediation chemicals can be in direct and sufficient contact with the soil and the underground water to react, so that the hexavalent chromium in the soil and the underground water can be completely reduced; meanwhile, an indissolvable stable compound is formed by the trivalent chromium and the useless loss of the remediation chemicals can be reduced; the potential of hydrogen of a stratum is balanced; and the remediation method is suitable for the large-area hexavalent chromium polluted stratums different in potential of hydrogen and moisture content.

Owner:SOUTHEAST UNIV

Method for remedying contaminated site through combination of nanoscale zero-valent iron and reducing microorganisms

ActiveCN104801540AAvoid reunionPromote degradationContaminated soil reclamationSite RemediationsInjection well

The invention relates to a contaminated site remediation method, in particular to utilization of nanoscale zero-valent iron particles and orthotopic injection of microbial bacteria in a site, namely, a contaminated site remediation technology adopting nanoscale zero-valent iron and a microorganism remediation technology. The method for remedying the contaminated site through combination of the nanoscale zero-valent iron and reducing microorganisms comprises steps as follows: a nanoscale zero-valent iron injection is injected to contaminated soil through an injection well, and the nanoscale zero-valent iron in the injection is coated with an organic polymer coating layer. The method is characterized in that after the nanoscale zero-valent iron injection coated with the organic polymer coating layer is injected and the nanoscale zero-valent iron in the injection is completely oxidized, a reducing bacterium solution is injected into the contaminated soil for microorganism remediation. The organic polymer layer on the surface of the nanoscale zero-valent iron can stop agglomeration of the nanoscale zero-valent iron, can promote growth of indigenous microorganisms and accelerates pollutant degradation. According to the remediation method, the synergistic effect for the nanoscale zero-valent iron remediation technology and the microorganism remediation technology for the contaminated site remediation is realized.

Owner:山东冽泉环保工程咨询有限公司

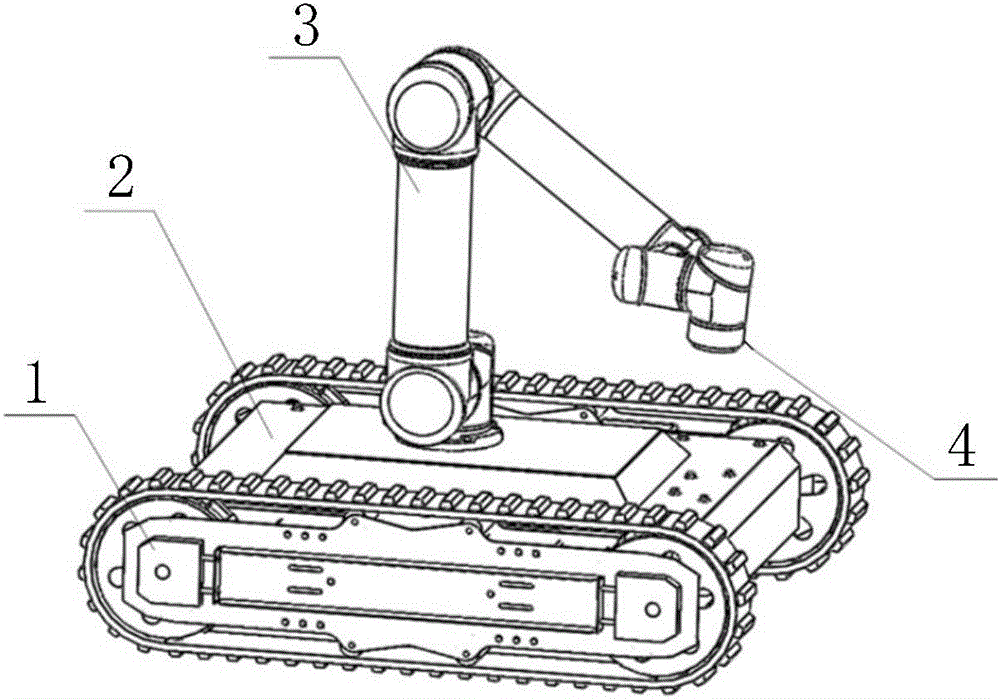

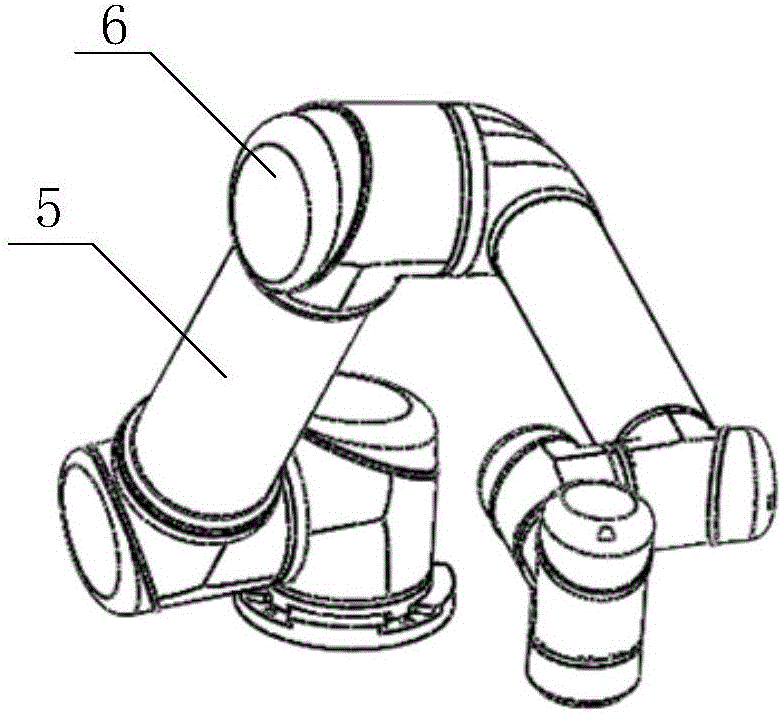

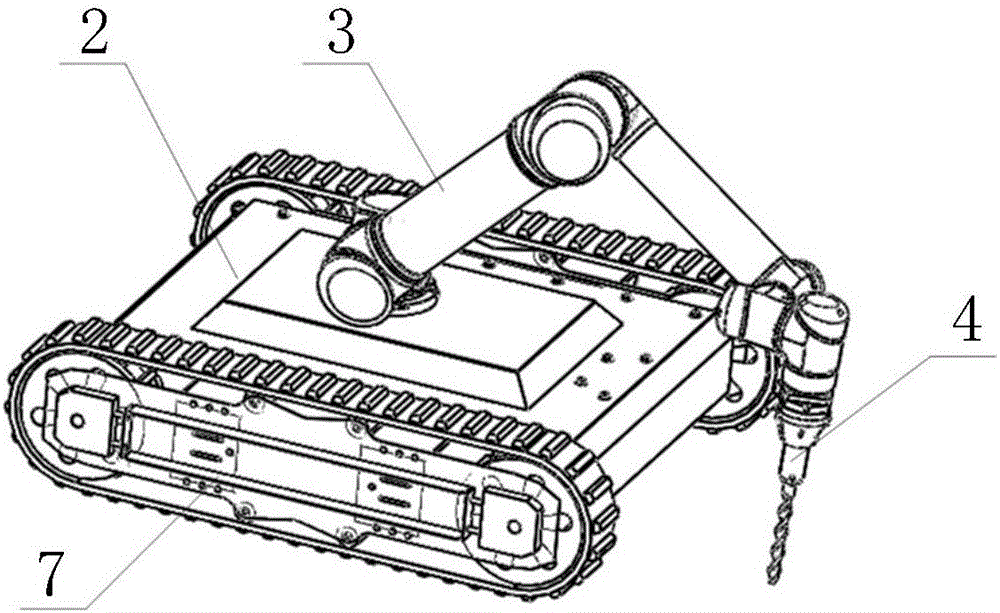

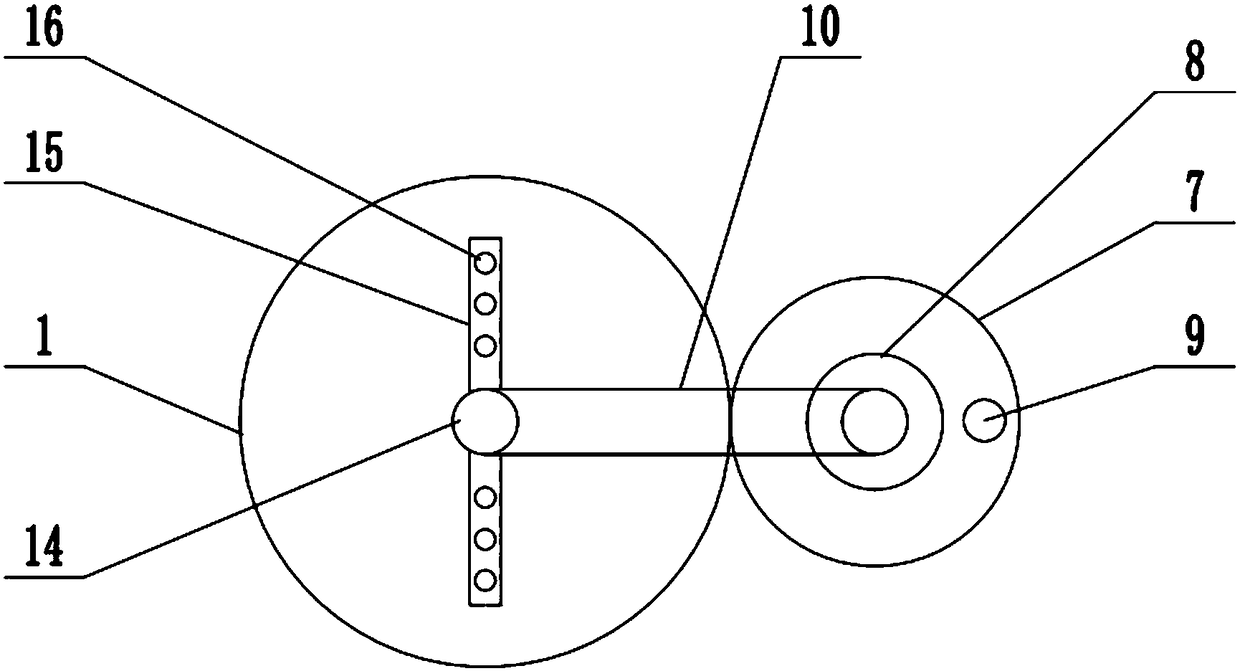

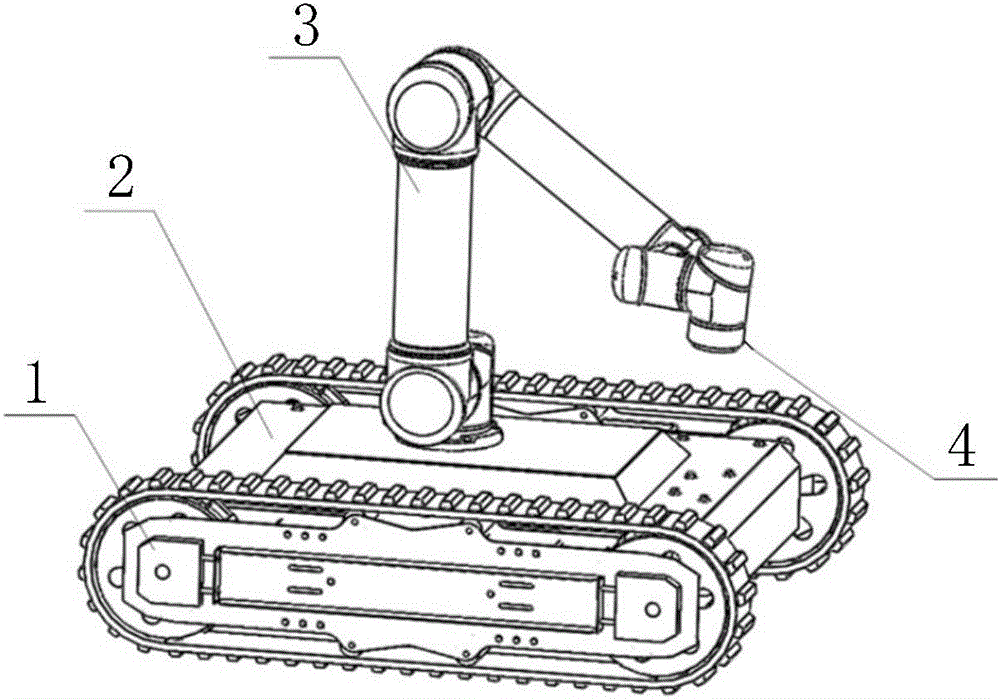

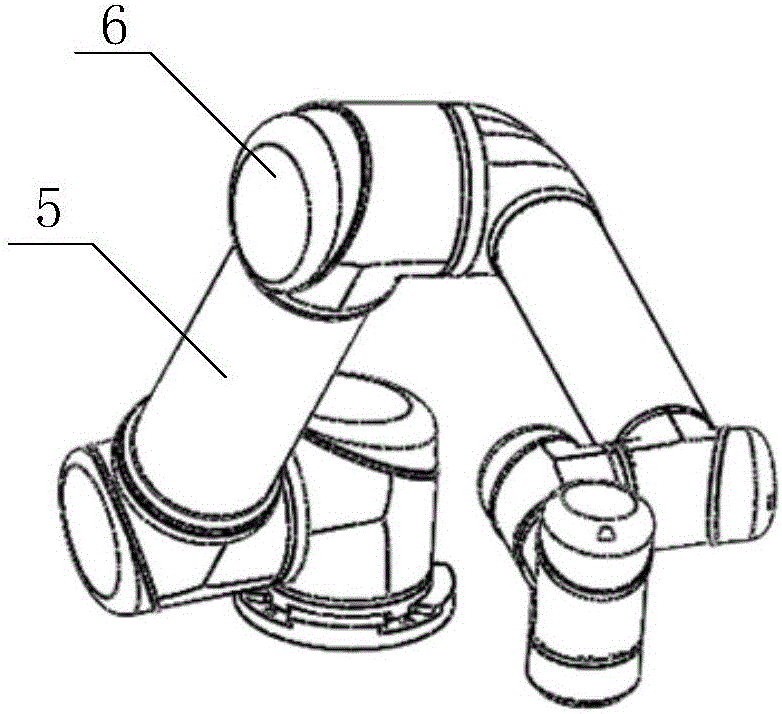

Track wheel pavement repair robot system and pavement repair method

InactiveCN106498834ASelf-healingImprove repair efficiencyRoads maintainenceEndless track vehiclesRobotic systemsControl system

The invention discloses a track wheel pavement repair robot system which comprises a robot body with a power system, wherein a mechanical arm is mounted on the robot body, and a pavement repair device is mounted on the mechanical arm; the robot body is also provided with a control system for controlling the mechanical arm; and the control system is provided with a wireless signal receiving device and electrically connected with the mechanical arm. Specifically, the pavement repair device comprises a grouting device and / or a percussion bit and / or a slotting device. The invention also discloses a pavement repair method. By adopting the robot system disclosed by the invention, intelligent repair can be realized; since only manual remote intervention is needed, the repair safety is improved to a certain degree; and the integrated modular mechanical arm can be disassembled and combined according to actual conditions, and an end repair tool is replaced, thereby improving the utilization efficiency of the modular mechanical arm.

