Method for preparing composite water evaporation inhibitor

An evaporation inhibitor and moisture technology, which is applied in chemical instruments and methods, reagents, and other chemical processes to achieve the effects of small prolonged attenuation, good stability, and reduced water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Weigh 1.25 g of cetyl alcohol and fully dissolve it in 50 g of ether to obtain a water evaporation inhibitor.

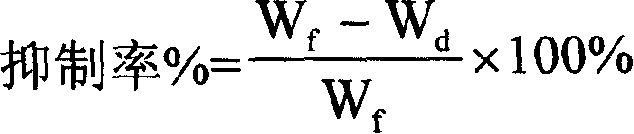

[0020] Take two identical porcelain plates with a surface area of 100cm 2 Left and right, inject 1000 grams of water respectively, add 30 microliters of inhibitor to one porcelain plate, and not add to the other porcelain plate. After standing at 30°C for 72 hours, weigh and calculate the water evaporation loss of the two porcelain plates, and pass The formula calculates the water evaporation inhibition rate of the spread inhibitor system. The results show that the water evaporation inhibition rate of the system is only 7%, which shows that the ethanol solution system of cetyl alcohol has poor water evaporation inhibition effect.

example 2

[0022] Weigh 1.25 g of cetyl alcohol and fully dissolve it in 50 g of ether to obtain a water evaporation inhibitor.

[0023] Take two identical porcelain plates with a surface area of 100cm 2 Left and right, inject 1000 grams of water respectively, add 30 microliters of inhibitor to one porcelain plate, and not add to the other porcelain plate. After standing at 30°C for 72 hours, weigh and calculate the water evaporation loss of the two porcelain plates, and pass The formula calculates the water evaporation inhibition rate of the spread inhibitor system. The results show that the water evaporation inhibition rate of the system is 25.1%, and the inhibition efficiency of the cetyl alcohol ether solution is higher than that of the cetyl alcohol ethanol solution in Example 1.

example 3

[0025] Weigh 0.9375 g of cetyl alcohol and 0.3125 g of n-butanol and fully dissolve them in 50 g of ether to obtain the water evaporation inhibitor.

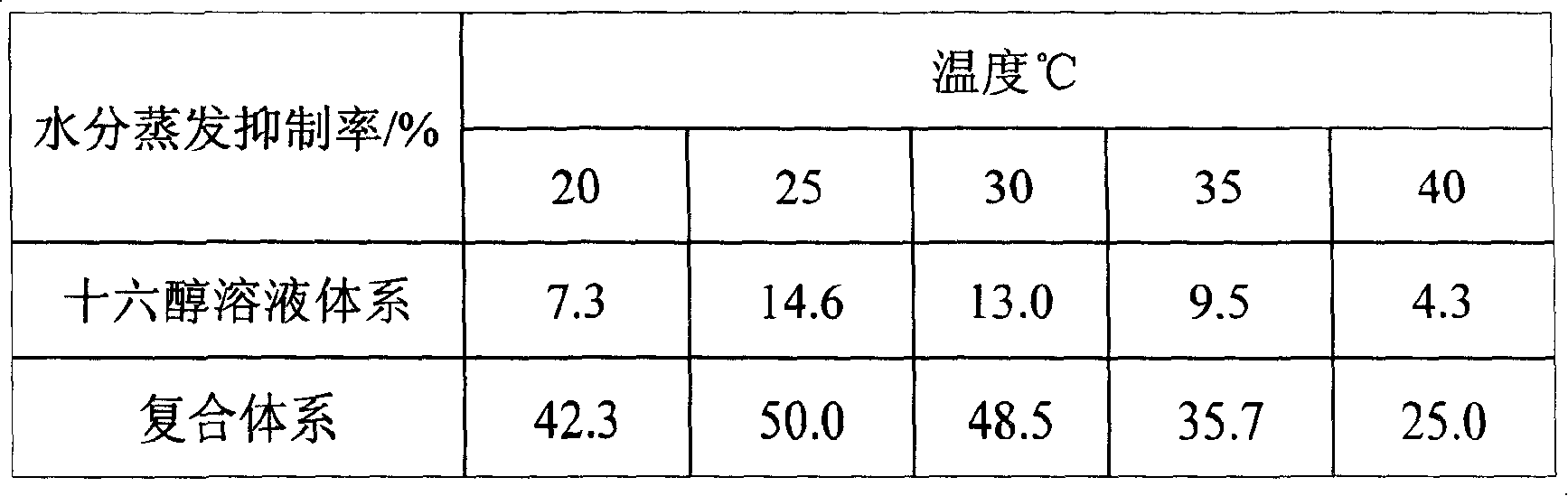

[0026] Take two identical porcelain plates with a surface area of 100cm 2 Left and right, inject 1000 grams of water respectively, add 30 microliters of inhibitor to one porcelain plate, and not add to the other porcelain plate. After standing at 30°C for 96 hours, weigh and calculate the water evaporation loss of the two porcelain plates, and pass The formula calculates the water evaporation inhibition rate of the spread inhibitor system. The results showed that the water evaporation of the porcelain plate with spreading inhibitor decreased obviously, and the water evaporation inhibition rate of the system reached 48.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com