Track wheel pavement repair robot system and pavement repair method

A robot system and repair method technology, applied in the track wheel pavement repair robot system and the pavement repair field, can solve problems such as work efficiency, personal safety, repair speed defects, unsuitable for road repair needs, and loss of manpower and material resources, etc., to achieve Effects of improving economy and safety, improving utilization efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

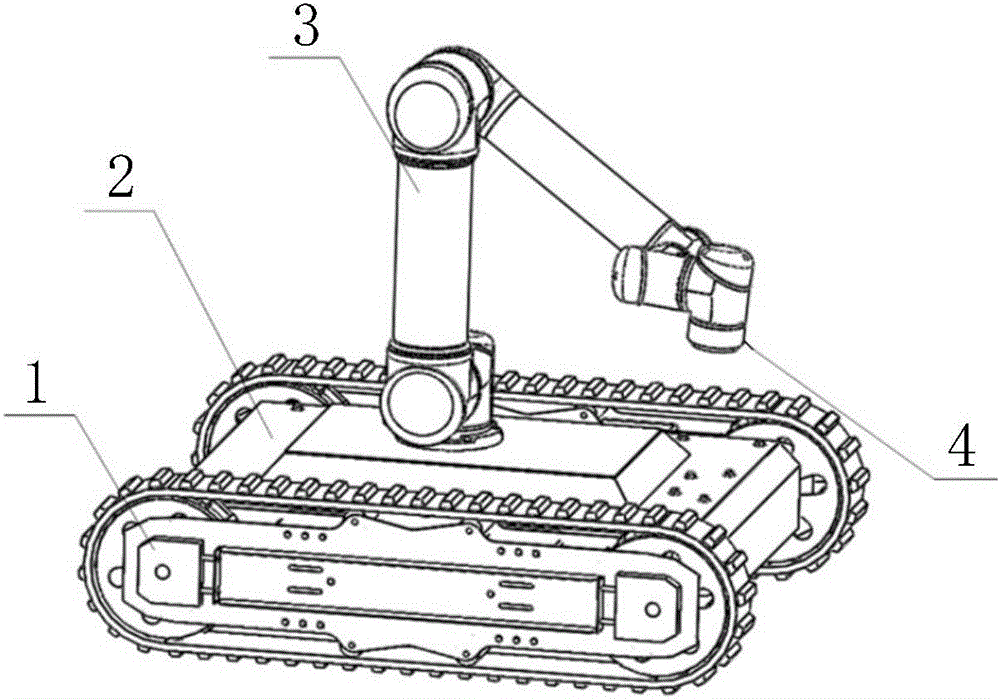

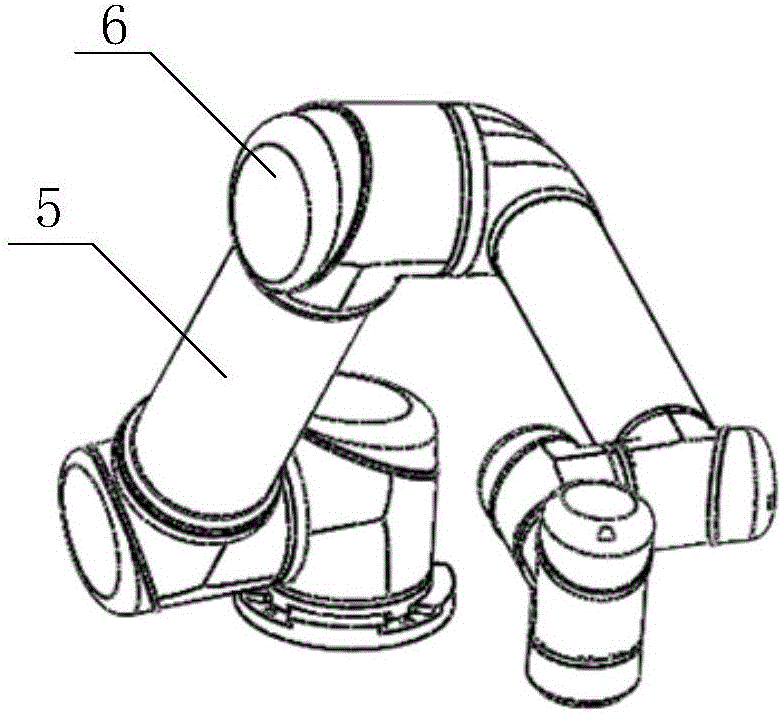

[0038] Embodiment 1 of the present invention: a crawler road surface repair robot system, including a robot body 2 with a power system 1, a robot arm 3 is installed on the robot body 2, and a road surface repair device 4 is installed on the robot arm 3 to form a set Road surface robot repair system; the robot body 2 is also provided with a control system for controlling the mechanical arm 3 , the control system has a wireless signal receiving device, and the control system is electrically connected to the mechanical arm 3 . Specifically, the road surface restoration device 4 includes a grouting device. The grouting device is composed of a mounting base, a connector, a hose, a cylinder, etc., and the mixture is injected into cracks or repaired areas through air pressure, hydraulic pressure, etc. In this embodiment, the mechanical arm 3 is composed of several connecting rods 5 which are hinged to each other in turn, and the adjacent connecting rods 5 are connected by a driving m...

Embodiment 2

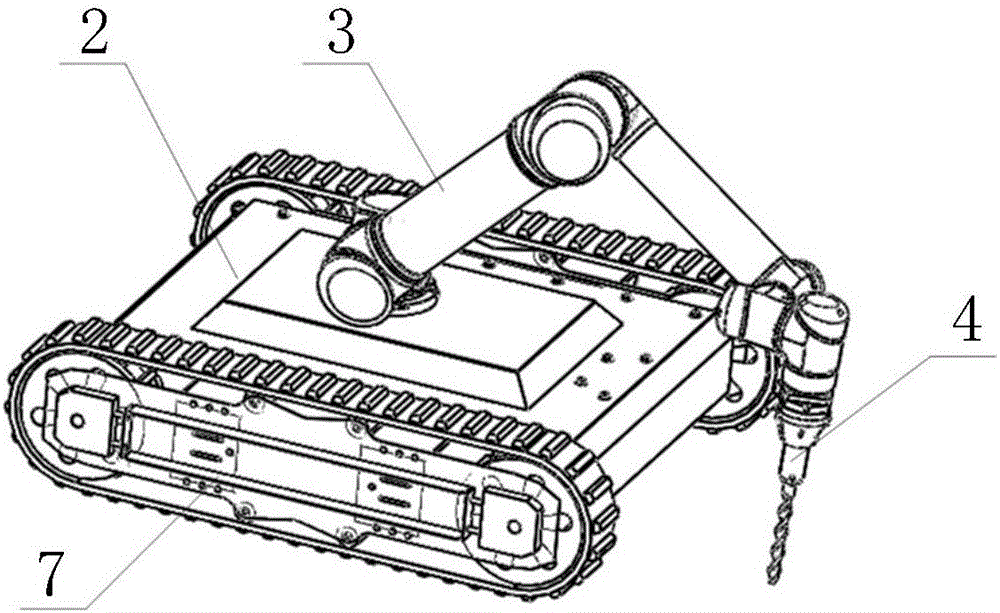