Owner:成都圭目机器人有限公司

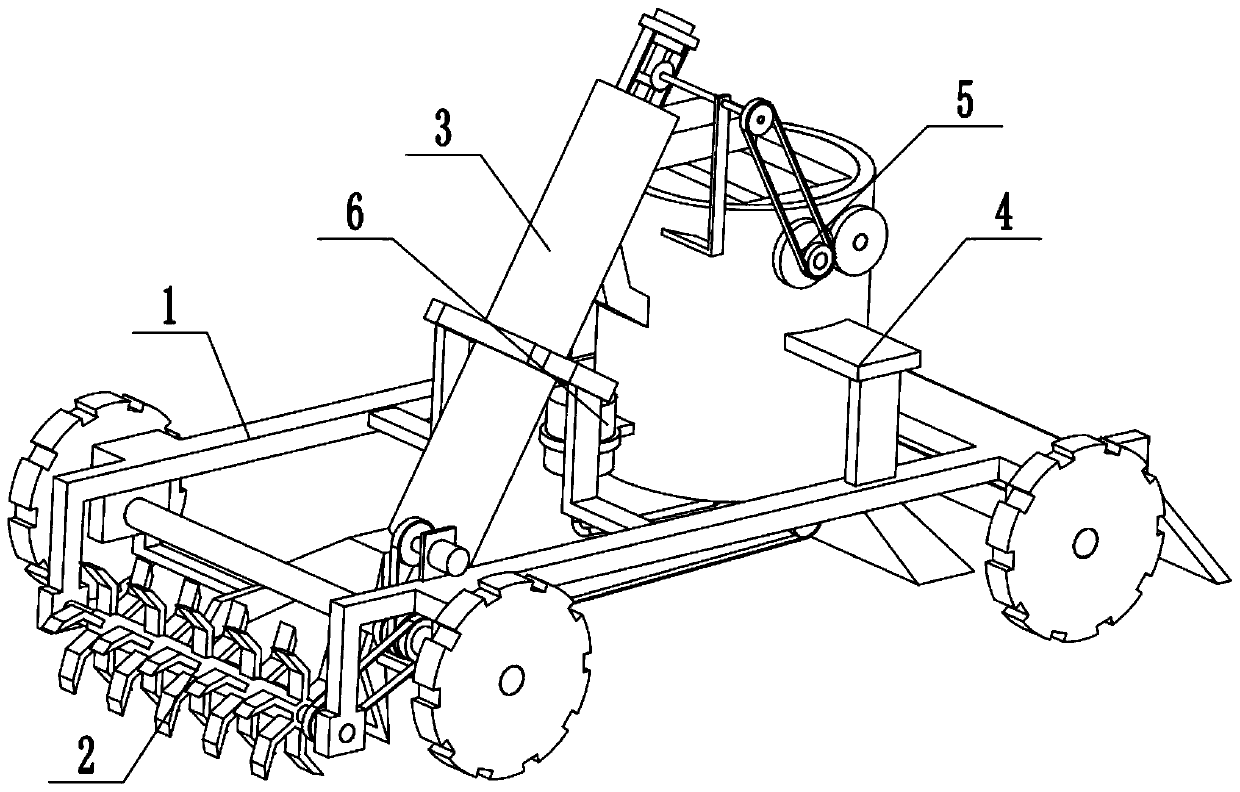

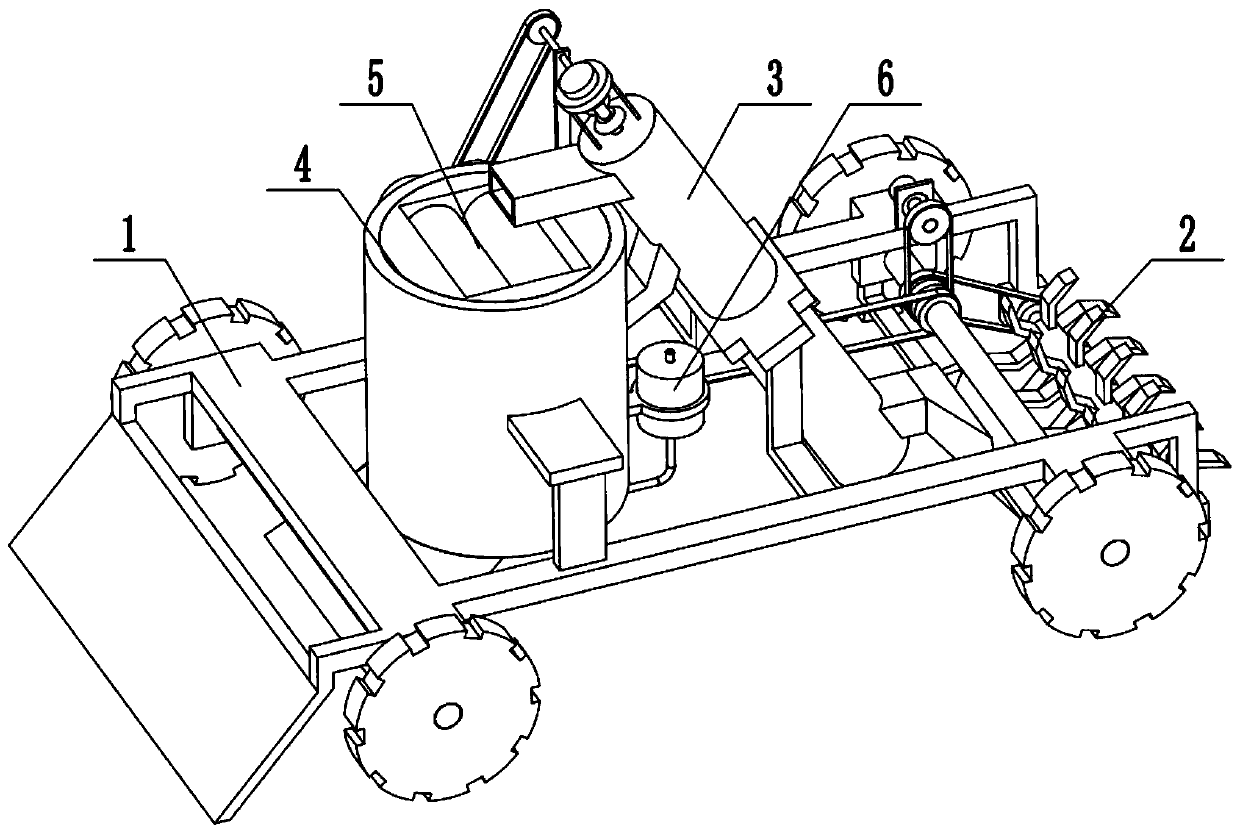

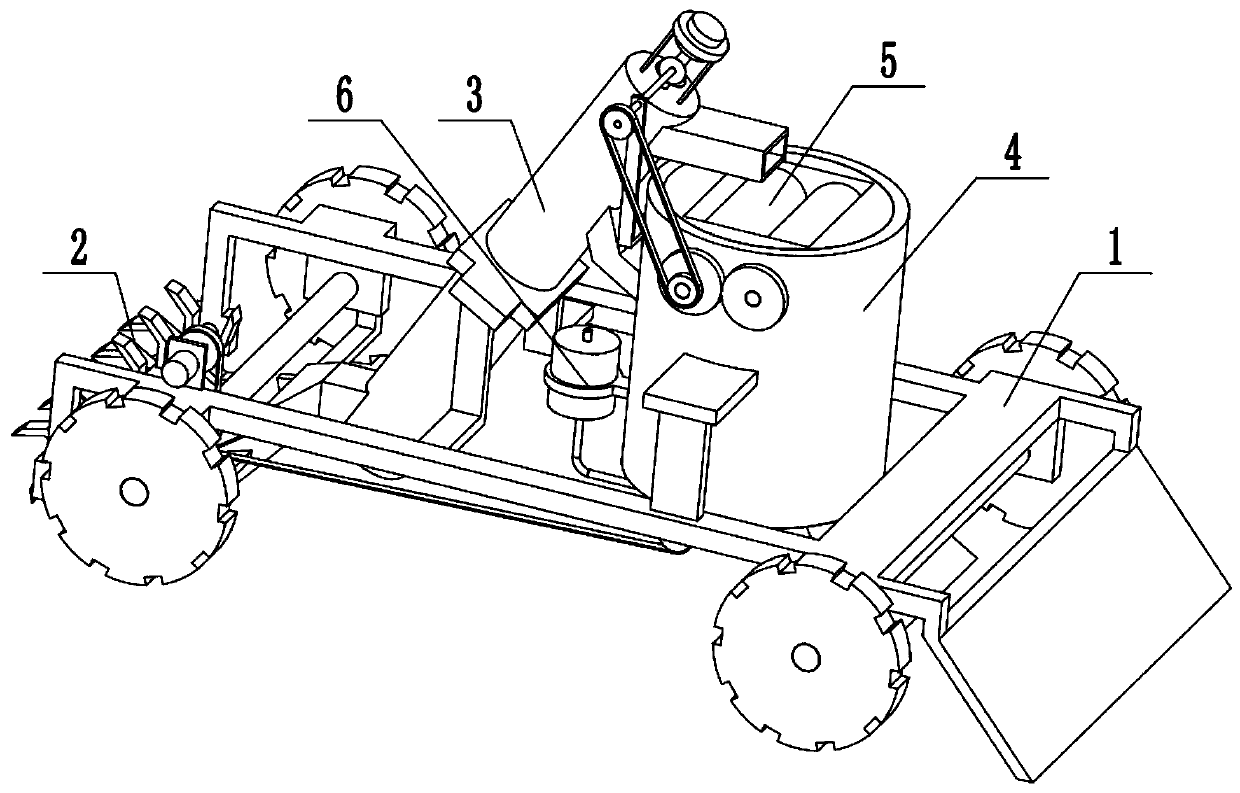

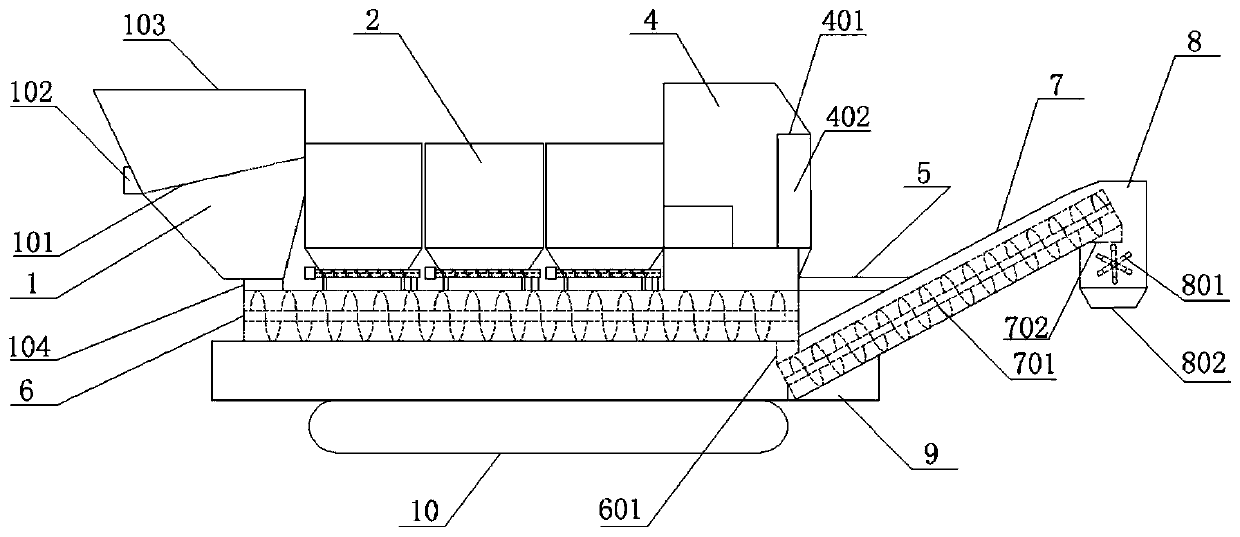

Metal contaminated soil remediation device

InactiveCN111034401AFully contactedGuaranteed repair effectSpadesSoil lifting machinesSoil scienceSoil remediation

The invention relates to the technical field of contaminated soil remediation treatment, in particular to a metal contaminated soil remediation device which comprises a movable bottom frame, a soil scarifying part, a soil collecting and conveying mechanism, a soil spraying barrel assembly, a soil block crushing mechanism and a soil spraying mechanism. The metal contaminated soil remediation devicehas the beneficial technical effects that soil blocks and crushed soil can be screened, the crushed soil makes direct contact with a spraying agent and then is discharged, large soil blocks are ground into crushed soil and then make contact with the spraying agent and then are discharged, a spray head conducts rotary spraying, full contact with soil can be performed, and the remediation effect isguaranteed. The soil scarifying part is arranged at one end of the movable bottom frame and is in transmission connection with the movable bottom frame, the soil collecting and conveying mechanism isarranged on the movable bottom frame, one end of the soil collecting and conveying mechanism is located on one side of the soil scarifying part, and the other end of the soil collecting and conveyingmechanism is located above the soil spraying barrel assembly. The soil spraying cylinder assembly is arranged at the other end of the movable bottom frame, and the soil block crushing mechanism is arranged above the soil spraying cylinder assembly.

