Bio-based self-repair gel based on boric acid ester bond

A bio-based, self-healing technology, applied in the field of functional polymer materials, can solve problems such as low repair efficiency, harsh repair conditions, and self-healing gel biotoxicity, and achieve short repair process, mild repair conditions, and excellent biological properties. compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a bio-based self-repair gel based on a borate bond, the method comprising the steps of:

[0024] (1) Synthesis of alginic acid-phenylboronic acid (Alg-APBA) modified biological macromolecules;

[0025] Weigh 1.98g of sodium alginate (Alg) into a three-necked flask, add 100mL of deionized water and stir to dissolve for 2 hours; add 1.92g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt salt (EDC·HCl), 2.30g N-hydroxysuccinimide (NHS) activation for 30mins; weigh 0.68g 3-aminophenylboronic acid (APBA) in a beaker and add 100mL deionized water, and drop its aqueous solution Add it to the Alg solution and react at room temperature for 24 hours. The product is first precipitated with ethanol, and then purified by dissolving the ethanol precipitate with deionized water. After repeated three times, it is dialyzed in deionized water for 7 days. After freeze-drying, light yellow flocculent fibers are obtained, which are Alg-APBA modified biomacromole...

Embodiment 2

[0031] A method for preparing a bio-based self-repair gel based on a borate bond, the method comprising the steps of:

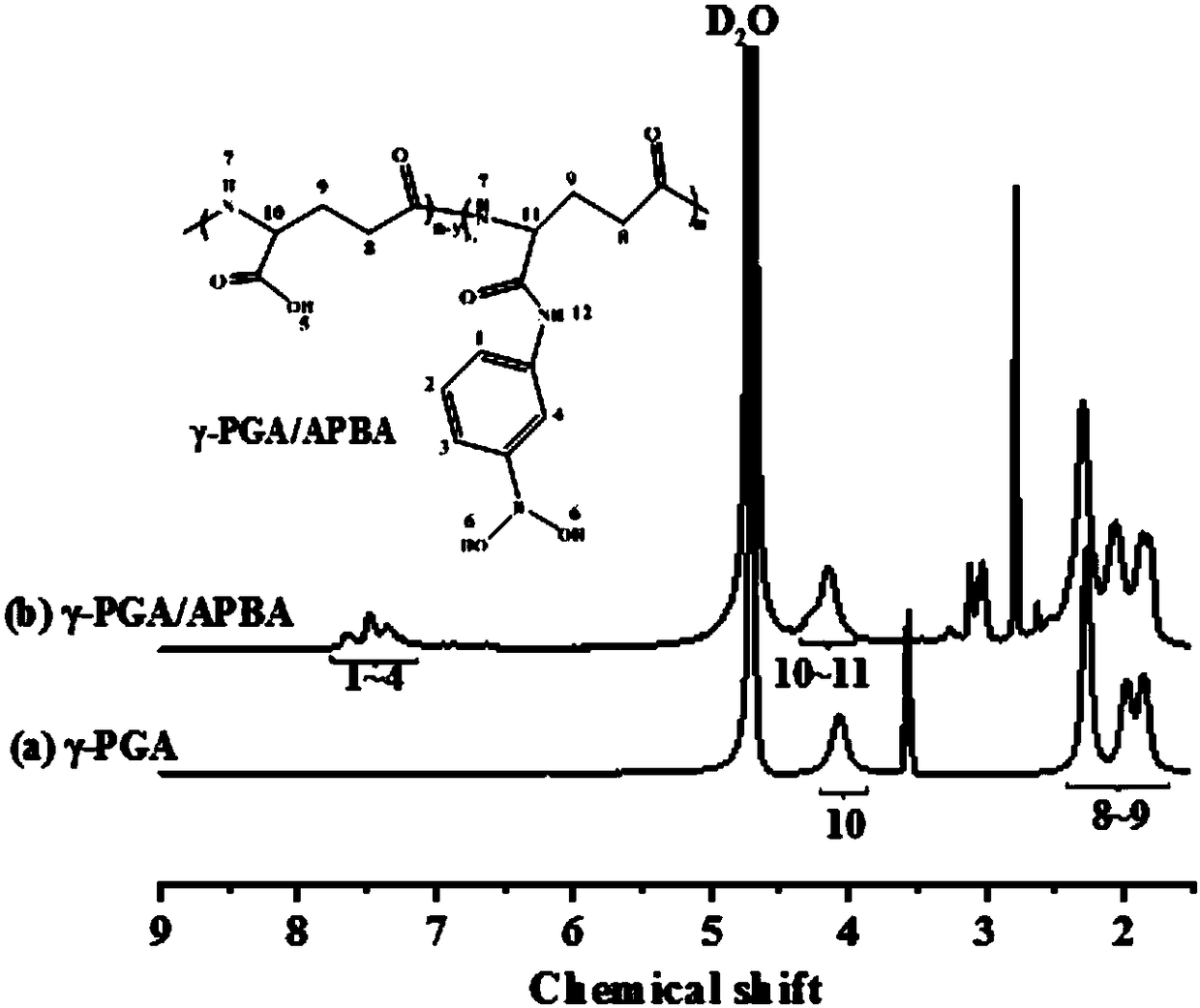

[0032] (1) Synthesis of polyglutamic acid-phenylboronic acid (γ-PGA-APBA) modified biological macromolecules;

[0033] Weigh 1.29g of polyglutamic acid (γ-PGA) in a three-necked flask, add 100mL of deionized water and then mechanically stir to dissolve for 2h; add 1.92g of 1-(3-dimethylaminopropyl)-3-ethylcarbodi imine hydrochloride (EDC·HCl), 2.30g N-hydroxysuccinimide (NHS) activation for 30mins; weigh 0.68g 3-aminophenylboronic acid (APBA) in a beaker and add 100mL deionized water, and The aqueous solution was added dropwise to the γ-PGA solution. After reacting at room temperature for 24 hours, the product was first precipitated with ethanol, and then purified by dissolving the ethanol precipitate with deionized water. After repeated three times, it was dialyzed in deionized water for 7 days. After freeze-drying, flocculent fibers were obtained, namely γ...

Embodiment 3

[0041] A method for preparing a bio-based self-repair gel based on a borate bond, the method comprising the steps of:

[0042] (1) Synthesis of hyaluronic acid-phenylboronic acid (HA-APBA) modified biomacromolecules;

[0043] Weigh 3.79g of hyaluronic acid (HA) into a three-necked flask, add 100mL of deionized water, and then mechanically stir to dissolve for 2h; add 1.92g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt salt (EDC·HCl), 2.30g N-hydroxysuccinimide (NHS) activation for 30mins; weigh 0.68g 3-aminophenylboronic acid (APBA) in a beaker and add 100mL deionized water, and drop its aqueous solution After adding to γ-PGA solution and reacting at room temperature for 24 hours, the product was first precipitated with ethanol, and then purified by dissolving the ethanol precipitate with deionized water. After repeated three times, it was dialyzed in deionized water for 7 days. After freeze-drying, flocculent fibers were obtained, namely HA-APBA, with a grafting rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com