[0041] Embodiment 2: A crawler road surface repair robot system, including a robot body 2 with a power system 1, a robot arm 3 is installed on the robot body 2, and a road surface repair device 4 is installed on the robot arm 3 to form a road surface robot Repair system; the robot body 2 is also provided with a control system for controlling the mechanical arm 3 , the control system has a wireless signal receiving device, and the control system is electrically connected with the mechanical arm 3 . The road repairing device 4 includes a percussion drill. The impact drill is mainly composed of a high-power motor, a cooling fan, a top-mounted impact module, a drill fixture, and a drill, and provides energy for the impact drill through electrical connections.

[0042] The mechanical arm 3 is composed of several connecting rods 5 which are hinged to each other in turn, and the adjacent connecting rods 5 are connected by a driving mechanism 6; in this embodiment, the driving mechani...

Embodiment 3

[0044] Embodiment 3: A crawler road surface repair robot system, including a robot body 2 with a power system 1, a robot arm 3 is installed on the robot body 2, and a road surface repair device 4 is installed on the robot arm 3 to form a road surface robot Repair system; the robot body 2 is also provided with a control system for controlling the mechanical arm 3 , the control system has a wireless signal receiving device, and the control system is electrically connected with the mechanical arm 3 . The road repairing device 4 includes a slotting device.

[0045] The control system includes a global positioning system, a gyroscope, an encoder and an obstacle avoidance laser radar. The system also includes a remote monitoring auxiliary system for remotely controlling the robot body 2, and the remote monitoring auxiliary system is connected to the robot body 2 through wireless communication. . The power system 1 includes four driving wheels 11 , and each driving wheel 11 has an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com