Owner:于瑞祚

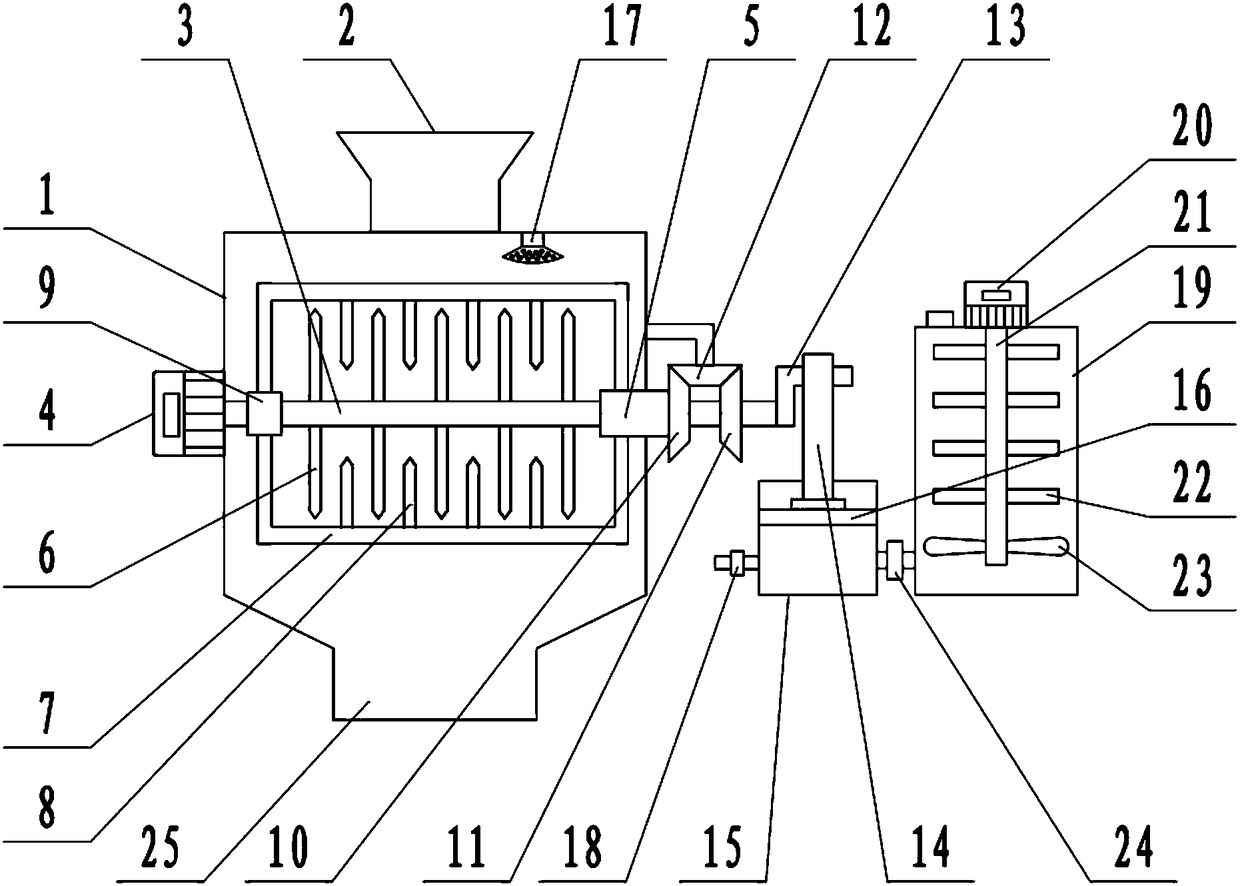

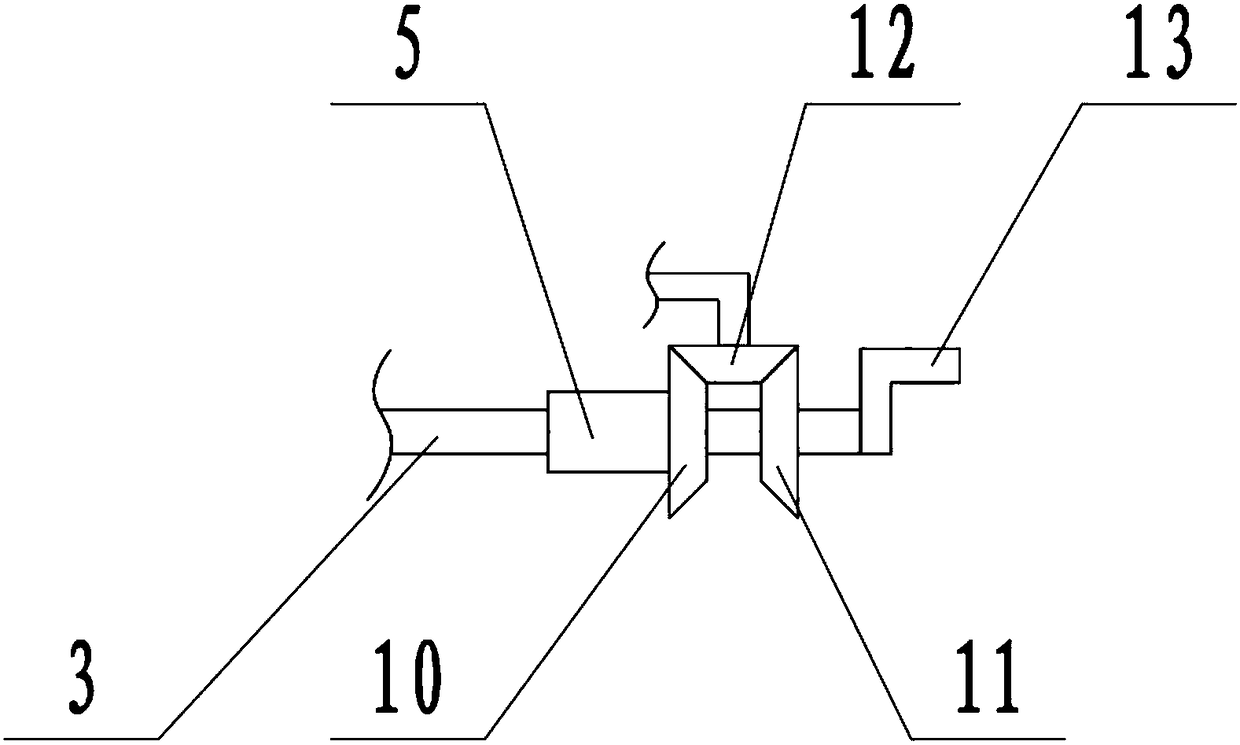

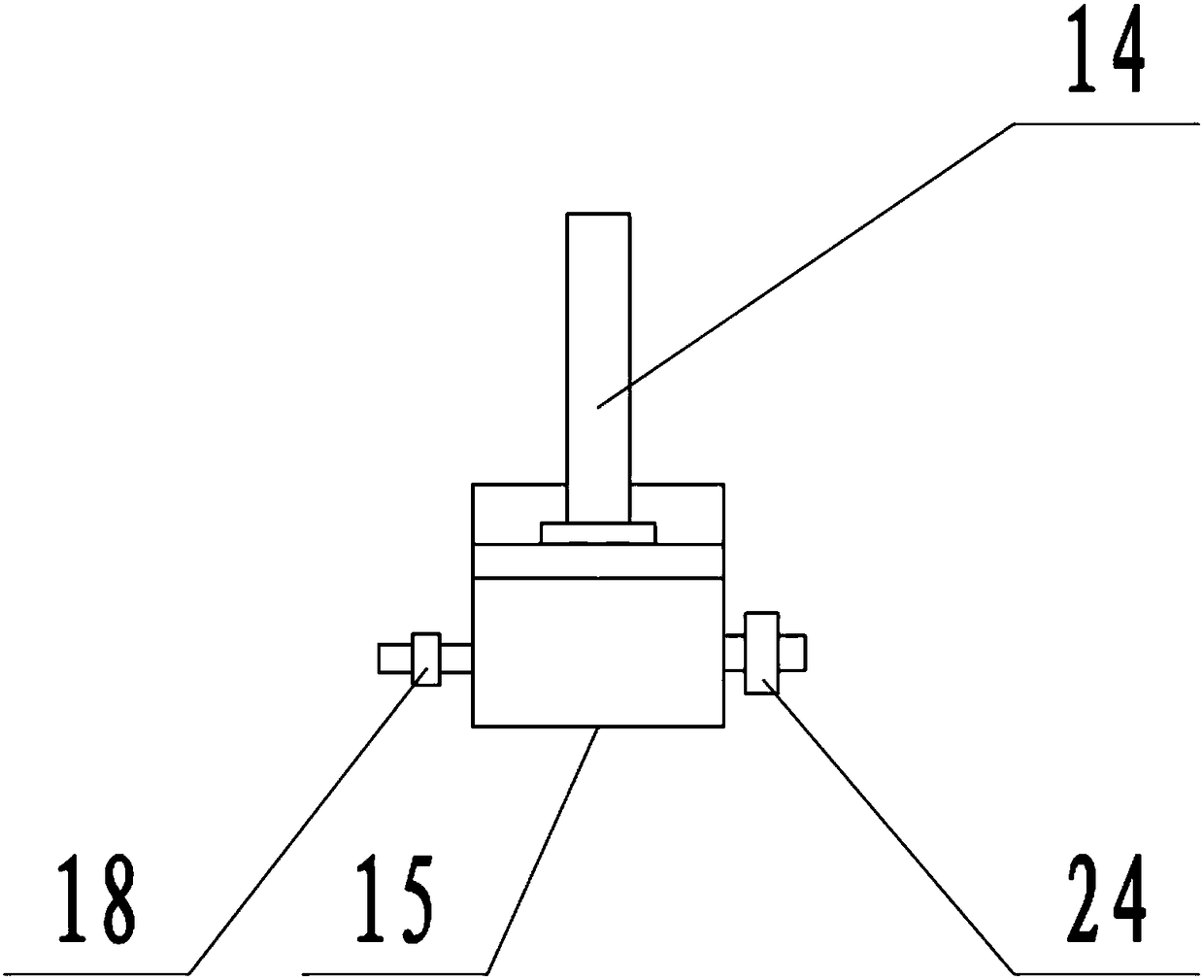

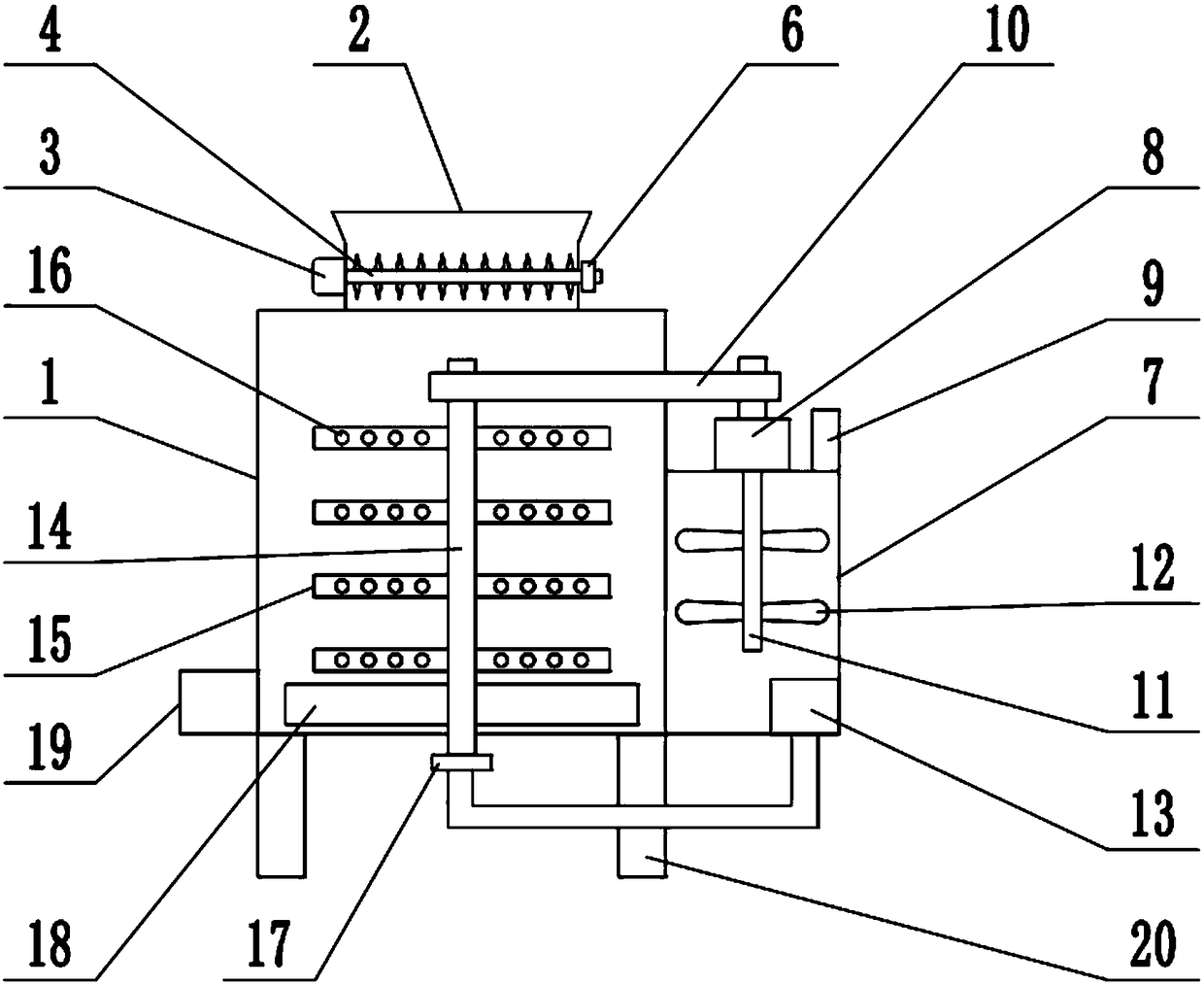

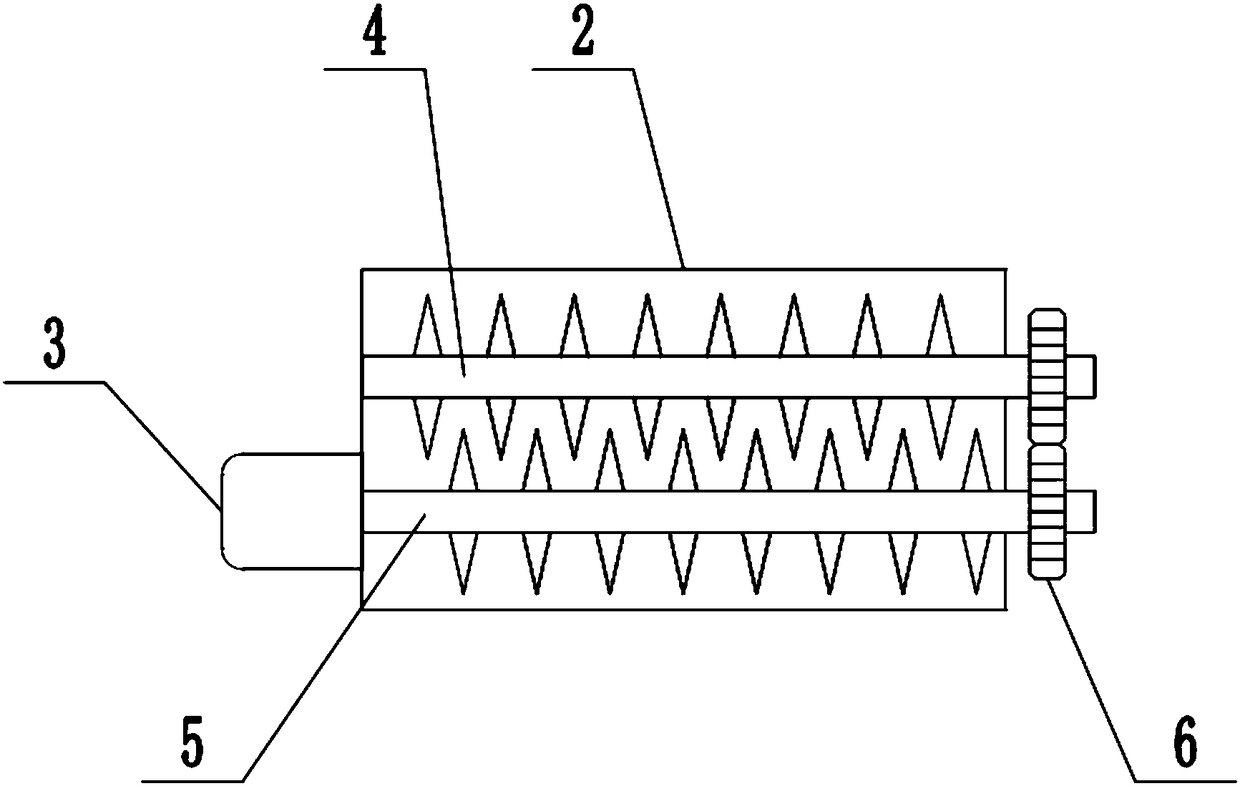

Soil repair and treatment equipment

InactiveCN108080411AImprove crushing efficiencyImprove governance effectTransportation and packagingRotary stirring mixersSoil treatmentEngineering

The invention discloses soil repair and treatment equipment, comprising a repair bin, a feeding hole, main crushing blades, stirring frames, a mixing drum and a discharge hole, wherein the outer wallof the left side of the repair bin is fixedly connected with a first motor, a shaft-extension end of the first motor is fixedly connected with a rotating shaft; a sleeve sleeves the rotating shaft; the stirring frames are respectively arranged at the upper side and the lower side of the sleeve; the plurality of main crushing blades are distributed on the rotating shaft; a plurality of auxiliary crushing blades are distributed on the stirring frames; the right end of the rotating shaft is fixedly connected with a crank, a connecting rod sleeves the crank, and the crank is rotatably connected with the connecting rod; a piston barrel is arranged under the crank. The stirring frames are used for stirring the soil, and the main crushing blades and the auxiliary crushing blades are matched for crushing the soil, so that the crushing efficiency of the soil is greatly increased, the soil is more evenly mixed with a repair agent, and the soil treatment effect is improved; the repair agent in the mixing drum is stirred by using stirring rods and stirring blades while the soil is treated, so that the repair agent is prevented from precipitating, and the repair effect is guaranteed.

Owner:陈前

Soil remediation ecological moisturizing method based on efficient stirring

ActiveCN111804724AScientific and reasonable structureEasy to useSievingDispersed particle filtrationSoil remediationElectric machine

The invention discloses a soil remediation ecological moisturizing method based on efficient stirring. A solution mixing and effect-improving mechanism comprises a mixing cylinder, a bracket, a secondrotating motor, a stirring rod, a stirring frame, a shovel plate, a discharge pipe, a water stop valve, a charging barrel, a filtering barrel, a chain wheel, a chain, a rotating rod, an upper grinding block, a lower grinding block, a channel, a spiral feeding plate, a feeding pipe, a rotary vane, a filtering barrel, a water outlet and a water inlet pipe, the bottom end of the mixing cylinder is fixedly connected with a bracket, safe and convenient use is realized, a solution mixing and efficiency improving mechanism is arranged, the second rotating motor drives the stirring rod to rotate, andthe two rotating rods are driven to move and rotate through transmission of the chain wheels and the chains, so that the repairing agent is crushed through cooperation of the upper grinding block andthe lower grinding block, the repairing agent can be rapidly mixed with water, meanwhile, the rotary vane and the filtering barrel are matched to filter the water, impurities in the water are reduced, and the effect of the mixed repairing liquid is prevented from being affected by too many impurities.

Owner:合肥润田规划设计有限公司

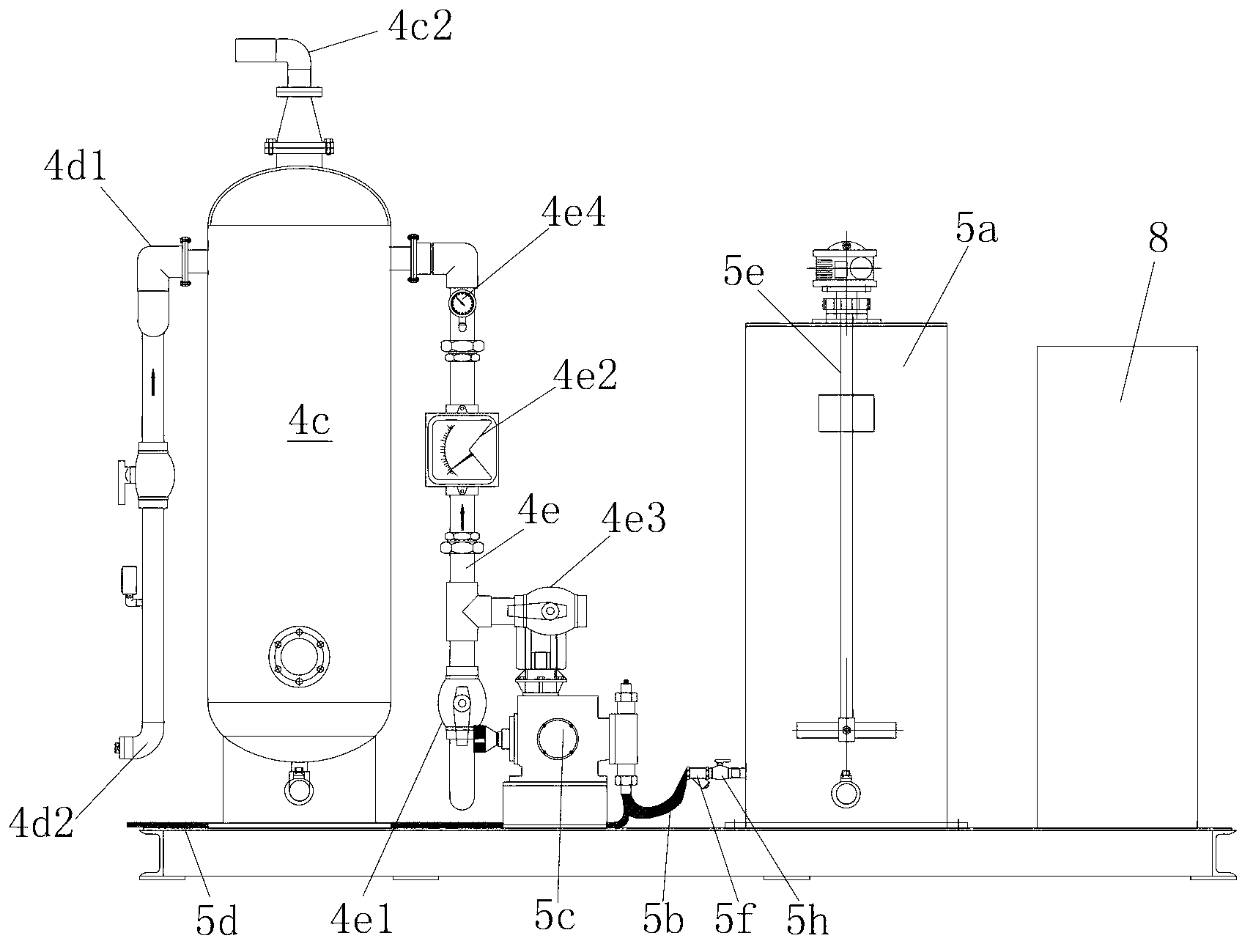

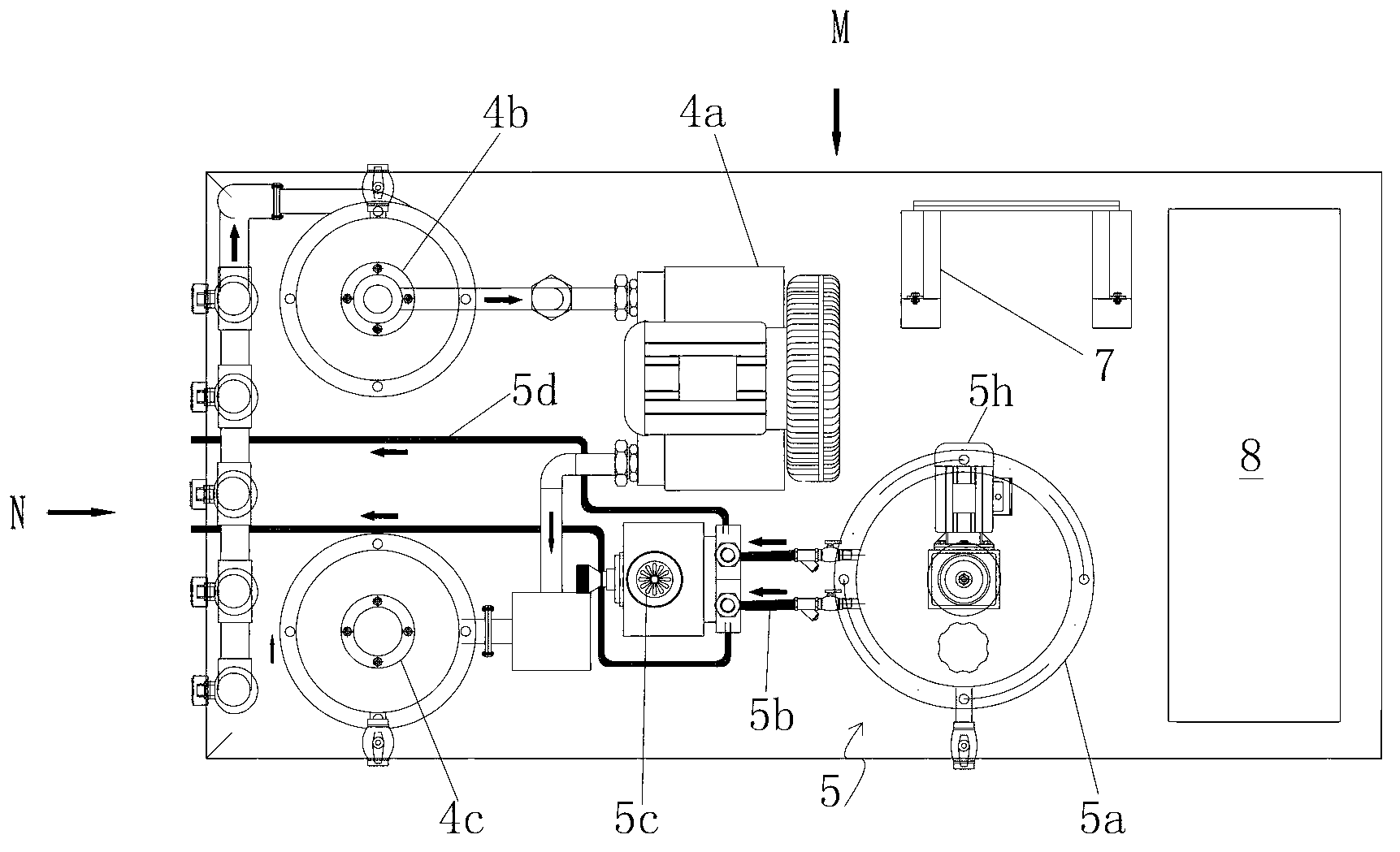

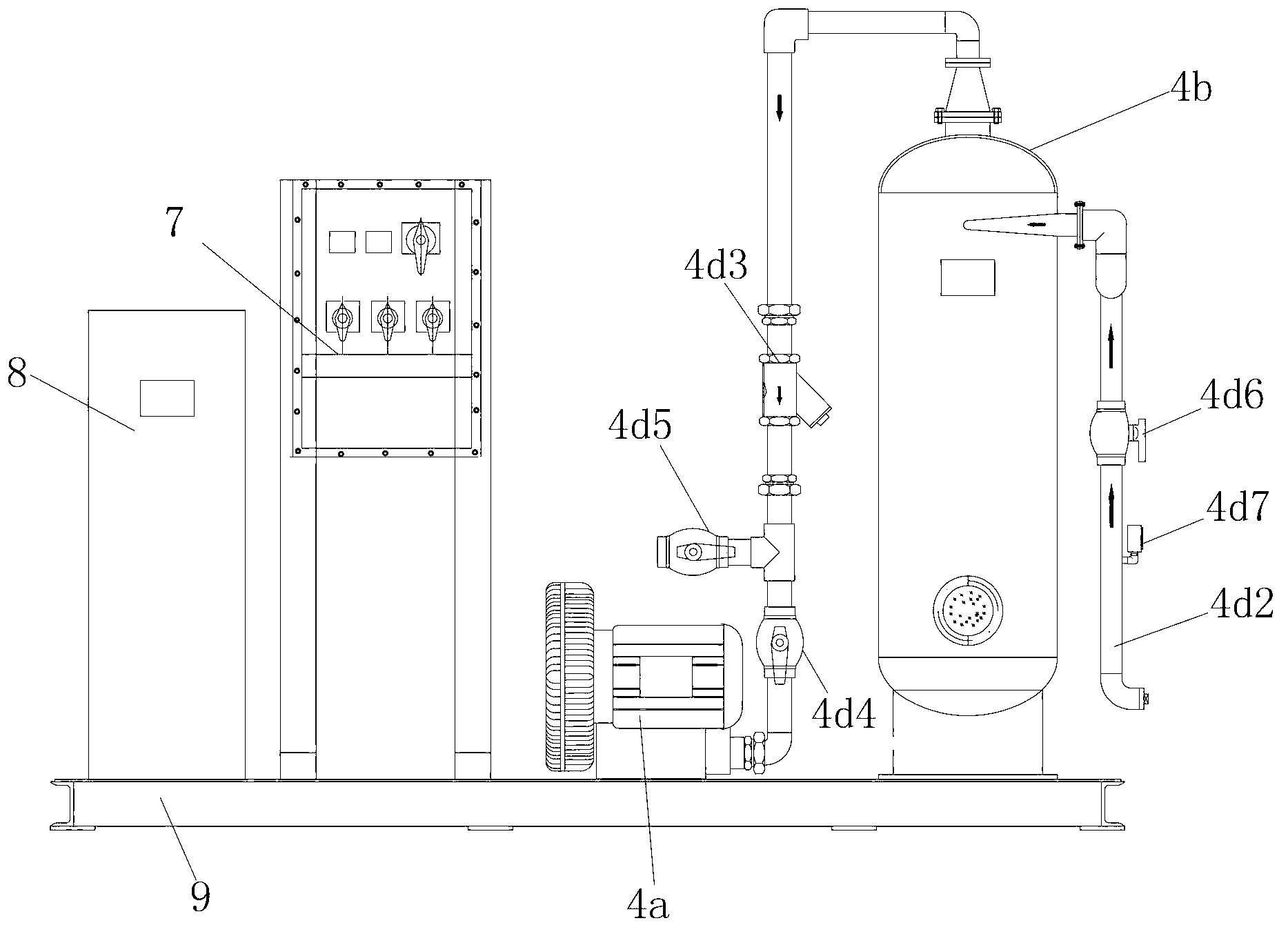

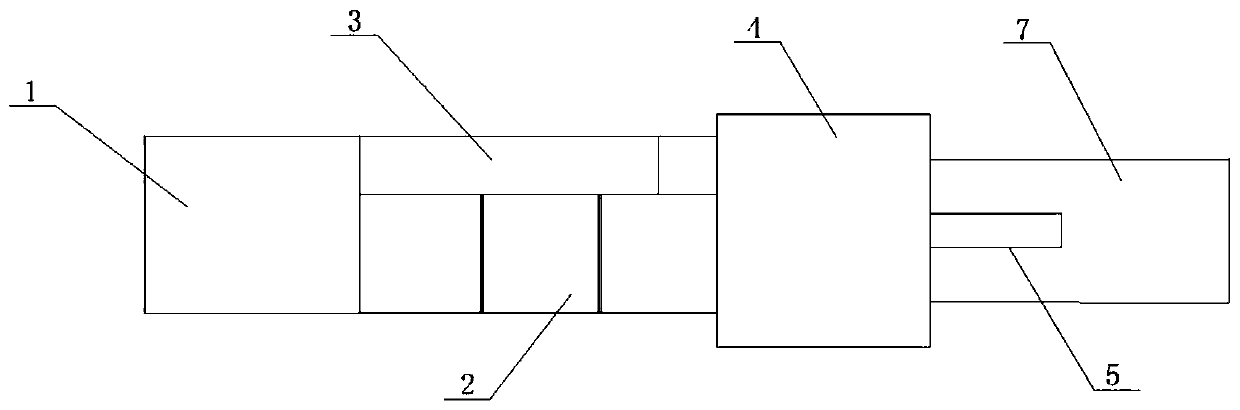

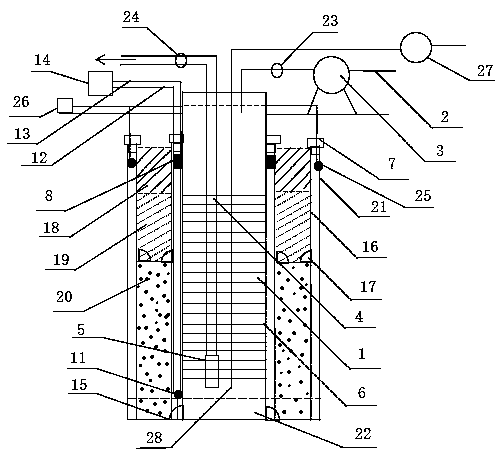

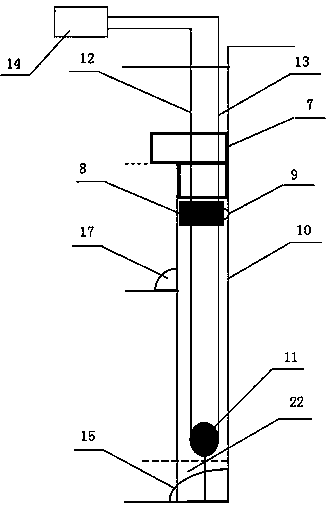

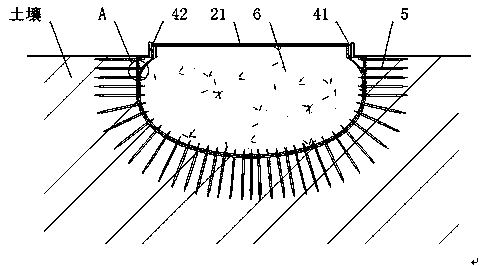

Light oil polluted unsaturated zone soil in-situ remediation apparatus and method thereof

ActiveCN103170498AGuaranteed repair effectLow costContaminated soil reclamationIn situ remediationNutrient solution

The invention relates to a light oil polluted unsaturated zone soil in-situ remediation apparatus and a method thereof. The apparatus comprises: a well group system which comprises a suction well, an injection well and a ventilation well, wherein the suction well has a suction well head, the injection well has an injection well head, and each of the suction well head and the injection well head is a multifunctional well head; a soil suction system which comprises a vortex vacuum pump, an oil-gas separator and an oil gas adsorber, wherein the oil gas separator has a separation gas inlet tube and a separation gas outlet tube, the oil gas adsorber has an adsorption gas inlet tube and an adsorption gas outlet tube, the separation gas inlet tube is connected with the suction well head through a suction tube group, the suction tube group is connected with the vortex vacuum pump, the separation gas outlet tube is connected with the adsorption gas inlet tube through an oil gas convey tube, and the adsorption gas outlet tube is communicated with the atmosphere; and a microbial remediation system which comprises a microbe and nutrient solution preparation tank, wherein an injection solution is contained in the microbe and nutrient solution preparation tank, the microbe and nutrient solution preparation tank is connected with the inlet of an injection metering pump through a solution suction pipeline, and the outlet of the injection metering pump is connected with the injection well head through an injection pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Through hole processing method

ActiveCN102130045AGood shape coverageReduce the possibility of failureSemiconductor/solid-state device manufacturingEngineeringDevice failure

The invention relates to a through hole processing method which comprises the following steps of: providing a masking film; etching a substrate according to the masking film to form a through hole; partially filling the through hole so as to form an insulated oxidization layer with fixed-shape coverage on the lateral wall of the through hole; and removing the masking film. The through hole processing method provided by the invention can eliminate the influence of a scallop appearance of the lateral wall of a silicon through-hole generated through a Bosh etching process on a follow-up process, and an insulated oxide layer thin film with a smooth surface is formed on the lateral wall of the silicon through-hole, therefore, the fixed-shape coverage performance of the insulated oxide layer thin film is improved, the follow-up silicon through-hole filling difficulty is reduced, and the reliability of device failure is finally reduced.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

Beam crane and its downward bent beam repairing method

The present invention relates to beam crane, and is especially one kind of self-repaired pre-stressed beam crane and the method of applying external pre-stress to repair the downwards bent beam of beam crane. The method of the present invention includes the following steps: 1. fixing stretching bearing and fixed bearing separately on two ends below the lower cover of the crane beam; 2. stringing steel strands separately in the fixing anchor beside the fixed bearing and the stretching anchor beside the stretching bearing to anchor the fixed end and to pressing the stretching anchor to the outer side of the stretching bearing; 3. regulating the initial stress of each steel strand with jack for equalized stress; 4. fixing 1-4 staying devices on the lower cover of the crane beam and setting the steel strands; and 5. stretching the steel strand of the stretching anchor with jack for the beam to bend upwards, anchoring the stretching end and regulating the staying devices for proper stress.

Owner:王冠华

Fast maintenance method for furnace lining of deslagging surface of converter

InactiveCN108660282AImproves washout propertiesEasy dischargeManufacturing convertersProcess efficiency improvementSmelting processTemperature difference

The invention provides a fast maintenance method for a furnace lining of a deslagging surface of a converter. The fast maintenance method for the furnace lining of the deslagging surface of the converter is applied to the technical field of iron and steel smelting processes, and comprises the maintenance steps of deslagging the converter, and remaining high-temperature residual furnace slags in the converter; adding bar steel scraps having temperature difference with the residual furnace slags into the converter, precipitating and condensing high-melting-point mineral substances in the furnaceslags under the action of the temperature difference of the bar steel scraps and the residual furnace slags, and adhering to the deslagging surface of the converter so as to replace a fettling material; and statically cooling the converter, and after finishing cooling, accomplishing the fast maintenance operation for the furnace lining of the deslagging surface of the converter. According to thefast maintenance method for the furnace lining of the deslagging surface of the converter provided by the invention, no cost input of the fettling material is required, the problems of the adverse effect on fettling and the environment pollution due to too long or too short sintering time are avoided, the molten steel end point components are ensured, the fettling time is effectively shortened, the converter operability is improved, and meanwhile, the fast maintenance method for the furnace lining of the deslagging surface of the converter has the characteristics of fast maintenance speed, good fettling effect, low fettling cost, safety, environment protection and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

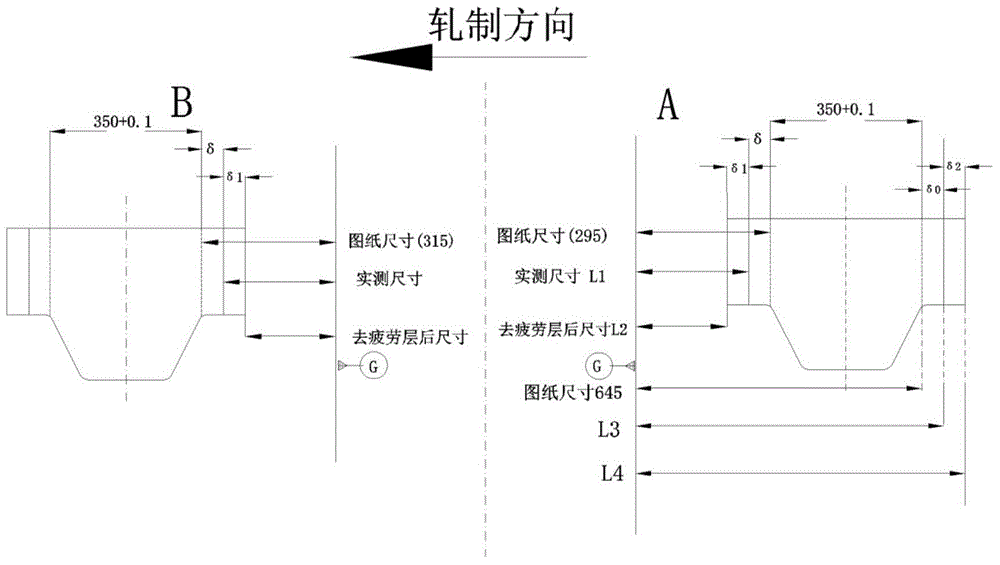

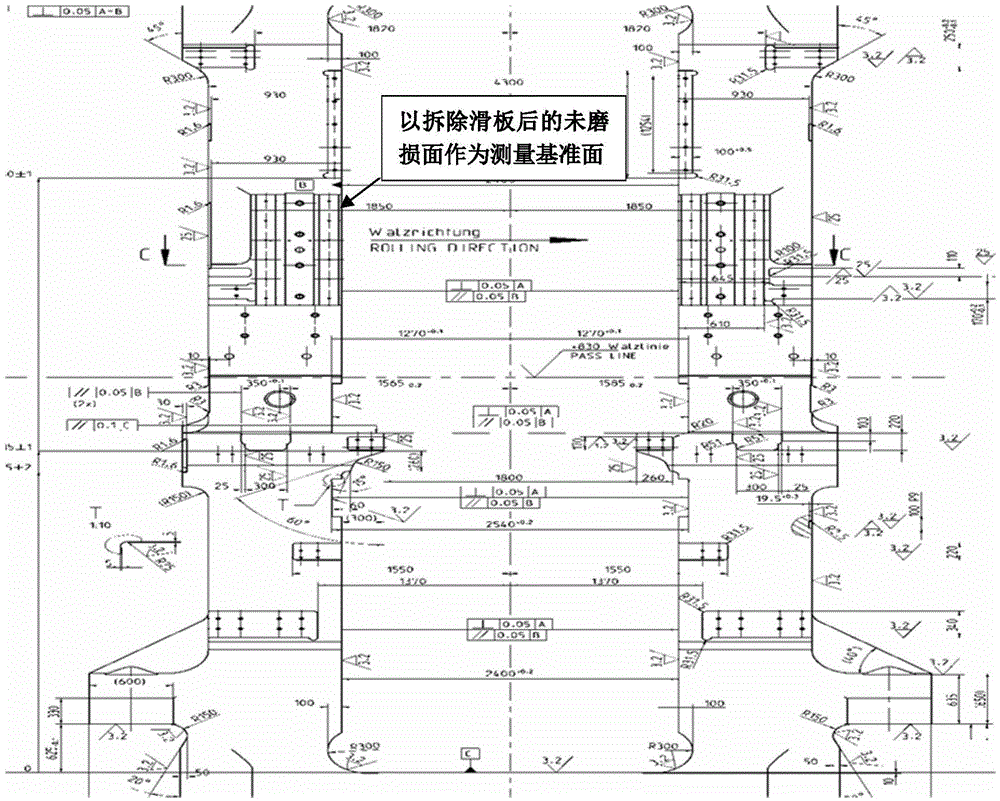

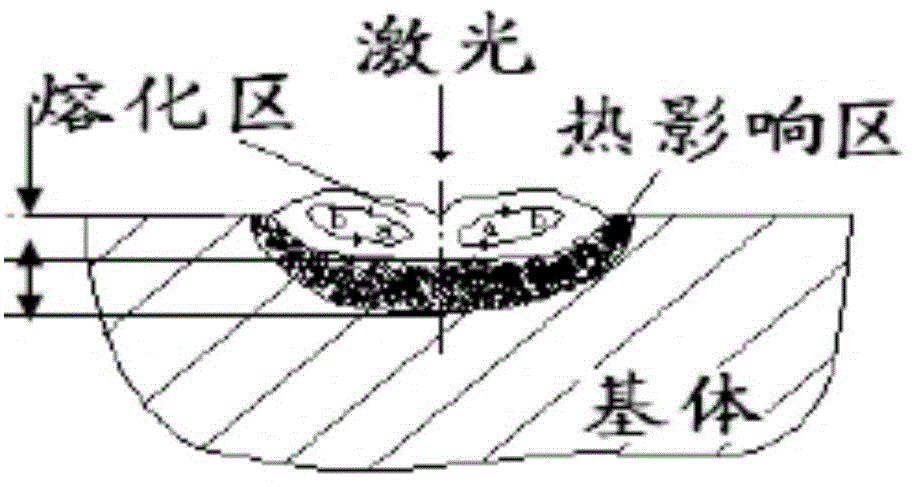

Laser cladding and on-line machining repair method for roughing mill housing roller positioning groove

ActiveCN104439881AGuaranteed repair effectQuality assuranceMetal rolling stand detailsMetal rolling arrangementsHeat-affected zoneEngineering

The invention relates to a laser cladding and on-line machining repair method for a roughing mill housing roller positioning groove, and belongs to the technical field of surface modification and equipment repair. Machining equipment comprises a 2500 movable boring and milling machine, an all-solid-state laser device, a mechanical hand, a manipulator, a pneumatic powder feeder, a self-made construction platform and the like. The technological process includes the steps of building the platform, leading in the equipment, adjusting, centering and fixing the equipment, performing rough machining, performing precision measurement for flaw detection, performing laser cladding, performing precision measurement for flaw detection, fine machining, performing precision measurement for flaw detection and tracking to verify the effect. The laser cladding and on-line machining repair method has the advantages that the equipment strength is not affected, hot stress influence during repair welding is avoided, while equipment accuracy is recovered, the outage time can be shortened, and the repair cost can be reduced; a metal base material can be effectively protected from abrasion or corrosion by selecting a repair material, the problem is prevented from occurring again, and the service life of the equipment is greatly prolonged; as only the surface of the base material is melt in a micro mode in the laser machining process, the area of a laser cladding heat affected zone is one tenth that of a heat affected zone of argon arc welding.

Owner:SHOUGANG CORPORATION

Farmland soil pollution treatment equipment

InactiveCN108607875AImprove repair efficiencyGuaranteed repair effectSoil lifting machinesTransportation and packagingSoil remediationDrive shaft

The invention discloses farmland soil pollution treatment equipment, which comprises a shell, a feed inlet, a liquid medicine box, a liquid inlet, a water pump, and support legs. A rotation shaft is arranged in the shell. Multiple stirring rods are arranged on the rotation shaft. The stirring rods are hollow and are communicated with the rotation shaft. Blowholes are distributed in the surfaces ofstirring rods. The right wall of the shell is fixedly connected to the liquid medicine box. A soil repairing agent is arranged in the liquid medicine box. A dual shaft motor is fixedly connected to the upper surface of the liquid medicine box. The soil is grinded by a driving shaft and a driven shaft to prevent the situation that the feed inlet is obstructed by soil; at the same time, the contactarea between soil and the soil repairing agent is enlarged, soil is fully contacted with the soil repairing agent, the soil repairing efficiency is improved; the soil repairing agent in the liquid medicine box is delivered into the shell by the water pump so as to mix the soil repairing agent with soil, when the soil is repaired, the soil is stirred so that the soil repairing agent and soil are more fully mixed, and the soil repairing efficiency is further improved.

Owner:COMMON TECH DEV CO LTD

Four-wheel drive road face repairing robot system and road face repairing method

InactiveCN106514607ASelf-healingImprove repair efficiencyProgramme-controlled manipulatorGripping headsRobotic systemsElectricity

The invention discloses a four-wheel drive road face repairing robot system. The four-wheel drive road face repairing robot system comprises a robot body with a power system. A mechanical arm is installed on the robot body, and a road face repairing device is installed on the mechanical arm. The robot body is further provided with a control system used for controlling the mechanical arm. The control system is provided with a wireless signal receiving device, and the control system is electrically connected with the mechanical arm. Specifically, the road face repairing device comprises a grouting device and / or a percussion bit and / or a slotting device. The invention further discloses a road face repairing method. The robot system can achieve intelligent repairing, and due to the fact that only artificial long-distance intervention is needed, safety during repairing is improved to a certain degree. The modular mechanical arm is integrated, the mechanical arm can be dismounted, mounted and combined according to the actual situation, the repairing tools at the tail end can be replaced, and the use efficiency of the modular mechanical arm is improved.

Owner:成都圭目机器人有限公司

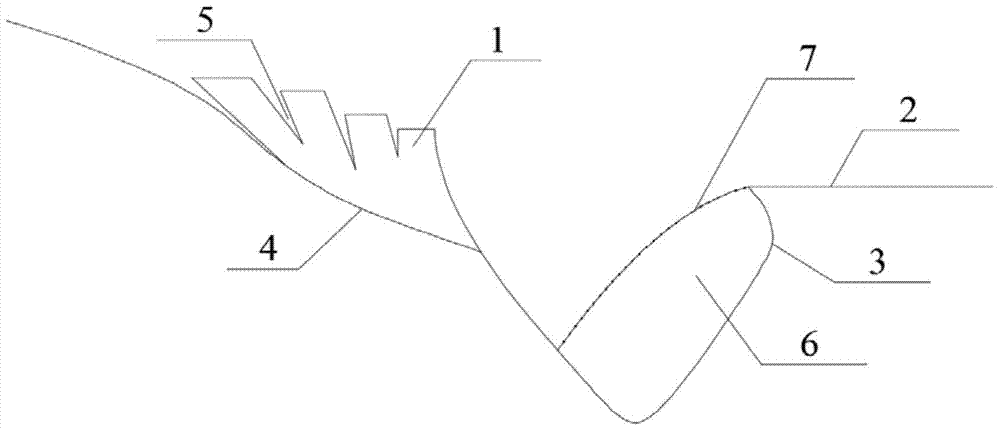

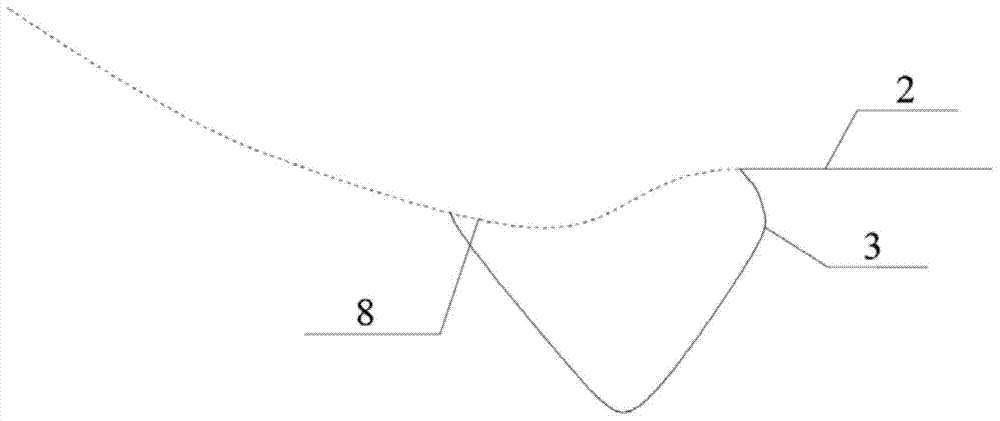

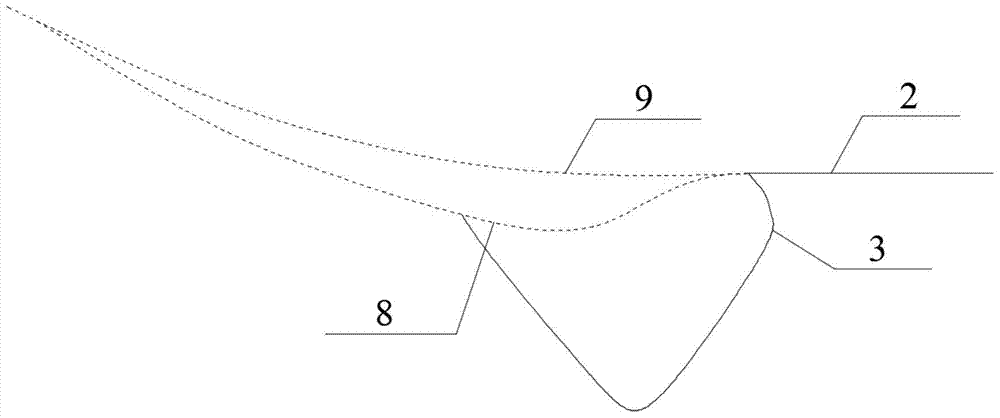

Restoration method for coal mine giant collapse pits

InactiveCN107023297AGuaranteed repair effectEnsure governance efficiencyUnderground miningSurface miningRestoration methodHeight difference

The invention discloses a restoration method for coal mine giant collapse pits. The method comprises the steps that whether the coal mine giant collapse pits are collapse pits in a zone with the relative height difference or collapse pits in a zone without the relative height difference are judged according to the topographic relief degree of the coal mine giant collapse pit, the collapse pits in the zone with the relative height difference and the collapse pits in the zone without the relative height difference are subjected to primary backfilling separately; water is sprayed to the giant collapse pits subjected to primary backfilling; and the collapse pits are subjected to secondary backfilling until the backfilling height in the pits is equal to the surface elevation. Through the mode that the collapse pits in the zone with the relative height difference adopts the different backfilling technologies, and solid waste backfilling is conducted in the relative low positions, so that the collapse pit governing efficiency is ensured, the bulldozing operation backfilling is conducted in the relative high positions, ground fractures around the collapse pits are restored, the collapse pits are backfilled, and the restoration effect of the collapse pits is ensured.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

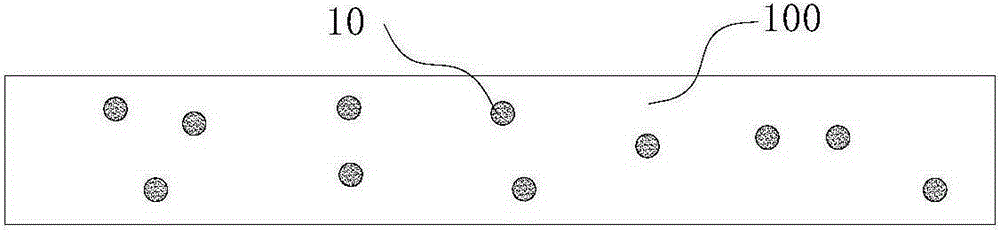

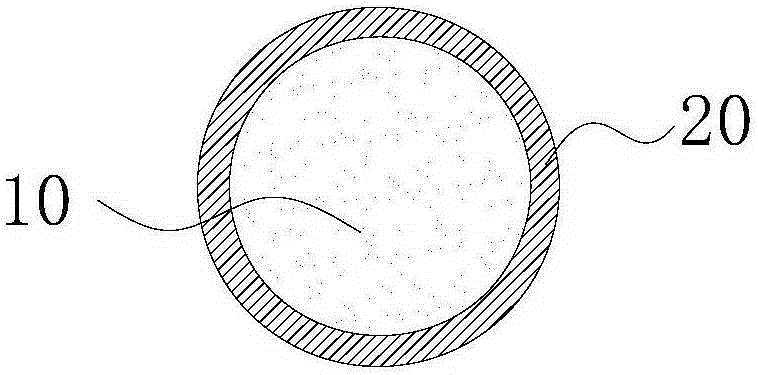

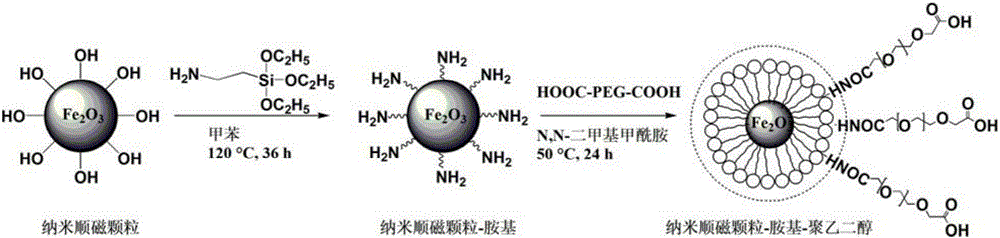

Magnetically-induced heating self-repairing thermoplastic nanocomposite material

ActiveCN105218999AGood dispersionEasy to useMagnetic materialsThermosetting polymerPolymer chemistry

The invention provides a magnetically-induced heating self-repairing thermoplastic nanocomposite material, and particularly provides a thermoplastic polymer product with the self-repairing function. The thermoplastic polymer product comprises a body and gamma-Fe2O3 nano-particles. The body is formed by a thermoplastic polymer. The gamma-Fe2O3 nano-particles are dispersed into the body. Accordingly, the gamma-Fe2O3 nano-particles induce the thermoplastic polymer body to complete the self-repairing function, the good chemical and mechanical performances are provided for the polymer product through the thermoplastic polymer body, and then the performance of the polymer product with the self-repairing function can be improved, so that the using effect of the polymer product is improved.

Owner:TSINGHUA UNIV

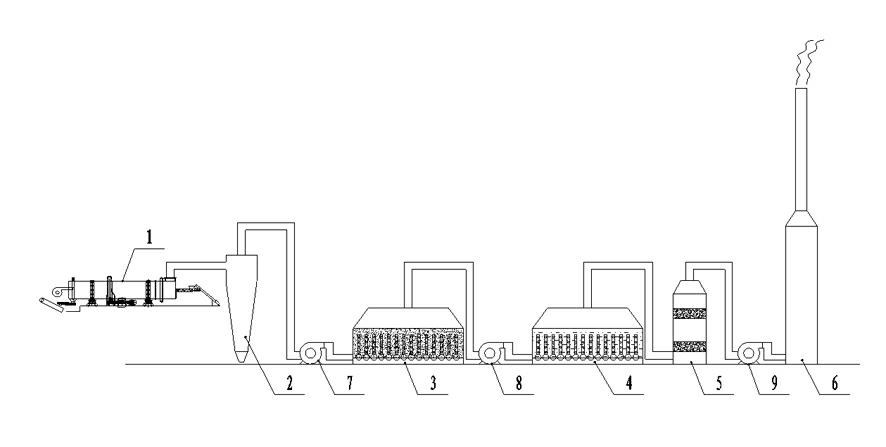

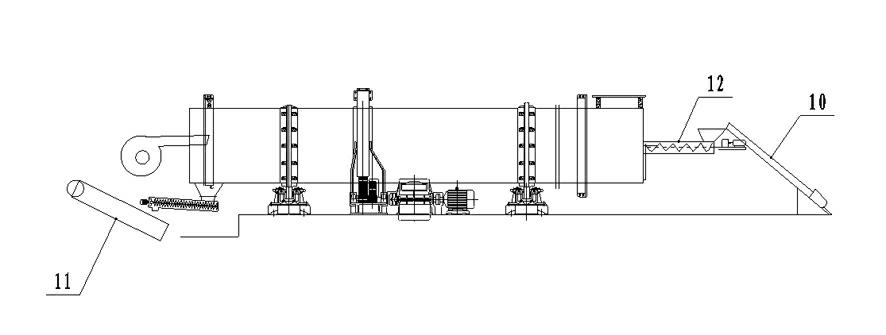

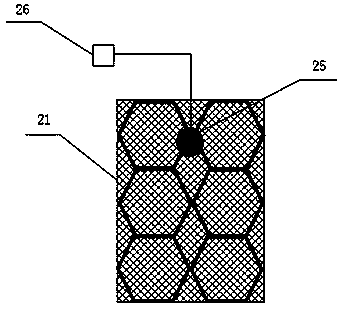

Remediation equipment for non-volatile organic polluted soil

ActiveCN102580994AReduce governance costsAvoid governance costsContaminated soil reclamationHigh energyEngineering

In order to solve the problems of high energy consumption, low treatment efficiency and low heat energy utilization rate in the prior art, the invention provides remediation equipment for non-volatile organic polluted soil. The remediation equipment comprises a rotary kiln, a cyclone dust remover, a soil pretreatment system, an oxidization reaction pool, an activated carbon adsorption tower and a chimney which are connected with one another through pipelines, wherein the upper end of the side wall of the cyclone dust remover is connected with the smoke outlet of the rotary kiln; the top of the cyclone dust remover is connected with the bottom of a treatment chamber of the soil pretreatment system through a pipeline; a gas collection cover of the soil pretreatment system is connected with a reaction pool of the oxidization reaction pool through a pipeline; a gas collection cover of the reaction pool is connected with the bottom of the activated carbon adsorption tower through a pipeline; and the top of the activated carbon adsorption tower is connected with the chimney through a pipeline. According to the remediation equipment, high-temperature smoke subjected to cyclone dust removal is used for pretreating the soil before cooling treatment, so that the moisture content in the soil is reduced, temperature of the soil is raised, and volatile organic pollution gas is separated out; and therefore, the heat carried by the smoke is recycled, and the heat energy utilization rate is increased.

Owner:山西省环境科学研究院

Method for restoring eutrophic tidal flat sediment habitat

ActiveCN104671626AEffective protectionPlay a buffer roleSeawater treatmentOn/in organic carrierEnvironmental resistanceEutrophication

The invention relates to a method for restoring a eutrophic tidal flat sediment habitat. The method comprises the following steps of: preparing bacteria solution; preparing stationary liquid; uniformly mixing and gelling the bacteria solution and the stationary liquid; preparing CaC12 solution; fixedly granulating the gelled bacteria solution; collecting and preserving; carrying out combined operation of plowing and environmental restoration bacteria immobilized particles; arranging shellfishes and clam worms; and regularly monitoring. The method disclosed by the invention is capable of effectively protecting bacterial strains and has the buffer function in an environment that physical and chemical factors are more severe; an effective vector can be provided for the bacterial strains, so that the bacterial strains have the bacteria restoration function effectively for a long time; by means of bioturbation of the shellfishes and the clam worms, the nitration and denitrification effects of sediments can also be effectively increased; and in addition, by means of combined use of the above methods, the method has good environment-friendly value and market application prospect to environmental restoration.

Owner:INST OF OCEANOLOGY & MARINE FISHERIES JIANGSU

Farmland pollution remediation equipment and method

InactiveCN104707863AEasy to moveImprove mechanizationContaminated soil reclamationProcess engineeringPollution Remediation

The invention discloses farmland pollution remediation equipment and a method. The equipment comprises a rack, a control compartment, an agent box, a liquid box, a conveying device, a lifting device I, a lifting device II, a stirring device I and a stirring device II, wherein the lifting device I and the lifting device II are fixed on the rack; the control compartment, the agent box, the liquid box, the conveying device, the stirring device I and the stirring device II are arranged at the upper part of the rack; and a front wheel and a rear wheel are arranged at the bottom of the rack. The equipment achieves mechanical and automatic operation of farmland remediation to the greatest extent, so that the operation efficiency and operation precision are improved; the labor is saved; the cost is lowered; the method for farmland pollution remediation with the equipment achieve permanent settlement of pollutants in polluted soil of a farmland and ensures remediation effect and timeliness.

Owner:爱土工程环境科技有限公司

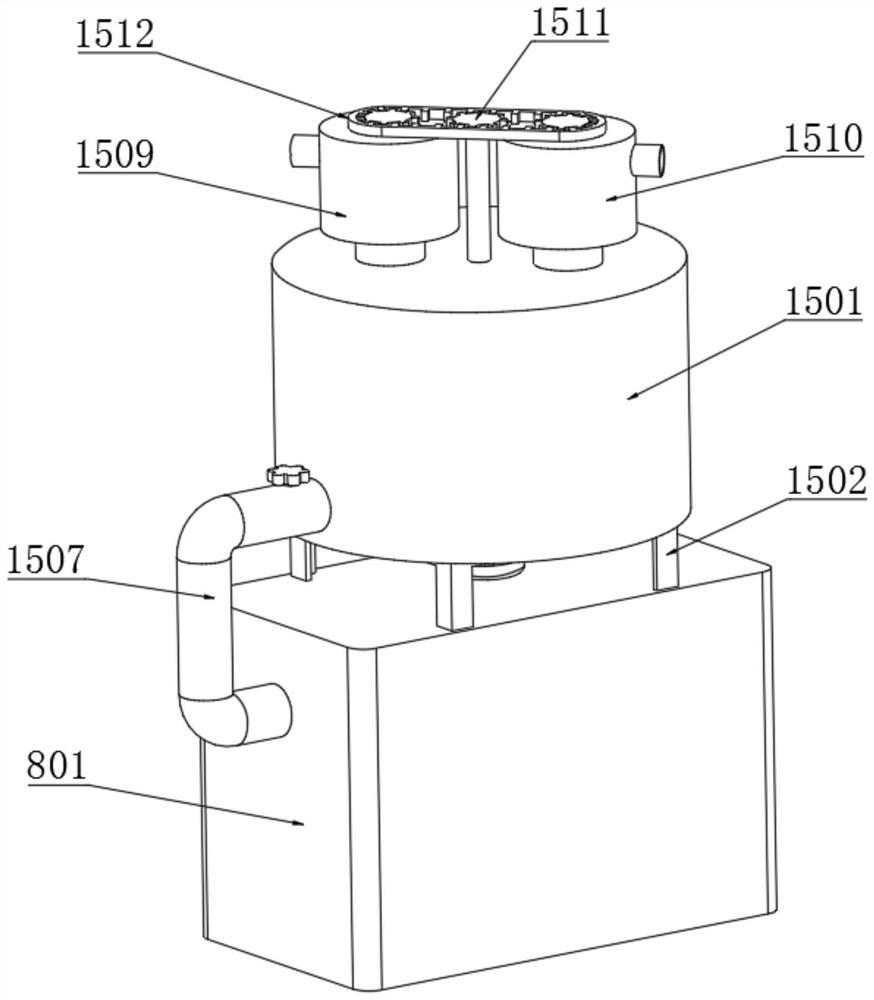

Intelligent integrated soil remediation device and method

PendingCN110116128AAccurate doseEfficient responseContaminated soil reclamationWater volumeHeavy metal compound

The invention discloses an intelligent integrated soil remediation device and method. The output ends of a crushing and screening system, a stepwise remediation material putting system and a liquid putting system of the device are all connected with the input end of a uniform mixing and stirring system, the output end of the uniform mixing and stirring system is connected with the input end of theuniform mixing and stirring system, and the output end of the uniform mixing and stirring system is connected with a discharging system. The remediation method comprises the operation steps of 1, determining remediation materials which need to be put and the water volume; 2, calculating the use quantity of the required remediation materials and the use amount of liquid; 3, starting all the systems; 4, putting soil in the crushing and screening system so that the soil can be uniformly mixed with the remediation materials, the liquid material or water for a reaction, and conveying the remediated soil to a maintenance area for maintenance; 5, conducting sampling detection on the remediated soil, and completing remediation when the soil is detected to be qualified. By means of the device andmethod, efficient curing / stabilizing remediation of heavy-metal-polluted soil, solid waste, sludge and other materials can be achieved, and the device and method have a good remediation effect on heavy-metal compound pollution soil.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

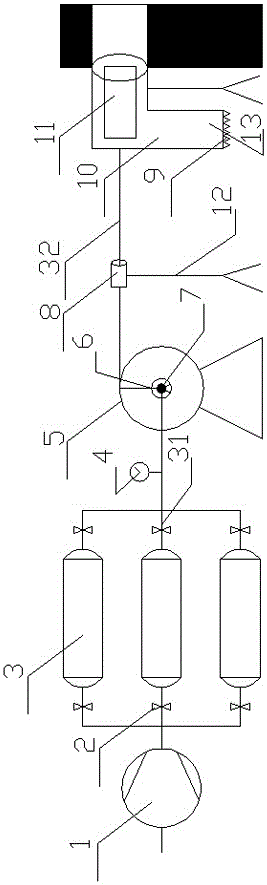

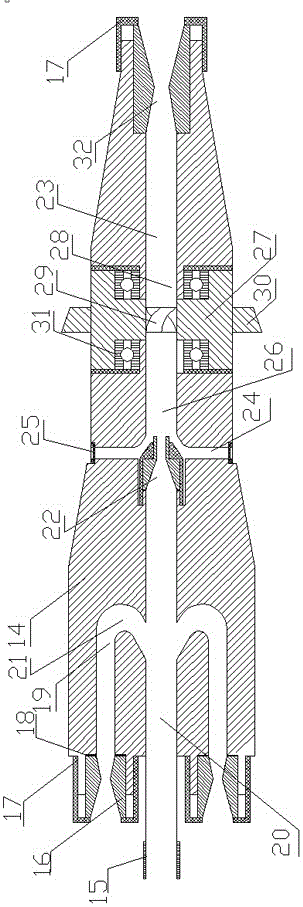

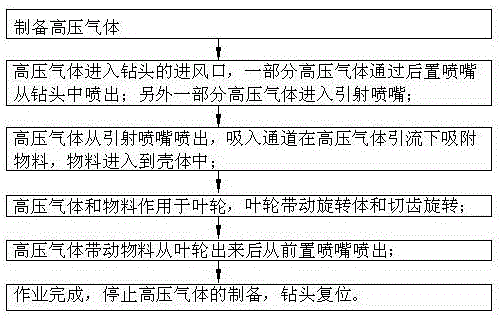

Underground self-propelled type high-pressure grinding air jet drilling repairing device and method

ActiveCN106437521AGuaranteed continuous additionGuaranteed jetDrill bitsConstructionsImpellerSpray nozzle

The invention relates to an underground self-propelled type high-pressure grinding air jet drilling repairing device and a method. The device comprises a high pressure air part, a drill bit and a hose, wherein the drill bit comprises a shell, an air inlet, a jetting nozzle, a mixing chamber, a rotator and a prepositioned nozzle; a rotating chamber is arranged in the rotator; the high pressure air part is communicated with the air inlet through the hose; a post-positioned nozzle is arranged at the head end of the shell; a suction channel is penetrated through a side wall of the shell; an impeller is arranged in the rotating chamber. The method comprises the following steps: 1) preparing high pressure air; 2) inputting the high pressure air to the air inlet of the drill bit; 3) spraying the high pressure air from the jetting nozzle; 4) causing the high pressure air and the coal dust act on the impeller; 5) utilizing the high pressure air to drive the coal dust to discharge from the impeller and then spraying the coal dust from the prepositioned nozzle; 6) completing the operation. According to the device and the method provided by the invention, the repairing for collapsed hole and blocked hole can be realized; higher coal breaking impact force can be acquired; the repairing for the drilling hole is benefited; the use efficiency of the drilling hole is increased.

Owner:HENAN POLYTECHNIC UNIV

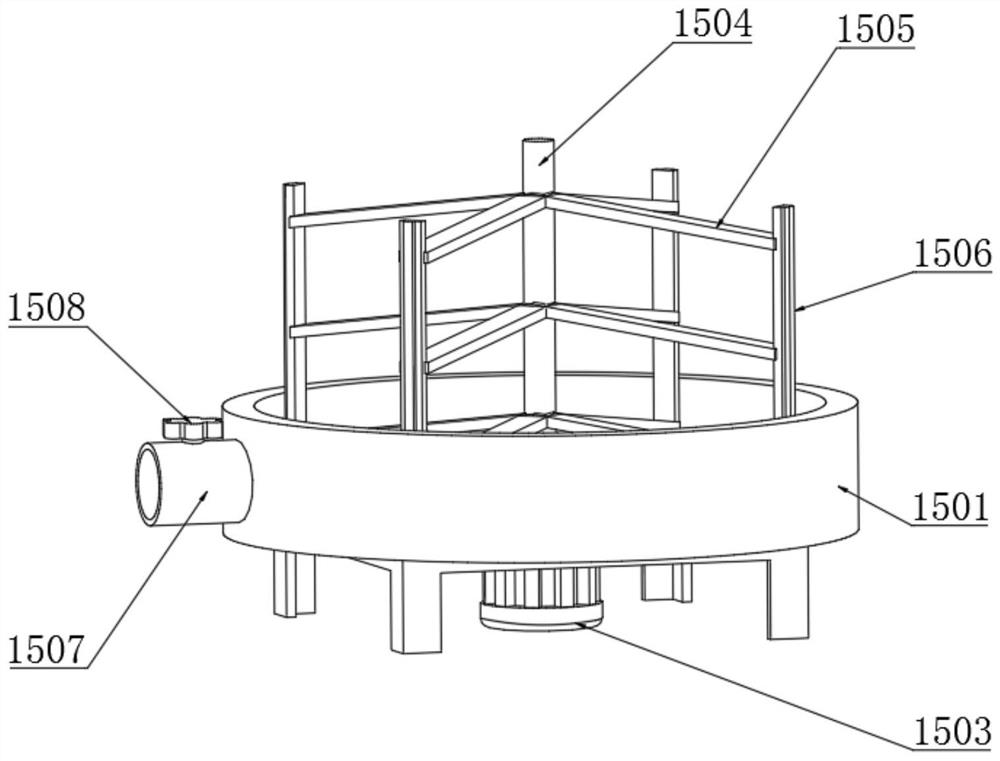

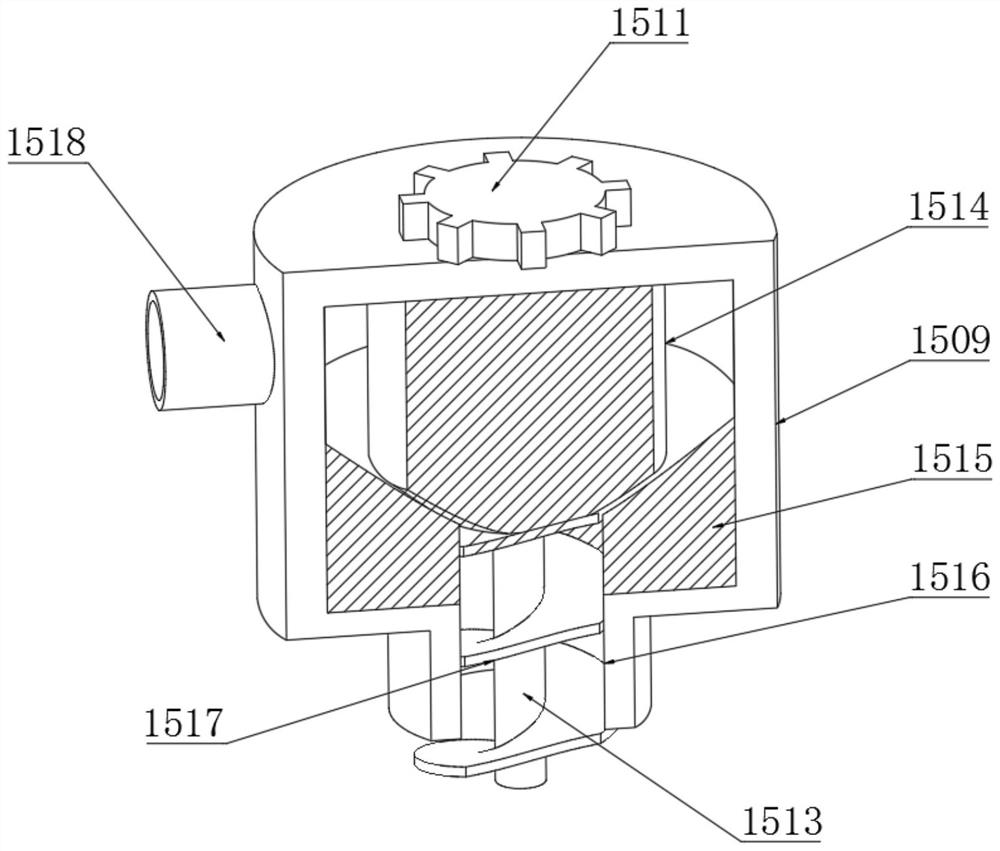

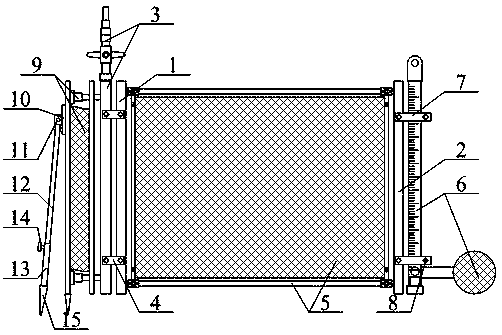

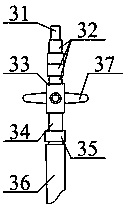

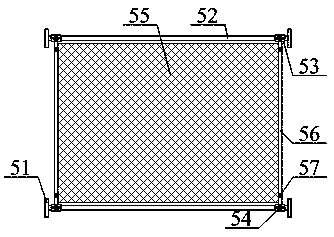

Wetland restoration enclosing device based on comprehensive protection structure

ActiveCN109458040AImprove integrityIncreased containment capacityClimate change adaptationMovable spraying apparatusSpray nozzlePesticide

The invention provides a wetland restoration enclosing device based on a comprehensive protection structure. The device comprises a main support column, an auxiliary support column, a self-rotating type wetland restoration liquid spray nozzle structure, fixed plates, a quick-release movable enclosing net structure, a wetland water level monitoring moving ball structure, fixed pieces, movable boltsand nuts, a comprehensive protective stretching wind and sand resistance net structure, a connecting base, a fixed liner, a rotating rod, a telescopic pipe, an adjusting bolt and buried cones, and the main support column longitudinally passes through the fixed plate to be installed on the right side of the self-rotating type wetland restoration liquid spray nozzle structure. Accordingly, by arranging a connecting pipe head, a swivel pipe joint, a liquid discharge pipe and a restoration nozzle, according to the wetland restoration requirements, an external restoration pipeline is connected through the connecting pipe head, and by means of multi-position rotation of the swivel pipe joint, restoration liquid can be sprayed to wetland through the liquid discharge pipe by passing through the restoration nozzle conveniently, so that liquid pesticide restoration function of the wetland is achieved, and the wetland completeness is increased.

Owner:SHANDONG AGRI SUSTAINABLE DEV INST

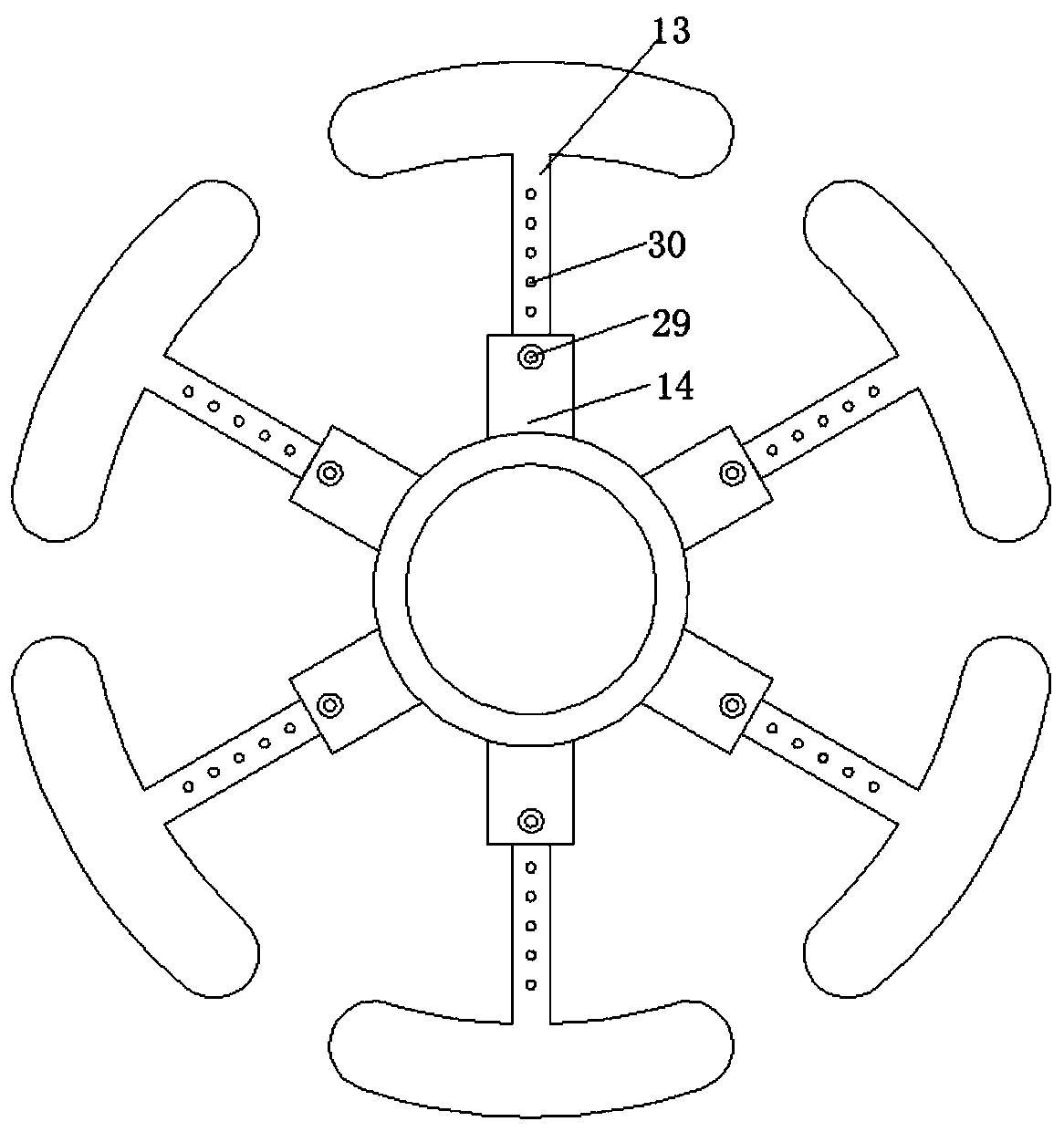

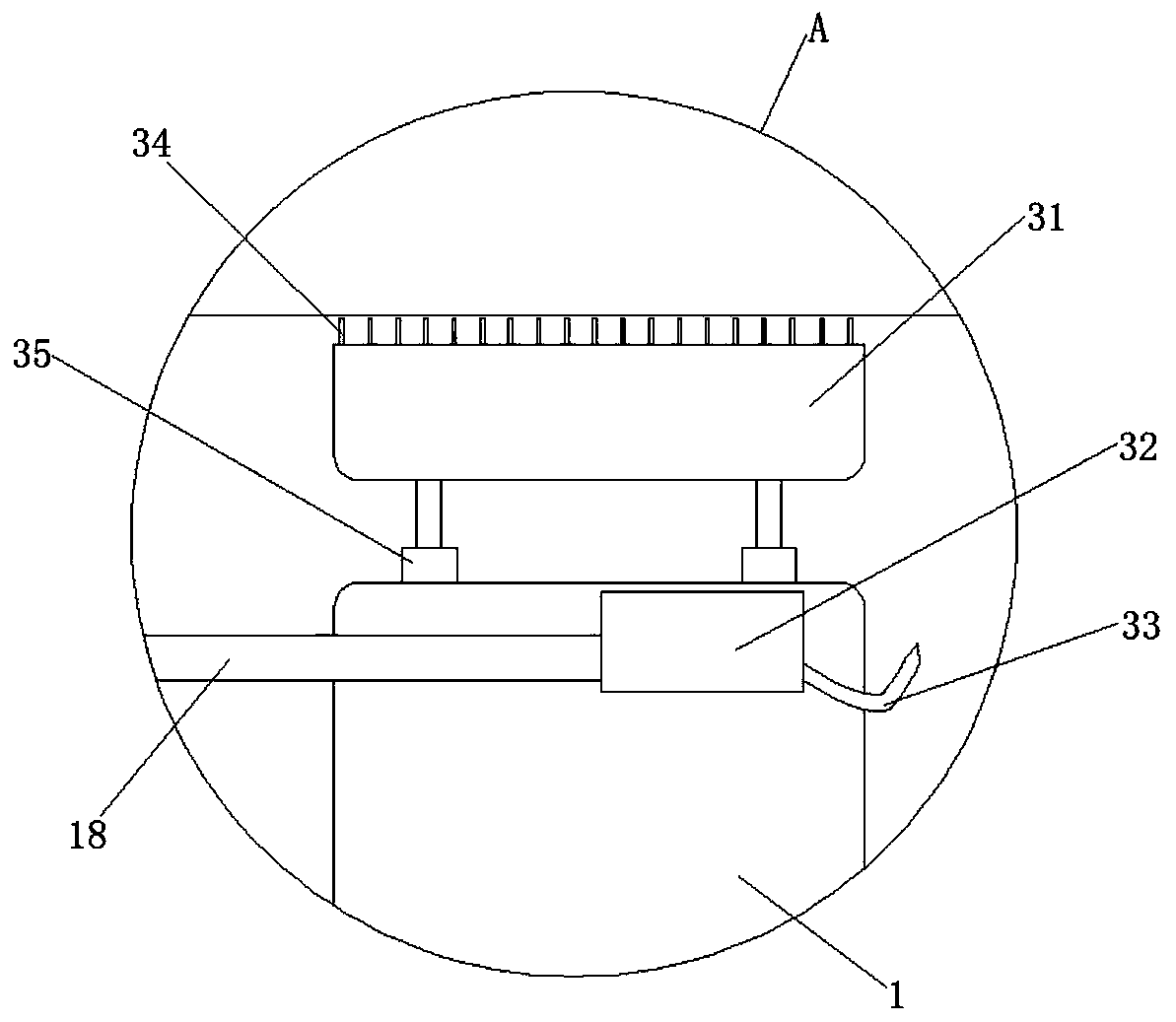

Repairing device and method for urban underground drainage pipeline

ActiveCN110042904AGuaranteed repair effectRepair uniformSewer pipelinesSubsurface drainageEngineering

The invention discloses a repairing device for an urban underground drainage pipeline. The repairing device includes a disk-shaped horizontal plate, a horizontal column and a capacity box fixedly sleeving the horizontal column, a clearing device for clearing impurities on the inner wall of the pipeline is installed on the horizontal plate, and the side wall of the capacity box is fixedly connectedwith a repairing mechanism for repairing the underground drainage pipeline. The invention further provides a repairing method of the urban underground drainage pipeline. The repairing method includesthe following steps that S1, a body of the repairing device is placed in the underground drainage pipeline; and S2, the height of a telescopic rod on the horizontal plate and a limiting pin and a pinhole on a sleeve and a hollow pipe are adjusted to adjust the heights of a brush and an arc-shaped block. According to the repairing device and method for the urban underground drainage pipeline, theinner wall of the pipeline is cleared and then cleaned through a cleaning device, the pipeline repairing effect is ensured, through arrangement of a motor, the repairing mechanism can be driven to rotate to make pipeline repairing more uniform, the clearing height and repairing height can be adjusted by the clearing device and the repairing mechanism, and the repairing device is suitable for drainage pipes with different pipe diameters and sizes.

Owner:SHANGHAI YUFAN ENVIRONMENTAL TECH CO LTD

Method for repairing scratch of automobile hub

The invention relates to a method for repairing the scratch of an automobile hub. The steps are simple, convenient and easy for realization, and no professional skills are needed; the repair of the scratch on the automobile hub can be realized by sanding of sand paper, scraping of a mixture and spraying of hub refinishing paint; the integral repair effect is good and the integral cost is low.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Multiphase extraction well system and installation and cleaning treatment method thereof

The invention relates to a multiphase extraction well system which comprises an extraction well pipe, a backwashing device, an automatic cleaning device, a screen box and an outer screen. A screen pipe with screen seams is arranged at the lower end of the extraction well pipe, and a gas-phase extraction pipe and a liquid-phase extraction pipe are arranged in the extraction well pipe. The backwashing device comprises a backwashing pipe arranged in the extraction well pipe. The automatic cleaning device is arranged between the extraction well pipe and the screen box and comprises a pipeline brush moving up and down. A biofilm layer is attached to the surface of the screen box, and a filler layer fills the inside of the screen box. The layer of outer screen is arranged outside the screen box,a screen vibrator is installed on the outer screen, and the screen vibrator is controlled by a vibration controller to vibrate. The invention also relates to a multiphase extraction well system installation and cleaning treatment method. The method is easy to operate and high in adaptability. The screen can be cleaned in the extraction process, so that the extraction well pipe and the screen arecleaned smoothly.

Owner:HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Efficient soil crushing treatment equipment

InactiveCN107999532AVolume qualifiedGuaranteed repair effectContaminated soil reclamationPulp and paper industryCentrifugal force

The invention discloses efficient soil crushing treatment equipment. The equipment comprises a machining box, supporting legs are symmetrically arranged on the left side and the right side of the processing machining box, and supporting sleeves are arranged at the lower ends of the supporting legs in a sliding mode; and rolling wheels are arranged at the lower ends of the supporting sleeves, wherein the rolling wheels facilitate carrying of the equipment, buffering springs are arranged in the supporting sleeves, and the buffering springs are used for connecting and fixing the supporting sleeves and the supporting legs. According to the efficient soil crushing treatment equipment, carrying is convenient, and the anti-seismic property is good; materials are subjected to circumferential crushing, and then are screened through filter cylinders, so that the size of the material is qualified when the materials are repaired, and the materials is fully contacted with repairing liquid in the later period; then the screened materials upwell along a lifting cylinder through a lifting blade, are scattered along dispersing buckets under the action of centrifugal force and are struck to the inner walls of fences; and conical blocks at water spraying ports also help to further scatter the materials, so that the materials are in full contact with the repairing liquid, the material repairing effect is guaranteed, and practicability is high.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Remediation method of chromium-contaminated soil

InactiveCN111570502AGuaranteed repair effectReduce repair costsAgriculture tools and machinesContaminated soil reclamationChromium contaminationSoil science

The invention discloses a remediation method of chromium-contaminated soil. The method comprises the following steps: (1), detecting the chromium contamination condition of soil, and determining a concentration distribution rule of hexavalent chromium in the chromium-contaminated soil; (2), with the soil layer depth with the hexavalent chromium transverse concentration distribution of 800-1300mg / kg as a boundary, distinguishing severe chromium-polluted soil from mild chromium-polluted risky soil; (3), stripping the severe chromium-contaminated soil, performing ex-situ remediation on the severechromium-contaminated soil, and performing in-situ remediation on the risky soil; (4), backfilling the remediated severely chromium-contaminated soil onto the remediated risky soil, adding humic acid, performing plowing, and planting plants capable of enriching chromium; (5), regularly harvesting, removing and reseeding plants capable of enriching chromium, and detecting the total chromium content above the boundary for at least 6 months; and (6), determining that the concentration of hexavalent chromium on the surface soil of the chromium-contaminated soil meets the restoration target concentration, and if the detection result is unstable, repeating the (5) until the detection concentration reaches the standard.

Owner:HANGZHOU NORMAL UNIV QIANJIANG COLLEGE

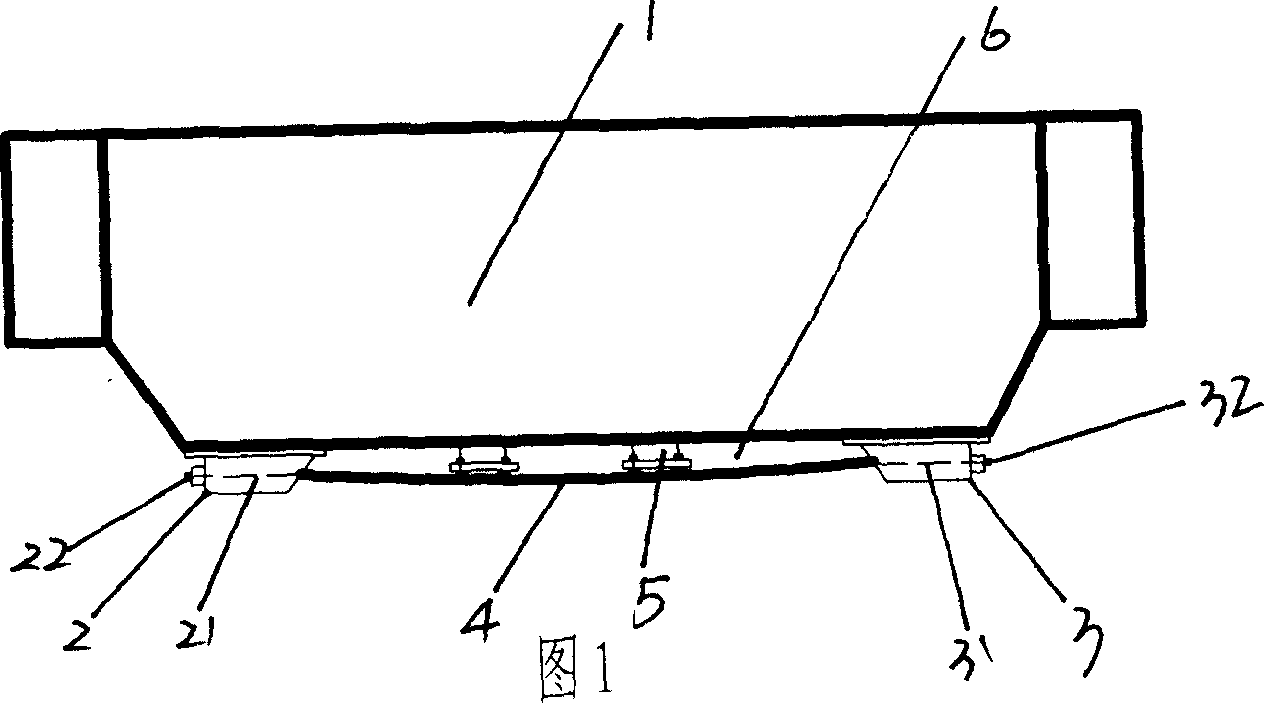

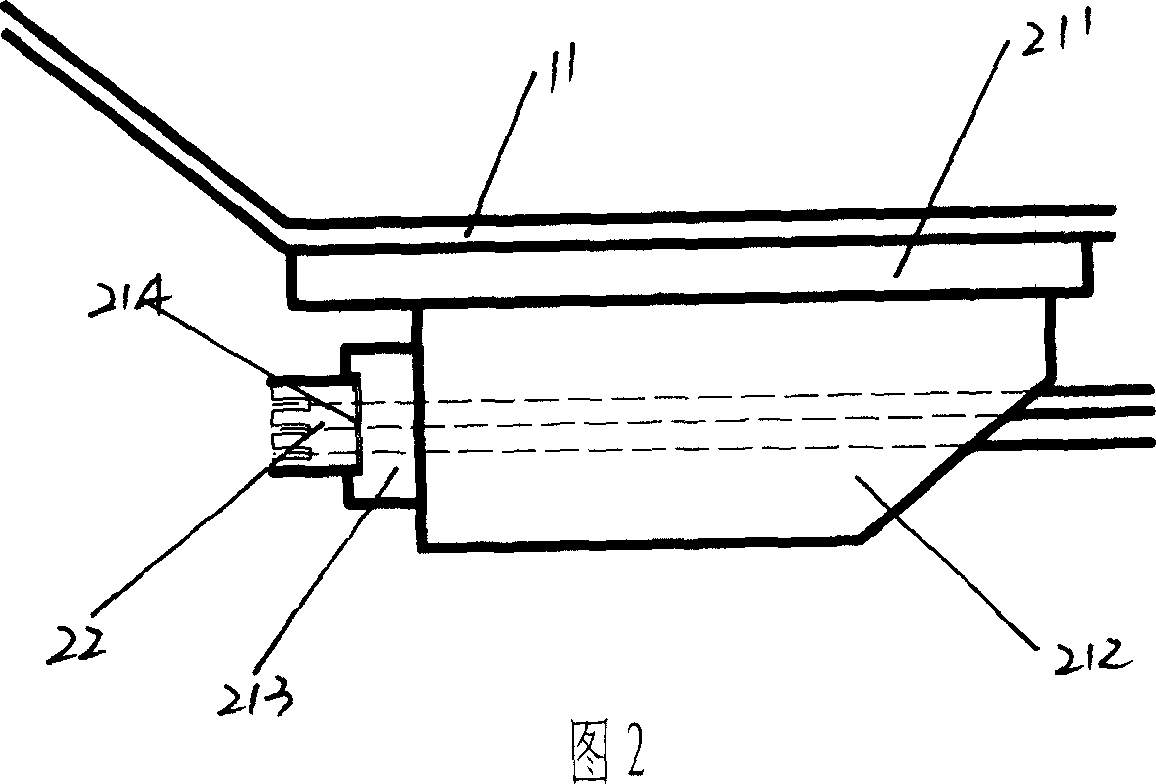

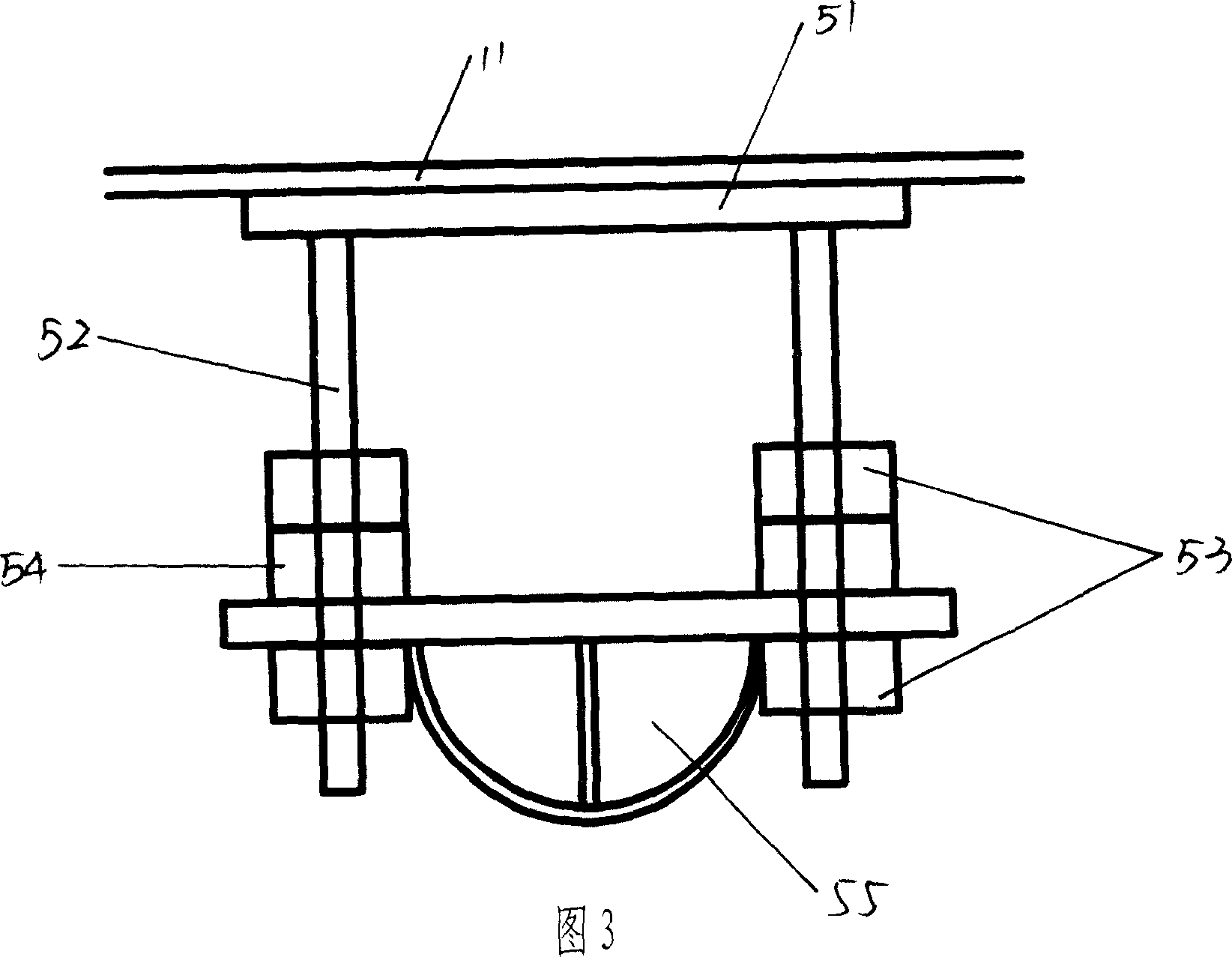

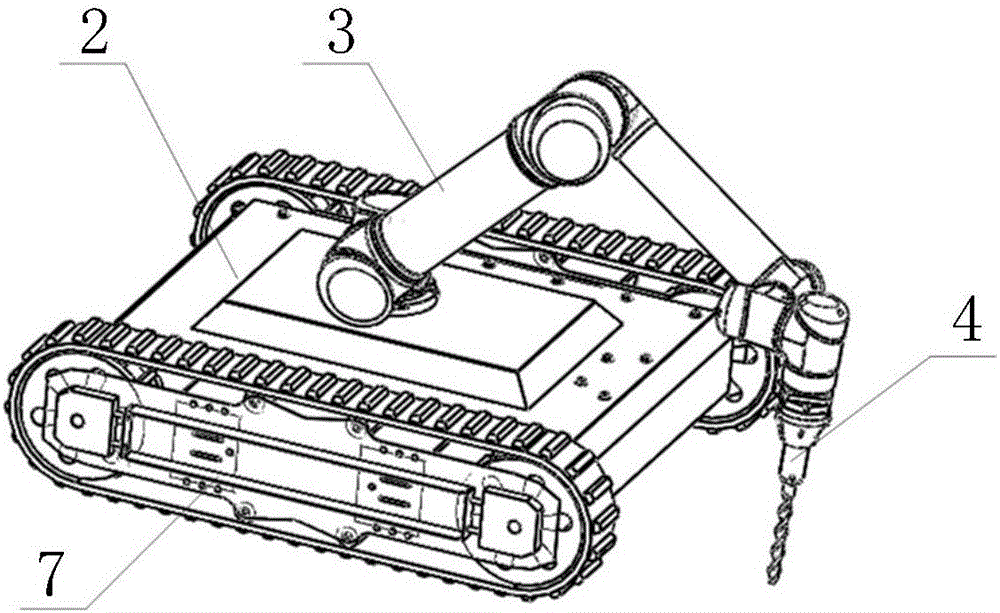

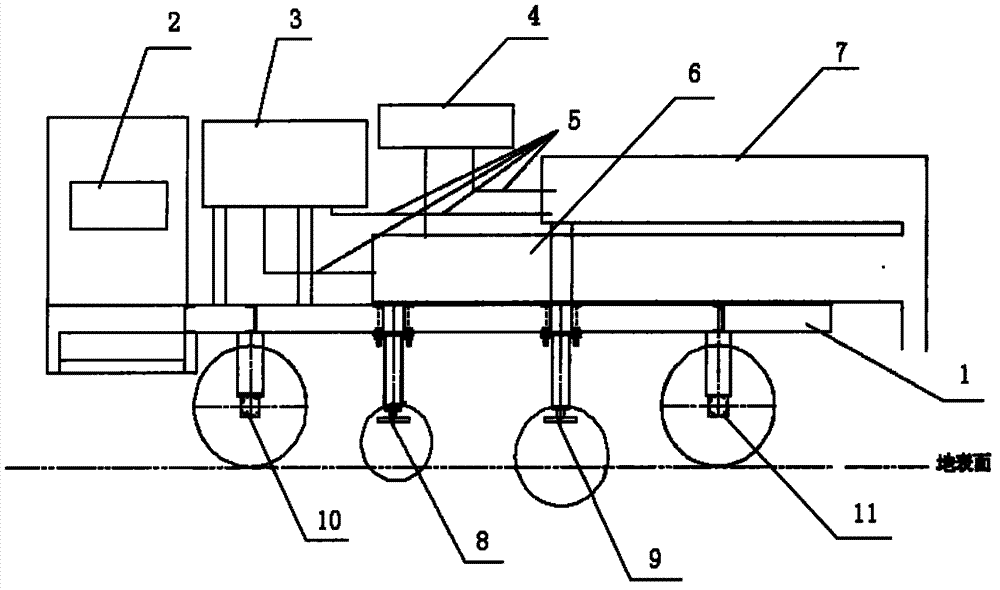

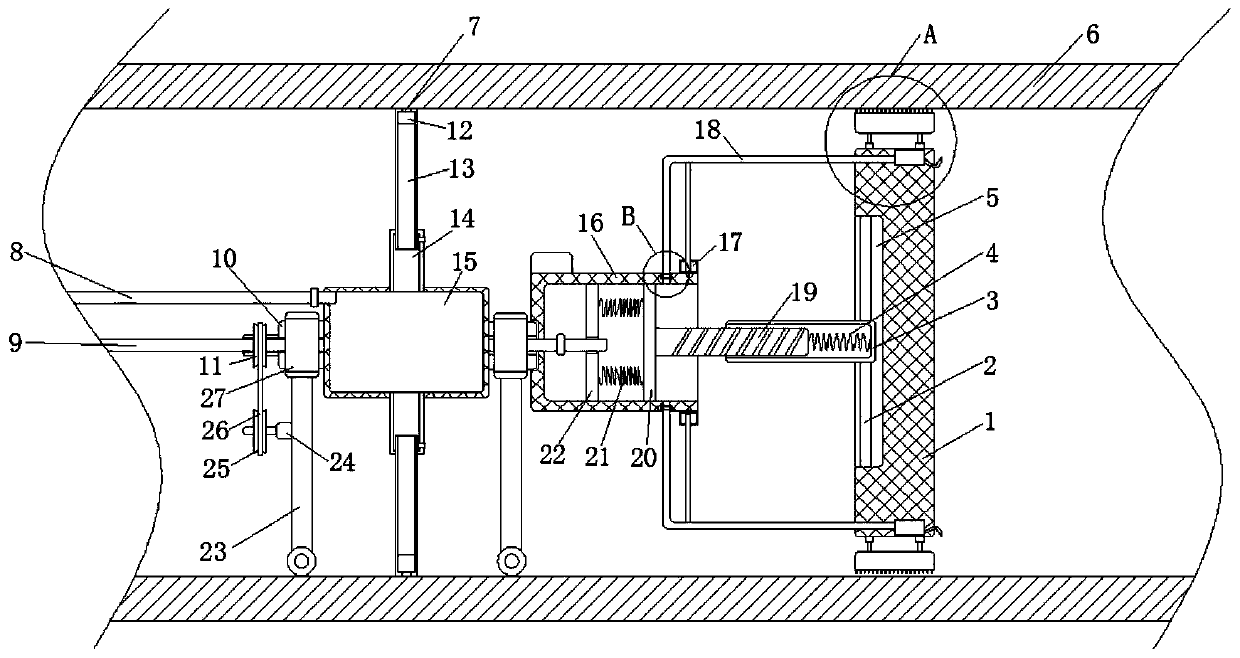

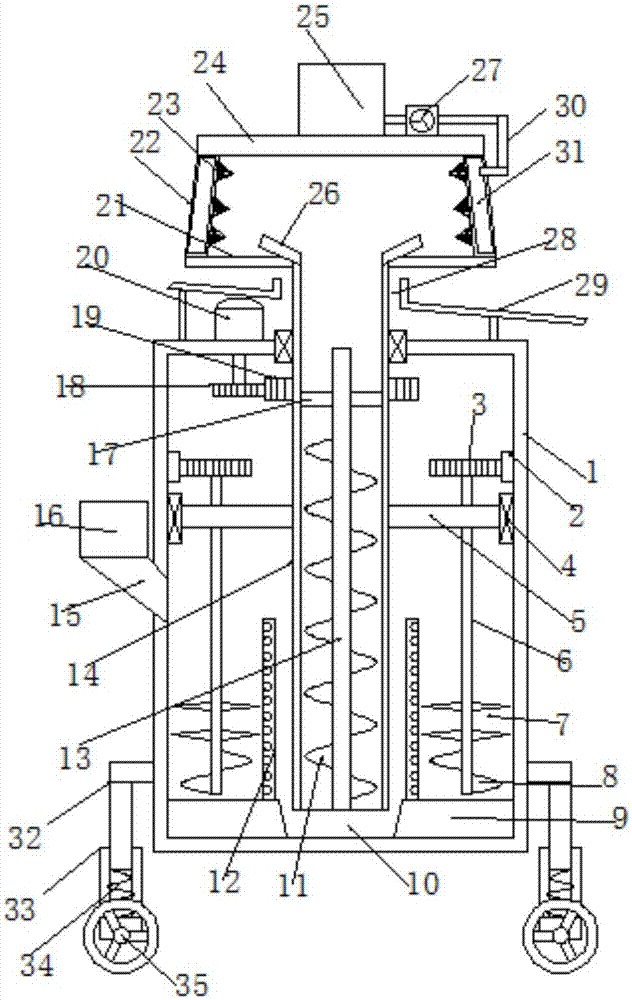

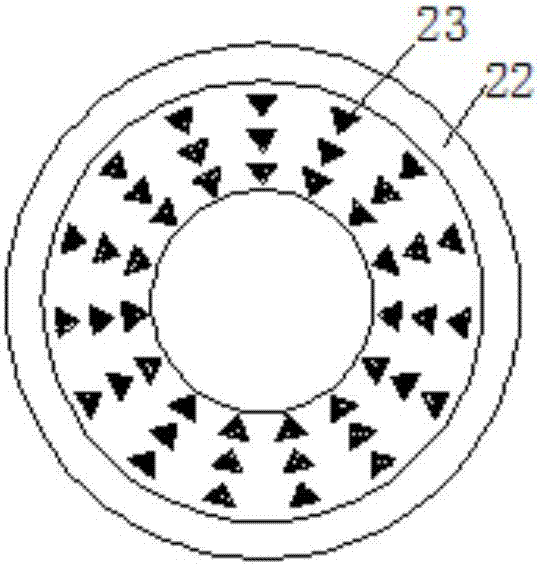

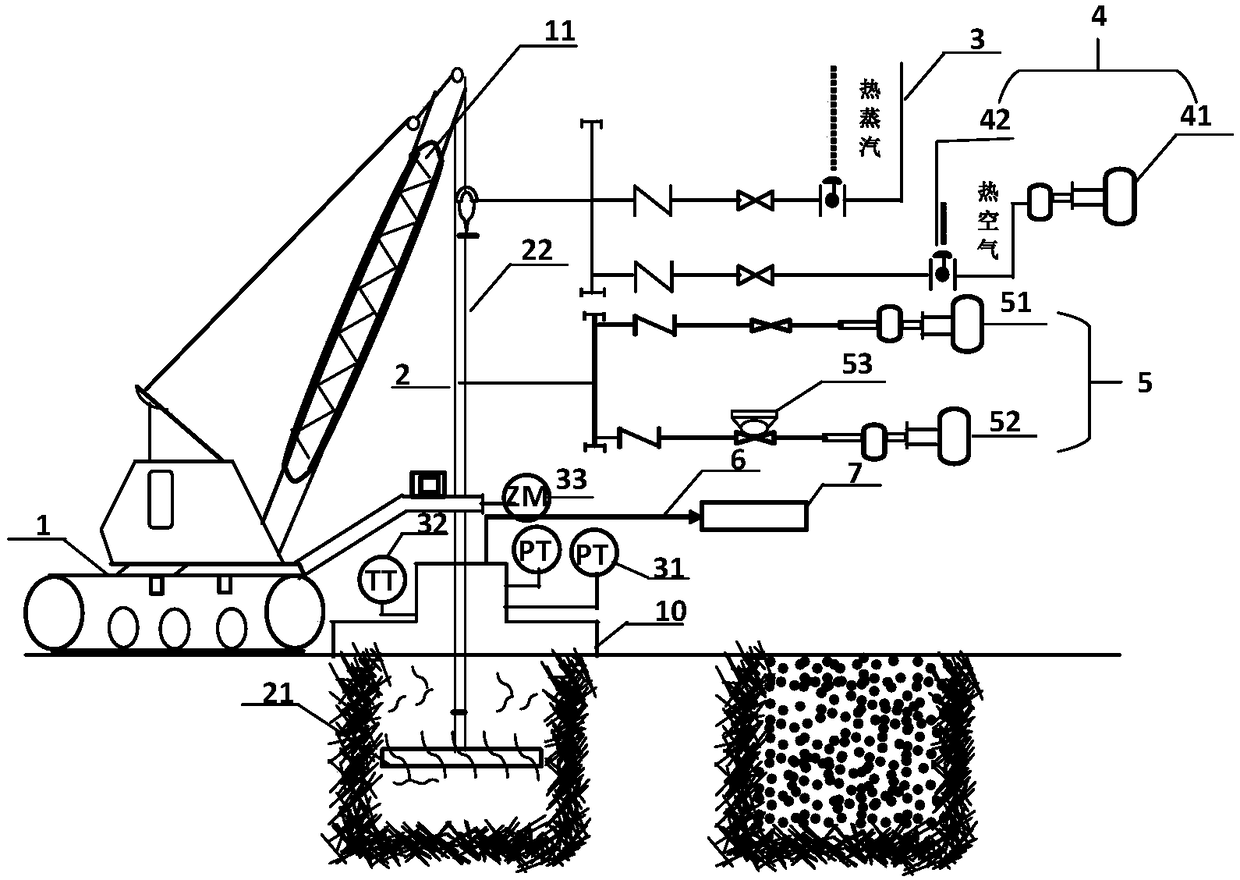

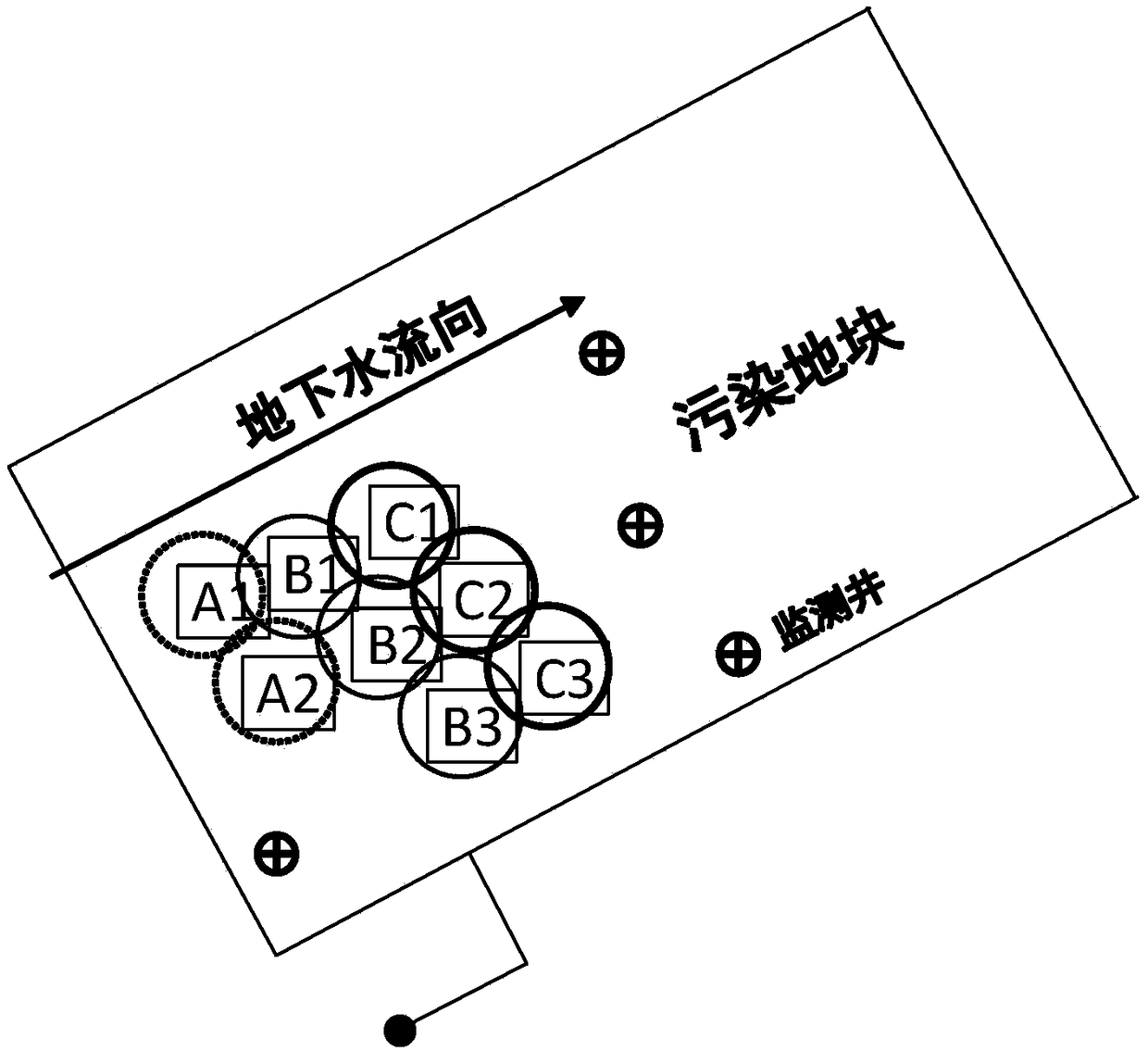

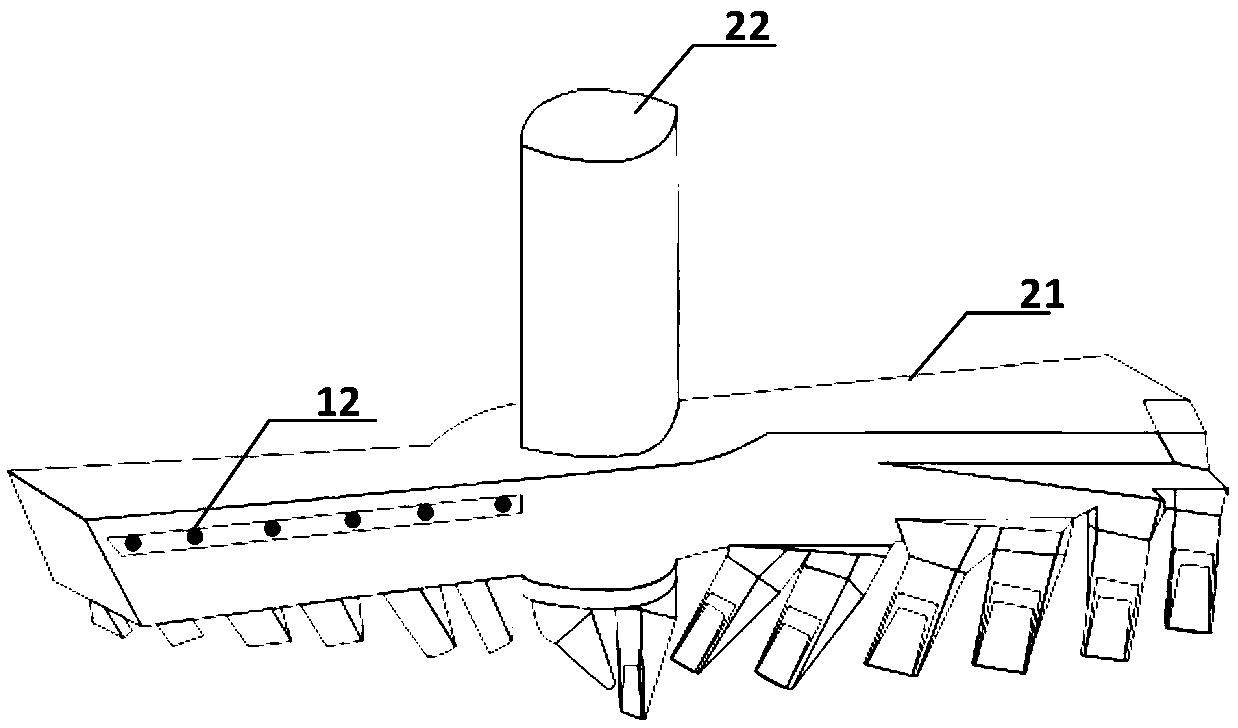

In-situ remediation system for contaminated site

ActiveCN109127698AProcessing depth can be adjusted at any timeStir wellContaminated soil reclamationIn situ remediationEngineering

The invention provides an in-situ remediation system for a contaminated site. The in-situ remediation system comprises a moving platform (1), a drill bit system (2), a hot steam injection system (3),a hot air injection system (4) and a chemical injection system (5) and is characterized in that the moving platform comprises a rigid support (11) and controls the drill bit system to move verticallythrough the support of the rigid support; the drill bit system comprises a drill bit (21) and a hollow rod (22) extending upwardly along the drill bit (21); the hot steam injection system (3) is started first to inject hot steam in an in-situ manner to heat soil, then the hot air injection system (4) is started to inject hot air to enhance organic pollutant volatilization towards the ground, the hot steam injection and the hot air injection are stopped when remediation reaches a preset degree, and the chemical injection system (5) is started to inject chemicals during the stirring of the drillbit system (2). The in-situ remediation system has the advantages that various process parameters can be flexibly and conveniently regulated, and the complex contaminated site can be efficiently remediated in an energy-saving manner.

Owner:山东冽泉环保工程咨询有限公司

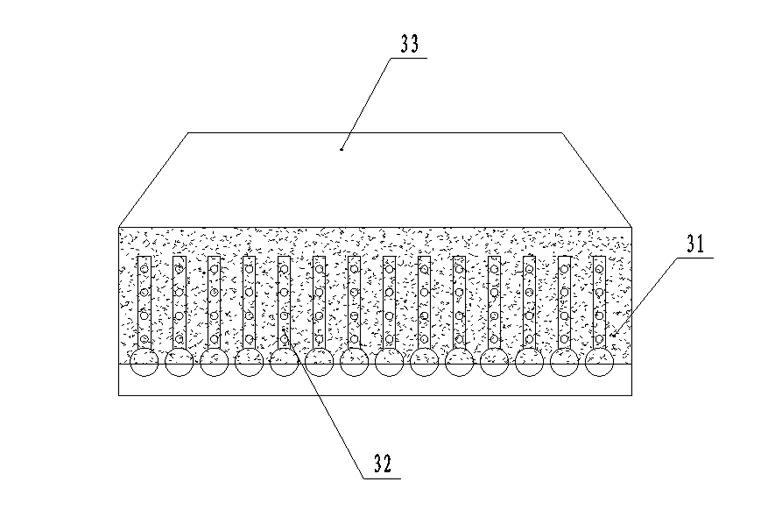

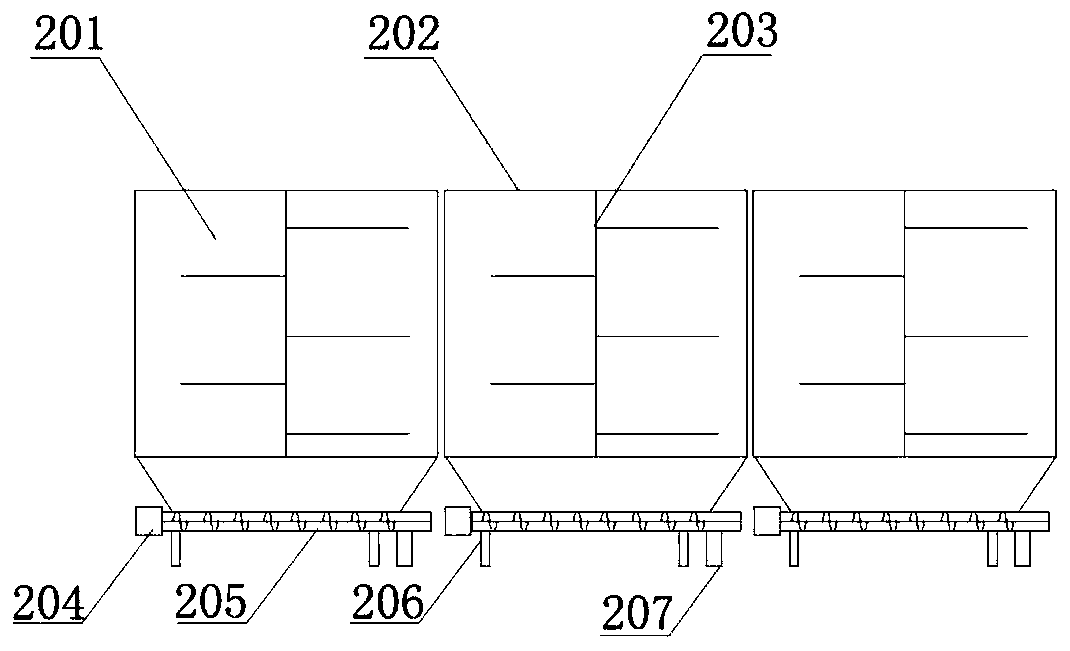

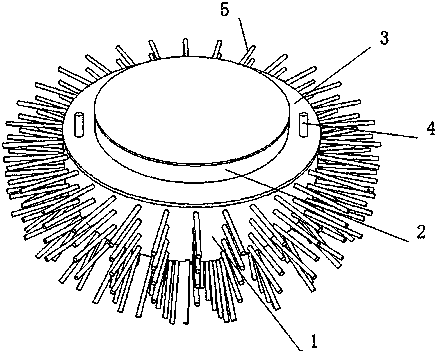

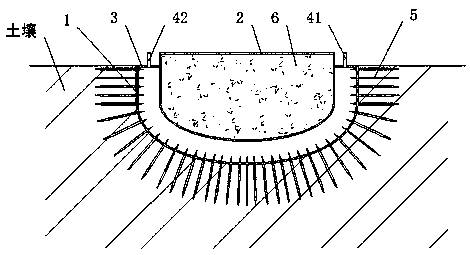

Continuous pre-buried bin for soil heavy metal remediation

ActiveCN111282988ABalance pHImprove repair efficiencyContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a continuous pre-buried bin for soil heavy metal remediation. The invention belongs to the field of soil remediation, and the invention discloses the continuous pre-buried binfor soil heavy metal remediation. A bidirectional continuous space is arranged, in a normal state, a buffer solution is released to surrounding soil through a plurality of diffusion whiskers, and thepH value of the soil is effectively balanced; when the buffer solution is released, the buffer solution can form an extrusion effect on the heavy metal ion adsorption powder adsorbing the heavy metalions in the diffusion whiskers, and is extruded from the end parts of the diffusion whiskers; in a negative pressure state, the inner deformation end is deformed, until the inner deformation end is communicated with the diffusion whiskers; new heavy metal ion adsorption powder can enter the diffusion whiskers; the heavy metal ion adsorption powder in the diffusion whiskers can be effectively supplemented, so that the heavy metal ion adsorption powder in the diffusion whiskers can be continuously updated, the sustainable adsorption effect of the pre-buried bin on the heavy metal ions is effectively guaranteed, and the soil remediation efficiency is effectively improved.

Owner:芷兰生态环境建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com